Abstract

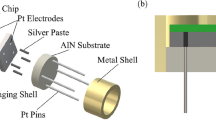

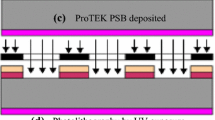

In the process of piezo-resistive pressure sensor packaging, a simple thermo-compression bonding setup has been fabricated to achieve the wire bonding interconnection of a silicon chip with printed circuit board. An annealed gold wire is joined onto a pad surface with a needle-like chisel under a force of 0.5–1.5 N/point. The temperature of the substrate was maintained in the range of 150–200°C and the temperature of the chisel was fixed at around 150°C during wire bonding operation. The tensile strength of the wire bonding was measured with a bonding tester by the destructive-pulling experiment and was found to be at the average of 132 mN/mm2. The microstructure of the bonding point was examined by scanning electron microscopy. The interface of the thermo-compression boning was shown to possess an acceptable level of reliability for a micro-electromechanical system (MEMS)-based device. The results showed that this setup can be easily operated for fabrication and is suitable for fabricating not only low-cost pressure sensors, but also other MEMS devices.

Similar content being viewed by others

References

Bao MH (2000) Micro mechanical transducers-pressure sensors. Elsevier, Amsterdam

Burla RK, Chen L, Zorman CA, Mehregany M (2009) Development of nickel wire bonding for high-temperature packaging of SiC devices. IEEE Trans Adv Pack 32:64

Crescini D, Ferrari V, Vajna ZK, Marioli D, Taroni A, Borgese A, Marinelli M, Milani E, Paoletti A, Tucciarone A (2003) Design and development of a piezoresistive pressure sensor on micromachined silicon for high-temperature applications and of a signal-conditioning electronic circuit. Microsyst Technol 9(6–7):431–435

Fahrner WR, Job R, Werner M (2001) Sensors and smart electronics in harsh environment applications. Microsyst Technol 7(4):138–144

Fraga MA, Massi M, Furlan H, Oliveira IC, Rasia LA, Mateus CFR (2011) Preliminary evaluation of the influence of the temperature on the performance of a piezoresistive pressure sensor based on a-SiC film. Microsyst Technol 17(3):477–480

Fragiacomo G, Ansbaek T, Pedersen T, Hansen O, Thomsen EV (2010) Analysis of small deflection touch mode behavior in capacitive pressure sensors. Sens Actuators A 161(1–2):114–119

Harmon GG (2010) Wire bonding in microelectronics. McGraw-Hill, New York

Kim Y, Kim H, Yoo HJ (2010) Electrical characterization of screen-printed circuits on the fabric. IEEE Trans Adv Pack 33(1):196

Lee WJ (2002) Mechanical properties of electroless Ni/Au wire bonded to an Al pad with the effects of chemical activation. Thin Solid Films 408(1–2):176–182

Lellouchi D, Dhennin J, Lafontan X, Veyrie D, Neal JFL, Pressecq F (2010) A new method for the hermeticity testing of wafer-level packaging. J Micromech Microeng 20(2):025031

Mohammadi AR, Bennington CPJ, Chiao M (2011) A hybrid capacitive pressure and temperature sensor fabricated by adhesive bonding technique for harsh environment of kraft pulp digesters. Microsyst Technol 17(1):149–160

Orthner MP, Buetefisch S, Magda J, Rieth LW, Solzbacher F (2010) Development, fabrication, and characterization of hydrogel based piezoresistive pressure sensors with perforated diaphragms. Sens Actuators A 161(1–2):29–38

Prasad SK (2004) Advanced wire bond interconnection technology. Kluwer Academic Publishers, Massachusetts

Unami N, Sakuma K, Mizuno J, Shoji S (2010) Effects of excimer irradiation treatment on thermocompression Au–Au Bonding. Japanese J Appl Phys 49(6):06GN12

Weinberg K, Bohme T (2009) Condensation and growth of kirkendall voids in intermetallic compounds. IEEE Trans Compon Pack Technol 32(3):684–692

Xie GX, Luo JB, Liu SH, Guo D, Zhang CH (2010) Bubble generation in a nanoconfined liquid film between dielectric-coated electrodes under alternating current electric fields. Appl Phys Lett 96:223104

Acknowledgments

This work was supported by the National Science Foundation of China (No. 51175238), the Starting Foundation of Jiangsu University Advanced Talent (No. 09JDG045), and Chinese Post Doctor Special science Foundation (No. 201003557) and Industrial Supporting Plan of Zhengjiang City (No. GY20100010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Yang, X., Zhang, Y. et al. A simple thermo-compression bonding setup for wire bonding interconnection in pressure sensor silicon chip packaging. Microsyst Technol 17, 1629 (2011). https://doi.org/10.1007/s00542-011-1345-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00542-011-1345-4