Abstract

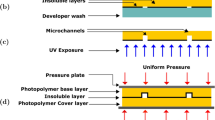

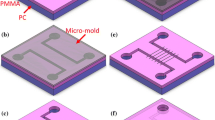

We report on the development of process capabilities for a polymer-based, multi-layer microelectrofluidic platform, namely: the hot embossing process, metallization on polymer and polymer bonding. Hot embossing experiments were conducted to look at the effects of load applied, embossing temperature and embossing time on the fidelity of line arrays representing micro channels. The results revealed that the embossing temperature was a more sensitive parameter than the others due to its large effect on the polymer material’s viscoelastic properties. Dynamic mechanical analysis (DMA) conducted on polymethyl methacrylate (PMMA) revealed a steep glass transition over a 20°C range, with the material losing more than 95% of its storage modulus. The data explained the hot embossing results, which showed large changes in the embossed channel dimensions when the temperature was within the glass transition range. It was demonstrated that the micro-printing of silver epoxy was a possible low-cost technique in the mass production of disposable lab chips. An interconnecting, three-dimensional network of electrical traces was fabricated, as well as a microfluidic device with interconnecting, three-dimensional network of micro channels.

Similar content being viewed by others

References

Bilenerg B, Nielsen T, Clausen B, Kristensen A (2004) PMMA to Su-8 bonding for polymer based lab-on-a-chip systems with integrated optics. J Micro Mech Micro Eng 14:814–818

Bohl B, Steger R, Zengerle R, Koltay P (2005) Multi-layer Su-8 lift-off technology for microfluidic devices. J Micro Mech Micro Eng 15:1125–1130

Chou SY, Krauss PR (1997) Imprint lithography with sub-10 nm feature size and high throughput. Micro Electron Eng 35:237–240

Hamrock BJ (1994) Fundamentals of fluid film lubrication. McGraw-Hill Inc., NJ

Heyderman LJ, Schift H, David C, Gobrecht J, Schweizer T (2000) Flow behaviour of thin polymer films used for hot embossing lithography. Micro Electron Eng 54:229–245

Lichtenberg J, De Rooij NF, Verpoorte E (2002) A microchip electrophoresis system with integrated in-plane electrodes for contactless conductivity detection. Electrophoresis 23:3769–3780

Rowland HD, King WP (2004) Polymer deformation and filling modes during microembossing. J Micro Mech Micro Eng 14:1625–1632

Scheer HC, Schulz H (2001) A contribution to the flow behaviour of thin polymer films during hot embossing lithography. Micro Electron Eng 56:311–332

Wu Z, Xanthopoulos N, Reymond F, Rossier JS, Girault HH (2002) Polymer microchips bonded by O2-plasma activation. Electrophoresis 23:782–790

Acknowledgment

This research is funded by the Agency for Science, Technology and Research (A*STAR), Singapore.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ng, S.H., Wang, Z.F., Tjeung, R.T. et al. Development of a multi-layer microelectrofluidic platform. Microsyst Technol 13, 1509–1515 (2007). https://doi.org/10.1007/s00542-006-0341-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-006-0341-6