Abstract

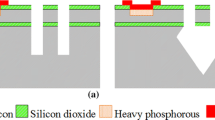

Refilled electrical isolation trenches are created for monolithic integration of high-aspect-ratio MEMS devices and circuitry in the same substrate. The refilled trenches electrically isolate the mechanical elements from each other while maintaining robust mechanical connection. It is found that silicon residue at the terminal of trench and metal stringers along indentation on trench surface are the two main fabrication issues, which often cause short circuit problem for MEMS devices with refilled isolation trenches. In this paper, fabrication challenges and solutions are presented for practical implementation of refilled electrical isolation trenches for high-aspect-ratio SOI MEMS devices. Test structures are designed to inline validate reliability of key steps in the process. Finally, an in-plane capacitive accelerometer is successfully fabricated on 50 μm SOI wafer with the improved fabrication process.

Similar content being viewed by others

References

Agarwal R, Xie J, Lau K, Sampatha PK, Ranganathan N, Singh J, Tsai M (2011) Challenges and solutions for fabricating isolation trenches for high aspect ratio sensors. Adv Mater Res 254:1–4

Arx M, Paul O, Baltes H (2000) Process-dependent thin-film thermal conductivities for thermal CMOS MEMS. J Microelectromech Syst 9:136–145

Brosnihan TJ, Bustillo JM, Pisano AP, Howe RT (1997) Embedded interconnect and electrical isolation for high-aspect-ratio SOI inertial instruments. Digest of technical papers of 9th international conference on solid state sensors. Actuators and Microsystems (TRANSDUCERS), Chicago, pp 637–640

Chang C, Abe T, Esashi M (2004) Trench filling characteristics of low stress TEOS/ozone oxide deposited by PECVD and SACVD. Microsyst Technol 10:97–102

Chen T, Kelly T, Collins D, Bain D, Berthold B, Brosnihan T, Denison T, Kuang J, Kane M, Weigold J (2005) The next generation integrated MEMS and CMOS process on SOI wafers for overdamped accelerometer. Digest of technical papers of 13th international conference on solid state sensors. Actuators and Microsystems (TRANSDUCERS), Seoul, pp 1122–1125

Hsu CP, Yip MC, Fang WL (2009) Implementation of a gap-closing differential capacitive sensing Z-axis accelerometer on an SOI wafer. J Micromech Microeng 19:075006

Kotb H, Isoird K, Morancho F, Theolier L, Conto TD (2009) Filling of very deep, wide trenches by BenzoCycloButene polymer. Microsyst Technol 15:1395–1400

Li X, Li G, Ren S, Qiao D (2013) Void-free trench isolation based on a new trench design. Microsyst Technol 19:757–761

Mu X, Zhou G, Yu H, Tsai M, Neo W, Kumar AS, Char F (2013) Electrostatic double T-shaped spring mechanism based MEMS device for circumferential scanning. IEEE J Microelectromech Syst 22:1147–1158

Sarajlic E, Berenschot E, Krijnen G, Elwenspoe M (2003) Versatile trench isolation technology for the fabrication of microactuators. Microelectron Eng 67:430–437

Schenk H, Durr P, Haase T, Kunze D, Sobe U, Lakner H, Kuck H (2000) Large deflection micromechanical scanning mirrors for linear scans and pattern generation. IEEE J Sel Top Quantum Electron 6:715–722

Trusov AA, Prikhodko IP, Zotov SA, Shkel AM (2011) Low-dissipation silicon tuning fork gyroscopes for rate and whole angle measurements. IEEE Sens J 11:2763–2770

Xie J, Agarwal R, Liu Y, Tsai M, Ranganathan N, Singh J (2011a) Compact electrode design for an in-plane accelerometer on SOI with refilled isolation trench. J Micromech Microeng 21:095005

Xie J, Lee C, Wang MF, Tsai M (2011b) Microstructures for characterization of Seebeck coefficient of doped polysilicon films. Microsyst Technol 17:77–83

Xu J, Tsai M (2012) A process-induced-frequency-drift resilient 32 kHz MEMS resonator. J Micromech Microeng 22:105029

Zaman MF, Sharma A, Hao Z, Ayazi F (2008) A mode-matched silicon-yaw tuning-fork gyroscope with subdegree-per-hour allan deviation bias instability. IEEE J Microelectromech Syst 17:1526–1536

Zhu Y, Yan G, Fan J, Zhou J, Liu X, Li Z, Wang Y (2005) Fabrication of keyhole-free ultra-deep high-aspect-ratio isolation trench and its applications. J Micromech Microeng 15:636–642

Acknowledgments

This work is supported by the “Fundamental Research Funds for the Central Universities” and the “Science Fund for Creative Research Groups of National Natural Science Foundation of China (No.: 51221004)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, J. Fabrication challenges and test structures for high-aspect-ratio SOI MEMS devices with refilled electrical isolation trenches. Microsyst Technol 21, 1719–1727 (2015). https://doi.org/10.1007/s00542-014-2357-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2357-7