Abstract

This work introduces the design, analysis, simulation, and a standard MEMS fabrication process for a three-dimensional micro-coil with a magnetic core and a digital switch configuration using a completely integrated, fully MEMS-compatible process to achieve a digitally controlled inductance. The proposed design can also be utilized as a micro-transformer. The proposed design consists of five identical 3D coils and their corresponding MEMS switches. These coils are digitally controlled to achieve a variable inductor ranging from one-fifth of the coil inductance up to five times the coil inductance. A standard five-layer Polymumps process is proposed to fabricate the micro-coils and the integrated switches. Each micro coil is anchored directly on-chip, which is connected to the input signal from one side, and the other is connected to the switch. The Ni-based magnetic core improves the coil’s response by confining and guiding the magnetic field in the magnetic device compared to Si core based by more than five times. The presented coil has the number of windings limited by the designed length and the minimum spacing that can be realized by standard optical lithography. The coil’s diameter is also restricted by the limits defined by optical lithography, whereas the maximum height realizable by the Polymumps process limits the height of the magnetic core and accordingly results in lower inductor performance. Based on this technique, we present coils ranging from 100 μm length and ten winding up to 1000 μm length and 100 windings. The new monolithically integrated MEMS switches act as selectors to achieve a variable inductance with digital control to allow the selection among n(n + 1)/2 inductance steps, where n is the number of coils.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Inductor, a passive electronic element, is one of the most important electronic elements along with other passive elements such as resistors, capacitors, and active elements such as diodes, transistors, and integrated circuits (IC) (Chaudhary 2022; Hah 2022). Conductor finds different applications in diverse areas ranging from filtering, tuning circuits, and oscillators up to complex RF circuits (Khodapanahandeh 2021; Iannacci 2021; Pirouznia et al. 2014; Hikmat et. al. 2017; Chomnawang et al. 2001). Inductors and transformers are crucial elements in switched-mode power supplies (Hoa Thanh et al. 2021), biomedical devices (Lefebvre et al. 2020; Sun Xuecheng et al. 2017), microfluidics (Cardoso et al. 2017; Komaragiri et al. 2019), and magnetic sensors (Zhi et al. 2019; Syms et al. 2005). Micro-coiled MEMS inductors offer significant advantages in these applications such as high quality factor and inductance. However, power MEMS inductors must have sufficient current handling capability, low electromagnetic interference, and low parasitic capacitance (Massin et al. 2002).

However, it remains the most complex element to be implemented using standard integrated circuit (IC) technology (Umesh Kumar et al. 1989). Although inductors are important as passive electronic elements in different application areas, such as sensors and actuators, their miniaturization has not been as successful as for resistors and capacitor passive electronic elements (Prasanth et al. 2014; Elamien et al. 2016; Mohabbatian et al. 2014). Thus, the MEMS community has directed a considerable amount of research effort to coil miniaturization during the past decades (Sharaf et al. 2022; Maluf et al. 2004; Gad-el-Hak 2006).

Microelectromechanical systems (MEMS) introduce many solutions for implementing diverse bulky physical sensors (Bustillo et al. 1998). Due to its powerful metrics such as low cost, small size, mass production, low power dissipations, high performance, and compatibility with standered IC technology fabrication processes (Zhang et al. 1993; Srikar et al. 2003). Many fields find MEMS technology a good solution that is appropriate to achieve all required aspects to implement different types of sensors efficiently (McMahon et al. 2000; Cao et al. 2000). Many researchers work toward achieving low area, high efficiency, and fabrication compatibility with standard MEMS and IC fabrication processes (Herrault et al. 2009; Ehrmann et al. 2007; Dohi et al. 2007; Klein et al. 2008).

Many categories of monolithic MEMS coils were reported. Among these there is a planar spiral-shaped micro coils (Rogge et al. 1995; Lochel et al. 1996), 3D solenoidal micro coils with rectangular cross-sections (Boero et al. 1998; Hidetoshi et al. 2007), and solenoids with circular cross-sections (Peck et al. 1995; Ahn et al. 1993). Micro coil emulates macro scale coil fabrication processes by focusing on achieving good characteristics such as a high level of integration, freedom in achievable coil inductance with and without magnetic core material, high quality factor, electrical winding insulation, high mechanical strength and stability, and low manufacturing and assembly costs (Ohnmacht et al. 2000; Kallenbach et al. 2006; Sohn et al. 2006; Seeber et al. 2001).

A transformer is a magnetic sensor used in many applications to transform the voltage and current between two networks. The process is performed through two types of coils named primary and secondary coils. Implementing micro coils through MEMS technology opens the flour to implement micro-transformers efficiently. Generally, miniaturized transformers that use MEMS techniques have many potential advantages, such as low power consumption, low cost, high efficiency, high quality factor (QF), and high-frequency operation (Shadid et al. 2018; Rizou et al. 2018; Lee et al. 2016; Jean-Philippe et al. 2019a).

This work introduces the design, analysis, simulation, and a suggested fabrication process for implementing a tall-profile magnetic core, 3D micro-coil with a magnetic core and a digital switch configuration using a completely integrated, fully MEMS-compatible process to achieve a digitally controlled variable inductance. The controlled variable inductor can be used to implement a broadband MEMS-Based band pass filter along with a digitally controlled variable capacitor introduced by the author (Sharaf et al. 2021; Hamid and Saeed (2019)). Also, the proposed design can be used to implement 3D microtransformer for different electronic applications. The proposed design provides reliability, mass production, and a high yield for the fabricated micro coils. A wonderful advantage beside the above is to achieve very low and high inductance values with wide tuning range from one fifth the coil inductance to five times the coil inductance. Also, implementing of 3D microtransformer can be easily achieved. The simulations show a standalone design for implementing micro coils through a standard Polymumps® process (Koester et al. 2003).

The rest of the paper is organized as follow. Section 2 introduces the proposed design, the results and discussion was introduced in Sect. 3, a proposed prosess flow was presented in Sect. 4 and finally the work was concluded in Sect. 5.

2 Proposed design

The proposed design implements the micro-coil in two successive layers and connects the two layers through vias opened in the magnetic core layer. This design allows the building of individual coils with variable inductance and micro transformers.

The proposed design introduced here implements five identical coils and five identical single-ended cantilevers to select the appropriate coil in series, in parallel, or in a combination selection between series/parallel.

Figure 1a shows the 3D layout of the proposed design. There are two anchors for electrical connections and mechanically support the micro coil to the substrate. The lower layer was deposited and patterned over the insulator to achieve electrical isolation from the substrate. This layer is fixed in the substrate. The magnetic core material is deposited and patterned over the lower layer. Through holes are opened in the magnetic core layer at predefined points to connect the top layer half winding of the coil to the lower layer half winding. Figure 1b shows the side view of the micro-coil. All anchors and the lower layer are fixed to the substrate resulting in a minimized stress gradient effect on the micro-coil.

To achieve a variable inductance, switches are added to the proposed design. It depends on a single-ended micro cantilever design. These cantilevers are controlled across voltage to select the required value of inductance by combinations of series and/or parallel connections. Regarding the design simplifications, the cantilevers are made to vibrate in-plane to substrate instead of out-of-plane vibrations.

Figure 1-b shows the top-view schematic diagram for the inductor along with the cantilever. The cantilever is a single-ended design fixed on one side, and the other is free to move. Two control electrodes are implemented on the two sides of the cantilever, one for series control and the other for parallel control. At the free tip of the cantilevers implemented, the electrical connection for the series and/or parallel connections. These configurations allow implementations of variable inductance ranging from one-fifth of a single coil inductance by connecting all cantilevers in a parallel configuration, up to five times the single coil inductance, in case of connecting the five coils in series.

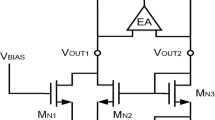

The lumped element circuit diagram is presented in Fig. 2. The input signal is connected to the first coil (L1) and, simultaneously, to the first parallel switch (the switch on the left of the diagram, namely, PSW1). The second terminal of the coil is connected to a parallel/ series switch (the switch on the right of the diagram, namely, PSSW1).

To connect a coil in a series configuration, then its parallel switch (PSW) should be disconnected at the same time the parallel/ series switch (PSSW) is closed so that its free tip is moved to the up position to select the first terminal of the next coil and so on. When connected in a parallel configuration, the parallel switch is closed so that the first coil terminal is connected to the first terminal of the next coil, and at the same time, the parallel/ series switch (PSSW) is closed so that it free tip moves to the down position to select the second terminal of the next coil and so on.

Introduced in Table 1 are the possible connection schemes for the five coils in both configurations and the resulting coil inductance. Figure 3 shows a bar graph for the total inductance of the proposed circuit as a function of the selection between series and parallel connections.

In general, the steps that can be obtained can be given by:

where n number of coils. Thus the total number of steps can be estimated by:

3 Results and discussion

The analytical results of the proposed design was introduced in the next sub section. Where as the simulation results is demonstrated and simulated using finite element analysis programs to verify the analytical results.

3.1 Analytical results

An inductor is basically just a coil of wire wound on a core which may be a magnetic material or air. According to Lenz’s Law, the magnetic field will induce the motion of charges to resist change in the current; thus, the inductance is equal to the electromotive force (EMF) per unit rate of change of the induced current. Inductance can be calculated using the following formula, in the units of Henry (H):

where N is the number of coil turns, A is the cross-sectional area of the coil, and l is the length of the coil, \({\mu }_{o}\) is a constant called the vacuum permeability constant and has the value 4π × 10–7 H/m, \({\mu }_{r}\) is the relative permeability of the magnetic core used, and it is a material dependent value. Changing the core material of the coil will change the, results in change the coil inductance.

The designed parameters are summarized in Table 2. A variety of coil cross sections, lengths, and core materials used are supposed in the analysis to achieve good performance for the designed micro coil.

3.2 Simulation results

Finite element analysis using COMSOL Multiphysics version 5.5 was used to simulate the behavior of the coil and verify the analytical results. The cantilever was mechanically and electrically simulated to extract its mode shapes, frequency, and response to applied DC control voltages. The coil was simulated to extract the total magnetic energy produced with a 1A driving current.

3.2.1 Mechanical simulation

The mechanical simulation was performed on the moving parts of the design, namely the microcantilever. Both modal analysis, to extract the mode shapes and their resonances, and frequency response analysis, to determine the displacement values and directions of moving the free tip in response to applied DC control voltage and the required DC load voltage, are performed.

3.2.1.1 Modal analysis

Modal analysis is extracted to determine the mode shapes of the moving parts and their resonance frequency. Figure 4a–c, represent the fundamental mode shape at 32.772 kHz. Figure 4d–f show the second mode shape at the resonance frequency of 81.848 kHz. It is clear that the second mode vibration is highly large in resonance than the fundamental mode and in shape is perpendicular to the substrate. The third mode shape with the resonance frequency of 205.33 kHz is shown in Fig. 4g–i. The third mode vibrates parallel to the substrate like the fundamental but with a very high frequency over the fundamental mode. Diving the cantilever with the resonance frequency of the fundamental mode guarantees the proper operation of the design of both magnitudes of in-plane displacement and the proper connection of the desired coil configuration, namely parallel or series ones.

a Fundamental mode shape at 32.772 kHz, moves right and left parallel to substrate; b the top view of the first mode; c the elevation view of the first mode shape; d second mode shape at 81.848 kHz, moves up and down perpendicular to substrate; e the top view of the second mode; f the elevation view of the second mode shape; g third mode shape at 205.33 kHz, moves right and left parallel to substrate; h the top view of the first mode; i the elevation view of the first mode shape

3.2.1.2 Frequency response analysis

Harmonic analysis was performed to investigate how much the design responds to the applied load and how it survives against load before it is destroyed. Figure 5a and b show the moving cantilever's response to the static load effect. The diving voltage starting from 1 to 15 voltage was applied to the left control electrode. The cantilever responds to the applied voltage by left in-plane displacement. Figure 5a represents the cantilever displacement at an applied voltage of 15 V on the left control electrode, whereas Fig. 5b represents the cantilever displacement for the right control electrode applied voltage of 15 V. Figure 5c and d represent the corresponding elevation view for Fig. 5a and b, respectively.

Figure 6a and b show the distribution of electric potential and electric field for the both cases introduces in Fig. 5. Figure 6a shows the electric potential along the cantilever in response to the applied voltage on the left electrode form 1 to 15 V. where Fig. 6b represents the other case of right actuation.

Figure 7a and b introduce the response of the cantilever beam to different applied voltages. It is clear that as the applied voltage increase, the beam displacement increase in both directions according to the applied control voltage. Figure 7a represents the left actuation, while Fig. 7b represents the right actuation.

Figure 8a and b represent the beam displacement at pull-in voltage against frequency. The pull-in voltage mentioned here refere to the required voltage to produce a free tip connection to the selected pad. The operation of the proposed design depends on the in-plane moving of the free tip of the cantilever to achieve perfect connection to a specific connection pad due to the selection of series and/or parallel combination. Thus the selction of the appropriate inductance value can be achieved. This analysis is based on driving the control electrodes with constant amplitude voltage with sinusoidal frequency around the fundamental mode frequency.

Figure 9a and b represent the static analysis for the point at the tip of the free end in response to the applied electric voltage on the control electrodes. Figure 9a represents the left actuation, while Fig. 9b represents the right actuation.

3.2.2 Electrical simulations

Simulating the behavior of the designed coil to alternating current (AC) at high frequency is a milestone step in coil simulation. COMSOL multiphysics domain is required to link the various area concerning this topic. Structure mechanics, AC/DC, and RF domain physics are used to determine the behavior of the coil at a high-frequency range. The simulation performed takes on the part of the coil consisting of ten turns for simplicity. Figure 10 represents a magnetic core surrounded by ten turns of the proposed coil. Three different magnetic core dimensions and three different magnetic materials for core were simulated.

Figure 11 shows the electric potential distribution along the 10 turns coil due to 1A excitation current. Due to the change in the core dimensions, the total length of the coil changed, resulting in different values of the electric potential distribution along the coil, as presented in Fig. 11a–c.

Figure 12 simulates the total magnetic flux produced due to the 1A excitation current. The magnetic flux density for the same core dimensions differs significantly by changing the magnetic core material.

Figure 13 simulates the magnetic flux density for 20 um thick magnetic core with different magnetic materials. As the core thickness increased, the magnetic flux density increased for the same simulated magnetic material in the previous Fig. 12.

Figure 14 compares the magnetic flux density in the case of air core and with Fe and Ni core materials. Using magnetic material as a magnetic core increase the total magnetic flux density. Fe and Ni materials give magnetic flux densities relatively close to each other and greater than the air core case.

Table 3 summarizes the evaluated inductance, resistance, and total energy extracted from the finite element analysis (COMSOL™). COMSOL™ evaluates the inductance using the current and the total magnetic energy. The inductance can be derived as the ratio of linked magnetic flux to current. For the case of a single coil, the inductance can also be calculated using current and magnetic energy. In particular, coil inductance can be expressed as:

where Wm is the total magnetic energy in space. And (I) is the excitation current. Putting current equals 1A in the analysis, then twice the magnetic energy reflected the inductance value. This comparison is interpreted in Fig. 15.

4 Process flow

Inductors consist of three materials: conductive material for windings, insulator material for electrical isolation between windings, and core material to concentrate the magnetic flux. The conductive material for windings is used to carry currents to produce the suitable magnetic flux. They are made of metals, such as copper (Cu). The insulator materials are dielectric thin films such as silicon oxide (SiO2), aluminum oxide (Al2O3), or silicon nitride (Si3N4). The inductor cores can be made of air or magnetic materials.

4.1 PolyMUMPs® technology

Standard five-layer PolyMUMPs® can be used to implement the proposed inductor and its control switches. This process has the drawback of a lower aspect ratio, which results in lower magnetic core thickness. Accordingly limits the inductor performance. The process starts with an electrically isolated silicon wafer. The first step is to deposit and pattern another oxide layer. The patterned area in the next oxide to define the anchor area, control electrodes for series and parallel selections, the connection from one stage to the next inductor stage, and the groves for inductor lower connectors. The second step is to deposit the control electrodes, connection pads, anchors, and lower inductor layer. The third step is to deposit and pattern an oxide layer for electrical isolation for inductor winding and magnetic core. The fourth step is to deposit and pattern the magnetic core material. Then deposit the side wall and top inductor windings. Finally, the structure is released at cantilever parts. Figure 16 shows a simplified 2D layout for the proposed process.

4.2 3D surface micromachinig technology

A more relaiable and effective thechnology is the 3D surface micromachining one. This process is suitable for building 3D micromachined inductors with low-profile air-core inductors, low-profile magnetic-core inductors, and tall-profile magnetic-core inductors (Michel et al. 2019b; Kim 2015).

Figure 17 shows a summarized process flow based on the 3D surface micromachining technology. The process starts with an SOI wafer. This wafer has two benefits. First, the silicon layer is used to implement the cantilever switches, control electrodes, connection pads, and support anchors. The second benefit is using the insulator layer as a seed to build the 3D inductor. Then a layer of Cu is electroplating and patterned to form the bottom winding of the coil. Next, a thin insulator layer was deposited and patterned, followed by the deposition and pattern of magnetic core material. Then, a conductive material, Cu, is deposited and patterned to define the vertical and top windings of the inductor. Then, an insulator layer was deposited and patterned to offer the required isolation between windings. Finally, the structure was released at the cantilever part to define the required switches.

5 Conclusion

This work reported the design, analysis, and simulation of 3D micro-coils. The proposed micro coil introduced here was compatible with slandered MEMS fabrication processes. The main idea presented here is how to achieve a digitally controlled variable inductor. Five in-plane cantilevers were used to implement five switches to select among five coils. The selection can be parallel or series or a combination of parallel/series schemes to achieve a required inductance value. Depending on the fabrication technology, any required number of coil turns and dimensions can be implemented with a suitable magnetic core material. Fifteen inductance steps were obtained, ranging from 0.2L (H) up to 5L (H) can be achieved. The simulations ensure the designed idea. Both mechanical and electrical simulations confirmed and emphasized the success of the main idea behind the proposed design.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Ahn CH, Allen MG (1993) A planar micromachined spiral inductor for integrated magnetic microactuator applications. J Micromech Microeng 3:37–44

Boero G, de Raad Iseli C, Besse PA, Popovicw RS (1998) An NMR magnetometer with planar microcoils and integrated electronics for signal detection and amplification. Sens Actuators A 67:18–23

Bustillo JM, Howe RT, Muller RS (1998) Surface micromachining for micro -electromechanical systems. Proc IEEE 86(8):1559–1561

Cao L, Kin TS, Mantell SC, Polla D (2000) Simulation and fabrication of piezoresistive membrane type MEMS strain sensors. Sens Actuators 80:273–279

Cardoso S, Leitao DC, Dias TM, Valadeiro J, Silva MD, Chicharo A, Silverio V, Gaspar J, Freitas PP (2017) Challenges and trends in magnetic sensor integration with microfluidics for biomedical applications. J Phys D 50:213001

Chaudhary R, Mudimela PR (2022) Comprehensive review of low pull-in voltage RF NEMS switches. Microsyst Technol. https://doi.org/10.1007/s00542-022-05392-8

Chomnawang N, Lee J-B (2001) On-chip 3D aircore microinductor for high-frequency applications using deformation of sacrificial polymer. In: Proc SPIE 4334, Smart Structures and Materials: Smart Electronics and MEMS, Newport Beach, CA, USA. Vol. 4334. pp 54–62. https://doi.org/10.1117/12.436627

Dohi T, Kuwana K, Matsumoto K, Shimoyama I (2007) A standing micro coil for a high resolution MRI. In: Proc IEEE Transducers. pp 1313–1316

Ehrmann K, Saillen N, Vincent F, Stettler M, Jordan M, Wurm FM, Besse P-A, Popovica R (2007) Microfabricated solenoids and Helmholtz coils for NMR spectroscopy of mammalian cells. Lab Chip 7:373–380

Elamien MB, Mahmoud SA (2016) A linear CMOS balanced output transconductor using double differential pair with source degeneration and adaptive biasing. In: Proc IEEE 59th Int Midwest Symp Circuits Syst (MWSCAS). pp. 1–4

Gad-el-Hak M (2006) MEMS introduction and fundamentals. CRC Press, Taylor & Francis Group, Boca Raton

Hah D (2022) Analytical design of MEMS variable capacitors based on shaped-finger comb-drives. Microsyst Technol 28:1423–1434. https://doi.org/10.1007/s00542-019-04362-x

Hamid R, Saeed Kh (2019) Design and simulation of a novel RF MEMS shunt capacitive switch with a unique spring for Ka-band applications. Microsyst Technol 25:531–540

Herrault F, Yorish S, Crittenden T, Allen MG (2009) Microfabricated, ultra-dense, three -dimensional metal coils. In: Proc IEEE Transducers. pp 1718–1721

Hikmat OF, Mohamed Ali MS (2017) RF MEMS inductors and their applications a review. J Microelectromech Syst 26(1):17–44. https://doi.org/10.1109/JMEMS.2016.2627039

Iannacci J (2021) Coupled electromechanical and electromagnetic simulation of radio frequency microelectromechanical-systems (RF-MEMS) based on compact models approach. Microsyst Technol 27:59–67. https://doi.org/10.1007/s00542-020-04903-9

Kallenbach M, Bussinger F, Kallenbach E, Hermann R (2006) Miniaturisation of magnetic actuators for small powerful industrial small size application. In: Proc ACTUATOR Bremen. pp 116–119

Khodapanahandeh M, Babaeihaselghobi A, Badri Ghavifekr H (2021) Design and simulation of a novel RF-MEMS tunable narrow band LC filter in the UHF band. Microsyst Technol 27:325–334. https://doi.org/10.1007/s00542-020-04959-7

Kim J, Kim M, Kim JK, Herrault F, Allen MG (2015) Anisotropic nanolaminatedCoNiFe cores integrated into micro inductors for high-frequency DC-DC power conversion. J Phys D Appl Phys 48:462001

Klein MJK, Ono T, Esashi M, Korvink JG (2008) Process for the fabrication of hollow core solenoidal microcoils in borosilicate glass. J Micromech Microeng 18:1–6

Koester DA, Cowen A, Mahadevan R, Stonefield M, Hardy B (2003) PolyMUMPs design handbook: a MUMPsfi process. MEMSCAP Inc, Durham

Krishnapriya S, Komaragiri R, Suja KJ (2019) Fabrication, characterization, and modelling of a novel via -less single metal level magnetic microcoil sensor for biosensing applications. Sens Actuators A 290:190–197

Kumar U, Shukla SK (1989) Analytical study of inductor simulation circuits. Active Passive Electron Compon 13:211–227

Le HT, Haque R, Ouyang Z, Lee SW, Fried SI, Zhao D, Qiu M, Han A (2021) MEMS inductor fabrication and emerging applications in power electronics and neurotechnologies. Microsyst Nanoeng 7:59

Lee SW, Fallegger F, Casse BDF, Fried SI (2016) Implantable microcoils for intracortical magnetic stimulation. Sci Adv 2:e600889

Lefebvre O, Cao HH, Cortés Francisco M, Woytasik M, Dufour-Gergam E, Ammar M, Martincic E (2020) Reusable embedded microcoils for magnetic nano-beads trapping in microfluidics: magnetic simulation and experiments. Micromachines 11(3):257. https://doi.org/10.3390/mi11030257

Lochel B, Maciossek A, Rothe M, Windbracke W (1996) Microcoils fabricated by UV depth lithography and galvanoplating. Sens Actuators A 54:663–8

Maluf N, Williams K (2004) An introduction to microelectromechanical systems engineering. Artech House Inc, Norwood

Massin C, Boero G, Vincent F, Abenhaim J, Besse PA, Popovic RS (2002) High-Q factor RF planar microcoils for micro-scale NMR spectroscopy. Sens Actuators A 97–98:280–288

McMahon JJ, Melzak JM, Zorman CA, Chung J, Mehregany M (2000) Deposition and characterization of in-situ boron doped polycrystalline silicon films for microelectromechanical systems applications. Mater Res Symp Proc 605:31–36

Michel J-P, Sibuet H, Buffet N, Bastien J-C, Hida R, Viala B, Poveda P, Berneux-Dugast A-S, Bruno E, Falub CV (2019) Ultra-low profile integrated magnetic inductors and transformers for HF applications. IEEE Trans Magn 55:1–7

Michel JP et al (2019b) Ultra-low profile integrated magnetic inductors and transformers for HF applications. IEEE Trans Magn 55:1–7

Mohabbatian N, Abbaspour-Sani E, Ghasemzadeh M (2014) An electrostatic tunable RF MEMS capacitor with improved quality factor. In: 2014 22nd Iranian Conference on Elec Eng (ICEE). pp 422–427. https://doi.org/10.1109/IranianCEE.2014.6999577

Ohnmacht M, Seidemann V, Büttgenbach S (2000) Microcoils and microrelays—an optimized multilayer fabrication process. Sens Actuators A 83:124–9

Peck TL, Magin RL, Lauterbur PC (1995) Design and analysis of microcoils for NMR microscopy. J Magn Reson B 108:114–124

Pirouznia P, Azizollah GB (2014) Analytical optimization of high performance and high quality factor MEMS spiral inductor. Prog Electromagn Res M 34:171–179. https://doi.org/10.2528/PIERM13121908

Prasanth N, Likhith BP, Anjum N, Gajendra KA (2014) Analysis of active resistors realized using CMOS technology. IOSR J VLSI Signal Process 4(2):7–11

Rizou ME, Prodromakis T (2018) Magnetic stimulation in the microscale: the development of a 6 × 6 array of micro-coils for stimulation of excitable cells in vitro. Biomed Phys Eng Express 4:025016

Rogge B, Schulz J, Mohr J, Thommes A, Menz W (1995) Fully batch fabricated magnetic microactuators using a two layer LIGA process. Proc IEEE Transducers 1:320–323

Seeber DA, Cooper RL, Ciobanu L, Pennington CH (2001) Design and testing of high sensitivity microreceiver coil apparatus for nuclear magnetic resonance and imaging. Rev Sci Instrum 72:2171–2179

Shadid R, Noghanian S (2018) A literature survey on wireless power transfer for biomedical devices. Int J Antennas Propag. https://doi.org/10.1155/2018/4382841

Sharaf A, Nasr A, Elshurafa AM, Serry M (2022) Design analysis and simulation of a digital RF MEMS varactor with high capacitive ratio. J Microsyst Technol 28:1831–1844. https://doi.org/10.1007/s00542-022-05318-4

Sohn LL, Herberg JL, Harteneck BD, Myers DR, Liddle JA (2006) Fabrication of an on-chip NMR microfluidics device. In: Proc μTAS (Tokyo, Japan). pp 1145–1147

Srikar VT, Spearing SM (2003) Materials selection in micromechanical design: an application of the Ashby approach. J Microelectromech Syst 12:3–10

Sun X, Feng Z, Zhi S, Lei C, Zhang D, Zhou Y (2017) An integrated Microfluidic system using a micro-fluxgate and micro spiral coil formagneticmicrobeads trapping and detecting. Sci Rep 7:1–8

Syms RRA, Ahmad MM, Young IR, Gilderdale D, Collins DJ, Leach MO (2005) Batch fabrication of micro-coils for MR spectroscopy on silicon. In: SENSORS, 2005 IEEE. p 4. https://doi.org/10.1109/ICSENS.2005.1597677

Takahashi H, Dohi T, Matsumoto K, Shimoyama I (2007) A micro planar coil for local high resolution magnetic resonance imaging. In: 2007 IEEE 20th International Conference on Micro Electro Mechanical Systems (MEMS), pp. 549–552. https://doi.org/10.1109/MEMSYS.2007.4433156

Zhang ZL, MacDonald NC (1993) Fabrication of submicron high-aspect-ratio GaAs actuators. J Microelectromech Syst 2(2):66–73

Zhi S, Sun X, Feng Z, Lei C, Zhou Y (2019) An innovative micro magnetic separator based on 3D micro-copper-coil exciting soft magnetictips and FeNi wires for bio-target sorting. Microfluid Nanofluid 23:1

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sharaf, A., Eladl, S.M., Nasr, A. et al. Design and simulation of a micro-coiled digitally-controlled variable inductor with a monolithically integrated MEMS switch. Microsyst Technol (2024). https://doi.org/10.1007/s00542-024-05644-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00542-024-05644-9