Abstract

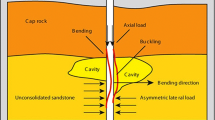

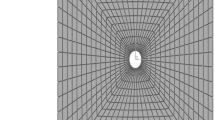

Numerous cases of casing failure have been reported worldwide. Depletion-induced compaction is one of the main factors that may cause casing failure. Stress perturbation in salt layers may accommodate rock flow which endangers the stability of cased wells. Besides, poor cementing jobs are recognized as one of the wellbore instability causes. These factors need to be considered to determine the mechanism behind the casing failure. In this study, the creep behavior of the caprock salt layer in the southwest Iranian oil fields is experimentally studied through a number of creep tests under conditions of elevated temperature and pressure. Then, a three-dimensional finite element analysis is utilized to examine the validity of various casing failure scenarios after calibrating the model with well logs and experimental data. The results confirmed that the combined effects of creep behavior of rock salt and cementing imperfection can be the main cause of failure in the wellbore under study, because the failure time and depth predicted by the numerical simulation were found to be in accordance with the real field data. By history matching, the geomechanical parameter of the salt layer has been modified for study of the casing failure in other wells in the same formation.

Similar content being viewed by others

Abbreviations

- \(S_{\text{V}}^\prime\) :

-

Vertical effective stress

- S V :

-

Vertical stress

- α :

-

Biot coefficient

- Pp:

-

Pore pressure

- ρ :

-

Density

- E :

-

Elastic modulus

- ν :

-

Poisson's ratio

- c :

-

Cohesion

- φ :

-

Friction angle

- \(S_{\text{H}}^\prime\) :

-

Maximum horizontal effective stress

- \(S_{\text{h}}^\prime\) :

-

Minimum horizontal effective stress

- Δt :

-

Time increment

- γ w :

-

Specific weight of the pore fluid

- k :

-

Permeability

- Δl :

-

Element size

- σ VM :

-

Total von Mises stress

- σ z :

-

Total overburden stress

- σ θ :

-

Total hoop stress

- σ r :

-

Total radial stress

- ΔL :

-

Length change

- L :

-

Initial length

- A o :

-

Outside area of the casing

- A i :

-

Inside area of the casing

- Δpi :

-

Changes in internal pressure

- Δpo :

-

Changes in external pressure

- \(\dot{\varepsilon }\) :

-

Strain rate

- Δσ :

-

Deviatoric stress

- A 0 :

-

Viscosity

- Q :

-

Activation energy

- n :

-

Stress power coefficient

- R :

-

Universal constant of gases

- T :

-

Absolute rock temperature

- \(\left. {\bar{\varepsilon }^{{{\text{pl}}}} } \right|_{0}\) :

-

Initial equivalent plastic strain

References

Albertz M, Beaumont C, Shimeld JW, Ings SJ, Gradmann S (2010) An investigation of salt tectonic structural styles in the Scotian Basin, offshore Atlantic Canada: 1. Comparison of observations with geometrically simple numerical models. Tectonics 29:TC4017. https://doi.org/10.1029/2009TC002539

Bellarby J (2009) Well completion design. Elsevier, Amsterdam

Chatar C, Imler MD (2010) Overcoming a difficult salt drilling environment in the Gulf of Mexico: a case stud. In: LADC/SPE drilling conference and exhibition, SPE, New Orleans

Cristescu ND, Hunsche U (1988) Time effects in rock mechanics. Wiley, New York, p 342

Deng JG, Huang RZ (1994) Computing method of casing loads in creep formation. Pet Drill Tech 22(4):21–43

Fjaer E, Holt RM, Horsrud P, Raaen AM (2008) Petroleum related rock mechanics, 2nd edn. Elsevier publishing, Amsterdam

Fredrich JT, Coblentz D, Fossum AF, Thorne BJ (2003) Stress perturbations adjacent to salt bodies in the deepwater Gulf of Mexico. SPE 84554, Sandia National Laboratories

Gholami R et al (2015) Geomechanical and numerical studies of casing damages in a reservoir with solid production. Springer, Vienna

Gorjian M (2010) The role of geomechanical behavior of evaporative formations to induce casing collapse in the Maroon oil field wells. MSc Thesis. Mining Engineering Rock Mechanics University of Tehran

Grosmangin M, Kokesh PP, Majani P (1961) A sonic method for analyzing the quality of cementation of borehole casings. Society of Petroleum Engineers

Hunsche U, Hampel A (1999) Rock salt—the mechanical properties of the host rock material for a radioactive waste repository. Eng Geol 52(3–4):271–291

Lao K, Bruno MS, Serajian V (2012) Analysis of salt creep and wall casing damage in high pressure and high temperature environments. OTC 23654, Offshore Technology Conference, Houston

Lautenschläger CER, Righetto GL, Albuquerque RAC, Inoue N, Fontoura SAB (2014) Effects of reservoir development on the wall casing behavior. ATHENA—Computational Geomechanics Group, GTEP, PUC-Rio, University of Rio de Janeiro, Brazil

Mahab Ghodss Consulting Engineers & Coyne Et Bellier (2005) Geotechnical characteristics of the dam foundation, Upper Gotvand dam & HEPP

Mehrgini B et al (2016a) Geo-mechanical characterization of a south Iran carbonate reservoir rock at ambient and reservoir temperatures. J Nat Gas Sci Eng 34:269–279

Mehrgini B, Memarian H, Dusseault MB, Ghavidel A, Heydarzadeh M (2016b) Geomechanical characteristics of common reservoir caprock in Iran (Gachsaran Formation), experimental and statistical analysis. J Nat Gas Sci Eng 34:898–907

Papavinasam S (2014) In corrosion control in the oil and gas industry; the oil and gas industry. Elsevier, Amsterdam, pp 1–39

Peng S, Fu J, Zhang J (2007) Borehole casing failure analysis in unconsolidated formations: a case study. J Petrol Sci Eng 59:226–238

Rolf B, Mohammed W, Mohsen P (2006) A preliminary study of casing collapse in Iran, Hydroquest report. Schlumberger Oil Company, Houston

Salehi S et al (2009) Casing collapse assessment and depth prediction with neural network system approach. J Petrol Sci Eng 69:156–162

Salehin S (2017) Investigation into engineering parameters of marls from Seydoon dam in Iran. J Rock Mech Geotech Eng 9:912–923

Schutjens PMTM, Snippe JR, Mahani H, Turner J, Ita J (2012) Production-induced stress change in and above a reservoir pierced by two salt domes: a geomechanical model and its applications. SPE J 17:80–97

Schutjens PMTM, Fokker P, Rai UBB, Kandpal J, Cid Alfaro MV, Hummel ND, Yuan R, Klever F, De Gennaro S, Vaibav J, Bourgeois F, Calvert M, Ditlevsen F, Hendriksen P, Derer C, Richards G, Price J, Bere A, Cain J (2019) Compaction- and shear-induced well deformation in tyra: geomechanics for impact on production. Rock Mech Rock Eng 52:5205–5224. https://doi.org/10.1007/s00603-019-01892-8

Shen X (2010) Subsidence prediction and casing integrity with respect to pore-pressure depletion with 3-D finite-element method. SPE Latin American and Caribbean Petroleum Engineering Conference Proceedings. https://doi.org/10.2118/138338-MS

ABAQUS-6.12 (2012) ABAQUS analysis user’s manual. ABAQUS 6.12, Dassault Systèmes Simulia Corp, Providence, RI, USA

Taheri SR, Pak A, Shad S, Mehrgini B, Razifar M (2020) Investigation of rock salt layer creep and its effects on casing collapse. Int J Min Sci Technol. https://doi.org/10.1016/j.ijmst.2020.02.001

Terzaghi K (1943) Theoretical soil mechanic. Wiley, New York

UPRI (Upstream Petroleum Research Institute) (2018) Problem recognition, data analysis, and geological investigation review; evaluation of enhanced oil recovery methods. Sharif University of Technology, Prepared for National Iranian South Oil Company

Veeken CAM, Wahleitner, JP, Keedy CR (1994) Experimental modeling of casing deformation in a compacting reservoir. SPE/ISRM 28090 In: Proc Eurock94, Delft, Netherlands, pp 497–506

Wang HY, Samuel R (2016) 3D geomechanical modeling of salt-creep behavior on wellbore casing for presalt reservoirs. SPE Drilling Completion 31:261–272. https://doi.org/10.2118/166144-PA

Zou LZ, Deng JG, Zeng YJ, Li J, Dong WZ (2008) Investigation of casing load calculation and casing design for deep salt formation. Pet Drill Technol 31:23–27

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors would like to appreciate the support of Iran National Science Foundation (INSF: Grant No. 96001589, Contract No. 96002219).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Definition of Equations

Appendix: Definition of Equations

The vertical effective stress at each depth is (Terzaghi 1943):

where, \(S_{{\text{V}}}^{^{\prime}}\) is the vertical effective stress, \(S_{{\text{V}}}^{{}}\) is the vertical stress integrated over the distance from the surface down to the desired depth according to density of the overlying layers (Table 1), and Pp is the pore pressure.

The horizontal effective stress at each depth can be estimated as follows (Fjaer et al. 2008):

where, \(S_{{\text{H}}}^{^{\prime}}\): Maximum horizontal effective stress, \(S_{{\text{h}}}^{^{\prime}}\): Minimum horizontal effective stress, \(\nu\): Poisson's ratio, and \({\text{S}}_{V}^{^{\prime}}\): Vertical effective stress.

The relationship between the minimum time increment and the element size in the numerical simulation is (Dassault Systèmes Simulia Corp. 2012):

where Δt is the time increment; γw is the specific weight of the pore fluid, E is the elastic modulus of the rock, k is the permeability of the rock, and Δl is the typical element size near the boundary condition.

Von Mises stress is stated as follows (Bellarby 2009):

where σVM is von Mises stress; σz is the overburden stress; σθ is hoop stress; and σr is the radial stress.

Rights and permissions

About this article

Cite this article

Taheri, S.R., Pak, A. Casing Failure in Salt Rock: Numerical Investigation of its Causes. Rock Mech Rock Eng 53, 3903–3918 (2020). https://doi.org/10.1007/s00603-020-02161-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-020-02161-9