Abstract

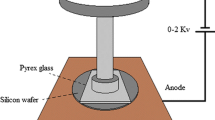

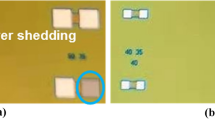

The 680 µm thick wafer is back-etched, leaving the thin film 3C-SiC as the flexible diaphragm to detect pressure. The etching processes are performed with three different KOH concentrations (35, 45 and 55 %), without and with 10 % IPA surfactant and the etching temperatures of 50 and 80 °C. Graphs are plotted on the effect of the etch rate and etch depth against these three parameters. In addition, the surface roughnesses of the diaphragms at these conditions are measured, photographed and analyzed. The results show that the back-etching of a 3C-SiC-on-Si wafer is fastest at higher temperature and KOH concentration and without IPA surfactant, but at the price of higher surface roughness. The addition of 10 % IPA reduces the surface roughness significantly. We also notice the increasing presence of micro-pipes at higher KOH concentration and etching temperature. The experiments are performed using bulge test method that induces the effects of dimensional layout diaphragm of 2,000 and 2,500 µm, the curve shows a good resemblance each other at pressure of 5.0 MPa. The maximum difference linearity of 2,000 and 2,500 µm is 98.7 and 97.1 %, respectively. It is revealed that the small layout dimensional can sustain the diaphragm at high pressure compare with large dimensional layout of 3,000 and 3,500 µm with the linearity is about 73.2 and 62.6 %, respectively.

Similar content being viewed by others

References

Alexander AL, Servey YD, Pavel AI, Mikhail EL (2012) Defect revelation and evaluation of 4H silicon carbide by optimized molten KOH etching method. Mater Sci Forum 740–742:243–246

Chung-Lin W, Ming-Chuen Y, Weileun F (2009) Improvement of specimen preparation process for bulge test using the combination of XeF2 and deep reactive ion etching. Jpn J Appl Phys 48:1–6

Hamid NA, Majlis BY, Yunas J, Noor MM (2012) The effect of isopropyl alcohol on anisotropic etched silicon for the fabrication of microheater chamber. 10th IEEE international conference on semiconductor electronics (ICSE), Malaysia

Jiang L, Cheung R (2009) A review of silicon development in MEMS applications. Int J Comput Mater Sci Eng 2:225–240

Johari J, Yunas J, Majlis BY (2009) Piezoelectric micropump for drug delivery system fabricated using two optical masks. Adv Mater Res 74:279–282

Mahajan S, Rokade MV, Ali ST, Rao KS, Munirathan NR, Prakash TL, Amalnerker DP (2013) Investigation of micropipe and defects in molten KOH etching of 6H n-silicon carbide (SiC) single crystal. Mater Lett 101:72–75

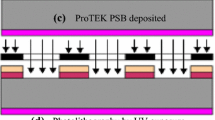

Marsi N, Majlis BY, Hamzah AA, Mohd-Yasin F (2014) Characterization of ProTEX PSB thin film as a photosensitive layer for MEMS capacitive pressure sensor diaphragm based on SiC-on-Si wafer. Key Eng Mater 594–595:1083–1086

Masakazu K, Noboru O, Jun T, Hirokatsu Y, Masatoshi K (1999) Mechanism of molten KOH etching of SiC single crystal: comparative study with thermal oxidation. Jpn J Appl Phys 38:4661–4665

Masashi K, Masaya I, Eisuke A, Perumalsamy R (2003) Electrochemical etching of 6H-SiC using aqueous KOH solution with low surface roughness. Jpn J Appl Phys 42:4233

Oliver P, Joao G (2008). Thin film characterization using the Bulge Test. Reliability of MEMS: testing of materials and devices

Rosminazuin AR, Badariah B, Burhanuddin YM, Gandi S (2013) ProTEK PSB coating as an alternative polymeric mask for KOH bulk etching of silicon. Microsyst Technol 19(6):905–914

Sunkari S, Das H, Carl H, Yaroslay K, Jeff C (2009) Surface morphology improvement and repeatable doping characterization of 4H-SiC epitaxy grown in 4° off-axis 4H-SiC wafers. Mater Sci Forum 615–617:423–426

Syvajarvi M, Yakimova R, Janzen E (2000) Anistropic etching of SiC. J Electrochem Soc 153(4):319–323

Van-Drop DH, Weyher JL, Kelly JJ (2007) Anodic etching of SiC alkaline solutions. J Electroanal Chem 599(2):260–266

Yong-Zhao Y, Yukari I, Koji S, Yishihiro S, Katsunori D, Hiroshi S, Takeshi B (2013) Dislocation revelation from (0001) carbon-face of 4H-SiC by using vaporized KOH at high temperature. Appl Phys Express 5:075601

Zhuang D, Edgar JH (2005) Wet etching GaN, AIN and SiC: a review. Mater Sci Eng, pp 1–46

Acknowledgments

The authors would like to thank the Institute Microengineering and Nanoelectonics (IMEN) of Universiti Kebangsaan Malaysia (UKM), Sciencefund MOSTI for supporting this project under grant 03-01-02-SF0849 and Queensland Micro- and Nanotechnology Centre (QMNC) of Griffith University for providing the resources and facilities in part at the Queensland node of the Australian National Fabrication Facility, a company established under the National Collaborative Research Infrastructure Strategy to provide nano and microfabrication facilities for Australia’s researchers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marsi, N., Majlis, B.Y., Mohd-Yasin, F. et al. The fabrication of back etching 3C-SiC-on-Si diaphragm employing KOH + IPA in MEMS capacitive pressure sensor. Microsyst Technol 21, 1651–1661 (2015). https://doi.org/10.1007/s00542-014-2267-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2267-8