Abstract

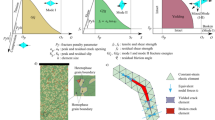

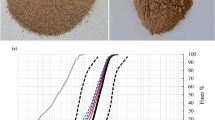

Effects of fracture toughness on the impingement of geomaterials (rocks and cementitious composites) by quartz particles at velocities between 40 and 140 m/s are investigated experimentally and analytically. If schist is excluded, relative erosion (in g/g) reduces according to a reverse power function if fracture toughness increases. The power exponent depends on impingement velocity, and it varies between −0.64 and −1.33. Lateral cracking erosion models, developed for brittle materials, deliver too high values for relative material erosion. This discrepancy is partly attributed to stress rate effects. Effects of R-curve behavior seem to be marginal. An integral approach E R = K 1 · E PR + (1 − K 1) · E LR is introduced, which considers erosion due to plastic deformation and lateral cracking. A transition function \(K_{1} = f\left( {K_{\text{Ic}}^{12/4} /\sigma_{\text{C}}^{23/4} } \right)\) is suggested in order to classify geomaterials according to their response against solid particle impingement.

Similar content being viewed by others

Abbreviations

- b :

-

Distribution shape parameter

- c :

-

Crack length

- c I :

-

Material parameter

- D :

-

Fracture toughness exponent

- d P :

-

Erodent particle diameter

- E K :

-

Kinetic energy erodent particle

- E M :

-

Young’s modulus target material

- E P :

-

Young’s modulus erodent material

- E R :

-

Relative erosion

- H M :

-

Hardness target material

- k :

-

Elastic parameter

- K 1 :

-

Erosion parameter

- KIc :

-

Fracture toughness target material

- m :

-

R-curve parameter

- M M :

-

Eroded target mass

- M P :

-

Erodent particle mass

- \(\dot{M}_{\text{P}}\) :

-

Erodent mass flow rate

- n :

-

Stress rate parameter

- P C :

-

Contact force

- r B :

-

Contact radius

- r P :

-

Particle radius

- t E :

-

Exposure time

- t P :

-

Contact time

- v P :

-

Erodent particle velocity

- β :

-

Indenter angle

- χ :

-

Transition parameter

- Γ Ic :

-

Critical energy release rate

- λ :

-

Distribution scale parameter

- ν M :

-

Poisson’s ratio target material

- ν P :

-

Poisson’s ratio erodent material

- ρ P :

-

Density erodent material

- ρ M :

-

Density target material

- \(\dot{\sigma }\) :

-

Stress rate

- σ C :

-

Compressive strength target material

- σ P :

-

Contact stress

- σ Y :

-

Yield stress

References

Amaral PM, Fernandes JC, Rosa LG (2009) Wear mechanisms in materials with granitic textures—applicability of a lateral crack system model. Wear 266:753–764

Bertram B (2008) Bruchenergie laufender Risse in Gestein. Dissertation, Bochum: Ruhr-Universität: 1988

Beste U, Lundvall A, Jacobson S (2004) Micro-scratch evaluation of rock types—a means to comprehend rock drill wear. Tribol Int 37:203–210

Blange JJ, van Nieuwkoop P (2011) Method of drilling and jet drilling system. Interns Patent Application, WO 2011/076845 A1, 30 June 2011

Breder K, Giannakopoulos AE (1990) Erosive wear in Al2O3 exhibiting Mode-I R-curve behavior. Ceram Eng Sci Proc 11:1046–1060

Breder K, De Portu G, Ritter JE, Fabbriche DD (1988) Erosion damage and strength degradation of zirconia-toughened alumina. J Amer Ceram Soc 71:770–775

Bujis M (1994) Erosion of glass as modeled by indentation theory. J Amer Ceram Soc 77:1676–1678

Bushby AJ, Swain MV (1995) Spherical indentations as a means for investigating the plastic deformation of ceramics. In: Bradt RC et al (eds) Plastic Deformation of Ceramics. Plenum Press, New York, pp 161–172

Chaudri MM, Walley SM (1978) A high-speed photographic investigation of the impact damage in sodalime and borosilicate glasses by small glass and steel spheres. In: Bradt RC et al (eds) Fracture Mechanics of Ceramics, vol 3. Plenum Press, New York, pp 349–364

Chen X, Hutchinson JW, Evans AG (2005) The mechanics of indentation induced lateral cracking. J Amer Ceram Soc 88(5):1233–1238

Chen P, Cui J, Zhou X (2013) Research on effects of pressure loading on rock lateral cracks under confining pressure. Adv Mater Res 838–841:850–853

Cui M, Zhay Y, Ji G (2011) Experimental study of rock breaking effect of steel particles. J Hydrodyn 23:241–246

Dai F, Chen R, Iqbal MJ, Xia K (2010) Dynamic cracked chevron notched Brazilian disc method for measuring rock fracture parameters. Int J Rock Mech Min Sci 47:606–613

Du Y, Wang R, Ni H, Ma L, Zhang S, Han Z (2011) Study on the rock-breaking performance of particles jet drilling technology. Electr J Geomech Engng 16:431–440

Du Y, Wang R, Ni H (2012) Feasibility of particle jet as a drilling medium for the development of deep complicated oil-gas reservoir. Adv Mater Res 361–363:465–468

Erarslan N, Williams DJ (2012) The damage mechanism of rock fatigue and its relationship to the fracture toughness of rocks. Int J Rock Mech Min Sci 56:15–26

Evans AG, Gulden ME, Rosenblatt ME (1978) Impact damage in brittle materials in the elastic–plastic response regime. Proc Roy Soc Lond A 361:343–356

Fischer-Cipps AC (2007) Introduction to Contact Mechanics. Springer, New-York

Gordon AT, Greg GG (2008) Particle drilling alters standard rock-cutting approach. World Oil 229(6):37–44

Gotzmann J (1989) Modellierung des Strahlverschleißes an keramischen Werkstoffen. Schmierungstechnik 20:324–329

Harder NJ, Curlett HB, Padgett O, Hazel B (2010) Impact excavation system and method with injection system. United States Patent, US 7,793,741 B2, 14 Sep 2010

Heßling M (1988) Grundlagenuntersuchungen über das Schneiden von Gestein mit abrasiven Höchstdruckwasserstrahlen. Dissertation, Aachen, RWTH Aachen

Huang H, Damjanac B, Detournay E (1998) Normal wedge indentation in rocks with lateral confinement. Rock Mech Rock Engng 31(2):81–94

Hutchings IM (1977) Strain rate effects in microparticle impact. J Phys D Appl Phys 10:L179–L184

Igrashi S, Bentur A, Mindess S (1996) Microhardness testing of cementitious materials. Advn Cem Bas Mat 4:48–57

Iqbal MJ, Mohanty B, Xia K (2008) Dynamic tensile strength and mode-I fracture toughness in granitic rocks. In: Proceedings 11th International Congress. Exposition, Orlando; Society for Experimental Mechanics 2–5 June 2008

Jung SJ, Prisbrey K, Wu G (1994) Prediction of rock hardness and drillability using acoustic signatures during indentation. Int J Rock Mech Min Sci Geomech Abstr 31:561–567

Kleis I, Kulu P (2008) Solid Particle Erosion. Springer, London

Knight CG, Swain MV, Chaudri MM (1977) Impact of small steel spheres on glass surfaces. J Mater Sci 12:1573–1586

Lambe TW (1969) Soil Mechanics. John Wiley, New York

Lambert DE, Ross CA (2000) Strain rate effects on dynamic fracture and strength. Int J Impact Eng 24:985–998

Marshall DB, Lawn BR, Evans AG (1982) Elastic/plastic indentation damage in ceramics: the lateral crack system. J Amer Ceram Soc 65:561–566

Maurer WCJ, Rinehart JS (1960) Impact crater formation in rock. J Appl Phys 31:1247–1252

Momber AW (2003a) Cavitation damage to geomaterials in a flowing system. J Mater Sci 38:747–757

Momber AW (2003b) An SEM-study of high-speed hydrodynamic erosion of cementitious composites. Compos B 34:135–142

Momber AW (2004) Damage to rocks and cementitious materials from solid impact. Rock Mech Rock Eng 37:57–82

Momber AW (2005) Hydrodemolition of concrete surfaces and reinforced concrete. Elsevier, London

Momber AW (2008) Blast Cleaning Technology. Springer, London

Momber AW (2013) Erosion of schist due to solid particle impingement. Rock Mech Rock Eng 46:849–857

Momber AW (2014) Effects of target material properties on solid particle erosion of geomaterials at different impingement velocities. Wear 319:69–83

Momber AW, Kovacevic R (1998) Principles of Abrasive Water Jet Machining. Springer, London

Momber AW, Budidharma E, Tjo R (2011) The separation of reinforced cementitious composites with a stream-line cutting tool. Res Conserv Recycl 55:507–514

Murakami Y (1987) Stress Intensity Handbook, vol 1. Pergamon Press, Oxford, pp 13–15

Murugesh L, Srinivasan S, Scattergood RO (1991) Models and material properties for erosion of ceramics. J Mater Eng 13:55–61

Ouchterlony F (1982) Review on fracture toughness testing of rock. SM Archives 71:131–211

Ouchterlony F (1990) Fracture toughness testing of rock with core based specimens. Eng Fract Mech 35:351–366

Pickering EG, Deshpande VS (2014) The ballistic impact of ceramics—an investigation into the effects of confinement and material properties. In: 4th International Conference on Impact Loading of Lightweight Structures. Cape Town, SA; 12–16 Jan 2014

Ritter JE (1985) Erosion damage in structural ceramics. Mater Sci Eng 71:194–201

Ritter JE, Strzepa P, Jakus K, Rosenfeld L, Buckman KJ (1984) Erosion damage in glass and alumina. J Amer Ceram Soc 67:769–774

Rogers CO, Pang SS, Kumano A, Goldsmith W (1986) Response of dry- and liquid-filled porous rocks to static and dynamic loading by variously-shaped projectiles. Rock Mech 19:235–260

Routbort JL, Matzke HJ (1983) On the correlation between solid-particle erosion and fracture parameters in SiC. J Mater Sci 18:1491–1496

Ruff AW, Wiederhorn SM (1979) Erosion by solid particle impact. In: Preece CM (ed) Erosion. Academic Press, New York, pp 69–126

Schmidt RA, Lutz TJ (1979) KIc and JIc of Westerley granite—effects of thickness and in-plane dimensions. In: Freiman SW (ed) Fracture Mechanics Applied to Brittle Materials. ASTM, New York, pp 166–182

Slikkerveer PJ, Verspui M, Skerka E (1999) Erosion and damage by hard spherical particles on glass. J Amer Ceram Soc 82:3173–3178

Szwedzicki T (1998) Indentation hardness testing of rock. Int J Rock Mech Min Sci 35:825–829

Tabor D (1951) The hardness of metals. Clarendon Press, Oxford

Tandon S, Faber KT (1999) Effects of loading rate on the fracture of cementitious materials. Cem Concr Res 29:397–406

Tibbitts GA, Galloway G, Vuyk A, Terry J (2009) Methods of using a particle impact drilling system for removing near-borehole damage, milling objects in a wellbore, under reaming, coring, perforating, assisting, annular flow, and associated methods. United States Patent Application Publication, US 2009/0218098 A1, 3 Sep 2009

Timoshenko S, Goodier JN (1970) Theory of Elasticity. McGraw-Hill, New York

Verhoef PN (1987) Sandblast testing of rock. Int J Rock Mech Min Sci 24:185–192

Verhoef PN, Kuipers TJ, Verwaal W (1984) The use of the sand-blast test to determine rock durability. Bull Int Assoc Engng Geol 29:457–461

Wallin K (2013) A simple fracture mechanical interpretation of size effects in concrete fracture toughness tests. Eng Fract Mech 99:18–29

Wang QZ, Yang JR, Zhang CG, Zhou Y (2014) Rock dynamic fracture toughness measured by using crack propagation gauge and universal function. In: 16th International Conference on Experimental Mechanics, Cambridge, UK; European Society Experimental Mechanics: 7–8 July 2014

Wiederhorn SM, Hockey BJ (1983) Effect of material parameters on the erosion resistance of brittle materials. J Mater Sci 18:766–780

Winslow DN (1984) A Rockwell hardness test for concrete. Cement Concr Aggreg 6:137–141

Zhang ZX, Kou SQ, Yu J, Yu Y, Jiang LG, Lindqvist PA (1999) Effects of loading rate on rock fracture. Int J Rock Mech Min Sci 36:597–611

Zhang ZX, Kou SQ, Jiang LG, Lindqvist PA (2000) Effects of loading rate on rock fracture: fracture characteristics and energy partitioning. Int J Rock Mech Min Sci 37:745–762

Zhang H, Song H, Kang Y, Huabng G, Qu C (2013) Experimental analysis on deformation evolution and crack propagation of rock under cyclic indentation. Rock Mech Rock Eng 46:1053–1059

Acknowledgments

The author is thankful to the German Academic Exchange Service (DAAD), Bonn, Germany, for providing an Exchange Lecturer Fellowship for a stay at the University of Cambridge, UK. Special thanks is addressed to the Fracture Group, Physics and Chemistry of Solids, Cavendish Laboratory, for its kind hospitality and the permission to use experimental facilities.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Calculation of Eroded Volume According to the Model of Chen et al. (2005)

The volume eroded by an impinging solid particle is estimated as follows (Chen et al. 2005):

Yield strength σ Y can be related to material hardness as follows (Tabor 1951):

The parameter c I is a material-dependent parameter; it can be estimated from a function f(E M/H M) provided by Bushby and Swain (1995). Hardness is linearly related to the compressive strength for many rocks and cement-based materials (Szwedzicki 1998; Winslow 1984; Igrashi et al. 1996). For the relationship between indentation hardness and uniaxial compressive strength of rock materials, the following correlation (R 2 = 0.974) can be applied (Jung et al. 1994):

The indenter angle β can be related to the ratio r B/r P for spherical indenters (Chen et al. 2005). The graph in Chen et al. (2005; Fig. 5, p. 1236), can be approximated with a second-power regression (R 2 = 0.991):

The contact radius can be calculated as follows (Fischer-Cipps 2007):

The ratio r B/r P can be expressed as follows:

The contact force generated by an impacting spherical solid particle can be calculated as follows (Knight et al. 1977):

The parameter k balances the elastic properties of erodent and target material as follows (Fischer-Cipps 2007):

From linear-elastic fracture mechanics, E M⋅Γ Ic can be expressed as follows:

Appendix B: Calculation of Stress Rates

Loading rate in terms of stress rate can be expressed as follows:

Here, σ P is the contact tensile stress, and t P is the period of contact. The tensile stress generated by an impinging spherical particle can be calculated as follows (Fischer-Cipps 2007):

Here, r B is the contact radius, and P C is the contact force. They are given in Appendix A. A solution for the contact time for elastic contact is provided by Timoshenko und Goodier (1970); it can be expressed as follows:

The parameter k is given in Appendix A. This period can increase notably, if plastic deformation, toughening or erodent fragmentation occurs. Thus, a plastic contact time shall be added. A solution for the contact time for plastic contact is provided by Chaudri und Walley (1978); it reads as follows:

It can be seen that this time period does not depend on impingement velocity. The equations deliver the following relationship:

Rights and permissions

About this article

Cite this article

Momber, A.W. Fracture Toughness Effects in Geomaterial Solid Particle Erosion. Rock Mech Rock Eng 48, 1573–1588 (2015). https://doi.org/10.1007/s00603-014-0658-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-014-0658-x