Abstract

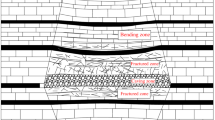

Understanding the evolution of gob compaction and related gas transport behavior is necessary for the planning and optimization of gas ventilation and control in longwall coal mines. In particular, the detachment of the undermined roof into the gob leaves a loosely compacted perimeter that skirts the longwall panel. This permeable gob perimeter in plan view forms as a result of shear separation from support provided by the solid ribs. This detachment and the resulting rotated and reduced stresses limit compaction, elevate permeability and exert significant control on gas flow during active longwall mining operations. We report gob compaction experiments on in-mine-collected fragmented rock and conduct mechanical compaction on stacked samples that are either uniformly coarsening upwards (case A) or are coarsening upwards, but capped by a segregated upper layer of coarse rock (case B). Observed compaction is linked to a capillary model representing porosity reduction and permeability evolution. As applied uniaxial stress increases from 0 to up to ~ 2000 kPa, the porosity decreases from 0.64 to 0.41(~ 36%) for the uniform stacked material (A) and but only from 0.66 to 0.51 (~ 23%) where the gob is topped with a layer of coarse “roof” rock simulants (B). Particle–particle self-adjustment dominates the compactive behavior at initial low stress and results in significant strain—followed by a linearly elastic region through the remainder of loading. The elastic regime is used to predict the permeability of the loosely compacted gob, considering the redistribution of stresses induced by shear collapse at the rib. Permeability evolution is scaled through the evolving compactive strains and particle size distribution of the fragmented rock, enabling results to be up-scaled to mine scale. These results provide a first rational method for analyzing the interactions between caved gob and the ventilation system towards mitigating gas concentrations and minimizing the hazard.

Data adapted from Pappas and Mark (1993)

Data adapted from Pappas and Mark (1993)

Raw data adapted from Pappas and Mark (1993)

Similar content being viewed by others

References

Adhikary DP, Guo H (2014) Modelling of longwall mining-induced strata permeability change. Rock Mech Rock Eng 48:345–359. https://doi.org/10.1007/s00603-014-0551-7

Alehossein H, Poulsen BA (2010) Stress analysis of longwall top coal caving. Int J Rock Mech Min Sci 47:30–41. https://doi.org/10.1016/j.ijrmms.2009.07.004

Arya LM, Paris JF (1981) A physico-empirical model to predict the soil moisture characteristic from particle-size distribution and bulk density data. Soil Sci Soc Am J 45:1218–1227

Auset M, Keller AA (2004) Pore-scale processes that control dispersion of colloids in saturated porous media. Water Resour Res. https://doi.org/10.1029/2003WR002800

Burke SP, Plummer WB (1928) Gas flow through packed columns. Ind Eng Chem 1(20):1196–1200. https://doi.org/10.1021/ie50227a025

Esterhuizen G, Karacan CÖ (2007) A methodology for determining gob permeability distributions and its application to reservoir modeling of coal mine longwalls. SME Ann Meet 88(1):012037

Fan L, Liu S (2017) A conceptual model to characterize and model compaction behavior and permeability evolution of broken rock mass in coal mine gobs. Int J Coal Geol 172:60–70. https://doi.org/10.1016/j.coal.2017.01.017

Forster I, Enever J (1992) Hydrogeological response of overburden strata to underground mining. Off. Energy Rep. 1:104

Guo H, Adhikary DP, Craig MS (2009) Simulation of mine water inflow and gas emission during longwall mining. Rock Mech Rock Eng 42:25–51. https://doi.org/10.1007/s00603-008-0168-9

Guo H, Todhunter C, Qu Q, Qin Z (2015) Longwall horizontal gas drainage through goaf pressure control. Int J Coal Geol 150–151:276–286. https://doi.org/10.1016/j.coal.2015.09.003

Jozefowicz RR (1997) The post-failure stress-permeability behaviour of coal measure rocks. PhD thesis. Univ. Nottingham

Karacan CÖ (2009a) Reconciling longwall gob gas reservoirs and venthole production performances using multiple rate drawdown well test analysis. Int J Coal Geol 80:181–195. https://doi.org/10.1016/j.coal.2009.09.006

Karacan CÖ (2009b) Forecasting gob gas venthole production performances using intelligent computing methods for optimum methane control in longwall coal mines. Int J Coal Geol 79:131–144. https://doi.org/10.1016/j.coal.2009.07.005

Karacan CÖ (2010) Prediction of porosity and permeability of caved zone in longwall gobs. Transp Porous Media 82:413–439. https://doi.org/10.1007/s11242-009-9437-7

Karacan CÖ, Esterhuizen GS, Schatzel SJ, Diamond WP (2007) Reservoir simulation-based modeling for characterizing longwall methane emissions and gob gas venthole production 71:225–245. https://doi.org/10.1016/j.coal.2006.08.003

Li L, Li F, Zhang Y, Yang D, Liu X (2020) Formation mechanism and height calculation of the caved zone and water-conducting fracture zone in solid backfill mining. Int J Coal Sci Technol 7(1):208–215

Liu S, Harpalani S (2014a) Determination of the effective stress law for deformation in coalbed methane reservoirs. Rock Mech Rock Eng 47:1809–1820. https://doi.org/10.1007/s00603-013-0492-6

Liu S, Harpalani S (2014b) Compressibility of sorptive porous media: part 1. Background ana theory. Am Assoc Pet Geol Bull 98:1761–1772. https://doi.org/10.1306/03241413133

Liu A, Liu S, Wang G, Sang G (2020a) Modeling of coal matrix apparent strains for sorbing gases using a transversely isotropic approach. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-020-02159-3

Liu A, Liu S, Wang G, Elsworth D (2020b) Predicting fugitive gas emissions from gob-to-face in longwall coal mines: coupled analytical and numerical modeling. Int J Heat Mass Transf 150:119392. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119392

Lowndes I, Reddish DJ, Ren T, Whittles DN, Hargreaves D (2002) Improved modeling to support the prediction of gas migration and emission from active longwall panels. Mine Vent. https://doi.org/10.1201/9781439833742.ch38

Mandelbrot BB (1982) the fractal geometry of nature. Freeman, New York, pp 23–117

Mortensen NA, Okkels F, Bruus H (2005) Reexamination of Hagen-Poiseuille flow: shape dependence of the hydraulic resistance in microchannels. Phys Rev E Stat Nonlinear Soft Matter Phys. https://doi.org/10.1103/PhysRevE.71.057301

Pappas DM, Mark C (1993). Behavior of simulated longwall gob material. Report of Investigations, US Department of the Interior. Bureau of Miness, RI-9458

Peng S (2008) Coal mine ground control, 3rd edn. Society for Mining, Metallurgy, and Exploration, Englewood

Rieu M, Sposito G (1991) Fractal fragmentation, soil porosity, and soil water properties: I. Theory 55:1231–1238

Sajjad A, Hossein J, Gholamreza Saeedi (2019) Prediction of face advance rate and determination of the operation efficiency in retreat longwall mining panel using rock engineering system. Int J Coal Sci Technol 6(3):419–429

Sirivithayapakorn S, Keller A (2003) Transport of colloids in saturated porous media: a pore-scale observation of the size exclusion effect and colloid acceleration. Water Resour Res. https://doi.org/10.1029/2002WR001583

Wang K, Liu A, Zhou AT (2017) Theoretical analysis of influencing factors on resistance in the process of gas migration in coal seams. Int J Min Sci Technol 27:315–319. https://doi.org/10.1016/j.ijmst.2017.01.011

Wang J, Elsworth D, Wu Y, Liu J, Zhu W, Liu Y (2018) The influence of fracturing fluids on fracturing processes: a comparison between water, oil and SC-CO2. Rock Mech Rock Eng 51:299–313. https://doi.org/10.1007/s00603-017-1326-8

Wang B, Dang F, Chao W, Miao Y, Li J, Chen F (2019) Surrounding rock deformation and stress evolution in pre-driven longwall recovery rooms at the end of mining stage. Int J Coal Sci Technol 6(4):536–546

Wang J, Wei W, Zhang J (2020) Theoretical description of drawing body shape in an inclined seam with longwall top coal caving mining. Int J Coal Sci Technol 7(1):182–195

Wu J, Yu B, Yun M (2008) A resistance model for flow through porous media. Transp Porous Media 71:331–343. https://doi.org/10.1007/s11242-007-9129-0

Yu B, Liu W (2004) Fractal analysis of permeabilities for porous media. AIChE J 50:46–57. https://doi.org/10.1002/aic.10004

Zhang C, Zhang L (2019) Permeability characteristics of broken coal and rock under cyclic loading and unloading. Nat Resour Res 28:1055–1069. https://doi.org/10.1007/s11053-018-9436-x

Zhang C, Tu S, Zhang L, Bai Q, Yuan Y, Wang F (2016) A methodology for determining the evolution law of gob permeability and its distributions in longwall coal mines. J Geophys Eng 13:181–193. https://doi.org/10.1088/1742-2132/13/2/181

Zhang C, Tu S, Zhao Y (2019) Compaction characteristics of the caving zone in a longwall goaf: a review. Environ Earth Sci 78:1–20. https://doi.org/10.1007/s12665-018-8037-7

Zhao J, Yin L, Guo W (2018) Stress-seepage coupling of cataclastic rock masses based on digital image technologies. Rock Mech Rock Eng 51:2355–2372. https://doi.org/10.1007/s00603-018-1474-5

Zhao Y, Zhou H, Zhong J, Liu D (2019) Study on the relation between damage and permeability of sandstone at depth under cyclic loading. Int J Coal Sci Technol 6(4):479–492

Zhu W, Li S, Niu L, Liu K, Xu T (2016) Experimental and numerical study on stress relaxation of sandstones disturbed by dynamic loading. Rock Mech Rock Eng 49:3963–3982. https://doi.org/10.1007/s00603-016-1049-2

Acknowledgements

This study was sponsored by the Alpha Foundation for the Improvement of Mine Safety and Health, Inc. (ALPHA FOUNDATION). The views, opinions, and recommendations expressed herein are solely those of the authors and do not imply any endorsement by the ALPHA FOUNDATION, its Directors and staff. We also thank our partner mine, Tangkou coal mine, for support and for providing access to the mine for field work. The data used in this study can be downloaded from the Zenodo website (https://zenodo.org/record/3929410).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest for this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

In this study, the raw experiment data for validating the proposed model was cited from Pappas and Mark (1993). In addition, the raw data was also organized by Karacan (2010). Pappas and Mark (1993) conducted compaction tests on gob materials collected from one site in a Virginia mine in the Pocahontas Coalbed, and two sites in an eastern Kentucky mine in the Harlan Coalbed. The test results of each simulated gob material were summarized in Table 2. The particle size distribution before and after corresponding loads were shown in Fig. 16 and the fragmentation fractal dimension \(D_{\text{F}}\) was calculated based on Eq. (18) and the results were summarized in Table 3. As shown in Fig. 10, the stress–strain curves were monitored and the corresponding displacements were obtained through the compaction experiments. Based on the stress–strain curves and the initial porosities (Table 2), the stress-dependent porosities can be calculated by referring the methods illustrated in Sect. 3.2.

Rights and permissions

About this article

Cite this article

Liu, A., Liu, S., Wang, G. et al. Continuous Compaction and Permeability Evolution in Longwall Gob Materials. Rock Mech Rock Eng 53, 5489–5510 (2020). https://doi.org/10.1007/s00603-020-02222-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-020-02222-z