Abstract

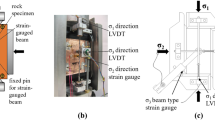

A true triaxial apparatus (TTA) was designed and fabricated at Northeastern University, Shenyang, China, by modifying the original Mogi type testing apparatus to emulate three-dimensional stress paths in deep mining and tunneling excavations. Such an apparatus can be used to investigate deformation and brittle failure behaviors of hard rocks as well as the cause of rockbursts. The novel TTA can capture the post-peak behavior of a 50 × 50 × 100 mm3 specimen. Technical improvements such as a considerable increase of the stiffness of the loading frames were implemented to deal with difficulties in TTA testing. The accuracy of the volume change measurement was improved and a combined pneumatic and hydraulic technique was applied to create a “floating” vertical loading frame. The end friction effect and the loading gap effect were evaluated using a series of tests. Repeatability tests, brittle failure tests in a loading stress path and an unloading stress path (unloading of σ 3) were carried out on granite specimens to verify the performance of the TTA. The test results show that the apparatus achieves its original design goal.

Similar content being viewed by others

References

Alexeev A, Revva V, Bachurin L, Prokhorov I (2008) The effect of stress state factor on fracture of sandstones under true triaxial loading. Int J Fracture 149:1–10

Bésuelle P, Hall SA (2011) Characterization of the strain localization in a porous rock in plane strain condition using a new true-triaxial apparatus. In: Bonelli S, Dascalu C, Nicot F (eds) Advances in bifurcation and degradation in geomaterials. Springer, pp 345–352

Cai M (2008) Influence of intermediate principal stress on rock fracturing and strength near excavation boundaries—Insight from numerical modeling. Int J Rock Mech Min 45:763–772

Chang C, Haimson B (2000) True triaxial strength and deformability of the German Continental Deep Drilling Program (KTB) deep hole amphibolite. J Geophys Res 105:18999–19013

Chang C, Haimson B (2012) A failure criterion for rocks based on true triaxial testing. Rock Mech Rock Eng 45(6):1007–1010

Chen JT, Feng XT (2006) True triaxial testing of rocks under high stress condition. Chin J Rock Mech Eng 25(8):1537–1543 (in Chinese)

Colmenares LB, Zoback MD (2002) A statistical evaluation of intact rock failure criteria constrained by polyaxial test data for five different rocks. Int J Rock Mech Min 39(6):695–729

Descamps F, Ramos da Silva M, Schroeder C, Verbrugge JC, Tshibangu JP (2012) Limiting envelopes of a dry porous limestone under true triaxial stress states. Int J Rock Mech Min 56:88–99

Fairhurst CE, Hudson JA (1999) Draft ISRM suggested method for the complete stress-strain curve for intact rock in uniaxial compression. Int J Rock Mech Min 36(3):279–289

Haimson B (2006) True triaxial stresses and the brittle fracture of rock. Pure appl Geophys 163:1101–1130

Haimson B, Chang C (2000) A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of Westerly granite. Int J Rock Mech Min. 37:285–296

Ingraham M, Issen K, Holcomb D (2013) Response of Castlegate sandstone to true triaxial states of stress. J Geophys Res 118:536–552

Kwasniewski M, Takahashi M, Li X (2003) Volume changes in sandstone under true triaxial compression conditions. In: 10th ISRM Congress, 2003. International Society for Rock Mechanics

Lee H, Haimson B (2011) True triaxial strength, deformability, and brittle failure of granodiorite from the San Andreas fault observatory at depth. Int J Rock Mech Min 48:1199–1207

Li XC, Shi L, Bai B, Li Q, Xu D, Feng X (2012) True-triaxial testing techniques for rocks—state of the art and future perspective. In: Kwasniewski M, Li X, Takahashi M (eds) True Triaxial Testing of Rocks. CRC Press, Boca Raton, FL, pp 3–18

Ma XD (2014) Failure characteristics of comparative, porous sandstone subjected to true triaxial stresses. PhD Thesis, The University of Wisconsin-Madison

Mogi K (1970) Effect of the triaxial stress system on rock failure. Rock Mech In Japan 1:53–55

Mogi K (1971) Fracture and flow of rocks under high triaxial compression. J Geophys Res 76:1255–1269

Mogi K (1972) Effect of the triaxial stress system on fracture and flow of rocks. Phys Earth Planet Inter 5:318–324

Mogi K (1977) Dilatancy of rocks under general triaxial stress state with special reference to earthquake precursors. J Phys Earth 25:S203–S217

Mogi K (2007) Experimental rock mechanics. CRC Press, London

Nasseri MHB, Goodfellow SD, Lombos L, Young RP (2014) 3-D transport and acoustic properties of Fontainebleau sandstone during true-triaxial deformation experiments. Int J Rock Mech Min 69:1–18

Pan PZ, Feng XT, Hudson JA (2012) The influence of the intermediate principal stress on rock failure behaviour: a numerical study. Eng Geol 124:109–118

Shi L, Li X, Bai B, Li Q, Feng X (2012) Numerical analysis of loading boundary effects in Mogi-type true triaxial tests. In: Kwasniewski M, Li X, Takahashi M (eds) True triaxial testing of rocks. CRC Press, Boca Raton, pp 19–33

Sibai M, Henry JP, Gros JC (1997) Hydraulic fracturing stress measurement using a true triaxial apparatus. Int J Rock Mech Min 34:289.e1–289.e10

Takahashi M, Koide H (1989) Effect of the intermediate principal stress on strength and deformation behavior of sedimentary rocks at the depth shallower than 2000 m. In: ISRM International Symposium, 1989. International Society for Rock Mechanics

Vernik L, Zoback MD (1992) Estimation of maximum horizontal principal stress magnitude from stress-induced well bore breakouts in the Cajon Pass Scientific Research borehole. J Geophys Res 97:5109–5119

Von Kármán T (1911) Festigkeitsversuche unter allseitigem. Druck Zeitschr Ver Dentsch Ing 55:1749–1757

You M (2009) True-triaxial strength criteria for rock. Int J Rock Mech Min 46(1):115–127

Zhang XW, Feng XT, Hao QZ (2014) A new type loading frame structure for follow-up loading. Chin Patent 201210055022:8

Zhao XG, Wang J, Cai M, Cheng C, Ma LK, Su R, Zhao F, Li DJ (2014) Influence of unloading rate on the strainburst characteristics of Beishan granite under true-triaxial unloading conditions. Rock Mech Rock Eng 47:467–483

Acknowledgments

The authors acknowledge the financial support from the National Natural Science Foundation of China under Grant No. 11232014 and 11572083. The work in this paper was partly supported by the Fundamental Research Funds for the Central Universities (N120401007). We are grateful to Prof. Bezalel Haimson (The University of Wisconsin, Madison) and Prof. Xiaochun Li (Institute of Rock and Soil Mechanics, Chinese Academy of Sciences, Wuhan) for their valuable suggestions and discussions during the development of this apparatus, and to Mr. Qingze Hao (Rising Sun Testing Instruments Co. LTD, Changchun) for the modification and improvements of the new apparatus. The authors also wish to thank Prof. Ming Cai for his valuable comments and English improvement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, XT., Zhang, X., Kong, R. et al. A Novel Mogi Type True Triaxial Testing Apparatus and Its Use to Obtain Complete Stress–Strain Curves of Hard Rocks. Rock Mech Rock Eng 49, 1649–1662 (2016). https://doi.org/10.1007/s00603-015-0875-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-015-0875-y