Abstract

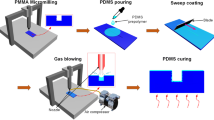

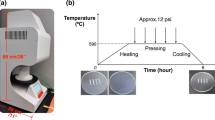

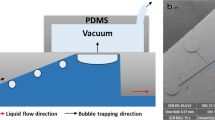

The study of multi-phase fluid flow in microfluidic devices provides an opportunity for researchers to characterize effective factors and mechanisms in microscale. The application of microtechnology in various fields of science and engineering has always raised different technical problems that require further research and developments. This paper aims to address the associated challenges with micromodel studies that employ the chemical (wet) etching method for making glass micromodels. To overcome these challenges, recent advances in chemical etching are modified and combined to decrease the construction time and costs. The general steps in the chemical etching process are masking, etching, and bonding. First, the common masking step [projecting the designed pattern (regular or irregular) on the acid-resistant layer] in this work is simplified by engraving the mirror plates with a CO2 laser. This new technique skips the required facilities for photoresist layer deposition and UV lithography by using direct laser beam machining of pre-coated soda lime glasses (mirror). Moreover, the variety of mirror products and flexible functionality of laser machines make it possible to create larger size models with any desirable flow pattern. Next, the general composition of solution used in the etching step and the operating conditions of thermal bonding step are modified based on recent investigations in literature to enhance the mechanical strength of the micromodel. Finally, the fabricated model with this procedure is applied in a two-phase flow visualization study to examine the practical features under experimental conditions.

Similar content being viewed by others

References

Abgrall P, Gue AM (2007) Lab-on-chip technologies: making a microfluidic network and coupling it into a complete microsystem—a review. J Micromech Microeng 17(5):R15

Chatenever A, Calhoun JC Jr (1952) Visual examinations of fluid behavior in porous media-part i. J Petrol Technol 4(6):149–156

Chen Q, Chen Q, Milanese D, Ferraris M, Fokine M (2007) Direct bonding and imprinting techniques for micro-fluidic devices fabrication in commercial soda-lime glass, Patent no. TO2007A000345

Chen Q, Li G, Jin Q-H, Zhao J-L, Ren Q-S, Xu Y-S (2007b) A rapid and low-cost procedure for fabrication of glass microfluidic devices. J Microelectromech Syst 16(5):1193–1200

Chen Q, Milanese D, Chen Q, Ferraris M, Righini GC (2008) Fabrication and direct bonding of photosensitive multicomponent silicate glasses for lossless planar waveguide splitters. J Non-Cryst Solids 354(12):1230–1234

Chen Q, Chen Q, Milanese D, Ferraris M (2009) Thermal assisted direct bonding between structured glasses for lab-on-chip technology. Microsyst Technol 15(12):1873

Chen Q, Chen Q, Ferraris M (2010) Optimization of thermal assisted direct bonding of soda-lime glasses for lab-on chip application. Microsyst Technol 16(4):527–532

Chuoke RL, van Meurs P, van der Poel C (1959) The instability of slow, immiscible, viscous liquid-liquid displacements in permeable media. Petrol Trans AIME 216:188–194

Deng W (2015) Development of glass-glass fusion bonding recipes for all-glass nanofluidic devices. The Ohio State University, Columbus

Dubey AK, Yadava V (2008) Laser beam machining—a review. Int J Mach Tools Manuf 48(6):609–628

Evstrapov AA (2017) Micro-and nanofluidic systems in devices for biological, medical and environmental research. J Phys Conf Series 917:22002 (IOP Publishing)

Fazal I, Berenschot E, Jansen H, Elwenspoek M (2005) Bond strength tests between silicon wafers and Duran tubes (fusion bonded fluidic interconnects). In: Solid-state sensors, actuators and microsystems, 2005. digest of technical papers. TRANSDUCERS’05. The 13th International Conference on (vol. 1, pp 936–939). IEEE

Hof LA, Abou Ziki J (2017) Micro-hole drilling on glass substrates—a review. Micromachines 8(2):53

Hull CW (1986) Apparatus for production of three-dimensional objects by stereolithography. Google Patents. Retrieved from https://www.google.com/patents/US4575330. Accessed 01 Aug 2017

Iliescu C, Tay EHF (2006) Wet etching of glass for MEMS applications. ROMJIST 9(4):285–310

Iliescu C, Tan KL, Tay FEH, Miao J (2005) Deep wet and dry etching of pyrex glass: a review. In: Proceedings of the ICMAT (Symposium F), Singapore, pp 75–78)

Itano M, Kern FW, Miyashita M, Ohmi T (1993) Particle removal from silicon wafer surface in wet cleaning process. IEEE Trans Semicond Manuf 6(3):258–267

Jewell TE, Thompson K (1994) Ringfield lithography. Google Patents. Retrieved from https://www.google.com/patents/US5315629

Karadimitriou NK, Hassanizadeh SM (2012) A review of micromodels and their use in two-phase flow studies. Vadose Zone J 11(3). https://doi.org/10.2136/vzj2011.0072

Kim HS, Devarenne TP, Han A (2018) Microfluidic systems for microalgal biotechnology: a review. Algal Res 30:149–161

Mattax CC, Kyte JR (1961) Ever see a water flood. Oil Gas J 59(42):115–128

McKellar M, Wardlaw NC (1982) A method of making two-dimensional glass micromodels of pore systems. J Can Petrol Technol 21(4):39–41

Sayah A, Solignac D, Cueni T, Gijs MAM (2000) Development of novel low temperature bonding technologies for microchip chemical analysis applications. Sens Actuators A 84(1):103–108

Sohrabi M, Tehrani DH, Danesh A, Henderson GD (2004) Visualization of oil recovery by water-alternating-gas injection using high-pressure micromodels. SPE J 9(3):290–301

Spierings G (1993) Wet chemical etching of silicate glasses in hydrofluoric acid based solutions. J Mater Sci 28(23):6261–6273

Stjernström M, Roeraade J (1998) Method for fabrication of microfluidic systems in glass. J Micromech Microeng 8(1):33

Unger MA, Chou H-P, Thorsen T, Scherer A, Quake SR (2000) Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 288(5463):113–116

Wegner MW, Christie JM (1983) Chemical etching of deformation sub-structures in quartz. Phys Chem Miner 9(2):67–78

Acknowledgements

The authors would like to thank Chevron Canada, Hibernia Management and Development Company (HMDC), Research and Development Corporation of Newfoundland and Labrador (RDC), Natural Sciences and Engineering Research Council of Canada (NSERC), and the Canadian Foundation for Innovation (CFI) for financial support. We thank our colleagues in the Hibernia EOR Research Group for their technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahmoodi, M., Mahdavi, S., James, L.A. et al. A quick method to fabricate large glass micromodel networks. Microsyst Technol 24, 2419–2427 (2018). https://doi.org/10.1007/s00542-018-3828-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-3828-z