Abstract

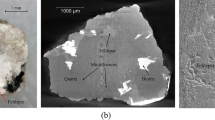

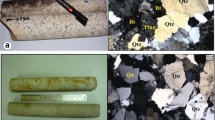

In rock engineering, size effects have been a topic of extensive research since the early 1960s, and despite many advances over the years, our understanding of size effect remains incomplete, especially for weak, porous, homogeneous rocks. Indeed, the vast majority of studies related to size effect have specifically considered low porosity rocks (generally crystalline). To bridge this gap in knowledge, we conducted unconfined compression tests on cubic limestone blocks ranging in size from 0.1 to 0.9 m. Texas Cream Limestone, which is a porous, homogeneous, weak rock, was chosen for this study. As this rock has not previously been studied in the literature, conventional compression tests and indirect tensile strength tests on cylindrical specimens were completed prior to testing the cube specimens. For the largest specimens, 3D digital image correlation (3D-DIC) was employed to track the surficial displacements as a function of the applied load. The tests revealed a lack of size effect for the entire range of block sizes considered. To evaluate size effects more broadly, data from prior studies on sedimentary rocks were compiled, and a tendency for the magnitude of the size effect on strength to decline with increasing porosity was noted. Some hypotheses regarding this trend are presented and evaluated based on strain-field heterogeneity metrics obtained from the 3D-DIC analysis.

Highlights

-

Unconfined compression tests were conducted on limestone blocks ranging in size from 0.1 m to 0.9 m side length.

-

Negligible size effect on strength was observed in this weak, porous, homogeneous limestone.

-

3D-Digital Image Correlation analysis was performed to obtain strain fields as a function of applied load for the two largest specimens.

-

Contrary to low-porosity rocks, more heterogeneity in strain field was noted in the axial direction in comparison to the lateral direction

-

A compilation of data from the literature indicates that increased porosity may dampen size effects.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author, [Sankhaneel Sinha], upon reasonable request.

Code Availability

Not applicable.

References

Abdelaziz A, Grasselli G (2021) How believable are published laboratory data? A deeper look into system-compliance and elastic modulus. J Rock Mech Geotech Eng 13(3):487–499

Alejano LR, Arzúa J, Estévez-Ventosa X, Suikkanen J (2020) Correcting indirect strain measurements in laboratory uniaxial compressive testing at various scales. Bull Eng Geol Env 79(9):4975–4997

Alejano LR, Estévez-Ventosa X, González-Fernández MA, Walton G, West IG, González-Molano NA, Alvarellos J (2021) A method to correct indirect strain measurements in laboratory uniaxial and triaxial compressive strength tests. Rock Mech Rock Eng 54(6):2643–2670

Al-Rkaby AH, Alafandi ZM (2015) Size effect on the unconfined compressive strength and Modulus of elasticity of limestone rock. Electron J Geotech Eng 20(12):1393–1401

Armstrong RT, Lanetc Z, Mostaghimi P, Zhuravljov A, Herring A, Robins V (2021) Correspondence of max-flow to the absolute permeability of porous systems. Phys Rev Fluids 6(5):054003

ASTM D7012-04 (2004) Standard test method for compressive strength and elastic moduli of intact rock core specimens under varying states of stress and temperatures. West Conshohocken, USA: ASTM International

ASTM D3967-16 (2016) Standard test method for splitting tensile strength of intact rock core specimens. West Conshohocken, PA

ASTM D4543-85 (2001) Standard practices for preparing rock core specimens and determining dimensional and shape tolerances. D4543. West Conshohocken, PA: American Society for Testing and Materials

Bandis S (1980) Experimental studies of scale effects on shear strength, and deformation of rock joints. PhD dissertation, University of Leeds

Baecher GB, Einstein HH (1981) Size effect in rock testing. Geophys Res Lett 8(7):671–674

Barczak TM (2000) NIOSH safety performance testing protocols for standing roof supports and longwall shields. In: Proceedings of the New Technology for Coal Mine Roof Support, Pittsburgh, PA: US Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication, no. 2000–151 pp 207–221

Barczak T (2005) An overview of standing roof support practices and developments in the United States. In: Proceedings of the Third South African Rock Engineering Symposium, Johannesburg, South Africa pp 301–334

Barton N (1990) Scale effects or sampling bias? In: Proceedings of international workshop scale effects in rock masses. Balkema, Rotterdam, pp 31–55

Bass JD (1995) Elasticity of minerals, glasses, and melts. Mineral Physics and Crystallography: A Handbook of Physical Constants 2:45–63

Baychev TG (2018) Pore space structure effects on flow in porous media. PhD thesis, The University of Manchester, United Kingdom

Bernaix J (1974) General report on theme 1. In: Proceedings of 3rd ISRM Conference, Vol. 1, Denver, United States

Biao ZH, Tianyu YU, Wenfeng DI, Xianying LI (2017) Effects of pore structure and distribution on strength of porous Cu-Sn-Ti alumina composites. Chin J Aeronaut 30(6):2004–2015

Brace WF (1981) The effect of size on mechanical properties of rock. Geophys Res Lett 8(7):651–652

Cai M (2010) Practical estimates of tensile strength and Hoek-Brown strength parameter mi of brittle rocks. Rock Mech Rock Eng 43(2):167–184

Çelik SB (2017) The effect of cubic specimen size on uniaxial compressive strength of carbonate rocks from Western Turkey. Arab J Geosci 10(19):1–5

Chang C, Zoback MD, Khaksar A (2006) Empirical relations between rock strength and physical properties in sedimentary rocks. J Petrol Sci Eng 51(3–4):223–237

Cheng JL, Yang SQ, Chen K, Ma D, Li FY, Wang LM (2017) Uniaxial experimental study of the acoustic emission and deformation behavior of composite rock based on 3D digital image correlation (DIC). Acta Mech Sin 33(6):999–1021

Cunha AP (1990) Scale effects in rock mass. In: Proceeding of International Workshop on Scale Effects in Rock Masses, Balkema

Cvitanović NŠ, Nikolić M, Ibrahimbegović A (2015) Influence of specimen shape deviations on uniaxial compressive strength of limestone and similar rocks. Int J Rock Mech Min Sci 80:357–372

Darlington WJ, Ranjith PG, Choi SK (2011) The effect of specimen size on strength and other properties in laboratory testing of rock and rock-like cementitious brittle materials. Rock Mech Rock Eng 44(5):513

Dey TN, Wang CY (1981) Some mechanisms of microcrack growth and interaction in compressive rock failure. Int J Rock Mech Mining Sci Geomech Abstracts 18(3):199–209

Diederichs MS (1999) Instability of hard rock masses: the role of tensile damage and relaxation. PhD thesis, University of Waterloo, Waterloo

Diederichs MS (2003) Rock fracture and collapse under low confinement conditions. Rock Mech Rock Eng 36(5):339–381

Diederichs MS (2007) The 2003 Canadian Geotechnical Colloquium: Mechanistic interpretation and practical application of damage and spalling prediction criteria for deep tunnelling. Can Geotech J 44(9):1082–1116

Diederichs MS, Martin CD (2010) Measurement of spalling parameters from laboratory testing. In: Proceedings of the ISRM International Symposium-EUROCK 2010

Du K, Su R, Tao M, Yang C, Momeni A, Wang S (2019) Specimen shape and cross-section effects on the mechanical properties of rocks under uniaxial compressive stress. Bull Eng Geol Env 78(8):6061–6074

Dunham RJ (1962) Classification of carbonate rocks according to depositional texture. Am Assoc Pet Geol Mem 1:108–121

Elliott GM, Brown ET (1985) Yield of a soft, high porosity rock. Geotechnique 35(4):413–423

Esterhuizen E, Mark C, Murphy MM (2010) Numerical model calibration for simulating coal pillars, gob and overburden response. In: Proceeding of the 29th international conference on ground control in mining, Morgantown, WV, pp 46–57

Fairhurst CE, Hudson JA (1999) Draft ISRM suggested method for the complete stress–strain curve for intact rock in uniaxial compression. Int J Rock Mech Min Sci 36:279–289

Farahmand K, Vazaios I, Diederichs MS, Vlachopoulos N (2018) Investigating the scale-dependency of the geometrical and mechanical properties of a moderately jointed rock using a synthetic rock mass (SRM) approach. Comput Geotech 95:162–179

Folk RL (1959) Practical petrographic classification of limestones. AAPG Bull 43(1):1–38

Gao M, Liang Z, Li Y, Wu X, Zhang M (2018) End and shape effects of brittle rock under uniaxial compression. Arab J Geosci 11(20):614

GOM (2016) Digital image correlation and strain computation basics. GOM, Braunschweig, Germany

Hackston A, Rutter E (2016) The Mohr-Coulomb criterion for intact rock strength and friction–a re-evaluation and consideration of failure under polyaxial stresses. Solid Earth 7(2):493–508

Hawkins AB (1998) Aspects of rock strength. Bull Eng Geol Env 57(1):17–30

Hawkins A, McConnell BJ (1991) Influence of geology on geomechanical properties of sandstones. In: Proceedings of the 7th ISRM Congress

Hemami B, Fakhimi A (2014) Numerical simulation of rock-loading machine interaction. In: Proceedings of the 48th US Rock Mechanics/ Geomechanics Symposium, Minneapolis, Minnesota Paper No. 74

Hoek E, Brown ET (1980) Underground excavations in rock. Institute of Mining and Metallurgy, London

Hoskins JR, Horino FG (1969) Influence of spherical head size and specimen diameters on the uniaxial compressive strength of rocks. US Department of the Interior, Bureau of Mines, Washington

Jackson R, Lau JSO (1990) The effect of specimen size on the laboratory mechanical properties of Lac du Bonnet grey granite. In: Proceedings of Scale effects in rock masses, Balkema, Rotterdam

Jaczkowski E, Ghazvinian E, Diederichs M (2017) Uniaxial compression and indirect tensile testing of Cobourg limestone: influence of scale, saturation and loading rate. Nuclear Waste Management Organization (NWMO-TR-2017-17)

Jamshidi A, Nikudel MR, Khamehchiyan M, Sahamieh RZ (2016) The effect of specimen diameter size on uniaxial compressive strength, P-wave velocity and the correlation between them. Geomech Geoeng 11(1):13–19

Kaiser PK, Kim B, Bewich RP, Valley B (2011) Rock mass strength at depth and implication for pillar design. Min Technol 120(3):170–179

Kaklis KN, Maurigiannakis SP, Agioutantis ZG, Stathogianni FK, Steiakakis EK (2015) Experimental investigation of the size effect on the mechanical properties on two natural building stones. In: Proceedings of 8th GRACM international congress on computational mechanics, Greece

Khishvand M, Akbarabadi M, Piri M (2016) Micro-scale experimental investigation of the effect of flow rate on trapping in sandstone and carbonate rock samples. Adv Water Resour 94:379–399

Kong X, Liu Q, Lu H (2021) Effects of rock specimen size on mechanical properties in laboratory testing. J Geotech Geoenviron Eng 147(5):04021013

Kranz RL (1983) Microcracks in rocks: a review. Tectonophysics 100(1–3):449–480

Lan H, Martin CD, Hu B (2010) Effect of heterogeneity of brittle rock on micromechanical extensile behavior during compression loading. J Geophys Res Solid Earth. https://doi.org/10.1029/2009JB006496

Li D, Song S, Zuo D, Wu W (2020) Effect of pore defects on mechanical properties of graphene reinforced aluminum nanocomposites. Metals 10(4):468

Li H, Song K, Tang M, Qin M, Liu Z, Qu M, Li B, Li Y (2021) Determination of scale effects on mechanical properties of Berea Sandstone. Geofluids 2021:1–12

Liaw HK, Kulkarni R, Chen S, Watson AT (1996) Characterization of fluid distributions in porous media by NMR techniques. AIChE J 42(2):538–546

Marker BR (2015) Bath stone and purbeck stone: a comparison in terms of criteria for global heritage stone resource designation. Episodes 38(2):118–123

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Mining Sci Geomech Abstracts 31(6):643–659

Martin CD (1997) Seventeenth Canadian geotechnical colloquium: the effect of cohesion loss and stress path on brittle rock strength. Can Geotech J 34(5):698–725

Masoumi H (2013) Investigation into the mechanical behaviour of intact rock at different sizes. Doctor of Philosophy thesis, University of New South Wales, Sydney

Masoumi H, Saydam S, Hagan PC (2016) Unified size-effect law for intact rock. Int J Geomech 16(2):04015059

Malyszko L, Bilko P, Kowalska E (2017) Determination of elastic constants in Brazilian tests Using Digital Image Correlation. In: Proceedings of the 2017 Baltic Geodetic Congress (BGC Geomatics), pp 153–157

Mogi K (1961) The influence of the dimensions of specimens on the fracture strength of rocks. Bull Earthquake Res Inst 40:175–185

Mokhtari M, Nath F, Hayatdavoudi A, Nizamutdinov R, Jiang S, Rizvi H (2019) Complex deformation of naturally fractured rocks. J Petrol Sci Eng 183:106410

Mortazavi A, Hassani FP, Shabani M (2009) A numerical investigation of rock pillar failure mechanism in underground openings. Comput Geotech 36(5):691–697

Munoz H, Taheri A, Chanda EK (2016) Pre-peak and post-peak rock strain characteristics during uniaxial compression by 3D digital image correlation. Rock Mech Rock Eng 49(7):2541–2554

Nishimatsu Y, Yamaguchi U, Motosugi K, Morita M (1969) The size effect and experimental error of the strength of rocks. J Min Mater Process Inst Jpn 18:1019–1025

Niu Y, Wang H, Shao S, Park SB (2016) In-situ warpage characterization of BGA packages with solder balls attached during reflow with 3D digital image correlation (DIC). In: Proceedings of the 2016 IEEE 66th Electronic Components and Technology Conference, pp 782–788

Nomikos P, Kaklis K, Agioutantis Z, Mavrigiannakis S (2020) Investigation of the size effect and the fracture process on the uniaxial compressive strength of the banded Alfas porous stone. Procedia Struct Integrity 26:285–292

Pan B, Qian K, Xie H, Asundi A (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review. Meas Sci Technol 20(6):062001

Pells PJ (2004) On the absence of size effects for substance strength of Hawkesbury Sandstone. Australian Geomech 39(1):79–83

Perras MA, Diederichs MS (2014) A review of the tensile strength of rock: concepts and testing. Geotech Geol Eng 32(2):525–546

Pratt HR, Black AD, Brown WS, Brace WF (1972) The effect of specimen size on the mechanical properties of unjointed diorite. Int J Rock Mech Mining Sci Geomech Abstracts 9(4):513–516

Prat M, Bisch P, Millard A, Mestat P, Pijaudier-Calot G (1995) La modélisation des ouvrages, vol 4. Hermes, Paris

Quiñones J, Arzúa J, Alejano LR, García-Bastante F, Ivars DM, Walton G (2017) Analysis of size effects on the geomechanical parameters of intact granite samples under unconfined conditions. Acta Geotech 12(6):1229–1242

Renani HR, Martin CD (2018) Modeling the progressive failure of hard rock pillars. Tunn Undergr Space Technol 74:71–81

Schwartz E, Saralaya R, Cuadra J, Hazeli K, Vanniamparambil PA, Carmi R, Kontsos A (2013) The use of digital image correlation for non-destructive and multi-scale damage quantification. In: Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2013, International Society for Optics and Photonics 86922H

Shirole D, Walton G, Hedayat A (2020) Experimental investigation of multi-scale strain-field heterogeneity in rocks. Int J Rock Mech Min Sci 127:104212

Sinha S, Walton G (2018) A progressive S-shaped yield criterion and its application to rock pillar behavior. Int J Rock Mech Min Sci 105:98–109

Sinha S, Walton G (2021) Investigation of pillar damage mechanisms and rock-support interaction using Bonded Block Models. Int J Rock Mech Min Sci 138:104652

Sinha S, Shirole D, Walton G (2021) Investigation of the micromechanical damage process in a granitic rock using an inelastic bonded block model (BBM). J Geophys Res: Solid Earth 125(3):55

Sitepu H (2009) Texture and structural refinement using neutron diffraction data from molybdite (MoO3) and calcite (CaCO3) powders and a Ni-rich Ni50. 7Ti49. 30 alloy. Powder Diffr 24(4):315–326

Sjöberg T, Kajberg J, Oldenburg M (2017) Fracture behaviour of Alloy 718 at high strain rates, elevated temperatures, and various stress triaxialities. Eng Fract Mech 178:231–242

Sprunt ES, Brace WF (1974) Direct observation of microcavities in crystalline rocks. Int J Rock Mech Mining Sci Geomech Abstracts 11(4):139–150

Stróżyk J, Tankiewicz M (2016) The elastic undrained modulus Eu50 for stiff consolidated clays related to the concept of stress historyad normalized soil properties. Studia Geotechnica Et Mechanica 38(3):67–72

Sutton MA, Orteu JJ, Schreier H (2009) Image correlation for shape, motion and deformation measurements: basic concepts, theory and applications. Springer Science & Business Media, USA

Tang Y, Okubo S, Xu J, Peng S (2019) Experimental study on damage behavior of rock in compression–tension cycle test using 3D Digital Image Correlation. Rock Mech Rock Eng 52(5):1387–1394

Tang CA, Tham LG, Lee PK, Tsui Y, Liu H (2000) Numerical studies of the influence of microstructure on rock failure in uniaxial compression—part II: constraint, slenderness and size effect. Int J Rock Mech Min Sci 37(4):571–583

Tapponnier P, Brace WF (1976) Development of stress-induced microcracks in Westerly granite. Int J Rock Mech Mining Sci Geomech Abstracts 13(4):103–112

Thuro K, Plinninger RJ, Zäh S, Schütz S (2001) Scale effects in rock strength properties. Part 1: Unconfined compressive test and Brazilian test. In: Proceedings of ISRM regional symposium, pp 169–174

Trilion Quality Systems (2020) Aramis training: surface preparation and patterning

Trilion Quality Systems (2021) How accurate are my measurements? https://faq.trilion.com/docs/how-accurate-are-my-measurements. Accessed 6 Dec 2021

Tuncay E, Hasancebi N (2009) The effect of length to diameter ratio of test specimens on the uniaxial compressive strength of rock. Bull Eng Geol Env 68(4):491–497

Vutukuri VS, Lama RD, Saluja SS (1974) Handbook on mechanical properties of rocks. Trans Tech Publications, Bay Village, OH

Walton G, Hedayat A, Kim E, Labrie D (2017) Post-yield strength and dilatancy evolution across the brittle–ductile transition in Indiana limestone. Rock Mech Rock Eng 50(7):1691–1710

Walton G (2018) Scale effects observed in compression testing of Stanstead granite including post-peak strength and dilatancy. Geotech Geol Eng 36(2):1091–1111

Walton G, Arzúa J, Alejano LR, Diederichs MS (2015) A laboratory-testing-based study on the strength, deformability, and dilatancy of carbonate rocks at low confinement. Rock Mech Rock Eng 48(3):941–958

Walton G (2021) A new perspective on the brittle-ductile transition of rocks. Rock Mech Rock Eng 10:1–4

Weber J, Cheshire MC, Bleuel M, Mildner D, Chang YJ, Ievlev A, Littrell KC, Ilavsky J, Stack AG, Anovitz LM (2021) Influence of microstructure on replacement and porosity generation during experimental dolomitization of limestones. Geochim Cosmochim Acta 303:137–158

Weibull W (1939) A statistical theory of strength of materials. IVB-Handl.

Wong TF, Baud P (2012) The brittle-ductile transition in porous rock: a review. J Struct Geol 44:25–53

Xing HZ, Zhang QB, Ruan D, Dehkhoda S, Lu GX, Zhao J (2018) Full-field measurement and fracture characterisations of rocks under dynamic loads using high-speed three-dimensional digital image correlation. Int J Impact Eng 113:61–72

Yoshinaka R, Osada M, Park H, Sasaki T, Sasaki K (2008) Practical determination of mechanical design parameters of intact rock considering scale effect. Eng Geol 96(3–4):173–186

Zhai H, Masoumi H, Zoorabadi M, Canbulat I (2020) Size-dependent behaviour of weak intact rocks. Rock Mech Rock Eng 53(8):3563–3587

Acknowledgements

The authors thank Thomas M Barczak, Earth Mechanics Institute at Colorado School of Mines (Bruce Yoshioka, Brent Duncan and Thyagarajan Muthu Vinayak) and NIOSH for assisting with the tests.

Funding

The research conducted for this study was primarily sponsored by the Alpha Foundation for the Improvement of Mine Safety and Health, Inc. (ALPHA FOUNDATION) under Grant Number AFC820-52. Additional funding was obtained from National Institute for Occupational Safety and Health (NIOSH) under Grant Number 200–2016-90154.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

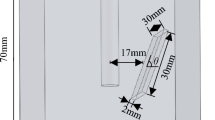

Appendix A: Geometrical Details of Test spEcimens

The mean and standard deviation of the heights of the 0.2–0.9 m specimens are listed in Table

A1, while the mean dimensions in three perpendicular directions are listed in Table

A2. The 0.1 m specimens were only measured once in the three perpendicular directions. While congruence in height measured along different vertical faces does not imply parallelism for the entirety of the loading surfaces (i.e. central portion versus edges), we believe it is reasonable to assume the surfaces to be planar when cut using a saw. Accordingly, the dimensions measured along the edges are considered to be representative of the entire loading surface.

The mean dimensions along the x, y, and z directions are most dissimilar for the 0.1 m specimens (Table 3). The reason is that the 0.1 m specimens were saw-cut from one 0.2 m block and then ground until two opposite faces were parallel. This grinding process and minor errors in sub-dividing the 0.2 m block led to the variation in the edge lengths. In any case, the width to height ratio of all 0.1 m specimens was within the interval [0.98, 1.06], and this change in aspect ratio is unlikely to affect the strengths in any meaningful way (Du et al. 2019).

The ASTM suggested method covering the preparation of UCS specimens (ASTM 4543-85, 2001) requires ends to be flat to ± 0.025 mm and not depart from perpendicularity to the longitudinal axis by more than 0.25 degrees (or 0.22 mm in 50 mm). It is noted here that the ASTM specifications were developed for smaller cylindrical specimens and possibly represent a lower bound (in terms of stringency) of specimen requirement (Cvitanović et al. 2015). The flatness of the 0.2–0.9 m specimens were not measured explicitly, but if the variability in specimen size (Table 2) is normalized with respect to the edge length, then all values are lower than the corresponding recommended value in Cvitanović et al. (2015). In terms of parallelism of the loading surfaces, if 2*variability/mean edge length is computed for all specimens in Table 2, then the value ranges from [0.0005, 0.0027]; the corresponding ASTM requirement is 0.0044. All specimens, therefore, satisfy the parallelism requirement of ASTM, but some of the specimens exceed the stricter ISRM stipulations (0.001 radians or 0.05 mm in 50 mm; Fairhurst and Hudson 1999). In any case, the fact that highly consistent stress–strain curves and fracture patterns were obtained (as reported in Sect. 4) provides confidence in the test results.

Appendix B: Adjustment in Strain Calculation due to Lighting Issues

During the calculation of strain heterogeneity, significant noise was observed in the strain field generated by GOM Correlate along the right edge of the 0.9 m specimen. The raw images captured by 3D-DIC were revisited, and some issues with lighting were identified. In particular, about ~ 0.35 m of the specimen right side was found to be darker than the rest of the image (Fig. 14a). This issue was not present in the 0.7 m specimen images, and the lighting was consistent across the entire surface. To filter out the noise in the DIC data, the mean and standard deviation of \({\varepsilon }_{yy}\) was computed within rectangular bins that were 0.75 mm wide (3 pixels) and spanned the entire specimen height. The results at 20%, 40%, 60%, and 80% peak strength are plotted against the X-coordinate of the bin midpoints in Fig. 14b–e. Since the standard deviation of the \({\varepsilon }_{yy}\) strain started to fluctuate dramatically in the rightmost ~ 350 mm region (Fig. 14b–e), that portion was omitted while preparing Fig. 9.

a Raw image from one of the 3D-DIC camera at a load level corresponding to 20% peak strength. Mean and standard deviation of \({\varepsilon }_{yy}\) strain field computed within rectangular strips 0.75 mm wide across the entire width of the specimen at b 20% peak strength, c 40% peak strength, d 60% peak strength, and e 80% peak strength. X-coordinate is the center point of the moving rectangular window

Appendix C: Discussion on the Two Outliers: Gambier Limestone and Bathstone

The data used to develop Fig. 12 are presented in Table

4. With respect to β, there are two notable outliers—Gambier Limestone and Bathstone. The exact reason why β < − 0.4 for these two rocks is not obvious. Gambier Limestone is reported to have ~ 44–50% porosity and is composed of 98% calcite (Khishvand et al. 2016; Zhai et al. 2020; Armstrong et al. 2021). It is hypothesized that such a homogeneous, high porosity rock can exhibit size effect if the pore size distribution itself is playing a role in the failure process (i.e. the volumetric proportion of larger pores is not attaining a constant value over the range of specimen sizes considered). This is somewhat evident in Fig. 1, where Gambier Limestone attains its maximum UCS at 119 mm size that is significantly larger than what is typical for most rock types (40–60 mm; Kong et al. 2021). Pores can act as crack arrestors or stress concentrators; in this case, it is possible that the pores interacted with the surface to lead to premature failure in the < 119 mm diameter specimens and continued to play a role in the failure process through internal mechanisms (e.g., stress concentrating around larger pores, crack initiation) in the larger specimens. The fact that larger pores can lower material strength has been illustrated by Biao et al. (2017) and Li et al. (2020) using composites. Khishvand et al. (2016) also recently reported pore diameters as large as 0.8 mm for Gambier Limestone. The same reasoning may or may not be applicable to Bathstone that has a porosity of 23–26% (Marker 2015), and there could also be an interaction between the pores and its oolitic structure (Elliot and Brown 1985). It is interesting, however, that the UCS of Bathstone drops by 25.7% between 54 and 74 mm diameter and only by 15% between 74 and 150 mm diameter.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sinha, S., Walton, G., Chaurasia, A. et al. Evaluating Size Effects for a Porous, Weak, Homogeneous Limestone. Rock Mech Rock Eng 56, 3755–3772 (2023). https://doi.org/10.1007/s00603-022-03148-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-03148-4