Abstract

It is very tiresome for a practiser to detect the best feasible sizing design of structural members including reinforced concrete columns that is a highly nonlinear and complicated structural engineering optimization problem. This is due to such a design is practically conducted via conventional trial-and-error computing methods in which resistance to external loads, cost efficiency, and aesthetic factors, etc. have to be considered. This study focuses on minimizing the design cost of primarily proposed reinforced concrete column design problem via three overnew swarm-based optimizers such as Coati Optimization Algorithm, Fox Optimizer and Pelican Optimization Algorithm (POA) that are firstly utilized for this purpose. In this regard, the type of steel rebar distribution, the characteristic strength of the concrete, the height and width of the column section, and the number and diameter of the rebars are treated as discrete design variables of the newly proposed complex reinforced concrete column design cost optimization problem. In solution, the design requirements specified in practice code provisions should also be met. Here, Turkish Building Earthquake Code 2018 specifications are considered as practice structural design constraints. Consequently, the algorithmic performances of three overnew swarm-based metaheuristic optimization algorithms are compared and evaluated in detail. Amongst them, the POA shows most fruitful algorithmic design solution performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In a reinforced concrete structure, columns transfer the load from the upper column and beams to a lower column and/or foundation [1]. In this context, it can be said that columns are the most crucial structural members in a reinforced concrete structure. On another note, strength to exterior loads, cost-efficiency and aesthetic are respectively taken into consideration as essential factors in the design of engineering structures [2]. It is practically impossible for a designer to use traditional manual-type trial and error calculations to determine the best design while accounting for abovementioned essential factors [3]. Additionally, the reinforced concrete designers should decide characteristic strength of the concrete, the height and width of the column section before the computation of design loads. Then, the type of rebar distribution should be determined, and the required area of steel rebars should also be calculated. Eventually, the number and diameter of the rebars are chosen from a ready list considering magnitude of required area of steel rebars [4]. Besides, this design has to comply with the requirements of practice code provisions of reinforced concrete design. Moreover, all design parameters should be selected from discrete sets to attain a real practical design [5]. Thus, optimum design of the reinforced concrete column is laboriousness for designers. However, it is possible to accurately carry out this entire hellacious design process with swarm-based optimization algorithms instead of time consuming trial and error method [6].

The process of finding the best possible solution to a design problem under specific constraints is recognized as optimization [7]. Engineering design problems are covered in this definition [8]. Thus, optimization has usage in many engineering disciplines such as geotechnics [9], transportation [10,11,12], wind turbine airfoil geometry and automotive magnetological brake designs [13], antenna design [14, 15], and so forth. It is worthy to mentioned that while designing, engineers have to consider safety, economy, and aesthetics into account. Economic goals are often the main focus of engineering design optimization [16, 17]. In this context, structural safety, practicability, and serviceability are principal requirements linked to practice structural design code provisions in structural design optimization problems.

The metaheuristic approaches are particularly remarkable in the field of optimization [18]. The metaheuristic optimization techniques have recently been created as innovative alternatives for existing mathematical based deterministic conventional optimization techniques for solving complicated design optimization problems [19]. The metaheuristics involve randomization, whereby randomly produced coefficients are included into the formulations of algorithm phases. This means that there is no guarantee to attain global optimum outcomes via metaheuristics. In addition, there are no complicated gradient-based computations in the metaheuristic techniques [20]. Hence, the metaheuristics can be applied to more complicated design optimization problems more effectively. As overnew nature-inspired metaheuristic algorithms, Coati Optimization Algorithm (COA) [21], Fox Optimizer (FOX) [22] and Pelican Optimization Algorithm (POA) [23] are freshly introduced in 2023. These techniques are developed by inspiring natural hunting and escaping phenomenon of the coatis, foxes and pelicans, respectively. There are limited studies including the usage of COA [24, 25], FOX [26, 27] and POA [28, 29] on the optimization of problems in the literature. However, there have not been encountered with any study which contains the implementation of COA, FOX and POA techniques on complex and nonlinear engineering design problems such as structural design cost optimization, so far. The reason COA, FOX and POA techniques are chosen as the optimizer tools of this study is based on a previous study of the authors where the algorithmic performances of COA, FOX and POA was tested on Multi-plane Disc Clutch Brake Design, which is a discrete complex engineering design problem. Thereby, as a preparatory study, their success on engineering design problems with discrete variables has been demonstrated [30].

There are previous studies about optimum design of standard reinforced concrete columns in literature as follows; Medeiros and Kripka studied on optimum design of reinforced concrete columns considering monetary and environmental costs in 2014. They found that higher strength concrete leads to better designs [31]. Bekdaş and Niğdeli investigated minimum-costed design of reinforced concrete columns utilizing education-based metaheuristic algorithms in 2016. They claimed that Teaching–Learning-Based Optimization is appropriate to attain optimal design of reinforced concrete columns [32]. Olivares and Tomas optimized reinforced concrete rectangular sections under compression and biaxial bending by using biologically-inspired metaheuristic optimization algorithms in 2017 [33]. Singh et al. [34] optimally designed a reinforced concrete column subjected to different types of axial loads and uniaxial moments using Genetic Algorithms in 2022. Niğdeli et al. [3] proposed a hybrid method that combines Harmony Search Algorithm as a metaheuristic method and multi-layer perceptions for design of reinforced concrete columns in 2023. Tunca and Çarbaş examined sustainable and cost-efficient design of reinforced concrete columns considering slenderness and eccentricity in 2024 [1]. Although all these mentioned studies included design of reinforced concrete columns, in none of them the type of steel rebar distribution on the reinforced concrete column sections is not considered as a design variable. Besides, in some of these studies, the material class of concrete was not considered as a design variable, but it was included in the design process as a constant value.

Eventually, it is primitively aimed to evaluate the algorithmic performances of Coati Optimization Algorithm (COA), Fox Optimizer (FOX) and Pelican Optimization Algorithm (POA) on design cost optimization of reinforced concrete column problems. It is important to underline here that the proposed discrete reinforced concrete design optimization problem is firstly and originally generated in this study. Hence, fundamental novelties and punchline of this study are that those three-novel swarm-based nature-inspired metaheuristic algorithms are primely utilized on a reinforced concrete column design cost optimization problem by considering the type of steel rebar distribution and the material class of concrete as design variables. The load bearing capacities of the reinforced concrete columns under 4 different design load cases are accomplished from simple formulas suggested by Cakiroglu and Ozer [35] utilized to slightly decrease calculation complexity. In the structural design cost optimization of a reinforced concrete column design problem, the type of rebar distribution, the characteristic strength of the concrete, the height and width of the column section, and the number and diameter are considered as discrete design variables. Furthermore, the reinforced concrete column design requirements of Turkish Building Earthquake Code (TBEC) [36] are considered as practical design constraints. Consequently, amongst the abovementioned three overnew swarm-based optimization algorithms, the POA has accomplished most fruitful algorithmic performance in discrete design cost optimization of a reinforced concrete column design problem which is classified as highly nonlinear and complicated structural engineering design problem.

The outline of the study can be mainly summarized as follows;

-

In the first Introduction section, the necessity of the proposed reinforced concrete columns design cost optimization and importance of this study are explained.

-

In the second Formulations of Reinforced Concrete Column Design Problem section, the design variables, formulation of the objective function, and design constraints of the pioneering proposed reinforced concrete column design problem are presented.

-

In the third Swarm-Based Metaheuristic Optimization Algorithms section, the utilized three-novel swarm-based nature-inspired metaheuristic algorithms are described.

-

The description of the considered optimization problem and the attained results are explained in the fourth Descriptions and Results section.

-

The general discussions of attained designs are given in fifth Discussions section.

-

Finally, conclusions of the conducted study are represented in sixth Concluding Remarks section.

2 Formulations of reinforced concrete column design problem

Before starting the necessary structural calculations, a reinforced concrete designer should estimate the characteristic strength of the concrete, the width and height of the column section under considered design forces [1]. Moreover, the design engineer should decide on the configuration of the steel rebar distribution in the cross section of the reinforced concrete column [35]. After all these choices/estimations, the required steel rebar area is calculated. Then, the designer should select the diameters of steel rebar from an available list to attain practicable structural design. The design procedure roughly mentioned here shows that the design variables of reinforced concrete column design should be taken as discrete [34]. Moreover, the attained final design should meet the requirements the practice code provisions, and the design should also be cost efficient. The cost-efficient optimal reinforced concrete design is directly related to the unit weight of the structural member [32]. The unit weight of the reinforced concrete column is considered as the objective function of design optimization problem. The next subsections present the structural specifications-based mathematical formulations for computing the unit cost of reinforced concrete column according to the related practice code provisions.

2.1 Design variables

As abovementioned, the reinforced concrete designer should firstly decide the characteristic strength of the concrete (\({f}_{\text{ck}}\)), the height (\(h\)) and the width (\(b\)) of the cross section of column. In static project of a reinforced concrete structure, the reinforced concrete column sizes are generally multiples of 5 cm and/or 10 cm [37]. Secondly, the suitable distribution of the steel rebars in a reinforced concrete column cross section should be selected. In Fig. 1, the generally preferred four types of these are illustrated [35].

Considering all these variables mentioned above, the required area of longitudinal rebar can be calculated. Finally, the number and the diameter of steel rebars (\({n}_{r}\), \({d}_{r}\)) are selected regarding required area of longitudinal rebar. In this context, distribution types of the steel rebars (\(\text{Type}\)), the characteristic strength of the concrete (\({f}_{\text{ck}}\)), the height (\(h\)) and width (\(b\)) of the cross section of column, and the number and diameter of steel rebars (\({n}_{r}\), \({d}_{r}\)) are considered as discrete variables of the design optimization problem. The considered design variables and constants are given in Table 1.

2.2 Objective function

The main goal is to get the lowest possible unit cost in the design of reinforced concrete column. The sum of the costs of concrete and steel is used to generate a cost-efficient objective function. So, the mathematical definition of the total cost is provided by Eq. (1).

Here, the unit costs of the steel rebar and the concrete are denoted by \({c}_{s}\) and \({c}_{c}\), respectively.

2.3 Design constraints

The practice codes of TBEC 2018 [36] specifications are considered to determine the constraints of reinforced concrete column design optimization problem as follows.

The steel rebar ratio should be between minimum and maximum values. In TBEC 2018, the minimum and maximum steel rebar ratio are specified as 0.01 and 0.04, respectively. So, Eqs. (2) and (3) are operated to check steel rebar ratio.

In Eqs. (2) and (3), \(\rho\) represents the steel rebar ratio of the reinforced concrete column section. Here, \(\rho\) can be computed by Eq. (4).

The reinforced concrete column must bear the design loads. Thus, the load bearing capacity of the reinforced concrete column should be checked via Eq. (5).

In Eq. (5), \({A}_{\text{sr}}\) is the required total cross section area of the longitudinal steel rebars. It can be easily computed through a simple equation suggested by Cakiroglu and Ozer [35] as given in Eq. (6).

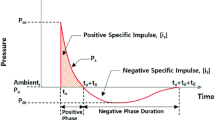

In Eq. (6), \({k}_{1}\) and \({k}_{2}\) represent adjustment factors and \(\mu\) is mechanical ratio of steel rebars. The \({k}_{1}\) is related to distribution types of the steel rebars in the concrete cross section depicted in Fig. 1 [35] and so \({k}_{1}\) is determined utilizing Fig. 2.

The four distribution types of the steel rebar in the concrete cross section [35]

In Fig. 2, \(n\) is a non-dimensional parameter and, it is computed via Eq. (7).

Here, the \({k}_{2}\) is an adjustment factor for thickness of the concrete cover and Eq. (8) is utilized to attain \({k}_{2}\).

In Eq. (8), \(\alpha\) coefficient is obtained via Eq. (9).

In Eq. (9), \({h}{\prime}\) is the minimum distance between center of steel rebar and outer edge of the column. In this study, value of \({h}{\prime}\) is taken as \({d}_{r}\)/2 + 30 mm considering confinement rebar and concrete cover as stated in TBEC 2018. To compute \(m\) in Eq. (8) and \(\mu\) in Eq. (6), Eq. (10) is operated.

In the TBEC 2018, the cross-sectional area of a reinforced concrete column (\({A}_{c}\)) is limited as shown in Eq. (11).

Here, \({{A}_{c}}_{\text{min}}\) is computed using Eq. (12).

In Eq. (12), \({N}_{d}\) represents the magnitude of normal design load on a reinforced concrete column. According to the definition of column in the TBEC 2018 [36], the ratio of the long side of the column to the short side should not exceed 7 as given in Eq. (13).

The total number of reinforcements in the section (\({n}_{r}\)) should be divided by the relevant integer (\(\text{mc}\)), considering the reinforcement distribution depicted in Fig. 1. Meanly, \({n}_{r}\) should be divided by 4 for Type 1 and Type 4, \({n}_{r}\) should be divided by 8 for Type 2, and \({n}_{r}\) should be divided by 16 for Type 3. This division rule is operated utilizing Eq. (14).

Finally, in TBEC 2018, the minimum number of steel rebar is given as 4, and the minimum diameter of steel rebar is given as 14 mm. These practice design rules are applied to the current design optimization problem through Eqs. (15) and (16).

The abovementioned design constraints of the proposed reinforced concrete column design problem are tabulated in Table 2.

2.4 Constraint handling

In the design optimization process conducted via metaheuristic algorithms, the candidate optimum designs are generated randomly. This randomization sometimes causes the generation of constraint-violating solution vectors. In such cases, the penalty functions expressed in the design constraints Eqs. (2, 3, 5, 11, 13–16) are processed during the algorithmic process. So, the fitness values of the constraint-violating solution vectors are computed via Eq. (17).

In Eq. (17), \(F\) and \(\text{Obj}\) are the fitness and objective values of candidate solution vector, \(g\) represents the penalty vectors attained via Eqs. (2, 3, 5, 11, 13–16). The value of 0 (zero) is assigned to any member of \(g\) in case of negative value. Thus, feasible candidate solution vectors are not violated in the algorithmic process.

3 Swarm-based metaheuristic optimization algorithms

The swarm-based metaheuristic optimization algorithms Coati Optimization Algorithm (COA) [20], Fox Optimizer (FOX) [21] and Pelican Optimization Algorithm (POA) [22] are selected as the optimizer tools in this study mimicking the searching behaviours of the animals in nature. The COA, FOX and POA have recently been developed in 2023 as three overnew swarm-based metaheuristic optimization algorithms. In this section, the standard methodologies of the COA, FOX and POA are presented and explained, respectively.

3.1 Coati optimization algorithm

The mathematical description and metaheuristic algorithmic steps of standard Coati Optimization Algorithm (COA) [21] is explained in this subsection. As omnivores, coatis consume both tiny vertebrate prey, such as lizards, rodents, crocodile eggs, and bird eggs, as well as invertebrates like tarantulas. Green iguanas are one of the coatis' preferred foods. A group of coatis chase these iguanas commonly seen in trees. Some of them climb trees to intimidate the iguana into jumping to the ground, while others attack it rapidly. However, coatis are vulnerable to predator attacks. Jaguars, ocelots, tayras, dogs, foxes, boa constrictors, maned wolves, anacondas, and jaguarundis are among the coati's predators. Large raptors like harpy eagles, black-and-chestnut eagles, and ornate hawk-eagles also hunt them. Hence, the coatis use sophisticated strategies to attack iguanas and avoid predators. The mimicking of these natural phenomena of coatis is the primary inspiration in constructing the COA technique. The COA is a population-based metaheuristic in which coatis are treated as population members of the algorithm. The positions of each coati in the search space define the values of the decision variables. As a result, in the COA, the positions of coatis represent a potential solution to the design problem. In algorithmic process, the positions of coatis are randomly generated via Eq. (18).

In Eq. (18), \(N\) is the number of coatis, \(j\) is the number of design variable. The \(\text{lb}\) and \(\text{ub}\) are the lower and upper bounds of design variables. \(r\) is a randomly generated number between 0 and 1. Thus, \({x}_{i,j}\) presents one dimension of the position of a coati. Fitness values of each coati are computed using its position considering objective function. Thus, the fitness vector is generated as in Eq. (19).

After the generation of the initial fitness vector, the hunting and attacking phase begins. During these phases, a half of coatis climbs a tree to terrify an iguana. The other half of coatis wait behind a tree till the iguana falls to the ground. The coatis attack and hunt the iguana shortly after it falls to the ground. This method causes coatis to shift positions. Climbing of coatis is simulated via Eq. (20).

In Eq. (20), \(I\) is a randomly selected integer number. It can be 1 or 2. After falling to the ground, the iguana is randomly positioned. The new position of the iguana is computed via Eq. (18). Coatis on the ground move based on this random position utilizing Eq. (21).

The estimated new location for each coati is suitable for the update process if it betters the value of the objective function; else, the coati remains in its former position.

A coati flees from its place when it is attacked by a predator. Coatis take position in a secure location near its present location. A random position is created close to each coati's location in order to imitate this behaviour via Eqs. (22) and (23).

In Eqs. (22) and (23), \({\text{lb}}_{j}^{\text{local}}\) and \({\text{ub}}_{j}^{\text{local}}\) are local lower bound and local upper bound of the \({x}_{i,j}\). The number of iterations is \(T\), and the value of iteration counter is symbolized as \(t\). An iteration of a COA techniques ends when locations of every coati in the search space has been updated. Up to the final iteration, the population is updated using Eqs. (20) through (23).

3.2 Fox optimizer

The mathematical description of standard Fox Optimizer (FOX) [22] metaheuristic algorithm is presented in this subsection. A fox may survive in a low-production habitat with few species. The hunts approach in the FOX algorithm is to how a red fox dives into the snow to search for its prey. Throughout the USA, Europe, Canada, Japan, Australia, and metropolitan regions in Europe, the red fox is the most common mammal. It inhabits a variety of environments, including mountains, forests, grasslands, and deserts. One kind of fox that consumes both plants and animals is the red fox. Being an omnivore, the fox is able to adjust its eating habits to suit its environment. Therefore, fox consumes fruit, vegetables, frogs, and fish. When there is snow on the ground, the hunter cannot see through it. The red fox makes random attempts to find prey. As a result, the red fox uses the prey's ultrasound to locate it. Then, nearing the prey requires time. The red fox understands how far away its prey is from it by using the time difference and the sound of the prey. The red fox measures the distance and then predicts how far it will have to jump to capture the prey. Random walking is done in accordance with the shortest amount of time and ideal position. In standard FOX technique, the red fox positions provide one possible way to solve the design problem. The locations of red foxes are generated at random by an algorithmic method using Eq. (24).

The FOX algorithm first initializes the population, often known as the \(X\) matrix. The locations of red foxes are represented by an \(X\). Next, the fitness values of each search agent are determined for each iteration using objective function. Each row in an \(X\) matrix has its fitness value as given in Eq. (25). The attained fitness values are compared to the fitness of other rows in order to get the \(BestFitness\) and \(Best Position\).

In FOX algorithm, there are two main phases called exploration and exploitation. Utilizing a random variable, the exploration and exploitation processes are balanced. Meanly, approximately 50% of the total iterations are assigned to exploration phase and the remaining 50% is assigned to exploitation phase. In exploitation phase, fox has new condition relating to the probability of killing the prey. The Eqs. (27) and (28) are utilizing for this purpose. The value of \(p\) is generated between 0 and 1. On condition that \(p\) is greater than 0.18, Eq. (26) is operated. Otherwise, Eq. (27) is utilized.

In Eqs. (26) and (27), \({c}_{1}\) and \({c}_{2}\) factors are within 0.0–0.18 and 0.19–1.0, respectively. The distance between fox and prey (\({\text{Dist}\_\text{Fox}\_\text{Prey}}_{\text{it}}\)) and magnitude of jump (\({\text{Jump}}_{\text{it}}\)) are computed utilizing Eqs. (28) to (31).

Here, the distance of sound travels (\({\text{Dist}\_S\_T}_{\text{it}}\)) is equal to multiplication of velocity (\({S}_{p}\_S\)) and time (\({\text{Time}\_S\_T}_{\text{it}}\)). Where \({\text{Time}\_S\_T}_{\text{it}}\) is a random number in the interval [0, 1] and the sound speed \({S}_{p}\_S\) equals 343 m/s in the air. In Eq. (31), \(t\) is the average time of sound travels and is squared owing to the jump's ups and downs, and 9.81 is the acceleration caused by gravity.

In exploration phase of FOX algorithm, the fox walks randomly to find prey in the search space. A minimal time variable called \(\text{Min}\_T\) and a variable called \(a\) are used to regulate the search, ensuring that the fox moves randomly toward the best position. \(\text{Min}\_T\) is computed considering the minimum value of \(tt\) as given in Eq. (32).

Here, \(a\) is calculated via Eq. (33).

In Eq. (33), \(it\) is the number of current iteration and \({\text{Max}}_{\text{it}}\) presents the maximum number of iterations. The exploration strategy of FOX algorithm for looking for a new location is explained by Eq. (34).

3.3 Pelican optimization algorithm

Pelicans are social animals that inhabit groups of several hundred individuals. The cognitive process of pelican behaviour and hunting technique has made these birds skilled hunters. Fish is the primary food source for pelicans; frogs, turtles, and crabs are only seldom eaten. They even consume seafood when they are really hungry. Pelicans frequently cooperate during hunting. Once they've located their prey, the pelicans plunge to attack. The fish are then forced to go to shallow water by their spreading wings on the water's surface, which makes it easier to catch fish. The method outlined above served as the primary source of inspiration for the design of the standard POA [23] metaheuristic optimization technique.

As population-based approach, the POA technique considers the pelicans as members of solution matrix. Based on their location in the search space, each member of the population provides candidate solution for the design optimization problem variables. Equation (35) is used to randomly initialize population members based on the upper and lower bounds.

In Eq. (35), \({x}_{i,j}\) is the jth design variable of the ith pelican. The \(N\) and \(m\) are the number of pelican and the number of design variable, respectively. \({u}_{j}\) and \({l}_{j}\) represent upper and lower limit of the jth design variable and, \(r\) represents a random number generated between 0 and 1.

The location of pelicans is represented as \(P\). Next, fitness values of all pelicans are computed for each iteration utilizing objective function. Each row in an \(P\) matrix has its fitness value as symbolized in Eq. (36).

In Eq. (36), \(F\) represents fitness values of a solution vector.

In the POA, the hunting process consists of two main phases as the moving towards prey and winging on the water surface. In the first main phase, a prey is generated in random location, and it is assumed that pelicans detect the location of prey. Here, the randomization in the generation of the prey improves the exploration capacity of the POA. The process of the moving toward the prey is operated utilizing Eq. (37).

In Eq. (37), \({x}_{i,j}^{P1}\) is new location of the ith pelican, \(I\) is a random integer number equals to 1 or 2. The \({p}_{j}\) is the jth column value of the randomly generated prey vector, and \({F}_{p}\) is its fitness value. Here, randomization in selection of the \(I\) enhance the exploration capacity of the POA. If the value of the fitness function is more optimum in new position, the value of \({x}_{i,j}^{P1}\) is considered. Otherwise, old value of \({x}_{i,j}\) is taken in this process.

In the second main phase, the pelicans lift the fish up by spreading their wings on the water's surface, then they catch the preys. This tactic helps pelicans catch more fish. Equation (38) provides a mathematical simulation of this pelican hunting activity.

In Eq. (38), \({x}_{i,j}^{P2}\) is new location coordinate of the ith pelican based on second phase. Here, \(0.2 \left(1-t/T\right)\) symbolizes neighbourhood radius of \({x}_{i,j}\). T and t are the maximum number of iteration and current number of iteration counter, respectively. Because of the huge value of neighbourhood radius in the first iterations, a greater region surrounding each member is considered by POA. However, in further iteration, value of neighbourhood radius gradually decreases and, exploitation capacity of the POA increase. As in the previous stage, it is decided whether the new value of \({x}_{i,j}\) will be accepted or not by comparing the new \({x}_{i,j}^{P2}\) value with the \({x}_{i,j}\) value at the end of the first stage.

The specific algorithmic parameters and the design ranges of the variables are tabulated in Table 3. Moreover, the optimization process of the proposed reinforced concrete column design problem is presented as a flowchart as shown in Fig. 3.

4 Descriptions and results

In this study, the structural design of a reinforced concrete column is investigated. The cross section of the reinforced concrete column is considered rectangular as in practice. Furthermore, various steel rebar configurations are preferred for reinforce concrete column design in practice. Thus, four different steel rebar configurations are depicted in Fig. 1 which are generally preferred. Simple formulas suggested by Cakiroglu and Ozer [35] are used to calculate the load carrying capacity of the reinforced concrete column. So, the calculation complexity is reasonably decreased.

As a part of complex structure, a reinforced concrete column can be exposed to different biaxial loading condition. Therefore, optimum design of a rectangular reinforced concrete column is investigated considering 4 different biaxial loading cases as given Table 4. In Table 4, Nd is the normal design force, Mdx and Mdy are the design moment in \(x\)- and \(y\)-directions, respectively.

The direction of the Nd, Mdx and Mdy on the general schematic three dimensional views of reinforced concrete column problem is depicted in Fig. 4.

The type of distribution of steel rebars in rectangular cross-sectioned reinforced concrete column (\(\text{Type}\)), the characteristic strength of the concrete (\({f}_{\text{ck}}\)), the height (\(h\)) and width (\(b\)) of the cross section of column, and the number and diameter of steel rebars (\({n}_{r}\), \({d}_{r}\)) are considered as discrete design variables of the optimum design problem. The increment values of the discrete design variables and their upper and lower bounds are tabulated in Table 5.

Related to Table 5, there are 675,000 different design combinations for reinforced concrete column design. As mentioned before, the objective of the reinforced concrete design problem is to achieve cost-efficient optimal design. Thus, in Table 6, unit prices of the steel and concrete are given to compute the total cost of the attained reinforced concrete column designs.

The reinforced concrete column design problem is optimized considering abovementioned design details. To evaluate the performance of COA, FOX, and POA optimizers, the population size and total number of iterations are taken constants as 30 and 1000, respectively [30]. The COA does not involve any specific algorithmic control parameter [21]. The FOX attains best algorithmic performance for value of \({c}_{1}\) and \({c}_{2}\) equal to 0.18 and 0.82, respectively [22]. The POA has the fruitful algorithmic performance when the value of \(R\) equal to 0.2 [23].

In this context, the reinforced concrete column design problem under 4 different load cases are ten times optimized independently utilizing overnew COA, FOX and POA aiming cost efficient design optimization. The attained optimal designs and algorithmic performances of utilized optimizers are given in following subsections.

4.1 Design of reinforced concrete column under load case-1

The rectangular cross-sectioned reinforced concrete column is independently minimized ten times utilizing different randomly generated initial seed values. Thus, stochastic based COA, FOX, and POA metaheuristic optimization algorithms are statistically validated. The minimum, maximum, median, standard deviation, and average values of the attained minimum coasted optimal designs are tabulated in Table 7. The box plot diagrams of the COA, FOX and POA are illustrated in Fig. 5. It is clearly seen from Table 7 and Fig. 5 that the most stable algorithmic performance characterization belongs to COA. Although the FOX attains a minimum cost value close to COA during the ten-time process, the standard deviation of FOX is considerably higher compared to COA and POA. When the best minimum costed designs are compared, the POA reaches the lowest design cost as 4.157 $/m. Thus, the COA and FOX generate 2.237% and 2.887% more expansive optimum designs than POA. Eventually, it is seen that the POA exceeds the local optimum and reaches the best optimum result, but the POA is second after COA in standard deviation, in other words, stable algorithmic performance.

Among ten independent optimization operations, details of the best reinforced concrete column designs for each swarm-based overnew metaheuristic are given in Table 8. It is seen from Table 8 that all design constraint values are equal or under the zero. This means that the optimum designs achieved by COA, FOX, and POA techniques can be acceptable as in the practical perspective of structural engineering. The most active design constraint for all designs is g4 which is about minimum concrete cross-section area.

The design search histories of COA, FOX and POA are illustrated in Fig. 6 for load-case 1. In Load Case-1, the COA, FOX and POA techniques yield final optimum design in 127th, 20th and 110th iterations, respectively. Figure 6 shows that the utilized optimization methods have sufficient convergence rates.

4.2 Design of reinforced concrete column under load case-2

The reinforced concrete column which is exposed to Load Case-2 independently optimized ten times using different randomly generated initial seed values. The minimum, maximum, median, standard deviation and average values of the attained minimum costed designs are gives in Table 9. Additionally, box plot diagrams of the COA, FOX and POA are illustrated in Fig. 7. Even though standard deviation of the COA and POA are very close to each other, Table 9 and Fig. 7 illustrate that POA presents more stable algorithmic performance than COA and FOX. The best minimum costed design of 4.413 $/m is reached by POA. The second and third minimum costed designs are attained by FOX and COA. The COA and FOX exceed 2.221% and 1.088% more expansive design optimum design than POA, respectively. In the Load Case-2, it can be said that POA reaches the most optimum design with a stable algorithmic performance.

The details of optimal reinforced concrete column designs attained by COA, FOX and POA under Load Case-2 are given in Table 10. In Table 10, the values of all design constraints are equal or under the zero. As in Load Case-1, the most active design constraint for all designs is g4 which is about minimum concrete cross-section area. The design histories of COA, FOX and POA are depicted in Fig. 8. It is seen from this figure that when FOX reaches an eventual optimum design in 16th iteration, the COA and FOX reach their final designs in 166th and 115th iterations, respectively.

4.3 Design of reinforced concrete column under load case-3

The reinforced concrete column under Load Case-3 independently minimized ten times using different random initial seed values. The minimum, maximum, median, standard deviation, and average values of the attained minimum costed designs are tabulated in Table 11. Furthermore, box plot diagrams of the COA, FOX and POA techniques are illustrated in Fig. 9. Table 11 and Fig. 9 illustrate that the COA has more stable algorithmic performance than FOX and POA for Load Case-3. While providing the least resilient algorithmic performance, the FOX succeeds in finding the lowest costed design of 5.232 $/m. The COA and POA yield same minimum design cost as 5.234 $/m. The difference is pretty low.

The best reinforced concrete column designs of COA, FOX and POA are tabulated in detail in Table 12. The values of all constraints are zero or positive number in mentioned table. The g7 named constraint is the most active limiter after g4 for all design. The design history charts of COA, FOX and POA are given in Fig. 10. Surprisingly, the FOX yields final optimal design in 10th iteration. The COA and POA exceed their eventual minimum costed designs in 78th and 872th iterations, respectively.

4.4 Design of reinforced concrete column under load case-4

The reinforced concrete column under Load Case-4 is ten times optimally designed utilizing different random initial seed values. In Table 13, the minimum, maximum, median, standard deviation, and average values of the obtained cost-efficient designs via COA, FOX, and POA optimization techniques of the reinforced concrete column are tabulated. Additionally, box plot diagrams of the COA, FOX and POA are given in Fig. 11. From the best to the worst, the POA, COA, and FOX represent the stable algorithmic performance ranking of the algorithms. When the COA and POA find the best minimum costed design as 5.017 $/m, the FOX attains 0.319% more expensive final design as 5.033 $/m. Eventually, it can be said that the POA acquires the most optimum design with a stable algorithmic performance.

The eventual values of the design variables and design constraints are given Table 14. In Table 14, the values of all design constraints are equal or under the zero. As in above-mentioned load cases, the most active design constraint for all design is g4 and the second dominant design constraint is g7 for Load Case-4.

In Fig. 12, the design histories of COA, FOX and POA are depicted. All overnew metaheuristic optimization algorithms exceed the minimum costed reinforced concrete designs in the first 50 iterations. The COA, FOX and POA yield their final designs at 32th, 5th and 41th iterations, respectively.

The attained results of reinforced concrete column design problem under 4 different load cases are presented as abovementioned. Accordingly, the all results indicate that the preselection complexity of critical values of design variables are optimally achieved by considering the type of steel rebar distribution and the material class of concrete as design variable in a reinforced concrete column section. In this context, the achieved results of newly proposed reinforced concrete column design cost optimization problem represent an accurate solution for a complex practical real-world structural engineering problem. However, it is not strictly claimed the operativeness of the obtained optimal designs since the unit cost and material circumstances may not be satisfied during time and/or location of construction site.

5 Discussions

In this study, the minimum design cost optimization of a reinforced concrete column is handled under effect of four different load cases. The handled structural optimum problem can be classified as highly nonlinear and complicated and it is firstly proposed in this study. In practise, a reinforced concrete designer should decide various design parameter before design calculation of a reinforced concrete column. The newly proposed design problem is inspired by the design process of a practicing structural engineer. In difference with previous studies in the literature, the configuration type of distribution of the steel rebars in cross section of the reinforced concrete column (\(\text{Type}\)) is considered as a design variable. Additionally, the steel rebar characteristic, the strength of the concrete (\({f}_{\text{ck}}\)), the height (\(h\)) and width (\(b\)) of the cross section of column, and the number and diameter of steel rebars (\({n}_{r}\), \({d}_{r}\)) are taken as discrete design variables of the complicated design optimization problem. The design constraints of the reinforced concrete design problem consist of the design requirements specified in TBEC 2018 practice code provisions. In the computation process of load carrying capacity of the reinforced concrete column, the simple formulas suggested by Cakiroglu and Ozer are utilized to slightly decrease the calculation complexity. In the design optimization process, three overnew swarm-based optimization algorithms such as Coati Optimization Algorithm (COA), Fox Optimizer (FOX), and Pelican Optimization Algorithm (POA) are considered as optimizers. These metaheuristic algorithms are firstly utilized to attain design optimization of such a nonlinear and complex discrete practical structural engineering design problem in this study. The general discussions on proposed practical design optimization of reinforced concrete problem by comparing three overnew optimization algorithms are as follows.

The first and main success of this study is that the proposed reinforced concrete column applicably designed via all overnew optimizers. The design constraint values of all attained designs are equal or greater than zero. Generally, the most active design constraints of the reinforced concrete column design are g4 and g6 and the second active ones are g1 and g7. These design constraints are according to minimum concrete area, requirement of number of rebar dividing required integer number, the minimum steel rebar ratio and the minimum number of the steel rebars, respectively.

The utilized optimizers generally find their final designs in the first 150 iterations out of 1000 iterations. All the design history charts and variations in attained optimum designs indicate that the proposed reinforced concrete column design problem is quite difficult, and the utilized optimization algorithms sometimes cannot escape from local optimum designs.

The authors detect that attained all configuration types of distribution of the steel rebars in cross section of the reinforced concrete column (\(\text{Type}\)) is found as \(\text{Type} 4\). However, while the all 120 optimum designs are considered, it is seen that all other configurations also selected via optimizers in some load cases. These are illustrated in Fig. 13. Figure 13 shows that all types can be selectable for an optimum column design. However, bidirectional moment force to optimizers to select Type 4 because of moment arm is higher than other type configurations under bidirectional moment. Figure 2 which is used to determine k1 coefficient is support this eventual hypothesis.

The box-plot diagrams and statistical result tables indicate that when COA shows more stable characteristic in Load Case-1 and Load Case-3, the POA gives most stable performance in Load Case-2 and Load Case-4. However, the FOX has worst stable algorithmic performance in all load cases. In Load Case-1 and Load Case-2, the best final designs are acquired by POA. The FOX attains the best design only Load Case-1 with a neglectable difference. In the Load Case 4, the COA and POA exceed best design together. The design history diagrams illustrate that the FOX has best convergence ratio. In the first two load cases, the POA has the second-best convergence ratio, while in the last two load cases, the COA has the second-best convergence ratio. In the light of all of these comparisons, it can be deducted that the most suitable algorithm is the POA to reach design optimization of reinforced concrete column design problem. Also, although the FOX yields rapidly, it tends to be caught at the local optimum. Besides, the COA has not performed badly, but even better than the FOX, it has failed to escape the local optimum.

It is worth noting that to provide insightful information about the relative effectiveness of other various metaheuristic algorithms across a range of application domains can be stated as the challenge part of this study.

6 Concluding remarks

This study presents the optimal design of a reinforced concrete column as a novel design optimization problem that serves as inspiration for practicing structural engineers during the design phase. The Coati Optimization Algorithm (COA), Fox Optimizer (FOX), and Pelican Optimization Algorithm (POA) are considered as optimizers which are overnew swarm-based nature-inspired metaheuristic optimization algorithms. The main findings as concluding remarks of this study are;

-

The main achievement of this study is that the newly proposed reinforced concrete column design problem can be discreetly optimized by satisfying the requirements of practical code provisions via three overnew swarm-based metaheuristics to reach design cost optimization.

-

The differences in the attained optimal designs indicate that using novel optimization algorithms might occasionally result in a local optimum. This is because the proposed reinforced concrete column design problem becomes quite complex with adding type of steel rebar distribution and the material class of concrete as design variable.

-

After considering all of these comparisons, it is possible to conclude that the POA is the best overnew algorithm for obtaining the design cost optimization of a reinforced concrete column. In comparison with POA, even if the COA does not show a bad convergence performance during optimization procedure, it relatively struggles to escape from the local optimum. However, it algorithmically performs better than FOX. Furthermore, even if the FOX algorithm generally seems to converge quickly to feasible design than others, it frequently stacks in the local optimum and fails at the end of the optimization process.

As future studies, the authors recommend that newly generated metaheuristic algorithms should be tested on different types of other real-world complex practical engineering design problems rather than the functional and/or benchmark engineering design problems to comprehend their realistic algorithmic performances.

Data availability

The data will be available upon reasonable request.

References

Tunca O, Carbas S (2024) Sustainable and cost-efficient design optimization of rectangular and circular-sectioned reinforced concrete columns considering slenderness and eccentricity. Structures 61:105989. https://doi.org/10.1016/j.istruc.2024.105989

Altay O, Cetindemir O, Aydogdu I (2023) Size optimization of planar truss systems using the modified salp swarm algorithm. Eng Optim. https://doi.org/10.1080/0305215X.2022.2160449

Nigdeli SM, Yücel M, Bekdaş G (2023) A hybrid artificial intelligence model for design of reinforced concrete columns. Neural Comput Appl 35:7867–7875. https://doi.org/10.1007/s00521-022-08164-7

Ngo N-T, Le HA, Pham T-P-T (2021) Integration of support vector regression and grey wolf optimization for estimating the ultimate bearing capacity in concrete-filled steel tube columns. Neural Comput Appl 33:8525–8542. https://doi.org/10.1007/s00521-020-05605-z

Tunca O (2024) Effect of the soil slope on the cost-efficient optimum discrete design of reinforced concrete isolated footings. Structures 59:105769. https://doi.org/10.1016/j.istruc.2023.105769

Chatterjee S, Sarkar S, Hore S et al (2017) Particle swarm optimization trained neural network for structural failure prediction of multistoried RC buildings. Neural Comput Appl 28:2005–2016. https://doi.org/10.1007/s00521-016-2190-2

Aydogdu I, Ormecioglu TO, Tunca O, Carbas S (2022) Design of large-scale real-size steel structures using various modified grasshopper optimization algorithms. Neural Comput Appl 34:13825–13848. https://doi.org/10.1007/s00521-022-07196-3

Uzer MS, Inan O (2023) Application of improved hybrid whale optimization algorithm to optimization problems. Neural Comput Appl 35:12433–12451. https://doi.org/10.1007/s00521-023-08370-x

Kalemci EN, İkizler SB, Dede T, Angın Z (2020) Design of reinforced concrete cantilever retaining wall using Grey wolf optimization algorithm. Structures 23:245–253. https://doi.org/10.1016/j.istruc.2019.09.013

Alizadeh M, Beheshti MTH, Ramezani A, Bolouki S (2023) An optimized hybrid methodology for short-term traffic forecasting in telecommunication networks. Trans Emerg Telecommun Technol 34:e4860. https://doi.org/10.1002/ett.4860

Alizadeh M, Beheshti MTH, Ramezani A, Saadatinezhad H (2020) Network Traffic Forecasting Based on Fixed Telecommunication Data Using Deep Learning. In: 2020 6th Iranian Conference on Signal Processing and Intelligent Systems (ICSPIS). IEEE, Mashhad. pp 1–7

Alizadeh M, Mousavi SE, Beheshti MTH, Ostadi A (2021) Combination of Feature Selection and Hybrid Classifier as to Network Intrusion Detection System Adopting FA, GWO, and BAT Optimizers. In: 2021 7th International Conference on Signal Processing and Intelligent Systems (ICSPIS). IEEE, Tehran pp 1–7

Younis A, Dong Z (2024) Adaptive surrogate assisted multi-objective optimization approach for highly nonlinear and complex engineering design problems. Appl Soft Comput 150:111065. https://doi.org/10.1016/j.asoc.2023.111065

Ustun D, Toktas F, Toktas A (2022) An optimized surrogate model using differential evolution algorithm for computing parameters of antennas. Int J Numer Modell 35:e2951. https://doi.org/10.1002/jnm.2951

Ustun D, Toktas F (2021) Surrogate-based computational analysis and design for H-shaped microstrip antenna. J Electromagn Waves Appl 35:71–82. https://doi.org/10.1080/09205071.2020.1828181

Aydoğdu İ, Akın A, Saka MP (2016) Design optimization of real world steel space frames using artificial bee colony algorithm with levy flight distribution. Adv Eng Softw 92:1–14. https://doi.org/10.1016/j.advengsoft.2015.10.013

Kazemzadeh Azad S, Hasançebi O, Saka MP (2014) Guided stochastic search technique for discrete sizing optimization of steel trusses: a design-driven heuristic approach. Comput Struct 134:62–74. https://doi.org/10.1016/j.compstruc.2014.01.005

Hozić D, Thore C-J, Cameron C, Loukil M (2023) Deterministic-based robust design optimization of composite structures under material uncertainty. Compos Struct 322:117336. https://doi.org/10.1016/j.compstruct.2023.117336

Saka MP, Dogan E (2012) Recent developments in metaheuristic algorithms: a review. Comput Technol Rev 5:31–78. https://doi.org/10.4203/ctr.5.2

Hasançebi O, Carbas S, Doğan E et al (2010) Comparison of non-deterministic search techniques in the optimum design of real size steel frames. Comput Struct 88:1033–1048. https://doi.org/10.1016/j.compstruc.2010.06.006

Dehghani M, Montazeri Z, Trojovská E, Trojovský P (2023) Coati optimization algorithm: a new bio-inspired metaheuristic algorithm for solving optimization problems. Knowl-Based Syst 259:110011. https://doi.org/10.1016/j.knosys.2022.110011

Mohammed H, Rashid T (2023) FOX: a FOX-inspired optimization algorithm. Appl Intell 53:1030–1050. https://doi.org/10.1007/s10489-022-03533-0

Trojovský P, Dehghani M (2022) Pelican optimization algorithm: a novel nature-inspired algorithm for engineering applications. Sensors 22:855. https://doi.org/10.3390/s22030855

Abou Houran M, Salman Bukhari SM, Zafar MH et al (2023) COA-CNN-LSTM: coati optimization algorithm-based hybrid deep learning model for PV/wind power forecasting in smart grid applications. Appl Energy 349:121638. https://doi.org/10.1016/j.apenergy.2023.121638

Tamilarasu P, Singaravel G (2023) Quality of service aware improved coati optimization algorithm for efficient task scheduling in cloud computing environment. J Eng Res. https://doi.org/10.1016/j.jer.2023.09.024

Jameel M, Abouhawwash M (2024) Multi-objective Mantis Search Algorithm (MOMSA): a novel approach for engineering design problems and validation. Comput Methods Appl Mech Eng 422:116840. https://doi.org/10.1016/j.cma.2024.116840

Alrahhal H, Jamous R (2023) RNN-AFOX: adaptive FOX-inspired-based technique for automated tuning of recurrent neural network hyper-parameters. Artif Intell Rev 56:1981–2011. https://doi.org/10.1007/s10462-023-10568-3

Chen X, Bai S, Li G et al (2024) A new transient NOx prediction model for diesel engine based on neural network model with Pelican optimization algorithm. Int J Engine Res 25:231–239. https://doi.org/10.1177/14680874231196050

Wang Z, Duan J, Xu H et al (2023) Enhanced pelican optimization algorithm for cluster head selection in heterogeneous wireless sensor networks. Sensors 23:7711. https://doi.org/10.3390/s23187711

Tunca O, Carbas S (2023) Multi-plane disc clutch brake design via new swarm-based metaheuristics. In: Proceeding Book of 4th International Conference on Engineering and Applied Natural Sciences ICEANS 2023. All Sciences Academy

de Medeiros GF, Kripka M (2014) Optimization of reinforced concrete columns according to different environmental impact assessment parameters. Eng Struct 59:185–194. https://doi.org/10.1016/j.engstruct.2013.10.045

Bekdaş G, Nigdeli SM (2016) Optimum design of reinforced concrete columns employing teaching-learning based optimization. Chall J Struct Mech. https://doi.org/10.20528/cjsmec.2016.11.030

Sánchez-Olivares G, Tomás A (2017) Improvements in meta-heuristic algorithms for minimum cost design of reinforced concrete rectangular sections under compression and biaxial bending. Eng Struct 130:162–179. https://doi.org/10.1016/j.engstruct.2016.10.010

Singh B, Singh Dhanoa G, Kaur L et al (2022) Cost optimization of RCC column using discrete optimisation method. Mater Today: Proc 48:1390–1394. https://doi.org/10.1016/j.matpr.2021.09.137

Cakıroglu A, Ozer E (1990) Dikdörtgen ve daire betonarme kesitlerde taşıma gücü formülleri ve yaklaşıklık mertebeleri. İMO Teknik Dergi 25–48

TBEC (2018) Turkish Building Earthquake Code Specifications for Design of Buildings under Seismic Effects. Ankara, Türkiye

Kaveh A, Rezazadeh Ardebili S (2023) Optimum design of 3D reinforced concrete frames using IPGO algorithm. Structures 48:1848–1855. https://doi.org/10.1016/j.istruc.2023.01.071

Acknowledgements

The authors gratefully acknowledge the support provided by The Scientific and Technological Research Council of Türkiye (Türkiye Bilimsel ve Teknolojik Araştırma Kurumu (TUBITAK)).

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest is reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tunca, O., Carbas, S. Design cost minimization of a reinforced concrete column section using overnew swarm-based optimization algorithms. Neural Comput & Applic (2024). https://doi.org/10.1007/s00521-024-09998-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00521-024-09998-z