Abstract

Exploring the mechanical properties and crack characteristics of granite at the grain scale is of greatly significant to understand brittle failures, such as spalling, slabbing, and rockburst of deep-buried hard rock under high geostress. The macroscopic engineering failure of a rock mass is often closely related to the microscopic mechanical properties and microstructure of the constituent minerals. This study derived the microscopic mechanical properties of granite minerals, including Young’s modulus, hardness, fracture toughness, and stiffness ratio based on nanoindentation tests. The relationship of the micromechanical parameters including Young’s modulus, hardness, and fracture toughness is presented in the following order: quartz > K-feldspar > plagioclase > biotite. A parameter calibration process that combines nanoindentation test and trial-and-error method was then proposed to reduce the randomness in the calibration process. This calibration process was adopted to the discrete element method simulation of granite, in which the microstructure of granite is specifically defined through a Voronoi tessellation. Finally, the microcrack evolution and crack characteristics of different minerals in granite were discussed based on the micro-X-ray computed tomography, scanning electron microscopy, and numerical results. The results reveal that the intragranular cracks play a crucial role in the failure process of brittle rocks and largely dominate the macroscopic properties of materials, in which the percentage of intragranular cracks increases from 61% to more than 80% when the compression test changes to the tension test.

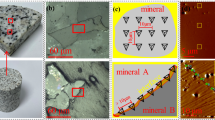

Modified from [22]

Modified from [22]

Modified from [75]

Similar content being viewed by others

Data availability

Data will be made available on request.

Abbreviations

- \(a\) :

-

Half-length of the precrack in the CSTBD specimen

- \(A_{{\text{c}}}\) :

-

Contact area of the indenter on the sample

- \(A_{\max }\) :

-

Maximum contact area of the indenter on the sample

- \(B\) :

-

Thickness of the CSTBD specimen

- \(d(p_{{\text{i}}} ,p_{{\text{j}}} )\) :

-

Euclidean distance

- \(E\) :

-

Young’s modulus

- \(E_{{\text{r}}}\) :

-

Reduced modulus

- \(E^{*}\) :

-

Linear elastic modulus

- \(\overline{E}^{*}\) :

-

Bond effective modulus

- \(E_{{\text{i}}}\) :

-

Young’s modulus of the indenter

- \(f_{{\text{I}}}\) :

-

Mode I normalized stress intensity factor

- \(F_{\max }\) :

-

Maximum tensile force

- \(G_{{\text{c}}}\) :

-

Critical energy release rate

- \(G\) :

-

Shear modulus

- \(h\) :

-

Indentation depth

- \(h_{{\text{c}}}\) :

-

Indentation contact depth

- \(h_{{\text{f}}}\) :

-

Residual indentation depth

- \(h_{{\text{m}}}\) :

-

Maximum indentation depth

- \(H\) :

-

Hardness

- \(K\) :

-

Bulk modulus

- \(K_{{{\text{{\rm I}C}}}}\) :

-

Tensile (mode I) fracture toughness

- \(k_{{\text{n}}}\) :

-

Normal stiffness

- \(k_{{\text{s}}}\) :

-

Shear stiffness

- \(k_{{{\text{ratio}}}}\) :

-

Normal-to-shear stiffness ratio

- \(\overline{k}_{{\text{n}}} /\overline{k}_{{\text{s}}}\) :

-

Bond normal-to-shear stiffness ratio

- \(P\) :

-

Applied loading force of the indenter

- \(P_{\max }\) :

-

Peak force of the indenter

- \(R\) :

-

Radius of the CSTBD specimen

- \(R_{\min }\) :

-

Minimum radius of the particle

- \(R_{\max } /R_{\min }\) :

-

Maximum-to-minimum radius ratio

- \(S\) :

-

Contact stiffness of the sample

- \(t\) :

-

Thickness of the contact interface

- \(U_{{{\text{crack}}}}\) :

-

Fracture energy

- \(U_{{\text{e}}}\) :

-

Recoverable elastic energy

- \(U_{{{\text{pp}}}}\) :

-

Pure plasticity energy

- \(U_{{\text{t}}}\) :

-

Total energy

- \(\nu\) :

-

Poisson’s ratio of the sample

- \(\nu_{{\text{i}}}\) :

-

Poisson’s ratios of the indenter

- \(\overline{c}\) :

-

Cohesion strength

- \(\overline{\phi }\) :

-

Friction angle

- \(\overline{\lambda }\) :

-

Radius multiplier

- \(\sigma_{c}\) :

-

Uniaxial compressive strength

- \(\sigma_{t}\) :

-

Brazilian tensile strength

- \(\overline{\sigma }_{{\text{c}}}\) :

-

Tensile strength

- \(\sigma_{c} /\sigma_{{\text{t}}}\) :

-

UCS-to-BTS ratio

- \(\varepsilon_{{\text{p}}}\) :

-

Peak strain

- \(\rho\) :

-

Density

- \(\mu\) :

-

Friction coefficient

- \({\mathbb{R}}^{2}\) :

-

Two-dimensional Euclidean plane

References

Feng XT, Zhou YY, Jiang Q (2019) Rock mechanics contributions to recent hydroelectric developments in China. J Rock Mech Geotech Eng 11(3):511–526

Xu DP, Huang X, Jiang Q, Li SJ, Zheng H, Qiu SL, Xu HS, Li YH, Li ZG, Ma XD (2021) Estimation of the three-dimensional in situ stress field around a large deep underground cavern group near a valley. J Rock Mech Geotech Eng 13(3):529–544

Xia YL, Feng XT, Yang CX, Li SJ, Xu DP, Jiang Q, Kong R, Li YH, Li ZG (2023) Mechanism of excavation-induced cracking of the protective layer of a rock bench in a large underground powerhouse under high tectonic stress. Eng Geol 312:106951

Li HB, Yang YG, Zhang XB, Zhou JW (2017) Deformation and failure analyses of large underground caverns during construction of the Houziyan Hydropower Station, Southwest China. Eng Fail Anal 88:164–185

Zhou J, Lan HX, Zhang LQ, Yang DX, Song J, Wang S (2019) Novel grain-based model for simulation of brittle failure of Alxa porphyritic granite. Eng Geol 251(9):100–114

Eberhardt E, Stimpson B, Stead D (1999) Effects of grain size on the initiation and propagation thresholds of stress-induced brittle fractures. Rock Mech Rock Eng 32(2):81–99

Xia K, Nasseri MHB, Mohanty B, Lu F, Chen R, Luo SN (2008) Effects of microstructures on dynamic compression of Barre granite. Int J Rock Mech Min Sci 45(6):879–887

Shao JF, Chau KT, Feng XT (2006) Modeling of anisotropic damage and creep deformation in brittle rocks. Int J Rock Mech Min Sci 43(4):582–592

Bahrani N, Kaiser PK (2016) Numerical investigation of the influence of specimen size on the unconfined strength of defected rocks. Comput Geotech 77:56–67

Hajiabdolmajid V, Kaiser PK, Martin CD (2002) Modelling brittle failure of rock. Int J Rock Mech Min Sci 39(6):731–741

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci Geomech Abstr 31(6):643–659

Peng J, Wong LNY, Teh CI (2017) Influence of grain size heterogeneity on strength and microcracking behavior of crystalline rocks. J Geophys Res Solid Earth 122(2):1054–1073

Saadat M, Taheri A (2020) A cohesive grain based model to simulate shear behaviour of rock joints with asperity damage in polycrystalline rock. Comput Geotech 117:103254

Wong TF (1982) Micromechanics of faulting in westerly granite. Int J Rock Mech Min Sci Geomech Abstr 19(2):49–64

Cai M, Kaiser PK, Tasaka Y, Maejima T, Morioka H, Minami M (2004) Generalized crack initiation and crack damage stress thresholds of brittle rock masses near underground excavations. Int J Rock Mech Min Sci 41(5):833–847

Jia LC, Chen M, Zhang W, Xu T, Zhou Y, Hou B, Jin Y (2013) Experimental study and numerical modeling of brittle fracture of carbonate rock under uniaxial compression. Mech Res Commun 50:58–62

Lan HX, Martin CD, Hu B (2010) Effect of heterogeneity of brittle rock on micromechanical extensile behavior during compression loading. J Geophys Res Solid Earth 115:B01202

Wang X, Cai M (2018) Modeling of brittle rock failure considering inter-and intra-grain contact failures. Comput Geotech 101:224–244

Tang XH, Zhang YH, Xu JJ, Rutqvist J, Hu MS, Wang ZZ, Liu QS (2022) Determining Young’s modulus of granite using accurate grain-based modeling with microscale rock mechanical experiments. Int J Rock Mech Min Sci 157:105167

Akono AT, Kabir P, Shi ZF, Fuchs S, Tsotsis TT, Jessen K, Werth CJ (2019) Modeling CO2–induced alterations in Mt. Simon sandstone via nanomechanics. Rock Mech Rock Eng 52:1353–1375

Constantinides G, Chandran KSR, Ulm FJ, Van-Vliet KJ (2006) Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater Sci Eng A 430(1–2):189–202

Liu XY, Xu DP, Li SJ, Qiu SL, Jiang Q (2023) An insight into the mechanical and fracture characterization of minerals and mineral interfaces in granite using nanoindentation and micro X-ray computed tomography. Rock Mech Rock Eng 56:3359–3375

Luo SM, Lu YH, Wu YK, Song JL, DeGroot DJ, Jin Y, Zhang GP (2020) Cross-scale characterization of the elasticity of shales: Statistical nanoindentation and data analytics. J Mech Phys Solids 140:103945

Wu YK, Li YC, Luo SM, Lu M, Zhou N, Wang DF, Zhang GP (2020) Multiscale elastic anisotropy of a shale characterized by cross-scale big data nanoindentation. Int J Rock Mech Min Sci 134:104458

Xu JJ, Tang XH, Wang ZZ, Feng YF, Bian K (2020) Investigating the softening of weak interlayers during landslides using nanoindentation experiments and simulations. Eng Geol 277:105801

Yang C, Xiong YQ, Wang JF, Li Y, Jiang WM (2020) Mechanical characterization of shale matrix minerals using phase–positioned nanoindentation and nano–dynamic mechanical analysis. Int J Coal Geol 229:103571

Ganneau FP, Constantinides G, Ulm FJ (2006) Dual-indentation technique for the assessment of strength properties of cohesive-frictional materials. Int J Solids Struct 43(6):1727–1745

Palkovic SD, Kupwade-Patil K, Yip S, Büyüköztürk O (2018) Random field finite element models with cohesive–frictional interactions of a hardened cement paste microstructure. J Mech Phys Solids 119:349–368

Xu JJ, Zhang YH, Rutqvist J, Hu MS, Wang ZZ, Tang XH (2023) Thermally induced microcracks in granite and their effect on the macroscale mechanical behavior. J Geophys Res Solid Earth 128(1)

Saadat M, Taheri A, Kawamura Y (2021) Investigating asperity damage of natural rock joints in polycrystalline rocks under confining pressure using grain-based model. Comput Geotech 135:104144

Zhang T, Yu LY, Li J, Ma LJ, Su HJ, Zhang MW, Xu XL, Peng YX (2022) Numerical investigation of the effects of the micro-parameters of the transgranular contact on the mechanical response of granite. Theor Appl Fract Mech 118:103259

Quey R, Dawson PR, Barbe F (2011) Large-scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. Comput Methods Appl Mech Eng 200(17):1729–1745

Wang ZH, Yang SL, Li LH, Tang YS, Xu GL (2021) A 3D Voronoi clump based model for simulating failure behavior of brittle rock. Eng Fract Mech 248(1):107720

Hu XJ, Gong XN, Hu HB, Guo PP, Ma JJ (2022) Cracking behavior and acoustic emission characteristics of heterogeneous granite with double pre-existing filled flaws and a circular hole under uniaxial compression: insights from grain-based discrete element method modeling. Bull Eng Geol Environ 81:162

Chen S, Yue ZQ, Tham LG, Lee PKK (2004) Modeling of the indirect tensile test for inhomogeneous granite using a digital image-based numerical method. Int J Rock Mech Min Sci 41:447–447

Chen S, Yue ZQ, Tham LG (2004) Digital image-based numerical modeling method for prediction of inhomogeneous rock failure. Int J Rock Mech Min Sci 41:939–957

Yue ZQ, Chen S, Tham LG (2003) Finite element modeling of geomaterials using digital image processing. Comput Geotech 30:375–397

Tan X, Konietzky H, Chen W (2016) Numerical simulation of heterogeneous rock using discrete element model based on digital image processing. Rock Mech Rock Eng 49:4957–4964

Hu XJ, Xie N, Zhu QZ, Chen L, Li PC (2020) Modeling damage evolution in heterogeneous granite using digital image-based grain-based model. Rock Mech Rock Eng 53(11):4925–4945

Li XF, Li HB, Zhang QB, Jiang JL, Zhao J (2018) Dynamic fragmentation of rock material: characteristic size, fragment distribution and pulverization law. Eng Fract Mech 199:739–759

Li XF, Zhang QB, Li HB, Zhao J (2018) Grain-based discrete element method (GB-DEM) modelling of multiscale fracturing in rocks under dynamic loading. Rock Mech Rock Eng 51:3785–3817

Zhang YH, Wong LNY, Chan KK (2019) An extended grain-based model accounting for microstructures in rock deformation. J Geophys Res Solid Earth 124:125–148

Mahabadi OK, Randall NX, Zong Z, Grasselli G (2012) A novel approach for micro-scale characterization and modeling of geomaterials incorporating actual material heterogeneity. Geophys Res Lett 39(1):1303

Wu ZJ, Ji XK, Liu QS, Fan LF (2020) Study of microstructure effect on the nonlinear mechanical behavior and failure process of rock using an image-based-FDEM model. Comput Geotech 121:103480

Itasca Consulting Group Inc (2016) Particle flow code (PFC), version 5.0. Minneapolis

Sun CL, Li GC, Gomah ME, Xu JH, Rong HY (2020) Meso–scale mechanical properties of mudstone investigated by nanoindentation. Eng Fract Mech 238:107245

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Manjunath GL, Jha B (2019) Geomechanical characterization of Gondwana shale across nano-micro-meso scales. Int J Rock Mech Min Sci 119:35–45

Cheng YT, Li ZY, Cheng CM (2002) Scaling relationships for indentation measurements. Philos Mag A 82:1821–1829

Zhang GP, Wei ZX, Ferrell RE (2009) Elastic modulus and hardness of muscovite and rectorite determined by nanoindentation. Appl Clay Sci 43:271–281

Liu KQ, Ostadhassan M (2017) Microstructural and geomechanical analysis of Bakken shale at nanoscale. J Pet Sci Eng 153:133–144

Pöhl F (2019) Pop-in behavior and elastic-to-plastic transition of polycrystalline pure iron during sharp nanoindentation. Sci Rep 9:1564–1583

Gao FQ, Stead D, Elmo D (2016) Numerical simulation of microstructure of brittle rock using a grain-breakable distinct element grain-based model. Comput Geotech 78:203–217

Li XF, Li HB, Liu LW, Liu YQ, Ju MH, Zhao J (2020) Investigating the crack initiation and propagation mechanism in brittle rocks using grain-based finite-discrete element method. Int J Rock Mech Min Sci 127:104219

Peng J, Wong LNY, Teh CI, Li Z (2018) Modeling micro-cracking behavior of Bukit Timah granite using grain-based model. Rock Mech Rock Eng 51(1):135–154

Yılmaz NG, Goktan RM, Kibici Y (2011) Relations between some quantitative petrographic characteristics and mechanical strength properties of granitic building stones. Int J Rock Mech Min Sci 48(3):506–513

Potyondy DO (2010) A grain-based model for rock: approaching the true microstructure, In: Proceedings of the rock mechanics in the Nordic Countries. Kongsberg, vol 9–12, pp 225–234

Liu G, Cai M (2020) Modeling time-dependent deformation behavior of brittle rock using grain-based stress corrosion method. Comput Geotech 118:103323

Farahmand K, Diederichs MS (2021) Calibration of coupled hydro-mechanical properties of grain-based model for simulating fracture process and associated pore pressure evolution in excavation damage zone around deep tunnels. J Rock Mech Geotech Eng 13(1):60–83

Hofmann H, Babadagli T, Yoon JS, Zang A (2015) A grain based modeling study of mineralogical factors affecting strength, elastic behavior and micro fracture development during compression tests in granites. Eng Fract Mech 147:261–275

Mayer JM, Stead D (2017) Exploration into the causes of uncertainty in UDEC grain boundary models. Comput Geotech 82:110–123

Liang K, Xie LZ, He B, Zhao P, Zhang Y, Hu WZ (2021) Effects of grain size distributions on the macro-mechanical behavior of rock salt using micro-based multiscale methods. Int J Rock Mech Min Sci 138:104592

Mavko G, Mukerji T, Dvorkin J (2009) The rock physics handbook. Cambridge University Press, Cambridge

Yang SQ, Huang YH, Jing HW, Liu XR (2014) Discrete element modeling on fracture coalescence behavior of red sandstone containing two unparallel fissures under uniaxial compression. Eng Geol 178:28–48

Liu WJ, Zhu XH, Shi CS (2020) On the failure mechanism of brittle granite in 2-D rock indentation. Geotech Test J 43(5):1–9

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44(7):997–1010

Zhou J, Zhang LQ, Yang DX, Braun A, Han ZH (2017) Investigation of the quasi-brittle failure of Alashan granite viewed from laboratory experiments and grain-based discrete element modeling. Mater 10:835

Bahrani N, Kaiser PK, Valley B (2014) Distinct element method simulation of an analogue for a highly interlocked, non-persistently jointed rockmass. Int J Rock Mech Min Sci 71:117–130

Moore DE, Lockner DA (1995) The role of microcracking in shear-fracture propagation in granite. J Struct Geol 17(1):95–111

Azar HF, Choupani N, Afshin H, Moghadam RH (2015) Effect of mineral admixtures on the mixed-mode (I/II) fracture characterization of cement mortar: CTS, CSTBD and SCB specimens. Eng Fract Mech 134:20–34

Zhou L, Gao WT, Yu LY, Zhu ZM, Chen JX, Wang XK (2022) Thermal effects on fracture toughness of cracked straight-through Brazilian disk green sandstone and granite. J Rock Mech Geotech Eng 14(5):1447–1460

Brace WF, Paulding BW, Scholz C (1966) Dilatancy in the fracture of crystalline rocks. J Geophys Res 71(16):3939–3953

Martin CD (1993) The strength of massive Lac du Bonnet granite around underground openings. Ph.D. thesis, University of Manitoba, Manitoba, Canada

Kotwaliwale N, Weckler PR, Brusewitz GH (2006) X-ray attenuation coefficients using polychromatic X-ray imaging of pecan components. Biosyst Eng 94(2):199–206

Fujii Y, Takemura T, Takahashi M, Lin WR (2007) Surface features of uniaxial tensile fractures and their relation to rock anisotropy in Inada granite. Int J Rock Mech Min Sci 44:98–107

Mahabadi OK, Tatone BSA, Grasselli G (2014) Influence of microscale heterogeneity and microstructure on the tensile behavior of crystalline rocks. J Geophys Res-Solid Earth 119:5324–5341

Nasseri MHB, Rezanezhad F, Young RP (2011) Analysis of fracture damage zone in anisotropic granitic rock using 3D X-ray CT scanning techniques. Int J Fract 168:1–13

Wong TF, Biegel R (1985) Effects of pressure on the micromechanics of faulting in San Marcos gabbro. J Struct Geol 7(6):737–749

Tapponnier P, Brace WF (1976) Development of stress-induced microcracks in Westerly granite. Int J Rock Mech Min Sci Geomech Abstr 13(4):103–112

Acknowledgements

This research as supported by the National Natural Science Foundation of China under Grant Nos. 51979268, 52279117, and 52279114.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Xy., Xu, Dp., Duan, Sq. et al. Study on the micromechanical and crack characteristics of granite based on nanoindentation test and discrete element method. Comp. Part. Mech. (2023). https://doi.org/10.1007/s40571-023-00664-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40571-023-00664-0