Abstract

The hydromechanical response of Opalinus Clay is being studied as a potential host formation for the long-term geological storage of nuclear waste. Two separate mine-by field experiments were conducted at Mont Terri rock laboratory, Switzerland: one in 1997–1998 (HD-B) and one in 2008 (MB Niche) to observe the claystone’s response to tunnel excavation. The data from both mine-by tests revealed an undrained pore pressure response dominated by significant pore pressure drop (i.e., a dilational tendency), even in instrumentation locations where stress-induced damage (‘failure’) was not anticipated. This response is not reproducible by conventional hydromechanical models unless very low yield envelopes are used to predict the onset of dilation. An alternative mechanism for the undrained dilational response of Opalinus Clay due primarily to unloading in the low confining stress regime is presented in this paper. The mechanism is derived from observed behaviour of the Opalinus Clay in the field and laboratory, and an understanding of the composition and geological history of the material. The model is based on mechanisms associated with liberation of latent strain energy, and associated residual stress (‘locked-in stress’ or ‘stress memory’) through microcrack formation. Mobilization of this internal stress on the undrained response of Opalinus Clay results in distinct regimes of hydromechanical response, dependent on confining stress levels, that is accounted for in the model. The model was implemented into the continuum finite difference code FLAC3D and produced good agreement with mine-by test observations.

Modified after Martin et al. (2015)

Modified from Martin and Christiansson (2009)

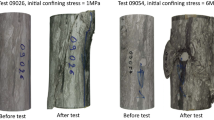

Data from Olalla et al. (1999)

Similar content being viewed by others

Notes

Itasca Consulting Group, Inc. (https://www.itascacg.com).

Abbreviations

- EDZ:

-

Excavation Damaged Zone

- EdZ:

-

Excavation Disturbed Zone

- LRSD:

-

Liberated Residual Stress Dilation

- REV:

-

Representative Elementary Volume

- UCS:

-

Unconfined Compressive Strength

- w :

-

Water content

- \(\nu \) :

-

Poisson ratio

- E :

-

Young’s modulus

- \(E_\mathrm{c}\) :

-

Young’s modulus (secant) in crack closure region

- K :

-

Bulk modulus of rock matrix

- \(K_\mathrm{s}\) :

-

Bulk modulus of rock grains

- \(K_\mathrm{w}\) :

-

Bulk modulus of water

- \(\epsilon _\mathrm{a}\) :

-

Axial strain

- \(\epsilon _\mathrm{cc}\) :

-

Crack Closure strain

- \(\epsilon _x,\epsilon _y,\epsilon _z\) :

-

Normal strain components

- \(\epsilon _\mathrm{v}\) :

-

Volumetric strain

- \(\epsilon _\mathrm{vc}\) :

-

Crack volumetric strain

- \(\sigma _x,\sigma _y,\sigma _z\) :

-

Normal stresses components

- \(\sigma _1,\sigma _2,\sigma _3\) :

-

Principal stresses

- \(\sigma _\mathrm{m}\) :

-

Mean stress

- \(\sigma _\mathrm{a}\) :

-

Axial stress

- \(\sigma _\mathrm{cc}\) :

-

Crack Closure stress in UCS test

- \(\sigma _\mathrm{ci}\) :

-

Crack Initiation stress in UCS test

- \(\sigma _\mathrm{cd}\) :

-

Crack Damage stress in UCS test

- \(\sigma _\mathrm{p}\) :

-

Peak stress (strength) in UCS test

- \(\sigma '\) :

-

Effective stress (with components)

- \(\sigma ^*\) :

-

Microstress (with components)

- \(\sigma _\mathrm{r}\) :

-

Residual (locked-in) stress

- \(\sigma _\mathrm{cr}\) :

-

Liberated residual stress

- \(\sigma _\mathrm{n}\) :

-

Net stress acting on REV

- \(\alpha \) :

-

Biot’s pore pressure coefficient

- p :

-

Pore pressure

- \(p_\mathrm{e}\) :

-

Excess pore pressure components

- \(p_\mathrm{s}\) :

-

Static pore pressure components

- V :

-

Volume (total)

- \(V_\mathrm{c}\) :

-

Crack volume

- k :

-

Hydraulic conductivity

- X / D :

-

Distance from tunnel face/tunnel diameter

- l :

-

Length of REV

- \(k_1,k_2\) :

-

Spring stiffness constants

References

Amann F, Martin C, Wild K (2015) The role of capillary suction and dilatancy on the interpretation of the confined strength of clay shales. In: International Society for Rock Mechanics, vol 2015 May, pp 1–10

Bahrani N, Valley B, Kaiser P (2015) Numerical simulation of drilling-induced core damage and its influence on mechanical properties of rocks under unconfined condition. Int J Rock Mech Min Sci 80:40–50

Biot MA (1941) General theory of three-dimensional consolidation. J Appl Phys 12(2):155–164

Bjerrum L (1967) Progressive failure in slopes of overconsolidated plastic clay and clay shales: Third Terzaghi Lecture. J Soil Mech Found Div ASCE 93(SM5):1–49

Bock H (2000) RA experiment: data report on rock mechanics—Mont Terri project. Tech. Rep. Nagra, Internal Report TN00-02, Q+S Consult, Germany

Bossart P, Jaeggi D, Nussbaum C (2017) Experiments on thermo-hydro-mechanical behaviour of Opalinus Clay at Mont Terri rock laboratory, Switzerland. J Rock Mech Geotech Eng 9(3):502–510

Corkum AG (2006) Non-linear behaviour of Opalinus Clay around underground excavations. Ph.D. Thesis, Department of Civil & Environmental Engineering, University of Alberta, Ph.D

Corkum AG, Martin CD (2007a) The mechanical behaviour of weak mudstone (Opalinus Clay) at low stresses. Int J Rock Mech Min Sci 44:196–209

Corkum AG, Martin CD (2007b) Modelling a mine-by test at the Mont Terri rock laboratory, Switzerland. Int J Rock Mech Min Sci 44:846–859

Crisci E, Ferrari A, Giger S, Laloui L (2019a) Anisotropic behaviour of shallow Opalinus Clay. In: Springer series in geomechanics and geoengineering, vol 217729, pp 442–448

Crisci E, Ferrari A, Giger S, Laloui L (2019b) Hydro-mechanical behaviour of shallow Opalinus Clay shale. Eng Geol 251:214–227

Eberhardt E, Stead D, Stimpson B (1999) Effects of sample disturbance on the stress-induced microfracturing characteristics of brittle rock. Can Geotech J 36(2):239–250

Friedman M (1972) Residual elastic strain in rocks. Tectonophysics 15(4):297–330

Hedberg H (1936) Gravitational compaction of clays and shales. J Appl Phys 31:241–287

Holzhausen GR, Johnson AM (1979) The concept of residual stress in rock. Tectonophysics 58(3–4):237–267

Jaeger JC (1971) Friction of rocks and stability of rock slopes. Géotechnique 21(2):97–134

Keller LM, Holzer L, Wepf R, Gasser P (2011) 3D geometry and topology of pore pathways in Opalinus Clay: implications for mass transport. Appl Clay Sci 52(1–2):85–95

Lavrov A (2003) The Kaiser effect in rocks: principles and stress estimation techniques. Int J Rock Mech Min Sci 40(2):151–171

Lim S, Martin C, Christiansson R (2015) Estimating in-situ stress magnitudes from core disking. Vitr Assist Reprod, p 159

Lisjak A, Garitte B, Grasselli G, Müller H, Vietor T (2015) The excavation of a circular tunnel in a bedded argillaceous rock (Opalinus Clay): short-term rock mass response and fdem numerical analysis. Tunn Undergr Sp Technol 45:227–248

Lozovyi S, Bauer A (2019) Static and dynamic stiffness measurements with Opalinus Clay. Geophys Prospect 67(4):997–1019

Maier G, Cocchetti G (2002) Fundamentals of direct methods in poroplasticity. In: Inelastic behaviour of structures under variable repeated loads. Springer, pp 91–113

Makhnenko R, Podladchikov Y (2018) Experimental poroviscoelasticity of common sedimentary rocks. J Geophys Res Solid Earth 123(9):7586–7603

Martin CD (1997) Seventeenth Canadian Geotechnical Colloquium: the effect of cohesion loss and stress path on brittle rock strength. Can Geotech J 34(5):698–725

Martin CD, Christiansson R (2009) Estimating the potential for spalling around a deep nuclear waste repository in crystalline rock. Int J Rock Mech Min Sci 46(2):219–228

Martin CD, Lanyon GW (2003) Measurement of in-situ stress in weak rocks at Mont Terri rock laboratory, Switzerland. Int J Rock Mech Min Sci 40:1077–1088

Martin CD, Stimpson B (1994) The effect of sample disturbance on laboratory properties of lac du bonnet granite. Can Geotech J 31(5):692–702

Martin CD, Macciotta R, Elwood D, Lan H, Vietor T (2015) MB Experiment evaluation of the Mont Terri mine-by response. Tech. Rep. Nagra, Technical Report 2009-02, University of Alberta

Müller G (1967) Diagenesis in argillaceous sediments. In: Developments in sedimentology, vol 8. Elsevier, pp 127–177

Olalla C, Martin ME, Sáez J (1999) ED-B Experiment: geotechnical laboratory test on Opalinus Clay rock samples. Tech. Rep. TN98-57, Mont Terri Project

Parisio F, Vilarrasa V, Laloui L (2018) Hydro-mechanical modeling of tunnel excavation in anisotropic shale with coupled damage-plasticity and micro-dilatant regularization. Rock Mech Rock Eng 51(12):3819–3833

Rice JR (1975) Stability of dilatant hardening for saturated rock masses. J Geophys Res 80(11):1531–1536

Räss L, Makhnenko R, Podladchikov Y, Laloui L (2017) Quantification of viscous creep influence on storage capacity of caprock. Energy Procedia 114:3237–3246

Skempton AW (1970) The consolidation of clays by gravitational compaction. Q J Geol Soc Lond 125:373–411

Tao M, Li X, Wu C (2012) Characteristics of the unloading process of rocks under high initial stress. Comput Geotech 45:83–92

Vermeer PA (1998) Non-associated plasticity for soils, concrete and rock. Phys Dry Granul Media 350:163–196

Wild K, Amann F (2018a) Experimental study of the hydro-mechanical response of Opalinus Clay–Part 1: pore pressure response and effective geomechanical properties under consideration of confinement and anisotropy. Eng Geol 237:32–41

Wild K, Amann F (2018b) Experimental study of the hydro-mechanical response of Opalinus Clay–Part 2: influence of the stress path on the pore pressure response. Eng Geol 237:92–101

Wild K, Barla M, Turinetti G, Amann F (2017a) A multi-stage triaxial testing procedure for low permeable geomaterials applied to Opalinus Clay. J Rock Mech Geotechn Eng 9(3):519–530

Wild K, Walter P, Amann F (2017b) The response of Opalinus Clay when exposed to cyclic relative humidity variations. Solid Earth 8(2):351–360

Wild KM (2016) Evaluation of the hydro-mechanical properties and behavior of Opalinus Clay. Ph.D. thesis, ETH

Wolf KH, Chilingarian GV (1992) Diagenesis, III. Elsevier, Amsterdam

Yong S, Loew S, Schuster K, Nussbaum C, Fidelibus C (2017) Characterisation of excavation-induced damage around a short test tunnel in the Opalinus Clay. Rock Mech Rock Eng 50(8):1959–1985

Yurikov A, Lebedev M, Pervukhina M, Gurevich B (2019) Water retention effects on elastic properties of Opalinus shale. Geophys Prospect 67(4):984–996

Acknowledgements

Professor C.D. Martin provided generous support throughout the study. Dr P. Blümling and Nagra staff provided helpful insight and resources. Professor N.R. Morgenstern suggested the potential role of diagenetic bonding and latent strain energy in the unique behaviour of claystones. Several colleagues kindly provided helpful comments and suggestions and the Journal’s reviewers helped to improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest with respect to this study and publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Corkum, A.G. A Model for Pore Pressure Response of a Claystone due to Liberated Residual Stress Dilation. Rock Mech Rock Eng 53, 587–600 (2020). https://doi.org/10.1007/s00603-019-01938-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-019-01938-x