Abstract

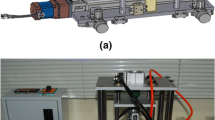

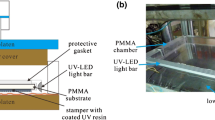

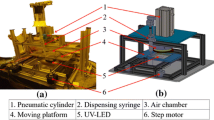

This study proposed a UV-curable micro-imprinting method for the fabrication of microstructure arrays using a self-made UV-sensitive material. Based on the custom-made micro-imprinting device with a UV light source, a series of experiments were conducted for the analysis of the compressive stress and radiation’s influences on the formation of microstructure array. The fabricated microstructures were measured with 3D laser confocal microscope, the result indicates that the proposed micro-imprinting technology with the self-made UV-sensitive material is of high replication precision with relatively low-cost, which could have wide potential application prospect for the fabrication of microstructures in optical-MEMS and microfluidics. The proposed method also has the ability for the rapid massive industrial fabrication of microstructure arrays.

Similar content being viewed by others

References

Al-Shammari RM, Manzo M, Gallo K, Rice JH, Rodriguez BJ (2017) Tunable wettability of ferroelectric lithium niobate surfaces: the role of engineered microstructure and tailored metallic nanostructures. J Phys Chem 121:6643–6649

Bian R et al (2015) Ultralong focal length microlens array fabricated based on SU-8 photoresist. Appl Opt 54:5088–5093

Chen E et al (2018) Flexible/curved backlight module with quantum-dots microstructure array for liquid crystal displays. Opt Express 26:3466–3482

Dupont T, Leclaire P, Panneton R, Umnova O (2018) A microstructure material design for low frequency sound absorption. Appl Acoust 136:86–93

Griss P, Enoksson P, Tolvanen-Laakso HK, Merilainen P, Ollmar S, Stemme G (2001) Micromachined electrodes for biopotential measurements. J Microelectromech Syst 10:10–16

Hobbs DS, MacLeod BD, Sabatino E, Mirov SB, Martyshkin DV (2012). Laser damage resistant anti-reflection microstructures for mid-infrared metal-ion doped ZnSe gain media. In: SPIE laser damage, SPIE. vol. 8530, p. 15

Hou C et al (2010) Maskless fabrication of concave microlens arrays on silica glasses by a femtosecond-laser-enhanced local wet etching method. Opt Express 18(19):20334–20343

Jinyou S, Ding Y, Chen X, Yaopei Z, Hongmiao T, Li X (2017). Method for manufacturing energy harvester comprising piezoelectric polymer microstructure array. ed: Google Patents

Yamamoto Y, Suzuki H, Onishi T, Okino T, Moriwaki T (2007) Precision grinding of microarray lens molding die with 4-axes controlled microwheel. Sci Technol Adv Mater 8:173–176

Yang B, Lee M (2014) Mask-free fabrication of inverted-pyramid texture on single-crystalline Si wafer. Opt Laser Technol 63:120–124

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jianyun, H., Changsong, Z., Fan, Y. et al. UV-curable micro-imprinting method for the fabrication of microstructure arrays. Microsyst Technol 25, 3311–3316 (2019). https://doi.org/10.1007/s00542-018-4219-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-4219-1