Abstract

In the past twenty years, besides the technological and innovative efforts for production processes, there have been activities for the recovery and quality improvement of waste based on the development of sustainable solutions. These activities bring us closer to zero waste by protecting natural resources and reducing the environmental impact of production facilities. One of the essential approaches in this process is the industrial symbiosis (IS) approach. Efforts to implement the industrial symbiosis approach in an industrial park constitute the motivation of the study. The study aims to identify alternative enterprises that can evaluate the wastes generated in the main production process of the foundry industry with industrial symbiosis and rank them to establish a symbiotic relationship. First, the Pythagorean Fuzzy Analytical Hierarchy Process (PF-AHP) model has been developed to evaluate organizational factors, waste-specific factors, and economic and environmental sustainability criteria for establishing an IS network among alternative businesses. Then, alternative businesses were ranked to establish a symbiosis network with the PF-TOPSIS method. The proposed method contributes to the solution of a real-life problem that may arise when there are multiple alternatives to cooperate in the field of industrial symbiosis. By contributing this framework to the literature, the robustness of the results has been demonstrated through sensitivity analysis and comparative analysis. According to the results obtained, it was seen that the importance levels of economic factors came to the fore. Furthermore, among the alternatives, enterprises with high waste exchange potential, such as cement, took first place in the ranking.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

For the coming years, industrial plants are turning to innovative approaches aiming at raw material valuation, more innovative use of cross-industry technologies, avoiding waste streams, and evaluating and reusing waste. Furthermore, among the strategic goals set by public and local authorities, including waste in the recycling process in the circular economy has become an important goal to maximize the value of by-products. In this context, industrial symbiosis networks, among the circular economy application tools, are among the most important tools to achieve this goal.

The casting industry, which is among the indispensable sectors of daily life and industry from automotive to aircraft industry, from automation parts to health products, is a sector with high potential for an industrial symbiosis network in terms of the amount of waste it generates. Moreover, the casting industry, one of the driving forces of the heavy industry, has an important place in the country's economy, both by meeting the needs of the heavy industry and by the foreign exchange and employment opportunities provided by the industry.

In the casting sector, wastes occur in the main production processes, such as model core making, core production, molding, casting, and cleaning. Various wastes such as foundry sand, slag, plastic and wood wastes, filter dust, paint, and wastewater emerge in these processes. In the literature, various studies [1] on the recovery of foundry wastes such as foundry sand and slag that appear in the foundry industry. However, this is not done based on an analytical approach within a system. Recycling and reusing the waste generated during the casting process in the foundries with methods that will not harm the environment will provide high-added value for the casting industry and other industries using these wastes. Natural resources are protected by transforming foundry wastes into resources, and economic benefits are obtained by saving raw materials. Moreover, environmental benefits are provided with a circular approach without disposal [2].

This study it is aimed to evaluate the most beneficial alternative to establish an IS network of wastes generated in the foundry industry. Determining which establishment to send the waste that will arise in the casting industry will maximize both economic and environmental benefits. For this reason, stakeholders in a designed industrial symbiosis network will be beneficial in achieving their goals.

Yazıcı et al. [3], the problem of determining the priority sector in which a symbiosis network will be established in an industrial park was discussed. As a result of the solution to the problem, the casting sector was determined as the priority sector for which a symbiosis network should be established. It has been emphasized that the waste generated by this sector due to its financial volume, production volume, and the amount of waste it generates, and the environmental effects of this waste should be evaluated with a symbiosis network. This study aims to list the alternative enterprises that can take the waste to provide economic and environmental benefits by re-evaluating the waste generated in the casting sector. Various studies have analyzed circular economy opportunities and industrial symbiosis establishment.

However, it can be identified that the gaps still exist in the literature. Studies in the literature are focused on economic and environmental impacts and lack a holistic approach that considers waste and essential factors specific to the businesses to cooperate [4,5,6]. There are no studies evaluating alternatives with analytical methods in partner selection in symbiosis network establishment [7]. Studies that consider the uncertainties in the symbiosis network and offer solutions with fuzzy methods are limited [7]. In this context, the study aims to fill these gaps in the literature.

In this study, we address these gaps with an analytical framework in selecting enterprises that will establish a symbiosis network for the wastes of the foundry industry in order to recycle the waste as a by-product. For this purpose, an application model that considers on closed-loop value chains is proposed. This business model facilitates the diffusion of R&D opportunities and reaches out to various stakeholders, such as policymakers and investors, to support the full implementation of certain process steps.

In the next sections of the study, related studies in the literature will be summarized. The third section presents the methods used to solve the problem. The fourth section summarizes the problem discussed and defines the criteria and alternatives. The fifth section constitutes the numerical results and discussion part of the study. Finally, the last section contains the results.

2 Literature review

In the field of industrial symbiosis, some studies deal with various decision problems related to the establishment and maintenance of the symbiosis network and the planning of material exchange [7]. In a significant part of the studies, the issues regarding the determination of the policies regarding establishing and maintaining the symbiosis network draw attention. In this study, the literature studies examined the problem of ranking the enterprises that will participate in the symbiosis network are summarized below.

Agudo et al. [8] evaluated businesses in six different industries to assess whether sectors are ready to establish an industrial symbiosis network. They evaluated companies in two dimensions to evaluate whether they were prepared for a symbiotic relationship. These dimensions are whether the business has the resources for change, and these resources are defined as waste, energy, and water. The other dimension is the capacity of enterprises for change. Trust, information, access conditions, and infrastructure factors are considered in this dimension. Among the studies evaluating the establishment process for the establishment of the IS network, calculating the importance levels of the criteria affecting the cooperation in the network [9], determining the importance levels of the criteria that are effective in the establishment of the sustainable IS network [10], the criteria preventing the establishment of the IS network. Similarly, Taqi et al. [11] investigated what the challenges are to the implementation of industrial symbiosis. He evaluated alternative challenges based on the opinions of academics and practitioners. There are various studies, such as calculating the importance levels [12]. Vimal et al. [13] evaluated the impact of IS networks on the competitiveness of businesses. In these studies, using multi-criteria decision-making (MCDM) methods, the criteria were ranked according to their importance. MCDM methods such as the analytical network process [9, 10], Analytical hierarchy process [13], DEMATEL [12] and VIKOR [14] It is among the methods used in solving decision problems that arise in the field of symbiosis. These and similar decision-making problems may arise at every stage of the process, and multi-criteria decision-making methods that allow mathematical and logical analysis can be used to solve these problems. When it is not possible to obtain clear information when using MCDM methods, fuzzy MCDM techniques can be used. In this field, the Pythagorean fuzzy AHP method is widely used in the literature. In studies on sustainability such as industrial symbiosis, the PF-AHP method has been used to weight criteria in solving sustainable supply chain [15], waste recycling in the circular economy[16] and circular supply chain [17] problems.

In the studies on the dynamic process of the industrial symbiosis network, there are analyzes for the creation of symbiotic relationships after the symbiosis network is established. According to Teh et al. [14] evaluates alternative symbiosis network configurations in the reuse of a product. The aim is to determine the symbiosis network model that will provide the highest benefit from the waste product. Configurations were evaluated with a multi-criteria decision-making model for decision makers. There are studies that offer solutions with a hybrid approach in the solution of decision problems that arise in the field of industrial symbiosis. Leong et al. [18] presents a multi-objective optimization approach to rank the preferences of each plant participating in the symbiosis network according to predefined criteria. An integrated AHP (IAHP) approach to establishing the optimum resource network in an EIP is presented in the study. The design criteria considered in the study include economic performance, environmental impact, connectivity and network reliability. Afshari et al. [19] presents a mixed integer linear programming (MILP) model that takes sustainability into account in the optimal design of an energy symbiosis network that also takes into account the fluctuation in energy demand in different seasons. Using a case study, the model was applied to a real-life situation. The results show that economic and environmental goals support a similar energy exchange network. However, social value preference promotes more symbiotic connections, which, as the results suggest, does not reduce the economic and environmental impact of the symbiotic network. For businesses operating with an industrial symbiosis network, there are also studies in the literature for production planning, taking into account the relationships in the symbiosis network. In Suzanne [20], we introduce a new production planning problem that arises between two production units in an industrial system. In the production process of a main product, a production residue arises in the initial production process. These residues are then used as raw materials or disposed of in the second production process. In secondary production, raw materials can also be purchased from an external supplier. The resulting unified production planning problem was expressed as a two-level one-piece lot size problem and the problem was proven to be an N-P hard problem. It is stated that the results of the study can be used to discuss the managerial implications of establishing an industrial symbiosis with suppliers. The literature summarized above shows that implementing industrial symbiosis has several challenges and how difficult it is to establish a symbiosis network [11]. Based on this, this study deals with a decision process problem aimed at facilitating the establishment of the industrial symbiosis network.

3 Methods

PF-AHP and PF-TOPSIS methods are used to solve the problem discussed in the study. These methods are applied on a fuzzy basis in order to take into account the uncertainties regarding the processes. The information about the Pythagorean fuzzy AHP and Pythagorean fuzzy TOPSIS used in the study is summarized in the next section.

The studies of Bellman and Zadeh [21] pioneered the introduction of fuzzy sets into the literature in multi-criteria decision-making methods. Fuzzy sets have advantages for the decision-maker. Fuzzy sets are considered when expert opinions cannot be clearly expressed numerically. At the same time, in case of uncertainty, it transforms the situation in which the variables are expressed linguistically into numerical values. While clear sets consider full members or non-members, fuzzy sets provide more realistic results as they also allow partial memberships [22]. The basic assumption in strict or classical set theory is that a definite limit determines the inclusion of an element in any set. If a number m is included in the set P, its membership value is expressed as 1; otherwise, if the number is not included in the set, the membership function is expressed as 0. The classical cluster membership function of the set P is shown by Eq. 1 [23].

In the fuzzy set theory developed by Zadeh [24], the m membership function, an element of the fuzzy set P in a universal domain set X, can take values between 0 and 1. The membership function is defined as \(\mu_{P} \left( x \right)\).. The values that x can take are shown in Eq. 2 [25].

Intuitionistic fuzzy set theory was presented by Atanassov [26] by expanding fuzzy set theory to provide an easier approach to expressing uncertainty. Unlike fuzzy sets, it defines the degree of membership of the element X as well as the degree of non-membership. In intuitive fuzzy set theory, membership and non-membership degrees take values in the range of [0,1]. Apart from these two parameters, he also defined a hesitation degree parameter. The intuitive fuzzy set P is defined in Eq. 3 [27].

\(x\). The degree to which element x belongs to the intuitive fuzzy set P is represented by \(\mu_{P} \left( x \right)\)., and the degree to which it does not belong to the intuitive fuzzy set P is represented by \(v_{P} \left( x \right)\). The sum of the degree of belonging and the degree of not belonging is equal to or less than 0 and 1 (Eq. 4).

When the process \(\mu_{P} \left( x \right) + v_{P} \left( x \right)\) is differentiated by 1, the value of the hesitation degree \(\pi_{P}\) parameter defined in intuitive fuzzy sets is obtained with Eq. 5 and Eq. 6.

Pythagorean fuzzy numbers, developed by Yager [28], were developed as a generalization to intuitive fuzzy sets that sometimes cannot cope with uncertainty. Pythagorean fuzzy sets are a more robust and flexible tool for solving uncertainty problems. Decision-makers can use these sets to express what they cnot express with intuitive fuzzy sets. Pythagorean fuzzy sets are more suitable for decision-makers in complex decision-making situations [29]. Fuzzy sets (FS) are widely used in the literature to model uncertain situations in MCDM problems [30, 31]. FS can express uncertainty in three different ways, such as membership, non-membership and hesitation function. However, in some cases where the membership degree and non-membership function are greater than one, Pythagorean Fuzzy Sets (PFS) are used to model uncertainty [17, 32]. PFS offers a wider range of definitions for membership degrees in evaluating decision makers. For this reason, it offers much stronger uncertainty modeling.

compared to other fuzzy sets [33]. PFS allows decision makers to express opinions that cannot be expressed in absolute values (numerical values). Therefore, PFS is preferred for analyzing practical decision-making problems [33, 34].

4 Pythagorean fuzzy AHP

The AHP technique was developed by Saaty in 1980 and is widely used in the literature [35]. It is among the most frequently used MCDM approaches in analyzing hierarchical and complex decision scenarios. AHP is an effective technique for dealing with difficult decision-making situations such as subjective judgments [36]. While the AHP method can be used in the most fundamental decision problems we may encounter in our daily lives, it is also applied in situations with complex difficulties in technical, operational, and strategic decision-making processes in many fields such as industry, education [37], health and military [38,39,40]. AHP is the most frequently used decision-making method to calculate criteria weight for multi-criteria decision-making situations. The AHP method was preferred for solution due to its algorithmic calculation ease and the hierarchical structure of the problem. In the problem addressed, firstly the weights of the criteria that are effective in evaluating the alternatives were calculated, and then the alternatives were listed. Therefore, the problem has a hierarchical structure. However, in the PF-AHP method, a broader definition set is presented for experts to evaluate the criteria. Membership functions are broader than other clusters. This advantage allows decision makers to make evaluations more easily and contributes to more precise results. In this section, we give the basic operations and steps of the Pythagorean fuzzy AHP method [15, 41]. The steps of the Pythagorean fuzzy AHP method are given in below.

Step 1: Creation of the pairwise comparison matrix (R) according to expert evaluations using the Pythagorean Fuzzy linguistic pairwise comparison scale in Table 1. \(R = \left( {r_{ij} } \right)_{m*m}\) according to the experts’ opinions. \(r_{ij}\) refers to the linguistic value of column j element in row i in the comparison matrix.

Step 2: Calculate the difference matrix \(D = \left( {d_{ij} } \right)_{m*m}\) between the lower \(\left( {d_{ijL} } \right)\) and upper \(\left( {d_{ijU} } \right)\) values of the membership and non-membership functions. Use Eqs. 7 and 8. In Eqs. 7 and 8, \(\mu_{ijL}\) is the lower limit of the membership function, \(\mu_{ijU}\) is the upper limit of the membership function, \(\upsilon_{ijL}\) is the lower limit of the non-membership function, and \(\upsilon_{ijU}\) is the upper limit of the non-membership function.

Step 3: Find the interval multiplicative matrix \(S = \left( {S_{ij} } \right)_{m*m}\) using Eq. 9 and Eq. 10. \(S_{ijL}\) and \(S_{ijU}\) is the lower and upper bound of the interval multiplicative matrix, respectively. Calculated by Eq. 9 and Eq. 10.

Step 4: Calculate the determinacy value \(\tau = \left( {\tau_{ij} } \right)_{m*m}\) using Eq. 11.

Step 5: Determine the matrix of weights. \(T = \left( {t_{ij} } \right)_{m*m}\) before normalization by multiplying the determinacy degrees with \(S = \left( {S_{ij} } \right)_{m*m}\) with matrix using Eq. 12.

Step 6: Calculate the normalized priority weights.

\(w_{i}\) using Eq. 13.

4.1 Pythagorean fuzzy TOPSIS

PFS is among the widely used fuzzy sets for solving MCDM problems under uncertainty. The classical TOPSIS approach has been extended for PFSs and named the Pythagorean fuzzy TOPSIS (PFTOPSIS) method (Rani et al., 2020). PF-TOPSIS is an MCDM technique based on choosing the solution with the shortest distance from the positive ideal solution and the longest distance from the negative ideal solution using Pythagorean fuzzy sets [42]. The algorithmic steps of the PF-TOPSIS, which consists of 5 steps, is shown in below [43].

Step 1: The Pythagorean fuzzy number-based in Table 2 decision matrix \(R = \left( {C_{j} \left( {x_{i} } \right)} \right)_{m*n}\) is constructed. Here \(C_{j} \left( {j = 1,2, \ldots , n} \right)\) and \(x_{i} \left( {i = 1,2, \ldots , m} \right)\) refer to the values of criteria and alternatives, respectively. The matrix form is as follows:

The linguistic expressions in Table 2 are used in the creation of the decision matrix.

Step 2: Positive ideal solution (\(x^{ + }\)) and negative ideal solutions (\(x^{ - }\)) are determined using Eqs. 15 and Eq. 16 as follows: \(\mu_{i}^{ + }\) and \(\upsilon_{i}^{ + }\) refer to the relevant µ and υ elements that have the maximum value of each criteria among all alternatives in the decision matrix.\( \mu_{i}^{ - }\) and \(\upsilon_{i}^{ - }\). refer to the relevant µ and υ elements that have the minimum value of each criteria among all alternatives in the decision matrix.

Step 3: Distances from Pythagorean fuzzy Positive Ideal Solutions \(D\left( {x_{i,} x^{ + } } \right)\) and Negative Ideal Solutions \( D\left( {x_{i,} x^{ - } } \right)\) are determined using Eqs. 17 and Eq. 18 as follows.

In general, the smaller \(D\left( {x_{i,} x^{ + } } \right)\). the better the alternative \(x_{i}\). and the bigger \(D\left( {x_{i,} x^{ - } } \right)\). the better the alternative \(x_{i} \). and let \(D_{\min } \left( {x_{i} ,x^{ + } } \right) = \min_{1 \le i \le m} D\left( {x_{i,} x^{ + } } \right)\) and \(D_{\max } \left( {x_{i} ,x^{ - } } \right) = \max_{1 \le i \le m} D\left( {x_{i,} x^{ - } } \right)\).

Step 4: In the fourth step \(\delta \left( {x_{i} } \right)\) the revised closeness of the alternative \(x_{i}\) is computed using Eq. 19 as follows:

Step 5: Finally, the best-ranking order of the alternatives is determined. The alternative with the highest revised coefficient value is the best alternative.

5 Problem statement

The problem addressed in the study is a decision problem related to evaluating the wastes generated in the casting sector enterprises that continue the production process actively in an industrial park in Ankara, Turkey, by establishing an industrial symbiosis network. Industrial park managers aim to establish a sustainable relationship to recycle the waste of enterprises operating in the foundry sector. In order to achieve this goal, the target of identifying alternative production facilities that can receive waste and prioritizing these facilities is defined as an essential decision step. In this process, the sectors that can receive the wastes of the casting industry and the businesses operating in these sectors have been determined. As a result, it has been determined that the wastes generated in the casting industry can be used in various sectors such as ceramic (Shi et al. 2008), cement (Başar ve Aksoy 2012), glass (Uysal ve Bahar 2018) chemical products and asphalt production. Furthermore, businesses operating in these sectors have been identified. The explanations and application results within the framework of the determined alternatives and criteria are summarized in the following sections.

6 Research methodology

The research methodology followed to solve the problem addressed in the study is presented in Fig. 1. We can summarize the research methodology in four stages. The first stage is about determining the criteria and alternatives that affect the decision problem and calculating the importance levels of the criteria. In this process, firstly, the criteria and alternatives that affect the decision are determined with the help of experts. Then, a comparison matrix with PF linguistic variables is established to evaluate the criteria. Subsequently, the importance levels of the criteria are calculated by following the steps in Sect. 3.1. In the second stage, steps are followed to rank the alternatives. First, linguistic evaluations of experts regarding the alternatives are taken. Then, linguistic assessments are used to create a decision matrix with Pythagorean fuzzy numbers. In the third stage, to obtain the final rankings of the alternatives, the PF-TOPSIS steps presented in Sect. 3.2 are applied respectively to obtain the closeness of the alternatives to the optimal solution. In this way, the ranking of the alternatives is calculated. In the fourth and final step of the research methodology, steps regarding sensitivity analysis are carried out. To compare the alternatives, the sensitivity of the results is analyzed with scenarios created by different criteria weights. Thus, the problem is solved with a holistic approach.

6.1 Determining of criteria and alternatives

The criteria affecting the installation of industrial symbiosis networks were determined in the light of the studies in the literature and expert opinions. In this process, the opinions of four experts were considered. Group decision-making techniques took expert opinions. A common opinion determined evaluations of each expert regarding the criteria. Information about the experts is summarized in Table 3.

The criteria determined from expert opinion and literature research were classified as main groups and subgroups. In the study, 13 sub-criteria were determined under four main criteria. The characteristics of the enterprises that will participate in the industrial symbiosis network are in the main group of organizational factors. Factors related to the waste that will be subject to change in the symbiosis network are in the main group of waste factors. The economic benefits of the symbiosis network are considered in the main group of economic factors, and the environmental benefits are in the main group of environmental factors. The explanations regarding the sub-criteria are summarized in Table 4.

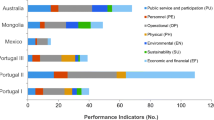

Alternative businesses were identified behind the determination of the criteria. Here, the sectors where the wastes generated in the casting sector can be used have been identified. At this point, expert opinions and literature studies were used. There are 260 enterprises from 30 different sectors in the industrial park where the application is made. Among these enterprises, 42 enterprises were determined as alternatives. Information on the sectors of the alternatives is presented in Table 5. The enterprises under the other column include enterprises in sectors such as iron and steel, which provide input to the foundry sector and can reuse the wastes in this sector.

7 Results and discussion

The numerical results of the study and the discussions on the results will be summarized under this title.

7.1 PF-AHP results

Comparison matrices were created by experts to calculate the alternatives with the PF-AHP method. The linguistic expressions in Table 1 were used in the creation of the comparison matrix. Comparison matrices created are given in Table 6.

The weights of the criteria were calculated by applying the PF-AHP steps summarized in Sect. 3.2. After calculating the weights of the main criteria, local weights were calculated for each sub-criteria group. In the main criteria, the weight of organizational factors is 21.10%, the weight of waste factors is 19.78%, the weight of economic factors is 38.03% and the weight of environmental factors is 21.10%. Global weights were obtained by multiplying the local weights with the weights of the main criteria. The calculated global criteria weights are summarized in Fig. 2.

According to the results, it has been determined that the most influential criteria in establishing a symbiotic relationship with each other is the financial benefit criteria, with a 16% importance level. This criteria is followed by the transportation costs criteria with a 14% significance level. These two criteria are close to each other in terms of importance, and both contain economic elements. Although businesses desire all the benefits of symbiosis networks, economic benefits have come to the fore compared to other criteria. This situation is also meaningful in the real sector. Since the primary purpose of establishing enterprises is to make a profit, they cannot be expected to be involved in activities and processes that do not have economic benefits.

On the other hand, the level of energy consumption and gas emissions, which are sub-criteria of environmental factors, and the level of importance of reliability criteria, which are sub-criteria of organizational factors, are very close. The significance level of these criteria is 10%. Businesses have to take various measures to avoid being exposed to environmental legislation and sanctions determined by public authorities. These measures have to bear various costs, such as waste disposal. For this reason, it attaches importance to the criteria related to environmental factors, taking into account the environmental benefits they will provide with the symbiosis network.

In addition, the enterprises to have cooperated must carry and use these wastes by environmental legislation. Otherwise, the waste receiver and the waste producer company are responsible for legal obligations. For this reason, the trust of enterprises in each other is essential to this relationship. In this context, the 10% significance level of the reliability criteria is a significant result.

The two criteria with the most negligible impact on the selection of the enterprises to which a symbiosis network will be established are the waste turnover rate with a 2% importance level and the production capacity criteria with a 3% importance level. Due to the high number of enterprises, the importance level of these two criteria could be higher. The waste generation potential of the foundry industry is relatively high. For this reason, the waste turnover rate of enterprises is relatively high. Although it is essential for the sustainability of the symbiosis network, it has low importance.

7.2 PF-TOPSIS results

The priority values of the alternatives were calculated by applying the PF-TOPSIS steps summarized in Sect. 3.3. The data matrix created for the calculations is given in Table 7.

The ranking of the alternatives according to the calculated priorities is summarized in Table 8. The first column of the table contains alternatives. It expresses the positive distance of the second alternatives from the optimal solution. The third column shows the negative distance to the optimal solution and the fourth column shows the final closeness to the optimal solution. In the last column, there is the ranking of the alternatives. In the table, \(D\left({x}_{i,}{x}^{+}\right)\) shows the positive distance, \(D\left({x}_{i,}{x}^{-}\right)\) shows the negative distance.

According to the PF-TOPSIS results, businesses operating in the cement sector were determined as the first alternative. These enterprises are the enterprises that have emerged in the foundry sector, incredibly demanding foundry sand. Foundry sand is the most common waste in the foundry industry in terms of quantity. It is also an essential input of the cement industry. As the third alternative, asphalt operation was determined. Iron slag, which emerges in the casting sector in asphalt production, is used as an input. Since these alternatives can receive high amounts of waste from the casting industry, they have significant gains in input costs. That is why it comes to the fore in the ranking. In addition to these alternatives, companies from the construction, ceramics, chemical, steel, and plastics industries are among the top 10 in the ranking. It is seen that the economic benefits of waste exchanges with these enterprises are high, the costs are low, and the reliability factors are high. Sensitivity was also made for the consistency of the results obtained in the study. The explanations and results of the sensitivity analysis are summarized in the next section.

8 Sensitivity analysis

Sensitivity analysis shows the changes in the priority and ranking of the alternatives when the weight of each criteria changes [6, 45]. Sensitivity analysis in multi-criteria decision-making methods is done differently in the literature. Among these are various applications, such as increasing or decreasing the weights of the criteria at a certain level, keeping the weight of one criteria constant, and changing the others [46]. This study performed a sensitivity analysis with a comprehensive combination of sensitivity analysis. While creating the combination, the actual criteria weights we obtained were used. In addition, a binary combination was created such that the weights of these criteria were replaced with each criteria in turn. The combinations created are summarized in Table 9.

The sensitivity of alternatives to changes in criteria weights was analyzed by creating 78 scenarios. The scenarios obtained by binary combinations of 13 criteria are summarized in Table 10. In Table 10, row S0 represents the criteria weights obtained in the study. The rows between S1 and S78 are the rows containing change scenarios. In these rows, 78 combinations were created by interchanging the criteria weights highlighted in bold font. According to the analysis results, the F3 alternative kept its ranking as the first alternative in all scenarios. Likewise, the F4 alternative was determined as the second alternative in all scenarios. The third alternative, F7, was replaced by the fourth alternative in four scenarios. It maintained its ranking in all other scenarios. The last-ranked F32 alternative was determined to be 38, the best rank in all scenarios. In general, the F32 alternative is ranked as the 42nd alternative. The companies in the top 10 in the ranking are summarized in Table 10. In the sensitivity analysis, it is seen that the companies in the top 10 in the ranking generally maintain their place in the top 10 in their scenarios.

In addition to the fact that the alternatives in the first place maintain their place in the ranking, it is seen that there is a change in the rankings in the scenarios where the weights of the criteria change significantly. When we examine the results on the graph in Fig. 3, the scenario with the highest complexity is the scenario groups between S50-S56 and S66-S76. In these scenarios, it is seen that there are significant changes in the ranking of many alternatives. The reason for this fluctuation emerges when the criteria weight change in these scenarios is examined. For example, in the S50 scenario, the C2.1 and C4.2 criteria have been replaced. The weights of these displaced criteria are 0.10 and 0.045, respectively. Hence C2.1. The weight of the criteria increased by more than 100%.

On the other hand, C4.2. The criteria has decreased by more than 50%. Therefore, when the change is significant, the order of the alternatives also changes. As a result, sensitivity analysis determines which criteria will affect the results with which weights.

In the study, a process related to solving a decision problem that arose during the establishment of the industrial symbiosis network was analyzed with decision analysis methods. Industrial symbiosis networks are similar in structure to logistics supply networks. As the basic assumption of the symbiosis approach, there is a cyclicality in the process, unlike the classical supply chain. Within the circular supply chain, businesses exchange waste materials in a closed-loop system. More than one problem may arise here. There may be both decision problems and problems regarding actors' actions within the system. In this study, the process of a decision problem was analyzed with decision-making methods. Actors are collaborating in this closed-loop system. Various approaches [47, 48], such as the adaptive reinforcement learning (ARL) approach, can monitor these actors and optimize the system.[47,48,49].

9 Comparison study

In order to compare the results of the approach proposed in the study, a comparative analysis was carried out between the results of an existing method with a similar algorithmic structure used in the literature. A fuzzy COPRAS approach to indicate consistency of results was applied for the same decision-making problem. COPRAS is the analytical MCDM technique for alternative rankings by Zavadskas et al. [50]. Fuzzy COPRAS method is used in sorting problems by developing applications of the COPRAS method with fuzzy sets to select alternatives [51]. Zarbakhshnia et al. [51] the solution to the problem was obtained by applying the steps of the F-COPRAS method outlined in the study, respectively. In the COPRAS technique, the types of criteria should be determined in terms of cost and benefit, and algorithm steps should be applied accordingly. In the study, criteria C21, C22, C31, C41, and C42 are cost-type criteria, and the rest are benefit type. The decision matrix regarding the problem's solution in Table 10 expresses the linguistic evaluations regarding the COPRAS method. Pairwise comparison matrix of the Fuzzy COPRAS method are presented in Table 11.

The comparison results with the proposed method are summarized in Table 12. According to Table 12, the F-COPRAS ranking of alternatives to establish a symbiosis network is highly consistent with the existing PF-TOPSIS model obtained with the proposed methodology. The F3 alternative was chosen as the first alternative in both methods. On the other hand, the F32 alternative ranked 42nd in the PF-TOPSIS method and 41st in the F-COPRAS method. Apart from these, some alternatives, such as F8 and F9, moved up one place in the F-COPRAS method, while the F7 alternative went down one place. Therefore, the results obtained are significantly consistent. In particular, there is no significant change in the rankings of the alternatives in the first and last rankings. These results show the consistency of the results.

10 Conclusion

In this study, we propose a decision analysis process in which alternatives are evaluated in order to reintroduce the wastes generated in the foundry industry by establishing an industrial symbiosis network. We offer a framework that considers the real sector realities for evaluating alternatives for establishing an industrial symbiosis network. In the study, different alternatives that are independent of each other and have the potential to establish cooperation are evaluated in terms of reintroducing the wastes generated in the casting industry.

In other words, alternatives that will establish a symbiotic relationship to sell the wastes of the enterprises operating in the casting sector are evaluated. Compared to the literature, where studies focus on a limited number of criteria, such as the environment and economy, this study creates a holistic framework in which some heterogeneous criteria are considered. Therefore, the multi-criteria combined with the multi-expert approach within the AHP helps to identify the importance of different criteria from the point of view of experts such as waste management specialists, academic staff, and environmental science. In this process, the importance level of the criteria was calculated with the PF-AHP method by applying a fuzzy-based approach for uncertain situations where the experts did not have detailed information. As a result, it is seen that economic factors come to the forefront with a 16% importance level in the selection of enterprises to establish a symbiosis network. On the other hand, transportation costs, which express the transportation costs of wastes, appear as the second criteria with 14% importance.

According to the results obtained with the PF-TOPSIS method in the evaluation of the alternatives, it has been determined that the enterprises operating in sectors such as cement, construction, asphalt, chemicals, and plastics are in the first place in establishing an industrial symbiosis network with the enterprises in the casting sector. The first and second alternatives are businesses operating in the cement sector. Therefore, the symbiosis network established with the enterprises in these sectors will provide more economic benefits, these alternative enterprises with high waste exchange potential have an organizationally reliable indicator, and the environmental impact will decrease with the symbiosis network to be established.

In order to test the sensitivity of the results, a sensitivity analysis consisting of 78 scenarios was performed, and the sensitivity of the alternatives to the criteria weights was analyzed. According to the results obtained, there was no significant change in the rankings of the alternatives, as the criteria weights did not create extreme changes. This demonstrates the robustness of the proposed approach. This proposed approach can be applied to similar decision processes in symbiosis networks. The decision process is a proposition that can help other stakeholders, as the criteria identified focus on general industrial symbiosis characteristics.

In future studies in this field, studies can be carried out to plan the product quantities and which business will send products to which business during the changing process of the problem. Material exchange between businesses can be calculated by establishing a mathematical model. Also, given the current economic instability in subsequent studies, a critical dimension is the increasing inflation rate. Therefore, possible solutions may also include a sensitivity analysis considering this factor. Another factor that may affect the results is the evolving trend of some criteria. For example, different environmental regulations worldwide demand harmonization in many countries soon. In addition, the technology available in each region is greatly affected by rapid technological developments, and therefore technological elements can be considered in further studies.

During the research process, difficulties were experienced in identifying alternative enterprises, and these difficulties were tried to be overcome with the data obtained from industrial park managers. At the same time, access to any financing was not provided for the study. The study was evaluated as specific to the casting industry, so the evaluations are limited to the casting industry.

Data availability

Data will be made available on request.

References

Quijorna N, Coz A, Andres A, Cheeseman C (2012) Recycling of Waelz slag and waste foundry sand in red clay bricks. Resour Conserv Recycl 65:1–10. https://doi.org/10.1016/J.RESCONREC.2012.05.004

Gürkan E, Çoruh S (2017) Atık Döküm Kumu İle Katyonik Boyarmaddelerin Adsorpsiyon Çalışmaları; Cationic Dyes Adsorption Onto Waste Foundry Sand: Equilibrium And Kinetics Studies. Celal Bayar Üniversitesi Fen Bilim Derg. https://doi.org/10.18466/cbayarfbe.319947

Yazıcı E, Alakaş HM, Eren T (2023) Prioritizing of sectors for establishing a sustainable industrial symbiosis network with Pythagorean fuzzy AHP- Pythagorean fuzzy TOPSIS method: a case of industrial park in Ankara. Environ Sci Pollut Res In Press.: https://doi.org/10.1007/S11356-023-27882-6

Watkins G, Husgafvel R, Pajunen N et al (2013) Overcoming institutional barriers in the development of novel process industry residue based symbiosis products—Case study at the EU level. Miner Eng 41:31–40. https://doi.org/10.1016/j.mineng.2012.10.003

Cravioto J, Yamasue E, Nguyen DQ, Huy TD (2021) Benefits of a regional co-processing scheme: The case of steel/iron and cement industries in Vietnam, Laos, and Cambodia. J Clean Prod 312:. https://doi.org/10.1016/j.jclepro.2021.127702

Falsafi M, Terkaj W, Guzzon M, et al (2023) Assessment of valorisation opportunities for secondary metallurgy slag through multi-criteria decision making. J Clean Prod 402:. https://doi.org/10.1016/j.jclepro.2023.136838

Yazıcı E, Alakaş HM, Eren T (2022) Analysis of operations research methods for decision problems in the industrial symbiosis: a literature review. Environ Sci Pollut Res Int. https://doi.org/10.1007/S11356-022-22507-W

Agudo FL, Bezerra BS, Paes LAB, GobboJúnior JA (2022) Proposal of an assessment tool to diagnose industrial symbiosis readiness. Sustain Prod Consum 30:916–929. https://doi.org/10.1016/J.SPC.2022.01.013

Sonel E, Gür Ş, Eren T (2022) Analysis of factors affecting industrial symbiosis collaboration. Environ Sci Pollut Res 29:8479–8486. https://doi.org/10.1007/S11356-021-16213-2

Alakaş HM, Gür Ş, Özcan E, Eren T (2020) Ranking of sustainability criteria for industrial symbiosis applications based on ANP. J Environ Eng Landsc Manag 28:192–201. https://doi.org/10.3846/jeelm.2020.13689

Taqi HMM, Meem EJ, Bhattacharjee P et al (2022) What are the challenges that make the journey towards industrial symbiosis complicated? J Clean Prod 370:133384. https://doi.org/10.1016/J.JCLEPRO.2022.133384

Bacudio LR, Benjamin MFD, Eusebio RCP et al (2016) Analyzing barriers to implementing industrial symbiosis networks using DEMATEL. Sustain Prod Consum 7:57–65. https://doi.org/10.1016/j.spc.2016.03.001

Vimal KEK, K J, Ameen T, et al (2020) An investigation on the impact of industrial symbiosis implementation on organizational performance using analytical hierarchical approach. Benchmarking 27:886–911. https://doi.org/10.1108/BIJ-12-2018-0423/FULL/XML

Teh KC, Lim SC, Andiappan V, Chew IML (2021) Evaluation of Palm Oil Eco-Industrial Park Configurations: VIKOR with Stability Analysis. Process Integr Optim Sustain 5:303–316. https://doi.org/10.1007/s41660-021-00168-5/Published

Shete PC, Ansari ZN, Kant R (2020) A Pythagorean fuzzy AHP approach and its application to evaluate the enablers of sustainable supply chain innovation. Sustain Prod Consum 23:77–93. https://doi.org/10.1016/J.SPC.2020.05.001

Yıldızbaşı A, Öztürk C, Yılmaz İ, Arıöz Y (2022) Key Challenges of Lithium-Ion Battery Recycling Process in Circular Economy Environment: Pythagorean Fuzzy AHP Approach. Lect Notes Networks Syst 308:561–568. https://doi.org/10.1007/978-3-030-85577-2_66/COVER

Lahane S, Kant R (2021) A hybrid Pythagorean fuzzy AHP—CoCoSo framework to rank the performance outcomes of circular supply chain due to adoption of its enablers. Waste Manag 130:48–60. https://doi.org/10.1016/j.wasman.2021.05.013

Leong YT, Lee JY, Tan RR et al (2017) Multi-objective optimization for resource network synthesis in eco-industrial parks using an integrated analytic hierarchy process. J Clean Prod 143:1268–1283. https://doi.org/10.1016/j.jclepro.2016.11.147

Afshari H, Tosarkani BM, Jaber MY, Searcy C (2020) The effect of environmental and social value objectives on optimal design in industrial energy symbiosis: A multi-objective approach. Resour Conserv Recycl 158:. https://doi.org/10.1016/j.resconrec.2020.104825

Suzanne E, Absi N, Borodin V, van den Heuvel W (2020) A single-item lot-sizing problem with a by-product and inventory capacities. Eur J Oper Res 287:844–855. https://doi.org/10.1016/J.EJOR.2020.05.017

Bellman RE, Zadeh LA (1970) Decision-Making in a Fuzzy Environment. Manage Sci 17:141–164

Fouladgar MM, Yazdani-Chamzini A, Lashgari A et al (2012) Maintanance Strategy Selection Using AHP and COPRAS under Fuzzy Environment. Int J Strateg Prop Manag 16:85–104. https://doi.org/10.3846/1648715X.2012.666657

Alkan N (2019) Sectoral Prioritization Analysis of Industry 4.0 in the Lean Supply Chain by using A Fuzzy Multi Criteria Decision Making Approach. Yıldız Technical University

Zadeh LA (1965) Fuzzy sets. Inf. Control 8:338–353. https://doi.org/10.1016/S0019-9958(65)90241-X

Gürsoy Z (2016) Türkiye’de Yaşayan Bireylerin Yaşam Memnuniyeti Düzeylerinin Bulanık Çok Kriterli Karar Verme Yöntemleriyle Belirlenmesş

Atanassov KT (1986) Intuitionistic fuzzy sets. Fuzzy Sets Syst 20:87–96

Yildirim BF (2019) Kredi Kartı Platformlarının Sezgisel Bulanık TOPSIS Yöntemi Kullanılarak Değerlendirilmesi. BDDK Bankacılık ve Finans Piyas 13:37–58

Yager RR (2014) Pythagorean membership grades in multicriteria decision making. IEEE Trans Fuzzy Syst 22:958–965. https://doi.org/10.1109/TFUZZ.2013.2278989

Mohd R, Abdullah L (2017) Pythagorean fuzzy analytic hierarchy process to multi-criteria decision making. In: AIP Conference Proceeding 1905

Abdullah L, Goh P (2019) Decision making method based on Pythagorean fuzzy sets and its application to solid waste management. Complex Intell Syst 5:185–198. https://doi.org/10.1007/S40747-019-0100-9/TABLES/16

Lahane S, Kant R (2021) Evaluating the circular supply chain implementation barriers using Pythagorean fuzzy AHP-DEMATEL approach. Clean Logist Supply Chain 2:100014. https://doi.org/10.1016/j.clscn.2021.100014

Mohagheghi V, Mousavi SM, Vahdani B (2017) Enhancing decision-making flexibility by introducing a new last aggregation evaluating approach based on multi-criteria group decision making and Pythagorean fuzzy sets. Appl Soft Comput J 61:527–535. https://doi.org/10.1016/J.ASOC.2017.08.003

Zhang X, Xu Z (2014) Extension of TOPSIS to Multiple Criteria Decision Making with Pythagorean Fuzzy Sets. Int J Intell Syst 29:1061–1078. https://doi.org/10.1002/INT.21676

Yucesan M, Kahraman G (2019) Risk evaluation and prevention in hydropower plant operations: A model based on Pythagorean fuzzy AHP. Energy Policy 126:343–351. https://doi.org/10.1016/j.enpol.2018.11.039

Saaty TL (1988) What is the Analytic Hierarchy Process? Math Model Decis Support NATO ASI Ser (Series F Comput Syst Sci 48:109–121. https://doi.org/10.1007/978-3-642-83555-1_5

Lin HF (2010) An application of fuzzy AHP for evaluating course website quality. Comput Educ 54:877–888. https://doi.org/10.1016/J.COMPEDU.2009.09.017

Çiftçi S, Pınarbaşı M, Yazıcı E, Alakaş HM (2023) Evaluation of the companies for applied education under fuzzy environment: a case in an industrial university. Neural Comput Appl 35:21675–21695. https://doi.org/10.1007/s00521-023-08926-x

Hezam IM, Nayeem MK, Foul A, Alrasheedi AF (2021) COVID-19 Vaccine: A neutrosophic MCDM approach for determining the priority groups. Results Phys 20:103654. https://doi.org/10.1016/j.rinp.2020.103654

Ayouni S, Menzli LJ, Hajjej F, Maddeh M (2019) A Hybrid Fuzzy DEMATEL-AHP/VIKOR Method for LMS Selection. Proceeding of the 18th European Conference on e-Learning. Denmark, Copenhagen, pp 47–58

Lahane S, Kant R (2021) Evaluation and ranking of solutions to mitigate circular supply chain risks. Sustain Prod Consum 27:753–773. https://doi.org/10.1016/J.SPC.2021.01.034

Ilbahar E, Karaşan A, Cebi S, Kahraman C (2018) A novel approach to risk assessment for occupational health and safety using Pythagorean fuzzy AHP & fuzzy inference system. Saf Sci 103:124–136. https://doi.org/10.1016/j.ssci.2017.10.025

Hajiaghaei-Keshteli M, Cenk Z, Erdebilli B et al (2023) Pythagorean Fuzzy TOPSIS Method for Green Supplier Selection in the Food Industry. Expert Syst Appl 224:120036. https://doi.org/10.1016/J.ESWA.2023.120036

Yucesan M, Gul M (2020) Hospital service quality evaluation: an integrated model based on Pythagorean fuzzy AHP and fuzzy TOPSIS. Soft Comput 24:3237–3255. https://doi.org/10.1007/s00500-019-04084-2

Oz NE, Mete S, Serin F, Gul M (2018) Risk assessment for clearing and grading process of a natural gas pipeline project: An extended TOPSIS model with Pythagorean fuzzy sets for prioritizing hazards. Hum Ecol Risk Assess An Int J 25:1615–1632. https://doi.org/10.1080/10807039.2018.1495057

Kabassi K, Martinis A (2021) Sensitivity Analysis of PROMETHEE II for the Evaluation of Environmental Websites. Appl Sci 2021, Vol 11, Page 9215 11:9215. https://doi.org/10.3390/APP11199215

Yazıcı E, Üner Sİ, Demir A et al (2022) Evaluation of supply sustainability of vaccine alternatives with multi-criteria decision-making methods. Int J Health Plann Manage 37:2421–2444. https://doi.org/10.1002/HPM.3481

Vu VT, Pham TL, Dao PN (2022) Disturbance observer-based adaptive reinforcement learning for perturbed uncertain surface vessels. ISA Trans 130:277–292. https://doi.org/10.1016/j.isatra.2022.03.027

Dao PN, Liu Y-C (2022). Adaptive reinforcement learning in control design for cooperating manipulator systems. https://doi.org/10.1002/asjc.2830

Chen L, Dai SL, Dong C (2022) Adaptive Optimal Tracking Control of an Underactuated Surface Vessel Using Actor-Critic Reinforcement Learning. IEEE Trans Neural Networks Learn Syst. https://doi.org/10.1109/TNNLS.2022.3214681

Zavadskas EK, Kaklauskas A, Sarka V (1994) The new method of multicriteria complex proportional assessmentof projects. Technol Econ Dev Econ 1:131–139

Zarbakhshnia N, Soleimani H, Ghaderi H (2018) Sustainable third-party reverse logistics provider evaluation and selection using fuzzy SWARA and developed fuzzy COPRAS in the presence of risk criteria. Appl Soft Comput 65:307–319. https://doi.org/10.1016/j.asoc.2018.01.023

Acknowledgements

Author EY is a 100/2000 The Council of Higher Education (CoHE) PhD Scholar in Operations Research subdivision.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yazıcı, E., Alakaş, H.M. & Eren, T. Selection of waste receiving companies for sustainable industrial symbiosis network: an application a case in Ankara for foundry industry waste. Neural Comput & Applic 36, 13009–13026 (2024). https://doi.org/10.1007/s00521-024-09683-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-024-09683-1