Abstract

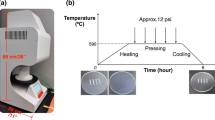

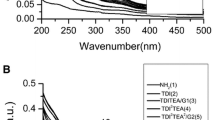

A thermal assisted direct bonding (TADB) technique between structured glasses is proposed for micro-fluidic device fabrication. The bonded glass pairs were characterized by optical microscopy, scanning electron microscopy (SEM), apparent shear strength tests and Vickers hardness measurements across the bonded interface. The optimisation of TADB parameters on flat glasses and on structured glasses was analysed. This technique is user-friendly and low cost, and can be considered for mass production of glass-based micro-fluidic devices.

Similar content being viewed by others

References

Chen Q (2008) Study of thermal assisted direct bonding techniques for optical waveguide and micro-fluidic device fabrication. PhD thesis, Politecnico di Torino, Italy

Chen Q, Chen Q, Milanese D, Ferraris M, Fokine M (2007) Direct bonding and imprinting techniques for micro-fluidic devices fabrication in commercial soda-lime glass, Patent N. TO2007A000345

Chen Q, Milanese D, Chen Q, Ferraris M et al (2008) Fabrication and direct bonding of photosensitive multi-component silicate glasses for lossless planar waveguide splitter. J Non-Cryst Solids 354:1230–1234. doi:10.1016/j.jnoncrysol.2006.11.045

Chen Q, Chen Q, Milanese D, Ferraris M (2009) Micro-structures fabrication on glasses for micro-fluidics by imprinting technique. J Microsyst technol 15:1067–1071

Czaplewski DA, Kameoka J, Mathers R, Coates et al (2003) Nanofluidic channels with elliptical cross sections formed using a nonlithographic process. Appl Phys Lett 83:4836–4838

Gui C, Albers H, Gardeniers JGE (1997) Fusion bonding of rough surfaces with polishing technique for silicon. J Microsyst Technol 3:122–128

Lai SI, Lin HY, Hu CT (2004) Effect of surface treatment on wafer direct bonding process. Mater Chem Phys 83:265–272

Lapides AA, Botvinkin MI, Zhabotinskii ME (2004) New method to determine the surface tension and viscosity of glass. J Chem Mater Sci 38:276–278

Lee DJ, Byeong Kwon Ju, Jang Jin (1999) Effects of a hydrophilic surface in anodic bonding. J Micromech Microeng 9:313–318

Mijatovic D et al (2005) The promise of nanotechnology for separation devices–from a top-down approach to nature-inspired separation devices. Lab Chip 5:492–500

Tong Q-Y, Gosele UM (1999) Wafer bonding and layer splitting for Microsystems. J Adv Mater 17:1409–1425

Werdich AA, Lima EA, Ivanov B, Ges I et al (2004) Microfluidic device to confine a single cardiac myocyte in a sub-nanoliter volume on a planar microelectrode array for cellular activity detection. Lab Chip 4:357–362

Acknowledgments

This work has been partially funded by AsiaLink EU (ASIA-LINK-CN/ASIA-LINK/004 (81206)) project. M.Salvo is kindly acknowledged for mechanical tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Q., Chen, Q., Milanese, D. et al. Thermal assisted direct bonding between structured glasses for lab-on-chip technology. Microsyst Technol 15, 1873–1877 (2009). https://doi.org/10.1007/s00542-009-0911-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-009-0911-5