Abstract

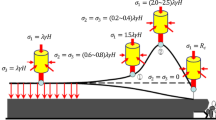

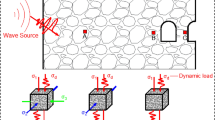

With the increase of coal extracting depth, a considerable number of dynamic disasters display the co-occurrence and coupling effect of rockburst and coal–gas outburst, which is defined as the disturbed compound dynamic disaster. In this study, two loading modes were adopted to investigate disaster characteristics using true triaxial apparatus. The stress states of one freed and the other five stressed faces were introduced to simulate actual stress conditions. Two high-speed cameras were used to capture the disaster process. The mechanical and strength properties, failure modes, and ejection kinetic energy were analyzed. Results showed that the compound dynamic disaster mainly exhibited local grain ejection, fragment spalling, large-scale grain ejection, plate bending, and ultimately failure. The strength of the sample first increased and then decreased slowly with the increase in the intermediate principal stress. After failure, a V-shaped coal-burst pit was formed, which was approximately parallel to the intermediate principal stress and perpendicular to the free face. The grain ejection exhibited obvious characteristics of spatial sorting, and the grain size decreased with the distance from the free face. The kinetic energy showed little change with increase in the intermediate principal stress in the displacement loading mode; whereas, it first increased and then decreased in the stress loading mode. The pressurized gas promotes the development of coal cracks and fully fractures the coal rock. Under the combined actions of the elastic energy stored in coal mass and the internal energy of pressurized gas, compound dynamic disasters may occur. Gas extraction and coal seam elastic softening techniques can effectively reduce and prevent the occurrence probability of compound dynamic disasters.

Similar content being viewed by others

Abbreviations

- σx, σy, σz :

-

Principal stresses in directions of X, Y, and Z, respectively (MPa)

- σ1, σ2, σ3 :

-

Major, intermediate, and minimax principal stresses, respectively (MPa)

- \( \bar{\sigma }_{1} \), \( \bar{\sigma }_{2} \), \( \bar{\sigma }_{3} \) :

-

Effective principal stresses (MPa)

- v1, v2 :

-

Loading rate of σ1 and σ2, respectively (MPa/s)

- β :

-

Stress loading speed ratio of σ2 to σ1

- ε1, ε2, ε3 :

-

Major, intermediate, and minimax principal strain, respectively

- W i :

-

Ejection energy (J)

- L i :

-

Distance of ejected grain from specimen face (cm)

- m i :

-

Mass of ejected grain (g)

- v i :

-

Speed of ejection grain (m/s)

- H :

-

Height of grains dropping (m)

- g:

-

Gravity acceleration (m/s2)

- t i :

-

Movement time of ejected grains (s)

- U :

-

Total energy (J)

- U d :

-

Dissipation energy (J)

- U e :

-

Releasable elastic strain energy (J)

- α:

-

Effective gas stress coefficient

- p :

-

Gas pressure (MPa)

- \( \varepsilon_{i}^{\text{e}} \) :

-

Elastic principal strain

- E c :

-

Elastic modulus (GPa)

- υ c :

-

Poisson’s ratio

- Q :

-

Energy required for coal rock particle cementation fracture (J)

- W :

-

Kinetic energy of coal rock fragments (J)

- λ :

-

Kinetic energy release ratio

- k :

-

Kinetic energy release rate

- p if :

-

Gas pressure in the crack (MPa)

- p 2 :

-

Atmospheric pressure (MPa)

- a :

-

Crack radius (m)

- h :

-

Distance of the crack to the free face (m)

- M 1 :

-

Coefficient affected by ratio a/h

- K c :

-

Crack toughness of gas-containing coal (MN/m3/2)

- η :

-

Effect coefficient of adjacent fractures

References

Aguado MD, Nicieza CG (2007) Control and prevention of gas outbursts in coal mines, Riosa-Olloniego coalfield, Spain. Int J Coal Geol 69:253–266

Alber M, Fritschen R, Bischoff M, Meier T (2009) Rock mechanical investigations of seismic events in a deep longwall coal mine. Int J Rock Mech Min Sci 46:408–426

Deng BZ, Yin GZ, Li MH, Zhang DM, Lu J, Liu YB, Chen JQ (2018) Feature of fractures induced by hydrofracturing treatment using water and L-CO2 as fracturing fluids in laboratory experiments. Fuel 226:35–46

Du K, Tao M, Li XB, Zhou J (2016) Experimental study of slabbing and rockburst induced by true-triaxial unloading and local dynamic disturbance. Rock Mech Rock Eng 49(9):3437–3453

Dvorsky P, Konicek P, Morkovska E, Palla L (2003) Rock blasting as a rockburst control measures in the safety pillar of SW crosscuts at Lazy Colliery in Orlova´. In: Proceedings of the 10th international scientific-technical conference-rockbursts 2003. Ustron´, 21–24 November 2003, pp 37–45

Feng XT, Zhang XW, Kong R, Wang G (2016) A novel mogi type true triaxial testing apparatus and its use to obtain complete stress-strain curves of hard rocks. Rock Mech Rock Eng 49:1649–1662

Haimson BC, Chang C (2000) A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of westerly granite. Int J Rock Mech Min Sci 37(1):285–296

He MC, Miao JL, Feng JL (2010) Rock burst process of limestone and its acoustic emission characteristics under true-triaxial unloading conditions. Inter J Rock Mech Min Sci 47(2):286–298

He MC, Zhao F, Cai M, Du S (2015) A novel experimental technique to simulate pillar burst in laboratory. Rock Mech Rock Eng 48:1833–1848

He J, Dou LM, Gong SY, Li J, Ma ZQ (2017) Rock burst assessment and prediction by dynamic and static stress analysis based on micro-seismic monitoring. Inter J Rock Mech Min Sci 93:46–53

Ingraham M, Issen K, Holcomb D (2013) Response of castlegate sandstone to true triaxial states of stress. J Geophys Res 118:536–552

Keshavarz A, Badalyan A, Carageorgos T, Bedrikovetsky P, Johnson R (2015) Stimulation of coal seam permeability by micro–sized graded proppant placement using selective fluid properties. Fuel 144:228–236

Li T, Cai MF, Cai M (2007) A review of mining-induced seismicity in China. Int J Rock Mech Min Sci 44:1149–1171

Li XB, Feng F, Li DY, Du K, Ranjith PG, Rostami J (2018) Failure characteristics of granite influenced by sample height–to–width ratios and intermediate principal stress under true–triaxial unloading conditions. Rock Mech Rock Eng 51:1321–1345

Liu T, Lin B, Yang W (2017) Impact of matrix–fracture interactions on coal permeability: model development and analysis. Fuel 207:522–532

Liu HH, Lin BQ, Mou JH, Yang W (2019) Mechanical evolution mechanism of coal and gas outburst. Rock Mech Rock Eng 52:1591–1597. https://doi.org/10.1007/s00603-018-1546-6

Lu J, Yin GZ, Li X, Li MH, Zhang DM, Zhang WZ, Kang QR (2019a) Deformation and CO2 gas permeability response of sandstone to mean and deviatoric stress variations under true triaxial stress conditions. Tunn Undergr Space Technol 84(02):259–272. https://doi.org/10.1016/j.tust.2018.11.023

Lu J, Yin GZ, Deng BZ, Zhang WZ, Li MH, Chai XW, Liu C, Liu YB (2019b) Permeability characteristics of layered composite coal-rock under true triaxial stress conditions. J Nat Gas Sci Eng 66(06):60–76

Ma XD, Haimson BC (2017) Failure characteristics of two porous sandstones subjected to true triaxial stresses. J Geophys Res 2017:122. https://doi.org/10.1002/2016JB013637

Ma TH, Tang CA, Tang SB, Kuang L, Yu Q, Kong DQ, Zhu X (2018) Rockburst mechanism and prediction based on microseismic monitoring. Inter J Rock Mech Min Sci 2018(110):177–188

Mazaira A, Konicek P (2015) Intense rockburst impacts in deep underground construction and their prevention. Can Geotech J 52:1426–1439

Petr K, Kamil S, Lubomir Rajendra S (2013) Long-hole destress blasting for rockburst control during deep underground coal mining. Inter J Rock Mech Min Sci 61:141–153

Przeczek A, Dvorsky P, Konicek P (2005) System of rock blasting in boreholes diameter more than 100 mm as a rockburst measure. In: Proceedings of the 12th international scientific-technical conference-rockbursts 2005. Ustron´, 24–24 November 2005, pp 253–269

Qin SQ, Jiao JJ, Tang CA, Li ZG (2006) Instability leading to coal bumps and nonlinear evolutionary mechanisms for a coal-pillar-and-roof system. Int J Solids Struct 43:7407–7423

Su GS, Jiang JQ, Zhai SB, Zhang GL (2017a) Influence of tunnel axis stress on strainburst: an experimental study. Rock Mech Rock Eng 50(6):1551–1567

Su GS, Chen ZY, Ju JW, Jiang JQ (2017b) Influence of temperature on the strainburst characteristics of granite under true triaxial loading conditions. Eng Geol 222:38–52

Wang YF, Cui F (2018) Energy evolution mechanism in process of sandstone failure and energy strength criterion. J Appl Geophys 154:21–28

Wang JC, Jiang FX, Meng XJ, Wang XY, Zhu ST, Feng Y (2016) Mechanism of rock burst occurrence in specially thick coal seam with rock parting. Rock Mech Rock Eng 49(5):1–13

Wang CJ, Yang SQ, Yang DD, Li XW, Jiang CL (2018) Experimental analysis of the intensity and evolution of coal and gas outbursts. Fuel 226:252–262

Xie HP, Li L, Peng R, Ju Y (2009) Energy analysis and criteria for structural failure of rocks. J Rock Mech Geotech Eng 1(1):11–20

Xie HP, Gao MZ, Zhang R, Peng GY, Wang WY, Li AQ (2019) Study on the mechanical properties and mechanical response of coal mining at 1000 m or deeper. Rock Mech Rock Eng 52(05):1475–1490

Xu LH, Jiang CL (2017) Initial desorption characterization of methane and carbon dioxide in coal and its influence on coal and gas outburst risk. Fuel 2017(203):700–706

Xue Y, Gao F, Teng T, Xing Y (2016) Effect of gas pressure on rock burst proneness indexes and energy dissipation of coal samples. Rock Mech Rock Eng 34:1737–1748

Yin GZ, Lu J, Li X, Bian G, Song ZL, Liu YB (2017) Influence of intermediate principal stress on dilation and strength characteristics of sandstone. J China Coal Soc 42(4):879–885 (in Chinese)

Zhang CL, Xu J, Peng SJ, Li QX, Yan FZ, Chen YX (2018) Dynamic behavior of gas pressure and optimization of borehole length in stress relaxation zone during coalbed methane production. Fuel 233:816–824

Zhang ZP, Xie HP, Zhang R, Zhang ZT, Gao MZ, Jia ZQ, Xie J (2019) Deformation damage and energy evolution characteristics of coal at different depths. Rock Mech Rock Eng 52(05):1491–1503

Zhao XG, Wang J, Cai M, Cheng C, Ma LK, Su R, Zhao F, Li DJ (2014) Influence of unloading rate on the strainburst characteristics of beishan granite under true triaxial unloading conditions. Rock Mech Rock Eng 47:467–483. https://doi.org/10.1007/s00603-013-0443-2

Zhao J, Xu H, Tang D, Mathews JP, Li S, Tao S (2016) A comparative evaluation of coal specific surface area by CO2 and N2 adsorption and its influence on CH4 adsorption capacity at different pore sizes. Fuel 183:420–431

Zhao W, Cheng YP, Guo PK, Jin K, Tu QY, Wang HF (2017) An analysis of the gas-solid plug flow formation: new insights into the coal failure process during coal and gas outbursts. Powder Technol 305:39–47

Zhao Y, Lin BQ, Liu T, Li QZ, Kong J (2018) Gas flow field evolution around hydraulic slotted borehole in anisotropic coal. J Nat Gas Sci Eng 58:189–200

Zhou HX, Gao J, Han K, Cheng YP (2018a) Permeability enhancements of borehole outburst cavitation in outburst prone coal seams. Inter J Rock Mech Min Sci 111:12–20

Zhou DW, Zhang GQ, Wang YY, Xing YK (2018b) Experimental investigation on fracture propagation modes in supercritical carbon dioxide fracturing using acoustic emission monitoring. Inter J Rock Mech Min Sci 111:111–119

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (Grant nos 51874053, 51434003, and 51804049), the China Postdoctoral Science Foundation Funded Project (Grant no 2017M612917), and the Chongqing Postdoctoral Research Project Special Funding (Grant no XM2017043). Thanks for the guidance of our doctoral supervisor professor Yin, who has died of illness in June 2019.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lu, J., Yin, G., Gao, H. et al. True Triaxial Experimental Study of Disturbed Compound Dynamic Disaster in Deep Underground Coal Mine. Rock Mech Rock Eng 53, 2347–2364 (2020). https://doi.org/10.1007/s00603-019-02041-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-019-02041-x