Abstract

3D printing is an emerging technology which can offer valuable insight into rock characterization and theoretical model verification due to the sample reproducibility. Also, it will allow for the samples to be built at various scales with controlled geometries and specification to facilitate different types of analysis. In this study, gypsum powder was used for printing blindly to evaluate if mechanical and pore network characteristics of the specimens would resemble a natural rock. For this purpose, cylindrical specimens with different sizes were manufactured without inputting any pore network CT digital image of a natural rock. The objective was to study mechanical properties and deformation behavior of such samples by conducting a series of uniaxial compressive strength tests. Scanning electron microscope was utilized to characterize the microstructures of rock matrix prior to and after the experiments were performed. By determining the representative element area and image processing techniques, the surface porosity of 3-D printed samples was measured to be 5.8%. The analysis of pore size and shape distribution demonstrated the dominance of intermediate pore size as the main feature. This study enabled us to propose a new classification criterion for the pore shape based on printing procedures. Additional microstructural elements, micro-fractures, in particular, were identified, analyzed and classified into three separate categories, including intrapore micro-fracture, interpore micro-fracture and micro-fracture perforating pores. Finally, this study compared the mechanical properties and microstructure of 3D printed gypsum samples with typical natural rocks, also revealed the limitations in 3-D printing and suggested printing materials should be chosen, specific to the goal of the research study.

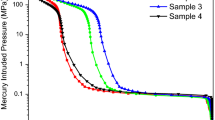

(modified from Kong. et al. 2017)

(modified from Kong et al. 2017)

(modified from Kong et al. 2017)

Similar content being viewed by others

References

Al Hinai A, Rezaee R, Esteban L, Labani M (2014) Comparisons of pore size distribution: a case from the Western Australian gas shale formations. J Unconv Oil Gas Resour 8:1–13

Alexeyev A, Ostadhassan M, Mohammed RA, Bubach B, Khatibi S, Li C, Kong L (2017) Well log based geomechanical and petrophysical analysis of the Bakken formation. In: 51st US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association

ASTM (1994) American Society for Testing and Materials. Annual book of ASTM standards, vol 04.08, Philadeplhia, PA, USA

ASTM (2000) American Society for Testing and Materials. Annual book of ASTM standards, vol 04.08, Philadeplhia, PA, USA

Ayatollahi M, Akbardoost J (2014) Size and geometry effects on rock fracture toughness: mode I fracture. Rock Mech Rock Eng 47:677–687

Bai B, Elgmati M, Zhang H, Wei M (2013) Rock characterization of Fayetteville shale gas plays. Fuel 105:645–652

Barton N, Bandis S et al (1982) Effects of block size on the shear behavior of jointed rock. In: The 23rd US symposium on rock mechanics (USRMS). American Rock Mechanics Association

Bernard S, Wirth R, Schreiber A, Bowen L, Aplin A, Mathia E, Schulz H, Horsfield B, Aplin A, Mathia E (2013) FIB-SEM and TEM investigations of an organic-rich shale maturation series from the lower Toarcian Posidonia Shale, Germany: nanoscale pore system and fluid-rock interactions. Electron Microsc Shale Hydrocarb Reserv AAPG Mem 102:53–66

Burns D, Cheng C, Wilkens R (1990) Sandstone pore aspect ratio spectra from direct observations and velocity inversion. In: International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts. Elsevier, pp 315–323

Campbell T, Williams C, Ivanova O, Garrett B (2011) Could 3D printing change the world. Technologies, Potential, and Implications of Additive Manufacturing, Atlantic Council, Washington, DC

Carmichael RS (1989) Physical properties of rocks and minerals. CRC Press, Boca Raton

Cheng CH, Toksöz MN (1979) Inversion of seismic velocities for the pore aspect ratio spectrum of a rock. J Geophys Res Solid Earth 84:7533–7543

Cox E (1927) A method of assigning numerical and percentage values to the degree of roundness of sand grains. J Paleontol 1:179–183

Darlington WJ, Ranjith PG, Choi S (2011) The effect of specimen size on strength and other properties in laboratory testing of rock and rock-like cementitious brittle materials. Rock Mech Rock Eng 44:513–529

Dinçer I, Acar A, Çobanoğlu I, Uras Y (2004) Correlation between Schmidt hardness, uniaxial compressive strength and Young’s modulus for andesites, basalts and tuffs. Bull Eng Geol Environ 63:141–148

Dowling NE (2012) Mechanical behavior of materials. Pearson, Boston, MA

Doyen PM (1988) Permeability, conductivity, and pore geometry of sandstone. J Geophys Res Solid Earth 93:7729–7740

Dyke C, Dobereiner L (1991) Evaluating the strength and deformability of sandstones. Q J Eng Geol Hydrol 24:123–134

Espitalie J, Madec M, Tissot B, Mennig J, Leplat P et al (1977) Source rock characterization method for petroleum exploration. In: Offshore Technology Conference. Offshore Technology Conference

Fener M (2011) The effect of rock sample dimension on the P-wave velocity. J Nondestruct Eval 30:99–105

Fereshtenejad S, Song J-J (2016) Fundamental study on applicability of powder-based 3D printer for physical modeling in rock mechanics. Rock Mech Rock Eng 49:2065–2074

Haftani M, Bohloli B, Nouri A, Javan MRM, Moosavi M (2014) Size effect in strength assessment by indentation testing on rock fragments. Int J Rock Mech Min Sci 65:141–148

Houben M, Desbois G, Urai J (2013) Pore morphology and distribution in the Shaly facies of Opalinus Clay (Mont Terri, Switzerland): Insights from representative 2D BIB–SEM investigations on mm to nm scale. Appl Clay Sci 71:82–97

Huang L, Stewart RR, Dyaur N, Baez-Franceschi J (2016) 3D-printed rock models: elastic properties and the effects of penny-shaped inclusions with fluid substitution. Geophysics 81:D669–D677

Ishutov S, Hasiuk FJ, Harding C, Gray JN (2015) 3D printing sandstone porosity models. Interpretation 3:SX49–SX61

Ishutov S, Hasiuk FJ, Fullmer SM, Buono AS, Gray JN, Harding C (2017) Resurrection of a reservoir sandstone from tomographic data using three-dimensional printing. AAPG Bull 101:1425–1443

Jiang C, Zhao G-F (2015) A preliminary study of 3D printing on rock mechanics. Rock Mech Rock Eng 48:1041–1050

Jiang C, Zhao G-F, Zhu J, Zhao Y-X, Shen L (2016) Investigation of dynamic crack coalescence using a gypsum-like 3D printing material. Rock Mech Rock Eng 49:3983–3998

Jin L, Wojtanowicz A (2013) Experimental and theoretical study of counter-current oil–water separation in wells with in-situ water injection. J Pet Sci Eng 109:250–259

Jin L, Pu H, Wang Y, Li Y (2015) The consideration of pore size distribution in organic-rich unconventional formations may increase oil production and reserve by 25%, Eagle Ford Case Study. In: Unconventional resources technology conference, San Antonio, Texas, 20–22 July 2015. Society of Exploration Geophysicists, American Association of Petroleum Geologists, Society of Petroleum Engineers, pp. 1770–1782

Jin L, Sorensen JA, Hawthorne SB, Smith SA, Pekot LJ, Bosshart NW, Burton-Kelly ME, Miller DJ, Grabanski CB, Gorecki CD, Steadman EN (2016) Improving oil recovery by use of carbon dioxide in the Bakken unconventional system: a laboratory investigation. SPE Reserv Eval Eng 20(03):602–612

Johnson RB, DeGraff JV (1988) Principles of engineering geology. Wiley, New York

Josh M, Esteban L, Piane D, Sarout C, Dewhurst J, Clennell D, M (2012) Laboratory characterisation of shale properties. J Pet Sci Eng 88:107–124

Kelly S, El-Sobky H, Torres-Verdín C, Balhoff MT (2016) Assessing the utility of FIB–SEM images for shale digital rock physics. Adv Water Resour 95:302–316

Kenyon W, Howard J, Sezginer A, Straley C, Matteson A, Horkowitz K, Ehrlich R et al (1989) Pore-size distribution and NMR in microporous cherty sandstones. In: SPWLA 30th annual logging symposium. Society of petrophysicists and well-log analysts

Kietzmann J, Pitt L, Berthon P (2015) Disruptions, decisions, and destinations: enter the age of 3-D printing and additive manufacturing. Bus Horiz 58:209–215

Klaver J, Schmatz J, Krooss B, Stockhausen M, Schwark L, Urai J (2016) Porosity and pore connectivity in immature and artificially matured source rock using BIB–SEM, WMI and MIP. In: Fifth EAGE Shale Workshop

Kong L, Ostadhassan M, Li C, Tamimi N (2017) Rock physics and geomechanics of 3-D printed rocks. In: 51st US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association

Kong L, Ostadhassan M, Li C, Tamimi N (2018) Pore characterization of 3D-printed gypsum rocks: a comprehensive approach. J Mater Sci 53:5063–5078. https://doi.org/10.1007/s10853-017-1953-1

Lee VK, Lanzi AM, Ngo H, Yoo S-S, Vincent PA, Dai G (2014) Generation of multi-scale vascular network system within 3D hydrogel using 3D bio-printing technology. Cell Mol Bioeng 7:460–472

Li C, Ostadhassan M, Kong L (2017) Nanochemo-mechanical characterization of organic shale through AFM and EDS. In: SEG Technical Program Expanded Abstracts 2017. Society of Exploration Geophysicists, pp 3837–3840

Lindquist WB, Venkatarangan A, Dunsmuir J, Wong T (2000) Pore and throat size distributions measured from synchrotron X-ray tomographic images of Fontainebleau sandstones. J Geophys Res Solid Earth 105:21509–21527

Ling K, He J, Pei P, Wang S, Ni X et al (2016) Comparisons of Biot’s coefficients of Bakken core samples measured by three methods. In: 50th US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association

Liu K, Ostadhassan M, Kong L et al (2017a) Pore structure heterogeneity in middle Bakken formation. In: 51st US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association

Liu K, Ostadhassan M, Li C (2017b) Quantifying the nano-mechanical signature of shale oil formations by nanoindentation. In: Unconventional Resources Technology Conference, Austin, Texas, 24–26 July 2017. Society of Exploration Geophysicists, American Association of Petroleum Geologists, Society of Petroleum Engineers, pp. 2075–2083

Loucks RG, Reed RM, Ruppel SC, Hammes U (2012) Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull 96:1071–1098

Mao M, He J, Li X, Zhang B, Lei Q, Liu Y, Li D (2017) The emerging frontiers and applications of high-resolution 3D printing. Micromachines 8:113

Moradian Z, Behnia M (2009) Predicting the uniaxial compressive strength and static Young’s modulus of intact sedimentary rocks using the ultrasonic test. Int J Geomech 9:14–19

Murphy SV, Atala A (2014) 3D bioprinting of tissues and organs. Nat Biotechnol 32:773–785

Nasseri M, Rao K, Ramamurthy T (2003) Anisotropic strength and deformational behavior of Himalayan schists. Int J Rock Mech Min Sci 40:3–23

Nelson PH (2009) Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull 93:329–340

Ngo TD, Kashani A, Imbalzano G, Nguyen KT, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 143:172

Ostadhassan M, Zeng Z, Jabbari H (2012a) Anisotropy analysis in shale using advanced sonic data-Bakken Case Study. AAPG Annual Convention and Exhibition, Salt Lake City

Ostadhassan M, Zeng Z, Zamiran S et al (2012b) Geomechanical modeling of an anisotropic formation-Bakken case study. In: 46th US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association

Rasouli V, Sutherland A (2014) Geomechanical characteristics of gas shales: a case study in the North Perth Basin. Rock Mech Rock Eng 47:2031–2046

Rybacki E, Reinicke A, Meier T, Makasi M, Dresen G (2015) What controls the mechanical properties of shale rocks? Part I: strength and Young’s modulus. J Pet Sci Eng 135:702–722

Santi PM, Holschen JE, Stephenson RW (2000) Improving elastic modulus measurements for rock based on geology. Environ Eng Geosci 6:333–346

Saraji S, Piri M (2015) The representative sample size in shale oil rocks and nano-scale characterization of transport properties. Int J Coal Geol 146:42–54

Schön JH (2015) Physical properties of rocks: fundamentals and principles of petrophysics. Elsevier, Amsterdam

Shalabi FI, Cording EJ, Al-Hattamleh OH (2007) Estimation of rock engineering properties using hardness tests. Eng Geol 90:138–147

Sone H, Zoback MD (2013) Mechanical properties of shale-gas reservoir rocks—Part 1: static and dynamic elastic properties and anisotropy. Geophysics 78:D381–D392

Sun K, Wei T-S, Ahn BY, Seo JY, Dillon SJ, Lewis JA (2013) 3D printing of interdigitated Li–ion microbattery architectures. Adv Mater 25:4539–4543

Suzuki A, Kewen L, Horne RN (2017) Potential utilizations of 3D printed fracture network model. In: 42nd Workshop on Geothermal Reservoir Engineering, February 13. Stanford University, Stanford

Takashimizu Y, Iiyoshi M (2016) New parameter of roundness R: circularity corrected by aspect ratio. Prog Earth Planet Sci 3:2

Thuro K, Plinninger R, Zäh S, Schütz S (2001) Scale effects in rock strength properties. Part 1: unconfined compressive test and Brazilian test. EUROCK 2001 Rock Mech.—Chall. Soc. pp 169–174

Tsukada K, Kawajiri A, Hashimoto Y, Makihara K, Tominaga R, Fujita M, Sato T (2017) Functional inkjet 3D printing system for customized electronics. In: Electronics packaging (ICEP), 2017 international conference on IEEE, pp. 5–6

Wang P, Yang T, Xu T, Cai M, Li C (2016) Numerical analysis on scale effect of elasticity, strength and failure patterns of jointed rock masses. Geosci J 20:539–549

Wawersik W, Fairhurst C (1970) A study of brittle rock fracture in laboratory compression experiments. In: International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts. Elsevier, 561IN7565–564IN14575

Wong L, Einstein H (2009) Crack coalescence in molded gypsum and Carrara marble: part 1. Macroscopic observations and interpretation. Rock Mech Rock Eng 42:475–511

Yang S, Dai Y, Han L, Jin Z (2009) Experimental study on mechanical behavior of brittle marble samples containing different flaws under uniaxial compression. Eng Fract Mech 76:1833–1845

Yang S, Yang D, Jing H, Li Y, Wang S (2012) An experimental study of the fracture coalescence behaviour of brittle sandstone specimens containing three fissures. Rock Mech Rock Eng 45:563–582

Yılmaz I, Sendır H (2002) Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng Geol 66:211–219

Zhao P, Wang Z, Sun Z, Cai J, Wang L (2017) Investigation on the pore structure and multifractal characteristics of tight oil reservoirs using NMR measurements: Permian Lucaogou Formation in Jimusaer Sag, Junggar Basin. Mar Pet Geol 86:1067–1081

Zhang Y, Lebedev M, Al-Yaseri A, Yu H, Xu X, Sarmadivaleh M, Barifcani A, Iglauer S (2018) Nanoscale rock mechanical property changes in heterogeneous coal after water adsorption. Fuel 218:23–32

Acknowledgements

The author thanks for the laboratory support from Dr. Kalpana Katti and Anurag Sharma, Department of Civil and Environmental Engineering, North Dakota State University, US. The author also appreciates the help of Dr. Xiaodong Hou at Institute for Energy Studies, University of North Dakota, US. Great thanks also goest to American Association of Petroleum Geologists Foundation for awarding me 2017 Grants-in-Aid Program, J. Ben Carsey, Sr. Memorial Grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kong, L., Ostadhassan, M., Li, C. et al. Can 3-D Printed Gypsum Samples Replicate Natural Rocks? An Experimental Study. Rock Mech Rock Eng 51, 3061–3074 (2018). https://doi.org/10.1007/s00603-018-1520-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-018-1520-3