Abstract

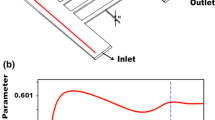

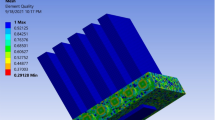

The present research article focuses on the mitigation of fluid flow and thermal non-uniformity in the microfluidic system resulting in hot spot mitigation in microelectronic devices. A concept of variable size microchannels is extended by implementing the mass and thermal mitigation methods. In the present study, 3-D numerical simulation is carried out to study the problem of fluid flow and thermal non-uniformity of \( \mathrm {Al_{2}O_{3}}\)/water nanofluid with three different nanoparticle concentrations (1–3 vol.%) in the microfluidic system. The computational domain is considered the entire microfluidic system, including parallel microchannels, inlet/outlet manifolds, and ports. Results are analysed and compared for flow and thermal field as well as pressure drop penalty. Results indicate that mass and thermal mitigation are effective methods of obtaining uniform mass distribution and thermal field among all the microchannels. The same brings pumping power penalty due to non-uniform size of the microchannels. It is observed that equalization of fluid velocity among all the microchannels leads to uniform thermal field of the MCHS. If the development of uneven thermal stresses cannot be tolerated in the specific application, the MCHS with thermal mitigation using variable size microchannels is the best design as applied to real-world applications, but at the cost of pumping power penalty.

Similar content being viewed by others

Abbreviations

- A :

-

Area of microchannel (\( \text{m}^{2} \))

- \(C_{p}\) :

-

Specific heat (J/kg K)

- D :

-

Diameter of microchannel (m)

- d :

-

Nanoparticle size (nm)

- \(D_{f}\) :

-

Fractal index (1.6–2.5)

- f :

-

Friction factor

- g :

-

Different grid schemes

- H :

-

Height of MCHS (m)

- h :

-

Heat transfer coefficient (\( {\text{W/m}}^{{\text{2}}} {\text{K}} \))

- i :

-

Microchannel number (\( 1\le \; i \;\le \; N \))

- j :

-

Iteration number (\( 0\le \; j \;\le \; M \))

- k :

-

Thermal conductivity (W/m K)

- L :

-

Length of MCHS (m)

- \(\dot{m} \) :

-

Mass flow rate (Kg/s)

- NMFR:

-

Normalized mass flow rate (\(\dot{m}_{{{\text{ch}} - i}} /\dot{m}_{{ch - {\text{avg}}}}\))

- NHTR :

-

Normalized heat transfer rate (\( \dot{Q}_{{{\text{ch}} - i}} /\dot{Q}_{{ch - {\text{avg}}}}\))

- N :

-

Total number of microchannel

- p :

-

Pressure (Pa)

- \( \dot{Q} \) :

-

Heat transfer rate (W)

- \(q^{''}\) :

-

Wall heat flux (\({\text{W/m}}^{{\text{2}}}\))

- r :

-

Nanoparticle radius (nm)

- S :

-

Spacing between microchannels (m)

- T:

-

Temperature (\(^{\circ }\mathrm {C}\))

- v :

-

Flow velocity (m/s)

- W :

-

Width of MCHS (m)

- x :

-

Local axial length of microchannel (m)

- \(x^{+}\) :

-

Dimensionless hydrodynamically developed length (\( \frac{L/D_{i}}{Re} \))

- \(x^{*}\) :

-

Dimensionless thermally developing length (\( \frac{x/D_{i}}{Re\;Pr} \))

- \(\alpha \) :

-

Nanoparticle Biot number

- \(\varepsilon \) :

-

Grid convergence index (\( \% \))

- \(\mu \) :

-

Dynamic viscosity (Pa s)

- \(\rho \) :

-

Density (\({\text{kg/m}}^{{\text{3}}}\))

- \(\phi \) :

-

Nanoparticle concentration (%)

- \(\varphi \) :

-

Non-uniformity factor

- Re:

-

Reynolds number \( (\frac{\rho \;v\;D}{\mu }) \)

- Pr:

-

Prandtl number \( (\frac{\mu \;C_{p}}{k}) \)

- Nu:

-

Local Nusselt number

- a :

-

Aggregates

- avg:

-

Average

- B :

-

Brownian motion

- bf:

-

Base fluid

- cr:

-

Critical

- f:

-

Fluid

- ch:

-

Channel

- in:

-

Inlet

- \( \dot{Q} \) :

-

Heat transfer rate

- \(\dot{m}\) :

-

Mass flow rate

- M:

-

Manifold

- max:

-

Maximum

- min:

-

Minimum

- nf:

-

Nanofluid

- np:

-

Nanoparticle

- p:

-

Port

- out:

-

Outlet

- s:

-

Solid

- \(\infty \) :

-

Ambient condition

References

ANSYS Inc (2013) ANSYS fluent® user’s guide release. ANSYS, Canonsburg, pp 724–746

Anbumeenakshi C, Thansekhar MR (2016) Experimental investigation of header shape and inlet configuration on flow maldistribution in microchannel. Exp Therm Fluid Sci 75:156–161. https://doi.org/10.1016/j.expthermflusci.2016.02.004

Chein R, Chen J (2009) Numerical study of the inlet/outlet arrangement effect on microchannel heat sink performance. Int J Therm Sci 48:1627–1638. https://doi.org/10.1016/j.ijthermalsci.2008.12.019

Chen H, Ding Y, Tan C (2007) Rheological behaviour of nanofluids. New J Phys 9:1–24. https://doi.org/10.1088/1367-2630/9/10/367

Cho ES, Choi JW, Yoon JS, Kim MS (2010a) Modeling and simulation on the mass flow distribution in microchannel heat sinks with non-uniform heat flux conditions. Int J Heat Mass Transf 53:1341–1348. https://doi.org/10.1016/j.ijheatmasstransfer.2009.12.025

Cho ES, Choi JW, Yoon JS, Kim MS (2010b) Experimental study on microchannel heat sinks considering mass flow distribution with non-uniform heat flux conditions. Int J Heat Mass Transf 53:2159–2168. https://doi.org/10.1016/j.ijheatmasstransfer.2009.12.026

Choi SUS, Eastman JA (1995) Enhancing thermal conductivity of fluids with nanoparticles. In: Proceedings of International Mechanical Engineering Congress and Exposition, pp 99–105

Corporation I (2018) 8th Generation Intel® Core Processor Family. pp 1–61

Dahiya A, Amer M, Sajjad U, Borah P, Sehgal SS, Singh H (2020) An experimental study on microchannel heat sink via different manifold arrangements. SN Appl Sci 2:1–11. https://doi.org/10.1007/s42452-019-1784-6

Krieger IM, Dougherty TJ (1959) A mechanism for non-newtonian flow in suspensions of rigid spheres. Trans Soc Rheol 3:137–152. https://doi.org/10.1122/1.548848

Kumar R, Singh G, Mikielewicz D (2018) A new approach for the mitigating of flow maldistribution in parallel microchannel heat sink. J Heat Transf 140:072401–10. https://doi.org/10.1115/1.4038830

Kumar R, Singh G, Mikielewicz D (2019) Numerical study on mitigation of flow maldistribution in parallel microchannel heat sink: channels variable width versus variable height approach. J Electron Packag 141:021009–11. https://doi.org/10.1115/1.4043158

Kumar R, Yadav V, Abiev RSH (2020) Concurrent removal of heat transfer and mass flow rate nonuniformities in parallel channels of microchannel heat sink. Theoret Found Chem Eng 54:77–90. https://doi.org/10.1134/s004057952001011x

Kumaraguruparan G, Kumaran RM, Sornakumar T, Sundararajan T (2011) A numerical and experimental investigation of flow maldistribution in a microchannel heat sink. Int Commun Heat Mass Transf 38:1349–1353. https://doi.org/10.1016/j.icheatmasstransfer.2011.08.020

Kumaran RM, Kumaraguruparan G, Sornakumar T (2013) Experimental and numerical studies of header design and inlet/outlet configurations on flow maldistribution in parallel microchannels. Appl Therm Eng 58:205–216. https://doi.org/10.1016/j.applthermaleng.2013.04.026

Leela V, Rajan KS (2014) Computational analysis of new microchannel heat sink configurations. Energy Convers Manag 86:595–604. https://doi.org/10.1016/j.enconman.2014.06.038

Leela V, Rajan KS (2015) Fine-tuning width and aspect ratio of an improved microchannel heat sink for energy-efficient thermal management. Energy Convers Manag 105:986–994. https://doi.org/10.1016/j.enconman.2015.08.068

Liu CK, Yang SJ, Chao YL, Liou KY, Wang CC (2013) Effect of non-uniform heating on the performance of the microchannel heat sinks. Int Commun Heat Mass Transf 43:57–62. https://doi.org/10.1016/j.icheatmasstransfer.2013.02.003

Lodhi M S, Sheorey T, Dutta G (2020a) Mitigation of flow and thermal non-uniformity in MEMS devices: Numerical Investigation. In: Proceedings of the 25th National and 3rd International ISHMT-ASTFE Heat and Mass Transfer Conference (IHMTC-2019), pp 263–268

Lodhi MS, Sheorey T, Dutta G (2020b) Single-phase fluid flow and heat transfer characteristics of nanofluid in a circular microchannel: development of flow and heat transfer correlations. J Mech Eng Sci 234:3689–3780. https://doi.org/10.1177/0954406220916537

Moore AL, Shi Li (2014) Emerging challenges and materials for thermal management of electronics. Mater Today 17:163–174. https://doi.org/10.1016/j.mattod.2014.04.003

Pak BC, Cho YI (1998) Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf 11:151–170. https://doi.org/10.1080/08916159808946559

Patankar SV (1980) Numerical heat transfer and fluid flow. Hemisphere Publishing Corporation, Washington, pp 1–206

Peterson GP, Ortega A (1990) Thermal control of electronic equipment and devices. Adv Heat Transf 20:181–314. https://doi.org/10.1016/S0065-2717(08)70028-5

Prasher R, Bhattacharya P, Phelan PE (2005) Thermal conductivity of nanoscale colloidal solutions (nanofluids). Phys Rev Lett 94:025901–025904

Prasher R, Bhattacharya P, Phelan PE (2006) Brownian-motion-based convective-conductive model for the effective thermal conductivity of nanofluids. J Heat Transf 128:588–595. https://doi.org/10.1115/1.21885090

Roache PJ (1994) Perspective: a method for uniform reporting of grid refinement studies. J Fluids Eng Trans ASME 116:405–413. https://doi.org/10.1115/1.4043158

Sehgal SS, Murugesan K, Mohapatra SK (2011) Experimental investigation of the effect of flow arrangements on the performance of a microchannel heat sink. Exp Heat Transf 24:215–233. https://doi.org/10.1080/08916152.2010.523808

Sehgal SS, Murugesan K, Mohapatra SK (2012) Effect of channel and plenum aspect ratios on the performance of microchannel heat sink under different flow arrangements. J Mech Sci Technol 26:2985–2994. https://doi.org/10.1007/s12206-012-0705-z

Siddique A, Medhi BJ, Agrawal A, Singh A, Saha SK (2017) Design of a collector shape for uniform flow distribution in microchannels. J Micromech Microeng. https://doi.org/10.1088/1361-6439/aa73eb

Siva VM, Pattamatta A, Das SK (2013) A numerical study of flow and temperature maldistribution in a parallel microchannel system for heat removal in microelectronic devices. J Therm Sci Eng Appl 5:041008–9. https://doi.org/10.1115/1.4024700

Siva VM, Pattamatta A, Das SK (2014a) Effect of flow maldistribution on the thermal performance of parallel microchannel cooling systems. Intl J Heat Mass Transf 73:424–428. https://doi.org/10.1016/j.ijheatmasstransfer.2014.02.017

Siva VM, Pattamatta A, Das SK (2014b) Investigation on flow maldistribution in parallel microchannel systems for integrated microelectronic device cooling. IEEE Trans Compon Packag Manuf Technol 4:438–450

Tang W, Sun L, Liu H, Xie G, Mo Z, Tang J (2017) Improvement of flow distribution and heat transfer performance of a self-similarity heat sink with a modification to its structure. Appl Therm Eng 121:163–171. https://doi.org/10.1016/j.applthermaleng.2017.04.051

Tang S, Zhao Y, Diao Y, Quan Z (2018) Effects of various inlet/outlet positions and header forms on flow distribution and thermal performance in microchannel heat sink. Microsyst Technol 24:2485–2497. https://doi.org/10.1007/s00542-017-3688-y

Tang W, Sun L, Li C, Liu H, Du M (2019) Improvements in performance of a self-similarity heat sink through structure modification. Heat Transf Eng. https://doi.org/10.1080/01457632.2019.1649939

Tuckerman DB, Pease RFW (1981) High-performance heat sinking for VLSI. IEEE Electron Dev Lett 2:126–129

Xia GD, Jiang J, Wang J, Zhai YL, Ma DD (2015a) Effects of different geometric structures on fluid flow and heat transfer performance in microchannel heat sinks. Int J Heat Mass Transf 80:439–447. https://doi.org/10.1016/j.ijheatmasstransfer.2014.08.095

Xia GD, Ma DD, Zhai YL, Jiang L, Liu R, Du M (2015b) Experimental and numerical study of fluid flow and heat transfer characteristics in microchannel heat sink with complex structure. Energy Convers Manag 105:848–857. https://doi.org/10.1016/j.enconman.2015.08.042

Xuan Y, Roetzel W (2000) Conception for heat transfer correlation of nanofluid. Int J Heat Mass Transf 43:3701–3707. https://doi.org/10.1016/S0017-9310(99)00369-5

Yadav V, Kumar R (2017) New method of flow maldistribution mitigation in parallel microchannel heat sink. Proc Fluids Eng Div Summer Meet. https://doi.org/10.1115/FEDSM2017-69084

Yadav V, Kumar R, Narain A (2019) Mitigation of flow maldistribution in parallel microchannel heat sink. IEEE Trans Compon Packag Manuf Technol 9:247–261

Acknowledgements

The authors would like to acknowledge PDPM Indian Institute of Information Technology, Design and Manufacturing (IIITDM), Jabalpur (MP), to provide financial support and the computational facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The Author(s) declare(s) that there are no potential conflicts of interest regarding the research, authorship, and publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lodhi, M.S., Sheorey, T. & Dutta, G. Mitigation of fluid flow and thermal non-uniformity of nanofluids in microfluidic systems applied to processor chip: a comparative analysis of mass versus thermal mitigation. Microsyst Technol 27, 1877–1893 (2021). https://doi.org/10.1007/s00542-020-05112-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-020-05112-0