Abstract

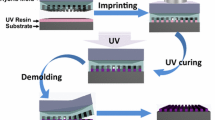

The role of capillary forces with nanoimprint is addressed. As the respective capillaries are the closed cavities of the stamp used for replication, the Laplace pressure together with the pressure of the gas phase inside the cavities dictate the equilibrium pressure in the polymer. Whether the cavities can be successfully filled, depends on the external pressure available from the imprint system, setting the pressure in the polymer, and on the sorption of any gaseous phase. Gas sorption is provided by the imprint polymer itself and may differ with different imprint materials and different imprint situations (imprint temperature, residual layer thickness). With soft stamps or composite stamps also the stamp itself may contribute to the overall gas sorption. Situations typical of different imprint techniques (thermal nanoimprint, UV-assisted nanoimprint, capillary force lithography) as well as of moulding during stamp replication are discussed in view of capillary effects. The discussion is illustrated by simple analytical estimations.

Similar content being viewed by others

References

Bogdanski N, Moellenbeck S, Scheer H-C (2008) Contact angles in a thermal imprint process. J Vac Sci Technol B26:2416–2420

Choi S-J, Yoo PJ, Baek SJ, Kim TW, Lee HH (2004) An ultraviolet-curable mold for sub-100-nm lithography. J Am Chem Soc 126:7744–7745

Choi S-J, Kim HN, Bae WG, Suh K-Y (2011) Modulus- and surface energy-tunable ultraviolet-curable polyurethane-acrylate: properties and applications. J Mat Chem. doi:10.1039/c1jm12201k

Chou SY, Krauss PR, Renstrom PR (1996) Nanoimprint lithography. J Vac Sci Technol B 14:4129–4133

Crank J (1975) The mathematics of diffusion. Clarendon, Oxford

Delamarche E, Schmid H, Michel B, Biebuyck H (1997) Stability of molded polydimethylsiloxane microstructures. Adv Mater 9:741–746

Finn A, Lu B, Kirchner R, Thrun X, Richter K, Fischer W-J (2013) High aspect ratio pattern collapse of polymeric UV-nano-imprint mold due to cleaning. Microelectron Eng 110:112–118

Good RJ (1992) Contact angle, wetting and adhesion: a critical review. J Adhes Sci Technol 6:1269–1302

Guo J (2004) Recent progress in nanoimprint technology and its applications. J Phys D Appl Phys 37:R123–R141

Hess HF, Pettibone D, Adler D, Bertsche K, Nordquist KJ, Mancini DP, Dauksher J, Resnick DJ (2004) Inspection of templates for imprint lithography. J Vac Sci Technol B22:3300–3305

Hirai Y, Harada S, Isaka S, Kobayashi M, Tanaka Y (2002) Nano-imprint lithography using replicated mold by Ni electroforming. Jpn J Appl Phys 41:4186–4189

Hiroshima H, Komuro M (2007) UV-nanoimprint with the assistance of gas condensation at atmospheric environmental pressure. J Vac Sci Technol B 25:2333–2336

Hui CY, Jagota A, Lin YY, Kramer EJ (2002) Constraints on microcontact printing imposed by stamp deformation. Langmuir 18:1394–1407

Israelachvili JN (2011) Intermoleular and surface forces. Academic Press Elsevier, Amsterdam

Kim YS, Suh KY, Lee HH (2001) Fabrication of three-dimensional microstructures by soft molding. Appl Phys Lett 79:2285–2287

Kim K-D, Altun A, Choi D-G, Jeong J-H (2008) A 4-in-based single-step UV-NIL tool using a low vacuum environment and additional air pressure. Microelectr Eng 85:2304–2308

Landau LD, Lifschitz EM (2007) Hydrodynamik, vol VI. Harry Deutsch, Frankfurt

Merkel TC, Bondar VI, Nangai K, Freeman BD, Pinnau I (2000) Gas sorption, diffusion and permeation in poly(dimethylsiloxane). J Polym Sci B 38:415–434

Möllenbeck S, Bogdanski N, Wissen M, Scheer H-C, Zajadacz J, Zimmer K (2007) Multiple replication of three-dimensional structures with undercuts. J Vac Sci Technol B25:247–251

Mühlberger M, Bergmair I, Klukowska A, Kolander A, Leichtfried H, Platzgummer E, Loeschner H, Ebm C, Grützner G, Schöftner R (2009) UV-NIL with working stamps made from Ormostamp. Microelectron Eng 86:691–693

Odom TW, Love JC, Wolfe DB, Paul KE, Whitesides G (2002) Improved pattern transfer in soft lithography using composite stamps. Langmuir 18:5314–5320

Park S, Schift H, Solak HH, Gobrecht J (2004) Stamps for nanoimprint lithography by extreme ultraviolet interference lithography. J Vac Sci Technol B 22:3246–3250

Roos N, Wissen M, Glinsner T, Scheer H-C (2003) Impact of vacuum environment on the hot embosing process. SPIE Proc 5037:211–218

Roth CB, Dutcher JR (2005) Glass transition and chain mobility in thin polymer films. J Electroanal Chem 584:13–22

Scheer H-C, Schulz H (2001) A contribution to the flow behaviour of thin polymer films during hot embossing lithography. Microelectron Eng 56:311–332

Scheer H-C, Bogdanski N, Wissen M (2005) Issues in nanoimprint processes: the imprint pressure. Jpn J Appl Phys 44:5609–5616

Scheer H-C, Häfner W, Fiedler A, Möllenbeck S, Bogdanski N (2008) Quality assessment of antisticking layers for thermal nanoimprint. J Vac Sci Technol B26:2380–2384

Scheer H-C, Bogdanski N, Möllenbeck S, Mayer A (2009) Recovery prevention via pressure control in thermal nanoimprint lithography. J Vac Sci Technol B27:2882–2887

Scheer H-C, Mayer A, Dhima K, Wang S, Steinberg C (2013) Challenges with high aspect ratio nanoimprint. Microsyst Technol. doi:10.1007/s00542-013-1968-8

Schift H (2008) Nanoimprint lithography: an old story in modern times? A review. J Vac Sci Technol B26:458–480

Schift H, Saxer S, Park S, Padeste C, Pieles U, Gobrecht J (2005) Controlled co-evaporation of silanes for nanoimprint stamps. Nanotechnology 16:S171–S175

Schift H, Spreu C, Saidani M, Bednarzik M, Gobrecht J, Klukowska A, Reuther F, Gruetzner G, Solak H (2009) Transparent hybrid polymer stamp copies with sub-50-nm resolution for thermal and UV nanoimprint. J Vac Sci Technol B27:2846–2849

Schmid H, Michel B (2000) Siloxane polymers for high-resolution, high-accuracy soft lithography. Macromolecules 33:3042–3049

Sperling LH (2001) Introduction to physical polymer science. Wiley, Hoboken

Suh KY, Lee HH (2002a) Capillary force lithography: large-area patterning, self-organization and anisotropic dewetting. Adv Funct Mater 12:405–413

Suh KY, Lee HH (2002b) Self-organized polymeric microstructures. Adv Mater 14:346–351

Suh KY, Chu S, Lee HH (2004) W-shaped meniscus from thin polymer films in microchannels. J Micromech Microeng 14:1185–1189

Taga A, Yasuda M, Kawata H, Hirai Y (2010) Impact of molecular size on resist filling process in nanoimprint lithography: molecular dynamics study. J Vac Sci Technol B 28:C6M68–C6M71

Tsunozaki K, Kawaguchi Y (2009) Preparation methods and characteristics of fluorinated polymers for mold replication. Microelectron Eng 86:694–696

van Delft F, van de Laar R, Verschuuren M, Platzgummer E, Loeschner H (2010) Template masters for substrate conformal imprint lithography generated by charged particle nanopatterning techniques. Proc SPIE 7545:75450S1–75450S12

van Krevelen DW (1990) Properties of polymers. Elsevier, Amsterdam

Vratzov B, Fuchs A, Lemme M, Henschel W, Kurz H (2003) Large scale ultraviolet-based nanoimprint lithography. J Vac Sci Technol B 21:2760–2764

Xu F, Stacey N, Watts M, Truskett V, McMackin I, Choi J, Schumaker P, Thompson E, Babbs D, Sreenivasan SV, Willson G, Schumaker N (2004) Development of imprint materials for the step and flash imprint lithography process. Proc SPIE 5374:232–241

Yoo PJ, Choi S-J, Kim JH, Suh D, Baek SJ, Kim TW, Lee HH (2004) Unconventional patterning with a modulus-tunable mold: from imprinting to microcontact printing. Chem Mater 16:5000–5005

Young T (1805) An essay on the cohesion of fluids. Philos Trans R Soc Lond 95:65–87

Zhao Y, Berenschot E, de Broer M, Jansen H, Tas N, Huskens J, Elwenspoek M (2008) Fabrication of silicon oxide stamp for nanoimprint lithography by edge lithography reinforced with silicon nitride. J Micromech Microeng 18:064013 (6 pp)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scheer, HC., Papenheim, M., Dhima, K. et al. Aspects of cavity filling with nano imprint. Microsyst Technol 21, 1595–1605 (2015). https://doi.org/10.1007/s00542-014-2376-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2376-4