Abstract

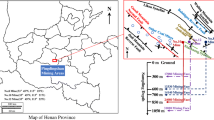

As shallow coal resources are gradually depleted, resource exploitation extends from the shallow into the deep, where the mechanical properties of the coal rocks change significantly. To study the mechanical properties and mining-induced response characteristics of deep coal rocks. On a laboratory scale, laboratory tests and mining mechanics simulations were conducted on coal samples recovered from 1000 m or deeper using a rock mechanics testing system called MTS815 Flex Test GT. On the engineering scale, considering the roadway Ji-14-31050, buried in Pingdingshan Coal Mine No. 12 as the research base, four parameters—anchor bolt stress, borehole stress, roof displacement, and roadway convergence distortion—were monitored to study the mining-induced mechanical response characteristics of the coal rocks. The laboratory-scale study showed that the tensile strength and deformation of the deep coal rocks were generally small when destroyed; the tensile strength was in the range of 0.07–0.15 MPa, indicating low strength and high brittleness; the average compression strength of the coal rocks at 1000 m or deeper was 111.7 MPa, which was significantly greater than that of coal rocks at shallower depths. The axial strain and volumetric strain of the deep coal rocks were also greater than those of the shallow coal rocks, indicating significant plasticity. Under the conditions of pillarless mining, the axial deformation, lateral deformation, and volume deformation of deep coal samples all show a large deformation platform near the peak stress, corresponding to the area in which the volumetric deformation showed a trend of expansion; furthermore, the peak stress was significantly lower in this area. The study on the engineering scale showed the coal mining-affected area (approximately 70 m) along the mining direction of the Ji-14-31050 coal mining face with a depth of over 1000 m in the Pingdingshan No. 12 mine was obviously larger than that of the shallow coal seams. As the mining face advanced, the anchor bolt stress, the roof separation, and the roadway section deformation showed similar patterns of increasing variation. In an area 30-m away from the mining face, the supporting pressure peaked, and the anchoring stress, roof separation, and tunnel cross-sectional deformation all changed significantly, displaying the surging phenomenon. At the same time, the roadway sidewall deformation was significantly greater than the deformation between the roof and floor. Clearly, as the mining depth extended deeper, the mining-induced stress field became increasingly more intense, and the coal mining-affected area increased noticeably. Meanwhile, the surrounding rock deformation and roof separation increased significantly, making it more difficult to control the stability of the rocks surrounding the roadway. The results of this study can provide guidance for roadway support, engineering design and mining technology optimization when mining at 1000 m or deeper.

Similar content being viewed by others

Abbreviations

- Ji-14-31050:

-

Coal-mine-working face

- Ji-14, Ji-15:

-

Coal seams

- σ 3 :

-

Minimum principal stress

- σ H :

-

Vertical stress

- YHW 19:

-

The model of mine roof displacement monitor

- D 3, D 4, D 5, D 6, D 7, D 8:

-

Identifier for the drill hole

References

Gao MZ, Jin WC, Dai ZX (2013) Relevance between abutment pressure and fractal dimension of crack network induced by mining. Int J Min Sci Tech 23(6):925–930

He MC, Miao JL, Feng JL (2010) Rock burst process of limestone and its acoustic emission characteristics under true-triaxial unloading conditions. Int J Rock Mech Min Sci 47(2):286–298

Hua AZ, You MQ (2001) Rock failure due to energy release during unloading and application to underground rock burst control. Tunn Undergr Sp Tech 16:241–246

Islam MR, Hayashi D, Kamruzzaman ABM (2009) Finite element modeling of stress distributions and problems for multi-slice pillarless mining in Bangladesh, with special reference to the Barapukuria coal mine. Int J Coal Geol 78(2):91–109

Jaeger JC (1967) Brittle fracture of rocks. Port City Press, Baltimore

Kwasniewski MA (1989) Laws of brittle failure and of BD transition in sandstones. In: Rock at great depth. A. A. Balkema, Rotterdam, pp 45–58

Li XB, Zhou ZL, Lok TS (2008) Innovative testing technique of rock subjected to coupled static and dynamic loads. Int J Rock Mech Min Sci 45(5):739–748

Luxbacher K, Westman E, Swanson P (2008) Three-dimensional time-lapse velocity tomography of an underground longwall panel. Int J Rock Mech Min Sci 45(4):478–485

Malan DF (1999) Time-dependent behaviour of deep level tabular excavations in hard rock. Rock Mech Rock Eng 32(2):123–155

Malan DF, Basson FRP (1998) Ultra-deep mining: the increased potential for squeezing conditions. J S Afr I Min Metall 98:353–364

Malan DF, Spottiswoode SM (1997) Time-dependent fracture zone behavior and seismicity surrounding deep level stopping operations. Rockbursts and seismicity in mines. A.A. Balkema, Rotterdam, pp 173–177

Meissner R, Kusznir NJ (1987) Crustal viscosity and the reflectivity of the lower crust. Ann Geophys Ser B Terr Planet Phys 5(4):365–373

Paterson MS (1958) Experimental deformation and faulting in Wombeyan marble. Geol Soc Am Bull 69(4):465–476

Shabanimashcool M, Li CC (2013) A numerical study of stress changes in barrier pillars and a border area in a longwall coal mine. Int J Coal Geol 106:39–47

Suchowerska AM, Merifield RS, Carter JP (2013) Vertical stress changes in multi-seam mining under supercritical longwall panels. Int J Rock Mech Min Sci 61:306–320

Wang H, Jiang Y, Zhao Y (2013) Numerical investigation of the dynamic mechanical state of a coal pillar during pillarless mining panel extraction. Rock Mech Rock Eng 46(5):1211–1221

Wang SL, Hao SP, Chen Y (2016) Numerical investigation of coal pillar failure under simultaneous static and dynamic loading. Int J Rock Mech Min Sci 84:59–68

Xie HQ, He Ch (2004) Study of the unloading characteristics of a rock mass using the triaxial test and damage mechanics. Int J Rock Mech Min Sci 41(3):74–80

Xie HP, Zhou HW, Liu JF, Gao F, Zhang R, Xue DJ, Zhang Y (2011) Mining-induced mechanical behavior in coal seams under different mining layouts. J China Coal Soc 1036(1067):1067–1074

Xie H, Zhao X, Liu J (2012) Influence of different mining layouts on the mechanical properties of coal. Int J Min Sci Tech 22(6):749–755

Xie J, Gao MZ, Zhang R (2016) Lessons learnt from measurements of vertical pressure at a top coal mining face at Datong Tashan mines, China. Rock Mech Rock Eng 49(7):2977–2983

Yang W, Lin B, Yan Q (2014) Stress redistribution of pillarless mining stope and gas control of multi-layer coal seams. Int J Rock Mech Min Sci 72:8–15

Yavuz H (2004) An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int J Rock Mech Min Sci 41(2):193–205

Acknowledgements

The study was financially supported by the National Key Research and Development Program of China (Grant No. 2016YFC0600701) and by the National Natural Science Foundation of China (Grant No. 51674170).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xie, H., Gao, M., Zhang, R. et al. Study on the Mechanical Properties and Mechanical Response of Coal Mining at 1000 m or Deeper. Rock Mech Rock Eng 52, 1475–1490 (2019). https://doi.org/10.1007/s00603-018-1509-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-018-1509-y