Abstract

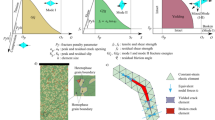

It is extremely important to investigate the mechanical properties and failure characteristics of granite at the mesoscale to understand the mesoscopic evolution mechanism of the time-dependent fracture of deep-buried hard rocks. This study explores the mesoscopic mechanical properties (i.e., hardness, Young’s modulus, and fracture toughness) of the primary granite minerals and their interfaces using nanoindentation. Micro X-ray computed tomography was used to analyze the fracture characteristics of the failed Brazilian disc of granite. Moreover, two homogenization upscaling methods were used to calculate granite’s Young’s modulus and compared with that from uniaxial compression test results. The results demonstrate the following: (1) The mechanical properties of granite minerals are related to the peak load of nanoindentation. Young’s modulus and hardness of quartz, K-feldspar, and plagioclase decrease with an increase in the peak load and tend to be stable when the peak load reaches 5000 μN, whereas Young’s modulus and hardness of biotite at multiple peak loads are in variability and irregularity. (2) Young’s modulus and hardness of quartz–plagioclase and quartz–biotite interfaces are between quartz and plagioclase and quartz and biotite, respectively. Furthermore, a linear formula is proposed to estimate fracture toughness based on Young’s modulus of granite minerals. (3) The generalized means method that predicts granite’s Young’s modulus is more accurate compared to the Mori–Tanaka method. (4) Under Brazilian splitting conditions, ~ 84% of tensile cracks along intragranular cracks primarily occur in feldspar minerals, while ~ 16% along grain boundaries occur at feldspar–biotite interfaces.

Highlights

-

Mesomechanical properties of granite minerals and mineral interfaces.

-

A linear relationship between the fracture toughness and Young’s modulus.

-

Homogenization methods used for upscaling the mesoscopic Young’s modulus of granite.

Similar content being viewed by others

Data Availability

Datasets related to this article are available from the corresponding author (dpxu@whrsm.ac.cn).

Abbreviations

- \(A_{{\text{c}}}\) :

-

Contact area of the indenter on the sample surface

- \(A_{\max }\) :

-

Maximum contact area of the indenter on the sample surface

- \(E\) and \(E_{{\text{r}}}\) :

-

Young’s modulus and reduced modulus of the sample

- \(E_{\hom }\) :

-

Homogenization Young’s modulus of granite

- \(E_{{\text{i}}}\) :

-

Young’s modulus of the indenter

- \(E_{{\text{u}}}\) :

-

Young’s modulus of the weakest mineral

- \(E_{{\text{w}}}\) :

-

Uniaxial compressive modulus of granite

- \(f_{{\text{i}}}\) :

-

Volume fraction of minerals

- \(G_{{\text{c}}}\) :

-

Critical energy release rate

- \(G_{\hom }\) :

-

Shear modulus of granite

- \(H\) :

-

Hardness of the sample

- \(h\) :

-

Indentation depth of the sample

- \(h\), \(h_{{\text{c}}}\), \(h_{{\text{f}}}\), and \(h_{{\text{m}}}\) :

-

Indentation depth, contact depth, residual depth, and maximum indentation depth

- \(J\) :

-

Scaling parameter

- \(K_{\hom }\) :

-

Bulk modulus of granite

- \(K_{{{\text{{\rm I}C}}}}\) :

-

Tensile (mode I) fracture toughness

- \(k_{{\text{s}}}\) and \(k_{{{\text{low}}}}\) :

-

Bulk moduli of the biotite and biotite porous matrix

- \(l\) :

-

Crack length

- \(M\) :

-

Specific mechanical property

- \(P\) :

-

Applied loading force of the indenter

- \(P_{\max }\) :

-

Peak force of the indenter

- \(S\) :

-

Contact stiffness of the sample

- \(U_{{{\text{crack}}}}\), \(U_{{{\text{pp}}}}\), \(U_{{{\text{ir}}}}\), \(U_{{\text{t}}}\), and \(U_{{\text{e}}}\) :

-

Fracture energy, pure plasticity energy, irreversible energy, total energy, and recoverable elastic energy

- \(V\) :

-

Volume fraction of the weakest mineral

- \(\alpha\) and \(\beta\) :

-

Power law fitting constants

- \(\gamma_{{\text{p}}}\) :

-

Plastic energy

- \(\omega\) :

-

Porosity of the biotite pore matrix

- \(\varepsilon\) :

-

A constant that depends on the indenter tip

- \(\mu_{{\text{s}}}\) and \(\mu_{{{\text{low}}}}\) :

-

Shear moduli of the biotite and biotite porous matrix

- \(\nu\) and \(\nu_{{\text{i}}}\) :

-

Poisson’s ratios of the sample and indenter

- \(\sigma_{{\text{f}}}\) :

-

Critical fracture stress

- \(E_{{\text{m}}}\), \(c\) and \(\varphi\) :

-

Young’s modulus, cohesion, and internal friction angle of minerals and mineral interfaces

References

Akono AT, Kabir P, Shi ZF et al (2019) Modeling CO2–induced alterations in Mt. Simon sandstone via nanomechanics. Rock Mech Rock Eng 52:1353–1375

Ayatollahi MR, Najafabadi MZ, Koloor SSR et al (2020) Mechanical characterization of heterogeneous polycrystalline rocks using nanoindentation method in combination with generalized means method. J Mech 36:813–823

Blake OO, Faulkner DR, Tatham DJ (2019) The role of fractures, effective pressure and loading on the difference between the static and dynamic Poisson’s ratio and Young’s modulus of Westerly granite. Int J Rock Mech Min Sci 116:87–98

Chen X, Ogasawara N, Zhao MH et al (2007) On the uniqueness of measuring elastoplastic properties from indentation: the indistinguishable mystical materials. J Mech Phys Solids 55(8):1618–1660

Chen Y, Hou YQ, Ji XP et al (2021) Characterization of surface mechanical properties of various aggregates from micro scale using AFM. Constr Build Mater 286:122847

Cheng YT, Li ZY, Cheng CM (2002) Scaling relationships for indentation measurements. Philos Mag A 82:1821–1829

Constantinides G, Chandran R-KS, Ulm FJ et al (2006) Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater Sci Eng A 430:189–202

Domnich V, Gogotsi Y, Dub S (2000) Effect of phase transformations on the shape of the unloading curve in the nanoindentation of silicon. Appl Phys Lett 76:2214–2216

Du JT, Whittle A-J, Hu LM et al (2021) Characterization of meso–scale mechanical properties of Longmaxi shale using grid microindentation experiments. J Rock Mech Geotech Eng 13:555–567

Duevel B, Haimson B (1997) Mechanical characterization of pink Lac du Bonnet granite: evidence of nonlinearity and anisotropy. Int J Rock Mech Min Sci 34:543–543

Eliyahu M, Emmanuel S, Ruarri J et al (2015) Mechanical properties of organic matter in shales mapped at the nanometer scale. Mar Pet Geol 59:294–304

Fujii Y, Takemura T, Takahashi M et al (2007) Surface features of uniaxial tensile fractures and their relation to rock anisotropy in Inada granite. Int J Rock Mech Min Sci 44:98–107

Goldsmith W, Sackman J-L, Ewerts C (1976) Static and dynamic fracture strength of Barre granite. Int J Rock Mech Min Sci 13:303–309

Guéry AAC, Cormery F, Shao JF, Kondo D (2010) A comparative micromechanical analysis of the effective properties of a geomaterial: effect of mineralogical compositions. Comput Geotech 37(5):585–593

Hay J (2009) Introduction to instrumented indentation testing. Exp Tech 33(6):66–72

Hu CL, Li ZJ (2015) A review on the mechanical properties of cement–based materials measured by nanoindentation. Constr Build Mater 90:80–90

Huang Y, Shen WQ, Shao JF et al (2014) Multi–scale modeling of time-dependent behavior of claystones with a viscoplastic compressible porous matrix. Mech Mater 79:25–34

Ji SC, Wang Q, Xia B et al (2004) Mechanical properties of multiphase materials and rocks: a phenomenological approach using generalized means. J Struct Geol 26:1377–1390

Jiang Q, Yang B, Yan F et al (2021) Morphological features and fractography analysis for in situ spalling in the China Jinping underground laboratory with a 2400 m burial depth. Tunn Undergr Space Technol 118:104194

Juliano T, Gogotsi Y, Domnich V (2003) Effect of indentation unloading conditions on phase transformation induced events in silicon. J Mater Res 18:1192–1201

Kuruppu MD, Obara Y, Ayatollahi MR et al (2014) ISRM–suggested method for determining the mode I static fracture toughness using semi–circular bend specimen. Rock Mech Rock Eng 47:267–274

Lawn BR, Wilshaw TR (1975) Fracture of brittle solids. Cambridge University Press, London

Li Y, Yang JH, Pan ZJ et al (2020) Nanoscale pore structure and mechanical property analysis of coal: an insight combining AFM and SEM images. Fuel 260:116352

Li YC, Luo SM, Lu M et al (2021) Cross–scale characterization of sandstones via statistical nanoindentation: evaluation of data analytics and upscaling models. Int J Rock Mech Min Sci 142:104738

Liu KQ, Ostadhassan M (2017) Microstructural and geomechanical analysis of Bakken shale at nanoscale. J Pet Sci Eng 153:133–144

Liu KQ, Ostadhassan M, Bubach B (2016) Applications of nano–indentation methods to estimate nanoscale mechanical properties of shale reservoir rocks. J Nat Gas Sci Eng 35:1310–1319

Liu L, Du GY, Li EB et al (2020) Fracture mechanical behaviors and acoustic emission characteristics of Beishan granite under CCNBD test. Chin J Rock Mech Eng 39(S2):3237–3244

Luo SM, Lu YH, Wu YK et al (2020) Cross–scale characterization of the elasticity of shales: statistical nanoindentation and data analytics. J Mech Phys Solids 140:103945

Luo SM, Kim DY, Wu YK et al (2021) Big data nanoindentation and analytics reveal the multi-staged, progressively-homogenized, depth-dependent upscaling of rocks’ properties. Rock Mech Rock Eng 54:1501–1532

Ma ZY, Gamage RP, Zhang CP (2020) Application of nanoindentation technology in rocks: a review. Geomech Geophys Geo 6(4):1–27

Ma ZY, Zhang CP, Gamage RP et al (2021) Uncovering the creep deformation mechanism of rock-forming minerals using nanoindentation. Int J Min Sci Technol 32(2):283–294

Mahabadi OK (2012) Investigating the influence of micro–scale heterogeneity and microstructure on the failure and mechanical behaviour of geomaterials. Toronto University, Canada

Mahabadi OK, Tatone BSA, Grasselli G (2014) Influence of microscale heterogeneity and microstructure on the tensile behavior of crystalline rocks. J Geophys Res-Solid Earth 119:5324–5341

Manjunath GL, Jha B (2019) Nanoscale fracture mechanics of Gondwana coal. Int J Coal Geol 204:102–112

Maruvanchery V, Kim E (2020) Mechanical characterization of thermally treated calcite–cemented sandstone using nanoindentation, scanning electron microscopy and automated mineralogy. Int J Rock Mech Min Sci 125:10415

Mavko G, Mukerji T, Dvorkin J (2009) The rock physics handbook. Cambridge University Press, London

Miller M, Bobko C, Vandamme M, Ulm FJ (2008) Surface roughness criteria for cement paste nanoindentation. Cem Concr Res 38:467–476

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall 21:571–574

Nasseri MHB, Grasselli G, Mohanty B (2010) Fracture toughness and fracture roughness in anisotropic granitic rocks. Rock Mech Rock Eng 43:403–415

Nasseri MHB, Rezanezhad F, Young RP (2011) Analysis of fracture damage zone in anisotropic granitic rock using 3D X-ray CT scanning techniques. Int J Fract 168:1–13

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Pöhl F (2019) Pop–in behavior and elastic–to–plastic transition of polycrystalline pure iron during sharp nanoindentation. Sci Rep 9:1564–1583

Shen WQ, Kondo D, Dormieux L et al (2013) A closed–form three scale model for ductile rocks with a plastically compressible porous matrix. Mech Mater 59:73–86

Shi X, Jiang S, Lu SF et al (2019) Investigation of mechanical properties of bedded shale by nanoindentation tests: a case study on Lower Silurian Longmaxi Formation of Youyang area in southeast Chongqing, China. Petrol Explor Dev 46:163–172

Sobhbidari F, Hu QH (2021) Recent advances in the mechanical characterization of shales at nano-to micro-scales: a review. Mech Mater 162:104043

Sun CL, Li GC, Gomah M-E et al (2020) Meso–scale mechanical properties of mudstone investigated by nanoindentation. Eng Fract Mech 238:107245

Sun CL, Li GC, Xu JH et al (2021) Rheological characteristics of mineral components in sandstone based on nanoindentation. Chin J Rock Mech Eng 40(1):77–87

Swan (1978) The mechanical properties of Stripa grantite. Lawrence Berkeley National Laboratory

Tabor D (1978) Phase transitions and indentation hardness of Ge and diamond. Nature 273:406–406

Tyurin AI, Victorov SD, Kochanov AN et al (2016) Methods of micro- and nanoindentation for characterization of local physical and mechanical properties of multiphase materials. AIP Conf Proc 1783:020227

Whittaker BN, Singh RN, Sun G (1992) Rock fracture mechanics: principles, design, and applications. Elsevier

Wu YK, Li YC, Luo SM et al (2020) Multiscale elastic anisotropy of a shale characterized by cross-scale big data nanoindentation. Int J Rock Mech Min Sci 134:104458

Xie HP, Li CB, Gao MZ et al (2021) Conceptualization and preliminary research on deep in situ rock mechanics. Chin J Rock Mech Eng 40(02):217–232

Xu JJ, Tang XH, Wang ZZ et al (2020) Investigating the softening of weak interlayers during landslides using nanoindentation experiments and simulations. Eng Geol 277:105801

Yang C, Xiong YQ, Wang J-F et al (2020) Mechanical characterization of shale matrix minerals using phase–positioned nanoindentation and nano–dynamic mechanical analysis. Int J Coal Geol 229:103571

Yu (2001) Measuring properties of rock from the site of permanent shiplock in three Gorges project. Test Report, Yangtze River Scientific Research Institute

Yuan CC, Xi XK (2011) On the correlation of Young’s modulus and the fracture strength of metallic glasses. J Appl Phys 109:033515

Zhang ZX (2002) An empirical relation between mode I fracture toughness and the tensile strength of rock. Int J Rock Mech Min Sci 39:401–406

Zhang G, Wei Z, Ferrell RE (2009) Elastic modulus and hardness of muscovite and rectorite determined by nanoindentation. Appl Clay Sci 43:271–281

Zhang F, Guo HQ, Zhao JJ et al (2017) Experimental study of micro–mechanical properties of granite. Chin J Rock Mech Eng 36:3864–3872

Zhang F, Guo HQ, Hu DW et al (2018) Characterization of the mechanical properties of a claystone by nano–indentation and homogenization. Acta Geotech 13:1395–1404

Acknowledgements

This research was funded by National Natural Science Foundation of China under Grant Nos. 51979268, 52279117, and 41877256.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Xy., Xu, Dp., Li, Sj. et al. An Insight into the Mechanical and Fracture Characterization of Minerals and Mineral Interfaces in Granite Using Nanoindentation and Micro X-Ray Computed Tomography. Rock Mech Rock Eng 56, 3359–3375 (2023). https://doi.org/10.1007/s00603-023-03221-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03221-6