Abstract

In this study, three typical limestones, including Tavel limestone, Indiana limestone, and Lixhe chalk, were selected from a large number of porous limestones. These limestones with different porosities have been largely studied in previous experimental investigations because of the complexity of mechanical behavior. According to previous experimental studies, porous limestones present two basic plastic mechanisms: plastic shear as a response at low confining pressures and plastic pore collapse at high confining pressures. In related to the plastic mechanisms, two types of plastic volumetric deformation are revealed: plastic compaction induced by pore collapse, and plastic dilatancy by plastic shearing. In this paper, a micromechanics-based plastic model is extended to describe the elastoplastic behavior of porous limestones. The plastic criterion of porous rock is explicitly dependent on the porosity in addition to being directly based on the relevant mechanical properties of solid matrix at the microscopic scale. An additional plastic hardening law for the solid matrix is proposed, in which two plastic deformation mechanisms are considered in hardening law of the solid matrix, including hardening effect caused by the local equivalent plastic deformation and weakening effect caused by the increase in porosity. Three typical porous limestones with different porosity are selected to validate the proposed model on both hydrostatic and triaxial compression tests. By comparing numerical predictions and experimental data, it is shown that the presented model can correctly describe the mechanical behavior of porous rocks.

Highlights

-

Limestones with different porosities have been largely studied in previous experimental investigations because of the complexity of mechanical behavior.

-

In related to the plastic mechanisms, two types of plastic volumetric deformation are revealed: plastic compaction induced by pore collapse, and plastic dilatancy by plastic shearing.

-

A micromechanics-based plastic model is extended to describe the elastoplastic behavior of porous limestones.

-

The plastic criterion of porous rock is explicitly dependent on the porosity in addition to being directly based on the relevant mechanical properties of solid matrix at the microscopic scale.

Similar content being viewed by others

References

Aubertin M, Li L (2004) A porosity-dependent inelastic criterion for engineering materials. Int J Plast 20(12):2179–2208

Aubertin M, Yahya OML, Julien M (1999) Modeling mixed hardening of alkali halides with a modified version of an internal state variables model. Int J Plast 15(10):1067–1088

Baud P, Schubnel A, Wong T-F (2000) Dilatancy, compaction, and failure mode in Solnhofen limestone. J Geophys Res Solid Earth 105(B8):19289–19303

Byerlee JD (1968) Brittle-ductile transition in rocks. J Geophys Res 73(14):4741–4750

Chen WF, Saleeb AF (1983) Constitutive-equations for engineering materials, vol 1, elasticity and modeling. Earth Sci Rev 19(2):167–168

Collin F, Cui YJ, Schroeder C, Charlier R (2002) Mechanical behaviour of Lixhe chalk partly saturated by oil and water: experiment and modelling. Int J Numer Anal Methods Geomech 26(9):897–924

Desai CS (1980) A general basis for yield, failure and potential functions in plasticity. Int J Numer Anal Methods Geomech 4(4):361–375

Desai CS (2000) Mechanics of materials and interfaces: the disturbed state concept. CRC Press, Boca Raton

DiMaggio FL, Sandler IS (1971) Material model for granular soils. J Eng Mech

Ehlers W (1995) A single-surface yield function for geomaterials. Arch Appl Mech 65(4):246–259

El Bied A, Sulem J, Martineau F (2002) Microstructure of shear zones in Fontainebleau sandstone. Int J Rock Mech Min Sci 39(7):917–932

Fredrich JT, Evans B, Wong T-F (1989) Micromechanics of the brittle to plastic transition in Carrara marble. J Geophys Res Solid Earth 94(B4):4129–4145

Gens A (1993) Conceptual bases for a constitutive model for bonded soils and weak rocks. Geotech Eng Hard Soils-Soft Rocks 1:485–494

Ghorbanbeigi H, Shen W, Yurtdas I, Shao J-F (2016) A micromechanics-based model for concrete materials subjected to carbonation. Int J Numer Anal Methods Geomech 40(8):1203–1218

Guo T, Faleskog J, Shih C (2008) Continuum modeling of a porous solid with pressure-sensitive dilatant matrix. J Mech Phys Solids 56(6):2188–2212

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I: yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99(1):2–15

Han B, Xie S, Shao J (2016) Experimental investigation on mechanical behavior and permeability evolution of a porous limestone under compression. Rock Mech Rock Eng 49(9):3425–3435

Han B, Shen W, Xie S, Shao J (2018) Influence of pore pressure on plastic deformation and strength of limestone under compressive stress. Acta Geotech 14:535–545

Han B, Shen W, Xie S, Shao J-F (2020) Plastic modeling of porous rocks in drained and undrained conditions. Comput Geotech 117:103277

Homand S, Shao J (2000) Mechanical behaviour of a porous chalk and water/chalk interaction. part i: experimental study. Oil & Gas Sci Technol 55(6):591–598

Horii H, Nemat-Nasser S (1985) Compression-induced microcrack growth in brittle solids: axial splitting and shear failure. J Geophys Res Solid Earth 90(B4):3105–3125

Jeong H-Y (2002) A new yield function and a hydrostatic stress-controlled void nucleation model for porous solids with pressure-sensitive matrices. Int J Solids Struct 39(5):1385–1403

Khoei A, Azami A (2005) A single cone-cap plasticity with an isotropic hardening rule for powder materials. Int J Mech Sci 47(1):94–109

Labuz JF, Dai S-T, Papamichos E (1996) Plane-strain compression of rock-like materials. Int J Rock Mech Min Sci Geomech Abstr 33:573–584

Lade PV (1977) Elasto-plastic stress-strain theory for cohesionless soil with curved yield surfaces. Int J Solids Struct 13(11):1019–1035

Lade PV (1997) Modelling the strengths of engineering materials in three dimensions. Mech Cohesive-frict Mater 2(4):339–356

Lade PV, Kim MK (1995) Single hardening constitutive model for soil, rock and concrete. Int J Solids Struct 32(14):1963–1978

Lewis RW, Khoei AR (2001) A plasticity model for metal powder forming processes. Int J Plast 17(12):1659–1692

Lin J, Shao J-F, Kondo D (2011) A two scale model of porous rocks with Drucker-Prager matrix: application to a sandstone. Mech Res Commun 38(8):602–606

Lin J, Xie S, Shao J-F, Kondo D (2012) A micromechanical modeling of ductile behavior of a porous chalk: Formulation, identification, and validation. Int J Numer Anal Methods Geomech 36(10):1245–1263

Lisabeth HP, Zhu W (2015) Effect of temperature and pore fluid on the strength of porous limestone. J Geophys Res Solid Earth 120(9):6191–6208

Maghous S, Dormieux L, Barthélémy J (2009) Micromechanical approach to the strength properties of frictional geomaterials. Eur J Mech-A/Solids 28(1):179–188

Mowar S, Zaman M, Stearns D, Roegiers J-C (1996) Micro-mechanisms of pore collapse in limestone. J Pet Sci Eng 15(2–4):221–235

Pastor J, Thoré P, Pastor F (2010) Limit analysis and numerical modeling of spherically porous solids with coulomb and Drucker-Prager matrices. J Comput Appl Math 234(7):2162–2174

Paterson M (1958) Experimental deformation and faulting in Wombeyan marble. Geol Soc Am Bull 69(4):465–476

Perić D, Ayari MA (2002) On the analytical solutions for the three-invariant cam clay model. Int J Plast 18(8):1061–1082

Schleicher F (1925) Die energiegrenze der elastizitat (plastizitatsbedingung). Z Angew Math Mech 5:478–479

Schroeder C (2003) Mechanical behaviour of partially and multiphase saturated chalks and fluid-skeleton interaction: main factor of chalk oil reservoirs compaction and related subsidence. Final report of the EU project (PASACHALK2)

Shao J (1987) Etude du comportement d’une craie blanche très poreuse et modélisation. Ph.D. thesis, Lille 1

Shao J, Henry J (1991) Development of an elastoplastic model for porous rock. Int J Plast 7(1–2):1–13

Shen W, Shao J (2016) An incremental micro-macro model for porous geomaterials with double porosity and inclusion. Int J Plast 83:37–54

Shen W, Shao J (2017) Some micromechanical models of elastoplastic behaviors of porous geomaterials. J Rock Mech Geotech Eng 9(1):1–17

Shen W, Shao J (2018) A micro-mechanics based elastic-plastic model for porous rocks: applications to sandstone and chalk. Acta Geotech 13:329–340

Shen W, Shao J-F, Kondo D, Gatmiri B (2012) A micro-macro model for clayey rocks with a plastic compressible porous matrix. Int J Plast 36:64–85

Shen W, Kondo D, Dormieux L, Shao J (2013) A closed-form three scale model for ductile rocks with a plastically compressible porous matrix. Mech Mater 59:73–86

Shen W, Lanoye E, Dormieux L, Kondo D (2014) Homogenization of saturated double porous media with Eshelby-like velocity field. Acta Geophys 62(5):1146–1162

Shen WQ, Shao J-F, Kondo D, De Saxce G (2015) A new macroscopic criterion of porous materials with a Mises-Schleicher compressible matrix. Eur J Mech-A/Solids 49:531–538

Shen W, Shao J-F, Burlion N, Liu Z (2020) A microstructure-based constitutive model for cement paste with chemical leaching effect. Mech Mater 150:103571

Sulem J, Ouffroukh H (2006) Hydromechanical behaviour of Fontainebleau sandstone. Rock Mech Rock Eng 39(3):185

Tarokh A, Li Y, Labuz JF (2017) Hardening in porous chalk from precompaction. Acta Geotech 12(4):949–953

Vajdova V, Baud P, Wong T-f (2004) Compaction, dilatancy, and failure in porous carbonate rocks. J Geophys Res Solid Earth 109(B5)

Wong T-F, Szeto H, Zhang J (1992) Effect of loading path and porosity on the failure mode of porous rocks. Appl Mech Rev 45(8):281–293

Xie S, Shao J-F (2006) Elastoplastic deformation of a porous rock and water interaction. Int J Plast 22(12):2195–2225

Xie S, Shao J (2012) Experimental investigation and poroplastic modelling of saturated porous geomaterials. Int J Plast 39:27–45

Xie S, Shao J-F (2015) An experimental study and constitutive modeling of saturated porous rocks. Rock Mech Rock Eng 48(1):223–234

Xie S, Shao J, Xu W (2011) Influences of chemical degradation on mechanical behaviour of a limestone. Int J Rock Mech Min Sci 48(5):741–747

Yu J, Chen S-J, Chen X, Zhang Y-Z, Cai Y-Y (2015) Experimental investigation on mechanical properties and permeability evolution of red sandstone after heat treatments. J Zhejiang Univ-SCIENCE A 16(9):749–759

Yu J, Yao W, Duan K, Liu X, Zhu Y (2020) Experimental study and discrete element method modeling of compression and permeability behaviors of weakly anisotropic sandstones. Int J Rock Mech Min Sci 134:104437

Zhang J, Wong T-F, Davis DM (1990) Micromechanics of pressure-induced grain crushing in porous rocks. Journal of Geophysical Research: Solid Earth 95(B1):341–352

Acknowledgements

Supported by China Postdoctoral Science Foundation funded project (Grant No. 2020M670077), Natural Science Foundation of China (Grant Nos. 42107214 and 52130905).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Macroscopic Yield Criterion of Porous Material with Mises–Schleicher Solid Matrix [Adapted from Han et al. (2020)]

Consider now a porous material constituted by an isotropic solid matrix and spherical voids. The porosity is denoted by \(\phi\). The Mises–Schleicher criterion (Schleicher 1925) for the local strength of solid matrix is written as

\({\sigma _m} = tr(\bar{\bar{\sigma }})/3\) is the mean stress and \({\sigma _{eq}} = \sqrt{{{3} \!{/} \!{2}}{{\bar{\bar{\sigma }} }_d}:{{\bar{ \bar{\sigma }}}_d}}\) with \({\bar{\bar{\sigma }} }_d = \bar{\bar{\sigma }} - {\sigma _m}\bar{ \bar{\delta }}\) is the deviatoric stress of the local stress tensor in the solid matrix. Two coefficients \({\sigma _0}\ge 0\) and \({\alpha }\ge 0\) are related to the uniaxial tension strength \(\sigma _t\) and the absolute value of uniaxial compression strength \(\sigma _c\) by

The parameter \(\alpha\) is generally called the friction coefficient, and it controls the ratio between the uniaxial compression strength and the uniaxial tension strength. The parameter \({\sigma _0}\) is physically related to the material cohesion. Due to its nonlinear form, the Mises–Schleicher criterion is more suitable than the linear Drucker–Prager criterion to account for the strength dissymmetry between compression and tension.

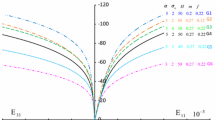

Denote \(\bar{\bar{\Sigma }}\) as the macroscopic stress tensor applied to the representative volume element (RVE) of the porous material. Adopting homogenization technique, Shen et al. (2015) derived a closed form of the macroscopic yield criterion of the porous material as a function of porosity and plastic parameters of solid matrix obeyed to the Mises–Schleicher criterion at the microscopic scale. Following the results given in Shen et al. (2015), the macroscopic criterion is written as follows:

\({\Sigma _m} = tr(\bar{\bar{\Sigma }} )/3\) is the macroscopic mean stress and \({\Sigma _{eq}} = \sqrt{{{3} \!{/ } \!{2}}{{\bar{\bar{\Sigma }} }_d}:{{\bar{ \bar{\Sigma }}}_d}}\) with \({\bar{\bar{\Sigma }} _d} = \bar{\bar{\Sigma }} - {\Sigma _m}\bar{\bar{\delta }}\) is the macroscopic deviatoric stress. s is a parameter controlling the shape of strength surface. W denotes the “Lambert W” function which satisfies \({W(x){e^{W(x)}} = x}\). W(x) has two branches: the upper branch \({W_0}(x) \ge - 1\) and the lower branch \({W_{ - 1}}(x) \le - 1\) (for \(- {e^{ - 1}} \le x < 0\) ). Furthermore, one gets \(W\left( {\phi p} \right) = {W_{ - 1}}\left( {\phi {p_ - }} \right)\) for compression zone and \(W\left( {\phi p} \right) = {W_0}\left( {\phi {p_ + }} \right)\) for tension zone. The coefficients \(p_ -\) and \(p_ +\) are functions of \(\alpha\) as follows:

Following a classical approach in the context of porous materials, the hardening variable \(\bar{\sigma }\) is introduced in (A.3) to replace \(\sigma _0\). The macroscopic plastic yield function is adopted in the following form (Han et al. 2020):

The yield criterion given in (A.6) was adapted to describe the plastic deformation of porous chalk under hydrostatic and triaxial compressive stress, and extended to describe the plastic deformation of porous sandstone under high confining pressure (Han et al. 2020).

Appendix B: Values of Parameters for Oil-Saturated Lixhe Chalk (Han et al. 2020)

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, B., Gong, Q.M., Du, X.L. et al. Elastoplastic Modelling of Porous Limestones with Porosity Dependency. Rock Mech Rock Eng 55, 7421–7444 (2022). https://doi.org/10.1007/s00603-022-03024-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-03024-1