Abstract

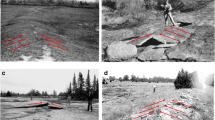

Near-surface buckling of horizontally laminated sedimentary rock has been reported to occur in Ontario, Canada and the Upper Midwestern U.S. where high horizontal in situ stresses occur. Often referred to as ‘pop ups’, these buckling events typically occur suddenly and are commonly accompanied by a rapid energy release akin to rock bursting. In recent years, this mode of instability has become a concern for surface mining and quarry operations, in particular in cases where the buckling failure creates a connection between an underlying aquifer and the excavation. Despite previous research on the topic of buckling instability, there remains many limitations in development of a design methodology to account for buckling failure. The main objective of this research study is to experimentally investigate a simple buckling failure mode, known as three hinge buckling (THB): buckling that involves rotation of a two-rock block configuration with a central hinge. An experimental testing procedure was developed to reproduce THB at laboratory scale, including the design and fabrication of a new testing apparatus and development of a testing methodology. A preliminary THB test was conducted and the results are presented. A simplified, elastic block numerical model was developed using the distinct element method code 3DEC in order to provide insight into the laboratory experiment. Overall, this newly-developed test was able to reproduce the THB failure experimentally in the laboratory and to provide an opportunity to observe the brittle buckling failure to obtain valuable, quantifiable information about the failure process.

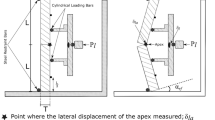

Modified after Roorda (1995)

Similar content being viewed by others

Notes

Abbreviations

- AE:

-

Acoustic emission

- DAQ:

-

Data acquisition system

- DCV:

-

Directional control valve

- DIC:

-

Digital image correlation

- LP:

-

Linear potentiometer

- LVDT:

-

Linear variable differential transducer

- THB:

-

Three hinge buckling

- UCS:

-

Unconfined compressive strength (test name)

- \(c_{\text{j}}\) :

-

Interface (joint) cohesion

- \(\delta_{\text{a}}\) :

-

Axial displacement of upper load platen

- \(\delta_{\text{l}}\) :

-

Lateral displacement measured from the reference tab

- E :

-

Young’s modulus

- \(\phi _{\text{j}}\) :

-

Interface (joint) friction angle

- \(K_{\text{n}}\) :

-

Interface normal stiffness

- \(K_{\text{s}}\) :

-

Interface shear stiffness

- L :

-

Length (vertical) of test block specimen

- \(\nu\) :

-

Poisson’s ratio

- \(P_{\text{a}}\) :

-

Axial load on THB block specimens

- \(P_{\text{l}}\) :

-

Lateral load on THB block specimens

- \(\rho\) :

-

Rock density

- \(\bar{\sigma }_{\text{H}}\) :

-

Maximum horizontal in situ stress

- \(\sigma _{\text{a}}\) :

-

Axial stress on block specimens (‘clamping stress’)

- \(\sigma _{\text{c}}\) :

-

Peak stress from the UCS test

- \(\sigma _{\text{t}}\) :

-

Tensile strength

- \(\sigma _{\text{ci}}\) :

-

Crack initiation stress from the UCS test

- \(\sigma _y\) :

-

Stress component in y direction

- \(t_{\text{j}}\) :

-

Interface (joint) tensile strength

- T :

-

Thickness of test block specimen in buckling direction

- W :

-

Width of test block specimen perpendicular to buckling

References

Adams J (1982) Stress-relief buckles in the McFarland quarry, Ottawa. Can J Earth Sci 19(10):1883–1887

ASTM C1609/C1609M-12 (12) standard test method for flexural performance of fiber-reinforced concrete (using beam with third-point loading) BT-Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading). Tech. Rep. C 1609/C 1609M-05

ASTM D4543 (2008) Standard practices for preparing rock core as cylindrical test specimens and verifying conformance to dimensional and shape tolerances. Astm D 4543–08:1–9

Boon CW (2019) Study of reinforcement support mechanisms for wide-span horse-shoe-shaped openings in horizontally layered jointed rock using the distinct element method. Rock Mech Rock Eng 52(4):1179–1191

Cavers DS (1981) Simple methods to analyze buckling of rock slopes. Rock Mech Rock Eng 14(2):87–104

Corkum AG, Asiri Y, El Naggar H, Kinakin D (2018) The leeb hardness test for rock: an updated methodology and UCS correlation. Rock Mech Rock Eng 51(3):665–675

Dawe JL, Seah CK (1989) Out-of-plane resistance of concrete masonry infilled panels

Diederichs MS, Kaiser PK (1999) Stability of large excavations in laminated hard rock masses: the voussoir analogue revisited. Int J Rock Mech Min Sci 36(1):97–117

Garza-Cruz TV, Pierce M, Kaiser P (2014) Use of 3DEC to study spalling and deformation associated with tunnelling at depth. In: Proceedings of the seventh international conference on deep and high stress mining, Australian Centre for Geomechanics, pp 421–434

ISRM (2007) The ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. International Society for Rock Mechanics (ISRM Blue Book), Springer, Suggested Methods Prepared by the Commission on Testing Methods

Itasca (2014) UDEC version 6.0 user manual. Itasca Consulting Group Inc., Minneapolis, Minnesota

Kulhawy FH (1975) Stress deformation properties of rock and rock discontinuities. Eng Geol 9(4):327–350

Li BQ, Einstein HH (2017) Comparison of visual and acoustic emission observations in a four point bending experiment on barre granite. Rock Mech Rock Eng 50(9):2277–2296

Martin CD, Read RS, Martino JB (1997) Observations of brittle failure around a circular test tunnel. Int J Rock Mech Min Sci 34(7):1065–1073

McDowell EL, McKee KE, Sevin E (1956) Arching action theory of masonry walls, vol 82

Roorda J (1995) The mechanics of a pop-up: a stress relief phenomenon. Can Geotech J 39(1):368–373

Roorda J, Thompson JC, White OL (1982) The analysis and prediction of lateral instability in highly stressed, near-surface rock strata. Can Geotech J 19(4):451–462

Sofianos A (1996) Analysis and design of an underground hard rock voussoir beam roof. Int J Rock Mech Min Sci Geomech Abstr 33(2):153–166

Tommasi P, Verrucci L, Campedel P, Veronese L, Pettinelli E, Ribacchi R (2009) Buckling of high natural slopes: the case of Lavini di Marco (Trento-Italy). Eng Geol 109(1–2):93–108

Wallach JL, Mohajer AA, McFall GH (1993) Pop-ups as geological indicators of earthquake-prone areas in intraplate eastern North America. Quaternary proceedings (January 1993)

White OL, Russell DJ (1982) High horizontal stresses in Southern Ontario—their orientation and their origin. In: IV congress international association of engineering geology, vol v

Acknowledgements

The authors would like to express gratitude to Itasca Consulting Group, Inc. for support as part of their mentorship program, in particular Dr Branko Damjanac. The authors would like to thank Dalhousie technicians Brian Kennedy, Jordan Maerz and Jesse Keane for valuable design input and assistance with apparatus fabrication.

Funding

Funding for the study was provided through the NSERC Discovery Grant and NSERC Engage Grant programs in cooperation with Dexter Construction Ltd as our partner organization.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflict of interest with respect to the study presented in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghasemi, M., Corkum, A.G. A Three Hinge Buckling Laboratory Test. Rock Mech Rock Eng 53, 4077–4090 (2020). https://doi.org/10.1007/s00603-020-02143-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-020-02143-x