Abstract

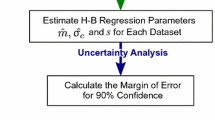

In an open-pit mine operation, the design of safe and economically viable slopes can be significantly influenced by the quality and quantity of collected geomechanical data. In several mining jurisdictions, codes and standards are available for reporting exploration data, but similar codes or guidelines are not formally available or enforced for geotechnical design. Current recommendations suggest a target level of confidence in the rock mass properties used for slope design. As these guidelines are qualitative and somewhat subjective, questions arise regarding the minimum number of tests to perform in order to reach the proposed level of confidence. This paper investigates the impact of defining a priori the required number of laboratory tests to conduct on rock core samples based on the geomechanical database of an operating open-pit mine in South Africa. In this review, to illustrate the process, the focus is on uniaxial compressive strength properties. Available strength data for 2 project stages were analysed using the small-sampling theory and the confidence interval approach. The results showed that the number of specimens was too low to obtain a reliable strength value for some geotechnical domains even if more specimens than the minimum proposed by the ISRM suggested methods were tested. Furthermore, the testing sequence used has an impact on the minimum number of specimens required. Current best practice cannot capture all possibilities regarding the geomechanical property distributions, and there is a demonstrated need for a method to determine the minimum number of specimens required while minimising the influence of the testing sequence.

Similar content being viewed by others

References

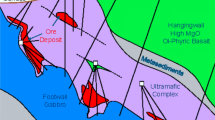

Basson IJ, Tennant D (2012) Review and 3D modelling of country rocks and major structures. Unpublished report no. VS-C-012-12, South Africa, TECT Geological Consulting, p 34

Basson IJ, Tennant D (2013) Review and 3D modelling of country rocks and major structures, 2013 update. Unpublished report no. TECT2013/019, South Africa, TECT Geological Consulting, p 38

Bieniawski ZT, Bernede MJ (1979) Suggested methods for determining the uniaxial compressive strength and deformability of rock materials. Int J Rock Mech Min Sci 16(2):137–140. doi:10.1016/0148-9062(79)91451-7

Canadian Institute of Mining (CIM) (2010) CIM definition standards—for mineral resources and mineral reserves. CIM Council, p 10

Fillion MH, Hadjigeorgiou H (2013) Reliability of strength estimates based on limited laboratory data. In: Proceedings of the slope stability in mining conference in Brisbane, Australia. Sept. 25–27, p 14

GEOVIA (Dassault Systemes) (2015) GEMS version 6.7.2, collaborative geology and mine planning solution, Toronto, Ontario, Canada. http://www.geovia.com/products/GEMS

Gill DE, Corthésy R, Leite MH (2005a) Determining the minimal number of specimens for laboratory testing of rock properties. Eng Geol 78:29–51. doi:10.1016/j.enggeo.2004.10.005

Gill DE, Corthésy R, Leite MH (2005b) A statistical approach for determining practical rock strength and deformability values from laboratory tests. Eng Geol 78:53–67. doi:10.1016/j.enggeo.2004.10.006

Gong W, Luo Z, Juang CH, Huang H, Zhang J, Wang L (2014) Optimization of site exploration program for improved prediction of tunnelling-induced ground settlement in clays. Comput Geotech 56:69–79. doi:10.1016/j.compgeo.2013.10.008

Hadjigeorgiou J (2012) Where do the data come from? In: Potvin Y (ed) Proceedings of the sixth international seminar on deep and high stress mining, Perth, Australia, pp 259–278, 28–30 March 2012

Haile A (2004) A reporting framework for geotechnical classification of mining projects. AuSIMM Bull 5:30–37

Harvey F, Venter J, Mulville D, Terbrugge P (2004) Geotechnical evaluation and slope design for the 200 m pit feasibility and 400 m pit pre-feasibility study. Unpublished report no. 3348385, Steffen, Robertson and Kirsten (South Africa) (Pty) Ltd, p 55

Hines WW, Montgomery DC, Goldsman DM, Borror CM (2003) Probability and statistics in engineering, 4th edn. Wiley, New York, p 655

Hoek E (1998) Reliability of the Hoek–Brown estimates of rock mass properties and their impact on design. Int J Rock Mech Min Sci 35(1):63–68. doi:10.1016/S0148-9062(97)00314-8

JORC (2004) Australian code for reporting of exploration results, mineral resources and ore reserves. AusIMM/MCA/AIG, p 31

Kostak B, Bielenstein HU (1971) Strength distribution in hard rock. Int J Rock Mech Min Sci 8:501–521. doi:10.1016/1365-1609(71)90015-3

Matheron G (1963) Principles of geostatistics. Econ Geol 58:1246–1266. doi:10.2113/gsecongeo.58.8.1246

Mathworks (2014) MATLAB Version R2014a, Language of technical computing, Natick, MA, United States of America. http://www.mathworks.com

Montgomery DC, Runger GC (2003) Applied statistics and probability for engineers, vol 3. Wiley, New York, p 706

Olsson U (2005) Confidence intervals for the mean of a log-normal distribution. J Stat Educ 13(1):8

Read J (2009) Data uncertainty. In: Read J, Stacey P (eds) Guidelines for open pit slope design. CRC Press, Balkema, pp 213–220

Read J, Stacey P (2009) Guidelines for open pit slope design. CRC Press, Balkema, p 496

Ruffolo RM, Shakoor A (2009) Variability of unconfined compressive strength in relation to number of test samples. Eng Geol 108:16–23. doi:10.1016/j.enggeo.2009.05.011

Sari M, Karpuz C (2006) Rock variability and establishing confining pressure levels for triaxial tests on rocks. Int J Rock Mech Min Sci 43:328–335. doi:10.1016/j.ijrmms.2005.06.010

Scott T, Barnett W (2013) Mine geotechnical model. Unpublished report no. 2CD002.022, SRK Consulting Canada Inc. Vancouver, B.C., p 38

Spiegel MR (1961) Theory and problems of statistics. Schaum’s Outline Series. McGraw-Hill, New York, p 359

Steffen OKH (1997) Planning of open pit mines on a risk basis. J S Afr Inst Min Metallog 97(2):47–56

Tang S, Yeh AB (2016) Approximate confidence intervals for the log-normal standard deviation. Qual Reliab Eng Int 32:715–725

Zhou XH, Gao S (1997) Confidence intervals for the log-normal mean. Stat Med 16:783–790

Acknowledgements

The authors gratefully acknowledge De Beers Group of Companies for allowing access to their geotechnical database and useful suggestions. The financial support of Anglo American and the Natural Science and Engineering Research Council of Canada is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Minimum Sample Size for Normally Distributed Data

The equations used to derive the minimum number of specimen for normally distributed data are from Hines et al. (2003). Equation 5 presents the two-sided confidence interval on the population mean:

where: μ = the population arithmetic mean, \( \overline{X} \) = the arithmetic sample mean, s = the sample standard deviation, \( t_{\alpha /2,\nu } \) = the confidence coefficient obtained from the Student t distribution for a two-sided confidence on μ, α = a parameter determined by the required confidence level, ν = the number of degrees of freedom, n = the number of specimens in the sample

In Equation 5, \( \overline{X} \) is the arithmetic sample mean and is defined by Equation 6, and s is the sample standard deviation and is defined by Equation 7.

where: \( X_{i} \) the values observed on each of the n specimens in the sample

The precision index p, which is the ratio of the upper and lower limits of the population mean interval is given by Equation 8:

By combining Eqs. 5 and 8, the true mean interval can also be defined using the precision index p (Eq. 9).

The left-hand terms of Eqs. 5 and 9 allow one to define Eq. 10.

The coefficient of variation cv in Eq. 10 is defined by:

The minimum number of specimens in a sample n can then be determined by expressing Eq. 10 in terms of n.

Appendix 2: Minimum Sample Size for Lognormally Distributed Data

The equations used to derive the minimum number of specimen for normally distributed data are from Olsson (2005). Equation 13 presents the two-sided confidence interval on the natural logarithm of the population mean of the lognormal distribution based on the Cox modified method.

where: \( X \) = the lognormally distributed random variable, \( Y \) = the normally distributed variable Y = ln(X), \( \overline{Y} \) = the arithmetic sample mean of variable Y = ln(X), \( S_{Y}^{2} \) = the variance of variable Y = ln(X), and \( S_{Y} \) = is the standard deviation of variable Y, \( t_{{\frac{\alpha }{2},\upsilon }} \) = the confidence coefficient obtained from the Student t distribution for a two-sided confidence on \( \mu_{X} \) = a parameter determined by the required confidence level, ν = the number of degrees of freedom and ν = n − 1, n = the number of specimens in the sample, µ x = Mean of the lognormally distributed variable X

The mean of the lognormally distributed variable X is given by Eq. 14.

where: µ Y = Mean of the normally distributed variable Y = ln(X). \( \sigma_{Y}^{2} \) = Variance of the population of the normally distributed variable Y = ln(X) and \( \sigma_{Y} \) = is the standard deviation of variable Y

The sample variance of the normally distributed variable Y = ln(X) is given by Eq. 15.

where: Y i = the values observed on each of the n specimens in the sample, \( n, \overline{Y} \) as described previously.

The precision index p is the ratio of the upper and lower limits of the population mean interval and is determined by Eq. 16.

Based on Eq. 16, the equation for the confidence interval on \( { \ln }\left( {\mu_{X} } \right) \) can be rewritten as Eq. 17.

The left term in Eq. 17 is then equal to the left term in Eq. 13.

The minimum number of specimens can be determined by isolating n in Eq. 18:

where the coefficient of variation of the normally distributed variable Y is defined by:

Rights and permissions

About this article

Cite this article

Fillion, MH., Hadjigeorgiou, J. Quantifying the Impact of Additional Laboratory Tests on the Quality of a Geomechanical Model. Rock Mech Rock Eng 50, 1097–1121 (2017). https://doi.org/10.1007/s00603-016-1160-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-016-1160-4