Abstract

The accuracy of the extracted parameters is important for studying the polyphase induction motor performance and/or the motor control schemes. An investigated and improved interior search algorithm (IISA) is presented in this study for extracting the optimal values of estimated parameters of six-phase and three-phase induction motors. This investigation was carried out on two polyphase induction motors as experimental research cases, utilizing features of manufacturer's operation. The estimated parameters show the high capability regarding the performance of the desired IISA optimizer. The performance of the proposed IISA is compared with different modern optimization algorithms including the basic ISA, and other state-of-the-art approaches. Experimental verifications are validated on two polyphase induction motors, called six-phase and three-phase induction motors. The obtained results show that the proposed method is very competitive in extracting the unknown parameters of different induction motor models with a high degree of closeness to the experimental records. Moreover, various statistical tests, such as the Wilcoxon rank test, stability analysis, and convergence analysis, have been conducted to justify the performance of the proposed IISA. From all the analyses, it has been revealed that the proposed IISA is a competitive method compared to other popular state-of-the-art competitors and ISA variant with accurately identified parameters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Motivation

Polyphase Induction Motors (PPIMs) are the largest, commonly used electrical machines in the industry [1]. These motors account for about 60% of the electrical-to-mechanical energy conversion [2]. For PPIMs to achieve the desired control performance, modeling quality is a critical factor. The large nonlinearity of the PPIM models is a critical issue [3]. Finding the unknown parameters of these machines is thus a difficult challenge. The problem of the PPIMs parameter estimation is described as a non-smooth and nonlinear problem of optimization [3]. The target of this problem is to minimize the deviation of estimated parameters from the actual ones. In this regard, the minimization of the difference between the actual parameters and the estimated ones represents the objective function, keeping these parameters within the permissible boundaries of operation. Many optimization algorithms have been proposed to ensure accurate parameter identification to follow the PPIM models requirements. This paper proposes the IISA as a new variant to find the optimal unknown PPIM parameters in this context.

1.2 Literature review

Modeling of induction motors in ac drive systems is seen to be a significant task. Especially, for PPIMs, the model’s parameters estimation target is to get the unknown variables with accuracy because of operation aspects and control drives [1, 4]. With high degree of accuracy, it is necessary to optimize the induction motors parameters costs effectively. According to IEEE Std 112-1991 IEEE Std 112-2004 [5] the locked rotor and no-load tests are used in to get the parameters of equivalent circuit the traditional methods.

The accuracy of the experimentally based methods estimated parameters is dependent on the accuracy degree of the monitoring, hardware cost and implementation procedures. As a result of these restrictions, various optimization technique providers offer a variety of innovative ways to achieve the goal of estimating parameters to an acceptable level [6]. So, several methods of optimization have been developed to estimate optimally the PPIMs equivalent circuits' parameters [7,8,9].

Several methods for determining the unknown parameters of PPIMs have been used in the literature. Various methods developed to estimate unknown PPIMs parameters have been reviewed in references [6, 10]. Previous initiatives are summarized in this section as follows:

-

Reference [11] proposed the artificial immune system to extract the PPIM parameters for optimization of the IMs parameters from manufacturer data and experimental tests.

-

Reference [12] addressed the Neural-network has been presented in form of training mechanism to find the parameter estimation problem solution.

-

Multi-objective algorithm has been developed in Ref. [13] to minimize the estimated results deviation from manufacturer data.

-

Reference [14] developed the shuffled frog-leaping has been presented to extract the PPIMs equivalent circuit parameters using manufacturer data.

-

Reference [15] estimated the six-phase induction motor parameters using modified standard tests. An improved equivalent circuit has been used to precede a zero-sequence test for improving the estimated parameters accuracy.

-

The particle swarm optimization technique was presented in Ref. [16].

-

A simplified model for PPIMs parameter estimation was proposed in Ref. [17].

-

Reference [18] introduced the shuffled frog-leaping algorithm for extracting the parameters estimation of induction motors using standard manufacturer data.

-

A differential evolution aims at finding the PPIMs parameter estimation has been developed in Ref. [19].

Also, the application of numerous optimization approaches to deal with the parameter estimation issue is demonstrated in the previous review; the field of optimization is both renewable and intriguing. For many real engineering problems, many optimization algorithms have been developed such as: particle swarm optimization (PSO) [20, 21], coyote optimization algorithm [22, 23], moth-flame optimization algorithm [24, 25], wind driven optimization algorithm [26], water cycle optimization algorithm [27], sunflower optimization algorithm [28, 29], fruit fly optimization [30, 31], forensic optimization algorithm for PV parameter estimation [32] and cat swarm optimizer [33]. For synchronous motor design, an intelligent diagnosis approach is proposed [34], for the PID controller parameters adjustment optimization method has been developed in Ref. [35], to assess the improved model of solar cells and generation production cost has been developed in Ref. [36], to solve the optimal power flow problem [37].

The interior search algorithm (ISA) [38] represents a novel inspired optimization method based on the decoration and interior design for global optimization. It introduces based on coupling of different search mechanisms, mirror search and composition optimization. The ISA contains only one tunable parameter with two different strategies are used to adjust it. Several constrained and unconstrained benchmark problems have been solved using this algorithm [38,39,40].

This paper aims at estimating the electrical and mechanical parameters of the PPIMs based on current and speed measurements through developing an improved ISA variant (IISA) through two improvements that are inserted into the original ISA. These two improvements are:

-

The composition group based-crossover strategy with the aim to provide enriched diversity of the solutions.

-

Employing a chaotic concept as a local search around the best solution to refine its quality during the searching process.

The performance of IISA is assessed compared with different modern optimization algorithms, namely genetic algorithm (GA), differential evolution (DE), Jaya algorithm (Jaya), gray wolf optimizer (GWO), sine cosine algorithm (SCA) [41], basic ISA and some state-of-the-art advanced optimization algorithms including chaotic antlion optimization (CALO), chaotic gravitational search algorithm (CGSA), chaotic electromagnetic field optimization algorithm (CEFOA), crossover-based sine cosine algorithm (CBSCA), crossover-based gravitational search (CBGSA), and crossover-based monarch butterfly optimization (CBMBO) for both six- and three-phase induction motors.

1.3 Contribution

The following are the primary characteristics of this paper:

-

The PPIM steady-state model is derived while the IISA is investigated to obtain the PPIM optimal unknown parameters from name plate data.

-

The deviation between the experimental data for the tested PPIMs from the estimated parameters is very small. Then, the capability of the proposed IISA is proved.

-

The performance of IISA is assessed and compared with basic state-of-the-art algorithms, GA, DE, Jaya, GWO, SCA, and ISA and some advanced state-of-the-art algorithms, CALO, CGSA, CEFOA, CBSCA, CBGSA, and CBMBO, for both PPIMs.

-

The assessment study clarifies the fast response of IISA compared with other competitive algorithms for the accurate identified parameters. The results also confirmed the potential robustness of the proposed IISA in comparison to others.

-

In terms of the quality indices, it can be revealed that the IISA is more promising algorithm as the identified parameters by the IISA can more accurately describe the actual characteristics of the induction motor models.

1.4 Organization

The sections that follow are arranged as: In Sect. 2, the mathematical representation of the PPIM steady-state characteristics is presented. In Sect. 3, the problem is designed as an optimization problem that specifies the constraints and objective. The proposed design procedure of IISA is presented in Sect. 4. In Sect. 5, the experimental setup and algorithms results, and discussion are presented. In Sect. 6, the findings are concluded.

2 The polyphase induction motor steady-state model

The steady-state equivalent circuit of the polyphase induction motor (PPIM) is shown in Fig. 1. The per-phase steady-state equivalent circuit of PPIM without mutual inductance separation of the stator winding is presented in [16]. The Thevenin equivalent circuit of PPIM is shown in Fig. 2. The voltage equation of the Thevenin equivalent circuit is computed as:

The Thevenin impedance of PPIM is computed as:

The rotor current of PPIM can be determined as:

The electromechanical torque can be calculated by Eq. (4) as:

The slip \(s_{mT}\) of PPIM at maximum torque can be determined from

the maximum torque at maximum slip can be calculated from:

The torque at starting can be obtained from

The power factor of input current can be calculated from

3 Problem formulation: objective function statement

The problem of parameter estimation is developed as a nonlinear optimization model. The aim of the objective function is to find the smallest deviation between the calculated and the manufacturer's nameplate data, such as the torques (starting, rated, and maximum), and the power factor at full load. The proposed method is constructed to estimate the motor parameters (leakage reactance of rotor and stator parts and resistance, and the magnetizing reactance of the motor's steady-state equivalent circuit). The objective function is calculated as:

The four terms in Eq. (9) are obtained through:

where \(\Delta F\) denoted the required objective function is represented by square error for the power factor of rated input current, starting, full load, and maximum torque, which should be minimized.

4 Optimization methodologies

In the following subsections, the basics of the ISA and the proposed IISA method are described in detail.

4.1 The basics of interior search algorithm (ISA)

ISA presents one of the stochastic optimization algorithms to solve optimization tasks [38]. It was developed based on the decoration and interior design architectures, where two main stages are involved. The first one presents the composition phase, where the composition of elements (i.e., solutions from the optimization viewpoint) is performed to achieve more fantastic and beautiful environment (i.e., best fitness from optimization viewpoint). The second stage represents the mirror search which aims for exploring best sights among the elements and the better one. The main features of the ISA can be described as:

-

(1)

Create a random population of elements within the problem space bounds, upper limit (\(\theta_{UL}\)) and lower limit (\(\theta_{LL}\)), and also report the fitness values regarding all elements.

-

(2)

(2) Record the best element that has been achieved minimum value for the objective function (i.e., for minimization problem). The best element is defined by \(\theta_{gb}^{k}\) for iteration \(k\), where \(gb\) represents the global best.

-

(3)

Randomly divide the population into two groups, namely the mirror group and composition group, through employing a switching parameter (\(\lambda\)). In this context, for the element \(A\), if \(r_{A} \le \lambda\), carryout the mirror or else the composition group is performed. Here \(r_{i}\) defines a random number within 0 and 1, \(i=1,2,\ldots ,PS\).\(PS\) denotes the population size.

-

(4)

For composition group, update their elements by the following rule as follows.

$$\theta_{i}^{k} = \theta_{LL}^{k} + r_{2} \cdot \left( {\theta_{UL}^{k} - \theta_{LL}^{k} } \right),\quad i = 1,2, \ldots ,PS$$(14)where \(\theta_{i}^{k}\) denotes the \(i{\text{th}}\) elements at the \({k}^{th}\) iteration and \(r_{2}\) defines a random number lies within interval [0, 1].

-

(5)

For the mirror group, the \(i{\text{th}}\) element at \(k{\text{th}}\) iteration of the mirror location (\(\theta_{m,i}^{k}\)) can be updated s follows.

$$\theta_{m,i}^{k} = r_{3} .\,\theta_{i}^{k - 1} + (1 - r_{3} ).\,\theta_{gb}^{k}$$(15)where \(r_{3}\) denotes a random number within the interval [0, 1]. In this regard, the virtual location for the candidate element depends on the mirror position, where this scenario can be implemented as follows.

$$\theta_{i}^{k} = 2\theta_{m,i}^{k} - \theta_{i}^{k - 1}$$(16) -

(6)

To enhance and improve the position quality of the global best solution, a random walk phase can be carried out as a local search way to potentially improve the global best position. This phase can be formulated as:

$$\theta_{gb}^{k} = \theta_{gb}^{k - 1} + r_{n} \times \gamma$$(17)where \(r_{n}\) defines a random numbers vector that are distributed normally and \(\gamma\) represents a user defined scaling factor which is taken as \(0.01\left( {\theta_{UL}^{k} - \theta_{LL}^{k} } \right)\).

-

(7)

Calculate the fitness for each element or position and perform the updating respect, if it is revival, where this step be considered as

$$\theta_{i}^{k} = \left\{ {\begin{array}{*{20}c} {\theta_{i}^{k} } & {f(\theta_{i}^{k} ) < f(\theta_{i}^{k - 1} )} \\ {\theta_{i}^{k - 1} } & {else} \\ \end{array} } \right.$$(18) -

(8)

Stop the procedures, if judgment criteria are met, otherwise repeat the procedures with starting from step 2. The pseudocode of the traditional version of ISA is illustrated in Fig. 3.

4.2 Proposed IISA algorithm

The improved ISA (IISA) is introduced based on two improvements, namely the composition group-based crossover strategy with the aim to provide enriched diversity of the solutions, while the second improvement employs a chaotic concept during the searching process as a local search around the best solution to refine its quality. The details behind the IISA are elaborated in the following subsections.

4.2.1 Composition phase using the crossover strategy

Within the composition group the traditional updating strategy of the element or the individual was developed based on random manner along with boundaries of the problem space which may deteriorate the performance behavior and diversity of the algorithm. To overcome these weaknesses, a crossover strategy is developed based on exploiting the experience of elements and thus to improve the diversity and the algorithm performance. Consider two individuals \(\theta_{l}^{k}\) and \(\theta_{r}^{k}\) are selected at random from the population. Consequently, the updating of the current element in terms of the crossover strategy is expressed as follows.

4.2.2 Local search-based chaos concept

The main feature of chaos distribution is contained in the ergodicity and mixing properties that can perform higher speeds in carrying out iterative step search than the standard stochastic search. The local search-based chaos (LSC) concept is introduced to effectively improve the performance and enrich the superiority of the algorithm. The LSC works with different initial points that are coupled with chaos maps to potentially achieve more enhanced ones. The LSC procedure can be established as:

Step 1. Chaos quantities In this step, a set of chaotic values is generated from a set of chaotic maps, where these values are formulated as matrix (\(M_{k}\)) form with size of \(N \times D\) as follows:

where \(N\) denotes the number of map functions,\(D\) defines the number of the decision (control) variables, \(q_{jd}^{k}\) defines the generated chaotic quantity inside the interval of (0, 1) for the chaotic map j on the dimension d at the iteration k.

Step 2. Mapping process In this step, the candidate solution, \({{\varvec{\uptheta}}} = \left( {\theta_{1} ,\theta_{2} ,...,\theta_{D} } \right)\), is mapped to another one according to the chaotic values of the matrix \(M_{k}\) as follows.

where \(Z_{k}^{{{\text{chaotic}}}}\) defines the matrix of mapped individual \({{\varvec{\uptheta}}}_{k}\) that is repeated \(N\) times, \(\lambda = k/T\) defines a weighting parameter and \(X_{k}^{FIC}\) denotes the matrix of new individuals that are generated chaotically. In this context, \(X_{k}^{{{\text{candidate}}}}\) is expressed as the best solution obtained from the ISA stage.

Step 3. Updating process Evaluate the matrix \(Z_{k}^{{{\text{chaotic}}}}\) and obtain the best one (\(Z_{k,best}^{{{\text{chaotic}}}}\)), where if \(f(Z_{k,best}^{{{\text{chaotic}}}} ) < f(\theta_{gb}^{k} )\) then replace \(\theta_{gb}^{k}\) with \(Z_{k,best}^{{{\text{chaotic}}}}\), otherwise maintains \(\theta_{gb}^{k}\). Stop the searching process if the maximum iteration is satisfied.

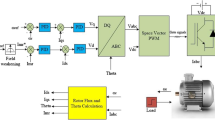

Based on above-mentioned modifications, the scenario of the proposed IISA is presented through the pseudocode of Algorithm 2 as appeared in Fig. 4, where the proposed IISA begins with a population of elements or solutions which are initialized randomly. These solutions go to the ISA phase to explore the search space and potentially attain the best solution by using the composition phase based on crossover strategy. Then, the best solution will enter the local search phase to refine its quality and to avoid predicament in the local solution rather than the global solution. In this regard, the better solution will be fed into the next iteration. This scenario is iteratively continued until the stopping condition is satisfied.

5 Applications

5.1 Experimental setup

DC and short- and open-circuit tests are three experimental tests that have been carried out on a 3 HP six-phase induction motors and 1/3 HP three-phase to get the equivalent circuit parameters. Figure 5 shows a photograph of the experimental set up at Faculty of Engineering; Kafrelsheikh University. According to the IEEE Std 112-2004 specifications for tests procedure for PPIM [5], the tests have been performed. Tables 1 and 2 represent, respectively, the recorded measurements for short-circuit and no-load tests for six- and three-phase induction motors.

5.2 Parameter settings for competitive algorithms

In this section, the proposed IISA is evaluated on parameters identification of the polyphase induction machines, i.e., 1/3 HP three-phase induction motor, and 3 HP six-phase induction motor. In this regard, the superior performance of the IISA is validate by carrying out the comparisons with other well-established optimizers including the genetic algorithm (GA) [42], differential evolution (DE) [43], Jaya algorithm (Jaya) [44], gray wolf optimizer (GWO) [45], sine cosine algorithm (SCA) [41], and basic ISA. For fair comparison, all of the implemented algorithms are carried out with the same maximum number of iterations (100) and population size with 60 individuals. It is notable that the maximum number of iterations and population size of IISA and ISA are set after running a few trials. Besides, each of the implemented algorithms is tested 20 times independently for every problem to reduce statistical errors. The parameter settings for all compared optimizers are based on the acclaimed suggestions in the corresponding literature and recorded in Table 3.

Firstly, the comparisons are claimed on the best outcomes represented by the square error values (i.e., Eq. (9)) to show the accuracy of each algorithm. And then, the statistical indices, convergence rates, stability analysis and statistical pairwise test are illustrated to evaluate and assess the robustness and convergence rate of each algorithm.

5.3 Results on the 1/3 HP 3-phase induction motor

The 1/3 HP, 3-phase induction motor parameters are estimated by merging the competitive optimization techniques that are GA, DE, Jaya, GWO, SCA, HPJOA [2], ISA and the proposed IISA. Table 4 explains the best equivalent circuit estimated parameters of the 1/3 HP 3-phase induction motor by the proposed IISA and implemented methods. It is note that the estimated parameters are recorded based on the best value of the objective function (least value of the square error).In the context of operational indices, a comparison of experimental and estimated values of the full load power factor and starting, maximum, full load torques has been made. In this sense, the IISA has lower fitness function (zero value for the square error) compared to the Jaya method which equals 1.68 × 10–5, GWO method which equals 1.73 × 10–5, GA method which equals 7.51 × 10–7, DE method which equals 1.68 × 10–5, SCA method which equals 4.90 × 10–5, and classical ISA method which equals 7.77 × 10–7. Although the fitness values for the presented algorithms seem to be are very close to that of the proposed IISA, the tiny reduction in the fitness value is significant as it is a prerequisite for accurate modeling.

To further confirm that the obtained results are not reached by chance, some statistical measures of the presented algorithms are carried out over 20 independent runs, where these measures are shown in Table 5. The mean value for fitness function quantifies the average accuracy, and standard deviation (St. dev.) of fitness function indicates the parameters estimation reliability.

From these results, the proposed IISA leads to the best competitive performance compared with other algorithms at acceptable statistical indices.

5.4 Results on the 3 HP, 6-phase, induction motor

For the six-phase induction motor, the best parameters of equivalent circuit for the six-phase induction motor obtained by presented algorithms that include the GA, DE, Jaya, GWO, SCA, HPJOA, ISA and the proposed IISA are recorded in Table 6. In this sense, the estimated parameters are obtained based on the best value of the fitness function (i.e., minimum value of the square error). The estimated motor parameters reveal that the proposed IISA achieves the lower fitness function (zero value for the square error as in Table 7) compared to the Jaya, GWO, GA, DE, SCA, HPJOA and ISA that have reached the fitness values with1.91 × 10–3, 6.02 × 10–4, 7.86 × 10–7, 1.91 × 10–3, 1.34 × 10–3, and 7.37 × 10–4, respectively. To further confirm that the obtained results are not reached by chance, some statistical measures of the presented algorithms are carried out over 20 independent runs, where these measures are shown in Table 7. The mean value for fitness function quantifies the average accuracy, and standard deviation (St. dev.) of fitness function indicates the parameters estimation reliability. The comparison between estimated and experimental parameters reveals that the proposed IISA can accurately predict the corresponding motor parameters with good level of precision.

5.5 Operating characteristic performance by estimated parameters for induction motor models

Figure 6 explains the torque-speed characteristic of 3-phase induction motor using the experimental test recorded parameters and the parameters estimated from presented algorithms including, Jaya, GWO, GA, DE, SCA, ISA and the proposed IISA. The torque-speed characteristic estimated by IISA parameters is very close to actual characteristic. The characteristics of rotor and stator current against speed using estimated parameters by the Jaya, GWO, GA, DE, SCA, ISA and the proposed IISA, and the presented algorithms are shown in Fig. 7a, b. Estimated current of stator and rotor using Jaya, GWO, GA, DE, SCA, ISA and the proposed IISA, the calculated parameters using IISA is very close to the actual characteristics.

The characteristics of power factor and magnetizing current versus speed of 3-phase induction motor using Jaya, GWO, GA, DE, SCA, ISA and IISA calculated parameters are shown in Fig. 7c, d. Estimated characteristics of power factor and magnetizing current using IISA calculated parameters has very small difference from the actual and give the better characteristics.

Figure 8 shows the torque-speed characteristics of 6-phase induction motor estimated from the measurements, Jaya, GWO, GA, DE, SCA, ISA parameters and IISA parameters. Estimated torque-speed characteristic using ISA calculated parameters has a little deviation from the measured torque-speed characteristic, while that using IISA is closer to real characteristic.

The stator and rotor current-speed characteristics of 6-phase induction motor using Jaya, GWO, GA, DE, SCA, ISA and IISA calculated parameters are declared in Fig. 9a, b. It is clear that the calculated rotor and stator current characteristics using ISA calculated parameters has deviation from the characteristic calculated by measured values, while estimated characteristics using IISA calculated parameters is very close to the actual characteristics. The power factor and magnetizing current characteristics versus speed of 6-phase induction motor using IISA calculated parameters are declared in Fig. 9c, d. Estimated power factor and magnetizing current characteristics using IISA calculated parameters has very small deviation from the measured characteristics.

5.6 Comparison with state-of-the-art optimization methods

In this section, proposed IISA was further investigated by comparing its performance with some advanced state-of-the-art optimization algorithms including chaotic ant lion optimization (CALO) [46], chaotic gravitational search algorithm (CGSA) [47], chaotic electromagnetic field optimization algorithm (CEFOA) [48], crossover-based sine cosine algorithm (CBSCA) [49], crossover-based gravitational search (CBGSA) [50], and crossover-based monarch butterfly optimization (CBMBO) [51]. The parameters’ values for the above competitors used for comparison were suggested as recommended in the original articles.

Table 8 records the results of the fitness function achieved by the IISA and advanced optimization competitors. It can be revealed from the table that IISA provides superior performance compared to the other state-of-the-art competitors in terms of solution accuracy on the 3-phase and 6-phase models. Furthermore, the optimal parameters for 3-phase and 6-phase models obtained by the optimization competitors are recorded in Table 9. For the 3-phase model, the IISA achieved to the global optimal solution with zero value for the objective function (i.e., minimization of the square error), other counterparts were unable to find a good solution as the achieving of the optimal solution for unknown parameters is prerequisite for accurate modeling.

The IISA won first place on 6-phase model, which reveals its very competitive results. Furthermore, it can be seen that the IISA presents a more stable performance in different runs as it possesses very small standard deviation close to zero value. The calculation time is also a significant metric for assessing an algorithm's performance. In order to further confirm the algorithm's efficiency, the average CPU calculation time of all competing optimizers on the two models regarding the induction machine is recorded in Table 10. From Fig. 10, it can be seen that the time taken by each algorithm on different models is different. No matter which model, CEFOA possesses the largest average CPU time, and ISA has the shortest average CPU time. IISA is not the fastest; it is relatively very close to other competing optimizers. Therefore, it can be affirmed that the IISA is a promising optimizer.

5.7 Statistical pairwise analysis: the Wilcox on signed-rank test (WSRT)

As in [52], the assessment of several optimization algorithms no free lunch theorems for optimization In this subsection, The WSRT is statistical pair wise test that was employed to determine the significant difference of obtained results by different methods [53]. This statistical evaluation metric rejects or accepts the hypothesis if the median of the achieved results by a pair of algorithms is different or equal. In this test, the statistical significance level (\(\alpha )\) is usually set to 0.05, and \(p\)-value examines that the results achieved by two different methods are significantly different or not. For a pair-side comparison on two individual samples, Table 11 shows the \(p\)-values computed using the nonparametric WSRT. The test was performed at a meaning level of 0.05, with 20 independent runs. Based on the reported results, it can be revealed that all \(p\)-values are less than 0.05, which confirms that the performance of IISA is significantly better than these state-of-the-art competing methods.

5.8 Convergence analysis

Convergence speed is an essential assessment to evaluate the behavior of performance of any algorithm during the course of iterations. To justify the convergence behavior of the proposed IISA, Fig. 11 represents the convergence curves for the IISA and the compared basic state-of-the-art algorithms, GA, DE, Jaya, GWO, SCA, and ISA on 100 iterations. Also, Fig. 11 shows the convergence curves of the proposed IISA compared with advanced state-of-the-art algorithms, namely CALO, CGSA, CEFOA, CBSCA, CBGSA, and CBMBO, on 100 iterations for the 3-phase and 6-phase models. The figures portray convergence behavior with taking the x-axis for the growth of the iterations and the iteration's best fitness as y-axis. It can be revealed from in Fig. 11 that the newly developed IISA methodology converges faster than other compared peers for the studied models of induction motor, affirms the superior performance ability of the IISA in describing the actual characteristics of induction motor models.

5.9 Stability analysis using the box plot behavior

Box plot behavior analysis is an important metric to evaluate the stability behavior of any optimization algorithm over the course of different independent runs. In this regard, the box plot diagram uses the inter quartile range to depict the box aspect, and the median value to represent the bar in the box.

The lowest width of the inter quartile range presents the most stable algorithm. As depicted in Fig. 12, it can be observed that the proposed IISA provides super narrow width for the inter quartile range than the compared basic and advanced state-of-the-art algorithms while dealing with the 3-phase and 6-phase models. Then, the depicted box plots advocate the supremacy of the IISA over the other peers.

6 Conclusions

This study has extracted the electrical equivalent circuit parameters of PPIM. The proposed IISA has been used to characterize the PPIM electrical model estimated parameters. Significant benefits of the proposed IISA compared with basic state-of-the-art algorithms like GA, DE, Jaya, GWO, SCA, and ISA and some advanced state-of-the-art algorithms like CALO, CGSA, CEFOA, CBSCA, CBGSA, and CBMBO are observed. Added to the estimated parameters obtained by using the competitive algorithms, the performance of the PPIMs is evaluated. High closeness between the experimental records and the estimated tests based on the extracted parameters. The results show that the proposed IISA methodology for extracting the optimal parameters of three- and six-phase induction devices is valid and reliable. The use of IISA also improves the operating performance of the PPIMs as it can accurately describe the actual characteristics of induction motor models. The suggested IISA's robustness is confirmed against other competing methods using some statistical indicators, including the Wilcoxon rank test, stability analysis, and convergence analysis. The record results and analyses have validated the developed IISA's superiority over the compared peers.

Although competitive performances and analysis have illustrated the efficiency of the proposed algorithms in estimating the parameters of the induction motor models over the other competitors, the incorporation of crossover strategy and chaotic concepts can take a slight time compared to their conventional counterpart. Moreover, there are still some limited issues that can be explored in future work. Firstly, the proposed IISA can be extended to deal with other complicated models of induction motor to exert its capability thoroughly. Secondly, the feasibility of the IISA can be further enhanced through the use of other optimization strategies and concepts. The authors would like to point out that IISA cannot be considered as a ubiquitous algorithm because no such algorithm exists that can deal with all optimization tasks as per the statement of the NFL theorem.

Data Availability Statement

Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

Abbreviations

- \({X}_{s}\) :

-

Stator reactance, Ω/Per phase

- \({R}_{s}\) :

-

Stator resistance, Ω/Per phase

- \({X}_{2}\) :

-

Rotor reactance, Ω/Per phase

- \({R}_{2}\) :

-

Rotor resistance, Ω/Per phase

- \({X}_{m}\) :

-

Magnetizing reactance, Ω/Per phase

- p :

-

Pole pairs

- \({V}_{ph}\) :

-

Stator voltage, V

- \(s\) :

-

Slip

- T d :

-

Developed torque, N m

- \({I}_{s}\) :

-

Motor stator current, A

- \({I}_{2}\) :

-

Motor rotor current, A

- \({I}_{st}\) :

-

Motor starting current, A

- T FL :

-

Motor full load torque, N m

- T st :

-

Motor starting torque, N m

- T max :

-

Motor maximum torque, N m

- m :

-

Number phases

- pf :

-

Power factor

- \(mpf\) :

-

Measured power factors

- \(epf\) :

-

Estimated power factors

- \({mT}_{\mathrm{max}}\) :

-

Measured motor maximum torques

- \({mT}_{d}\) :

-

Measured developed torques

- \({eT}_{d}\) :

-

Estimated developed torques

- \({eT}_{st}\) :

-

Measured motor starting torques

- \({eT}_{\mathrm{max}}\) :

-

Estimated motor maximum torques

- \({eT}_{st}\) :

-

Estimated motor starting torques

References

Abdelwanis MI, El-Sehiemy RA (2019) A fuzzy-based controller of a modified six-phase induction motor driving a pumping system. Iran J Sci Technol Trans Electr Eng 43(1):153–165. https://doi.org/10.1007/s40998-018-0066-4

Abdelwanis MI, Sehiemy RA, Hamida MA (2021) Hybrid optimization algorithm for parameter estimation of poly-phase induction motors with experimental verification. Energy AI 5:100083. https://doi.org/10.1016/j.egyai.2021.100083

Duan F, Živanović R (2016) Induction motor stator fault detection by a condition monitoring scheme based on parameter estimation algorithms. Electr Power Components Syst 44(10):1138–1148. https://doi.org/10.1080/15325008.2015.1089336

Bhowmick D, Manna M, Chowdhury SK (2018) Estimation of equivalent circuit parameters of transformer and induction motor from load data. IEEE Trans Ind Appl 5(3):2784–2791. https://doi.org/10.1109/TIA.2018.2790378

IEEE—Institute of Electrical and Electronics Engineers (2017) Standard test procedure for polyphase induction motors and generators (ANSI), IEEE Std 112–2017. IEEE Stand 112:3–5. https://doi.org/10.1109/IEEESTD.2018.8291810.

Singh GK (2002) Multi-phase induction machine drive research—a survey. Electr Power Syst Res 61(2):139–147. https://doi.org/10.1016/S0378-7796(02)00007-X

Hannan MA, Ali JA, Mohamed A, Hussain A (2018) Optimization techniques to enhance the performance of induction motor drives: a review. Renew Sustain Energy Rev. https://doi.org/10.1016/j.rser.2017.05.240

Koubaa Y (2004) Recursive identification of induction motor parameters. Simul Model Pract Theory 12(5):363–381. https://doi.org/10.1016/j.simpat.2004.04.003

Lindenmeyer D, Dommel HW, Moshref A, Kundur P (2001) An induction motor parameter estimation method. Int J Electr Power Energy Syst 23(4):251–262. https://doi.org/10.1016/S0142-0615(00)00060-0

Toliyat HA, Levi E, Raina M (2002) A review of RFO induction motor parameter estimation techniques. IEEE Power Eng Rev 22(7):52–52

Sakthivel VP, Bhuvaneswari R, Subramanian S (2010) Artificial immune system for parameter estimation of induction motor. Expert Syst Appl 37(8):6109–6115. https://doi.org/10.1016/j.eswa.2010.02.034

Wlas M, Krzeminski Z, Toliyat HA (2008) Neural-network-based parameter estimations of induction motors. IEEE Trans Ind Electron 55(4):1783–1794. https://doi.org/10.1109/TIE.2008.918615

Sakthivel VPÃ, Bhuvaneswari R, Subramanian S (2010) Engineering applications of artificial intelligence multi-objective parameter estimation of induction motor using particle swarm optimization. Eng Appl Artif Intell 23(3):302–312. https://doi.org/10.1016/j.engappai.2009.06.004

Perez I, Gomez-Gonzalez M, Jurado F (2013) Estimation of induction motor parameters using shuffled frog-leaping algorithm. Electr Eng 95(3):267–275. https://doi.org/10.1007/s00202-012-0261-7

Che HS, Abdel-Khalik AS, Dordevic O, Levi E (2017) Parameter estimation of asymmetrical six-phase induction machines using modified standard tests. IEEE Trans Ind Electron 64(8):6075–6085

Bijan MG, Pillay P (2019) Efficiency estimation of the induction machine by particle swarm optimization using rapid test data with range constraints. IEEE Trans Ind Electron 66(8):5883–5894. https://doi.org/10.1109/TIE.2018.2873121

Bucci G, Ciancetta F, Fiorucci E, Ometto A, Segreto MA (2019) A simplified indirect technique for the measurement of mechanical power in three-phase asynchronous motors. Int J Emerg Electr Power Syst 20(2)

Gomez-Gonzalez M, Jurado F, Pérez I (2012) Shuffled frog-leaping algorithm for parameter estimation of a double-cage asynchronous machine. IET Electr Power Appl 6(8):484–490

Guedes JJ, Castoldi MF, Goedtel A, Agulhari CM, Sanches DS (2018) Parameters estimation of three-phase induction motors using differential evolution. Electr Power Syst Res 154:204–212. https://doi.org/10.1016/j.epsr.2017.08.033

Eberhart R, Kennedy J (1995) A new optimizer using particle swarm theory. In: Proceedings of the sixth international symposium on micro machine and human science, pp 39–43. https://doi.org/10.1109/MHS.1995.494215

Ly H-B, Nguyen MH, Pham BT (2021) Metaheuristic optimization of Levenberg–Marquardt-based artificial neural network using particle swarm optimization for prediction of foamed concrete compressive strength. Neural Comput Appl 33(24):17331–17351. https://doi.org/10.1007/s00521-021-06321-y

Abdelwanis MI, Abaza A, El-Sehiemy RA, Ibrahim MN, Rezk H (2020) Parameter estimation of electric power transformers using coyote optimization algorithm with experimental verification. IEEE Access 8:50036–50044. https://doi.org/10.1109/ACCESS.2020.2978398

Kaymaz E, Duman S, Guvenc U (2021) Optimal power flow solution with stochastic wind power using the Lévy coyote optimization algorithm. Neural Comput Appl 33(12):6775–6804. https://doi.org/10.1007/s00521-020-05455-9

Mittal T (2022) A hybrid moth flame optimization and variable neighbourhood search technique for optimal design of IIR filters. Neural Comput Appl 34(1):689–704. https://doi.org/10.1007/s00521-021-06379-8

Elsakaan AA, El-sehiemy RA, Kaddah SS, Elsaid MI (2018) An enhanced moth-flame optimizer for solving non-smooth economic dispatch problems with emissions. Energy 157:1063–1078. https://doi.org/10.1016/j.energy.2018.06.088

Shaheen AM, El-Sehiemy RA, Farrag SM (2018) A novel framework for power loss minimization by modified wind driven optimization algorithm. In: Proceedings of 2018 international conference on innovative trends in computer engineering, ITCE 2018, vol 2018, pp 344–349. https://doi.org/10.1109/ITCE.2018.8316648

El-Ela AAA, El-Sehiemy RA, Abbas AS (2018) Optimal placement and sizing of distributed generation and capacitor banks in distribution systems using water cycle algorithm. IEEE Syst J. https://doi.org/10.1109/JSYST.2018.2796847

Abdelwanis MI, El-Sehiemy RA (2022) Efficient parameter estimation procedure using sunflower optimization algorithm for six-phase induction motor. Rev Roum DES Sci Tech Électrotechnique Énergétique 67(3):259–264

Gomes GF, da Cunha SS, Ancelotti AC (2019) A sunflower optimization (SFO) algorithm applied to damage identification on laminated composite plates. Eng Comput 35(2):619–626. https://doi.org/10.1007/s00366-018-0620-8

Zhou R, Liu Q, Wang J, Han X, Wang L (2021) Modified semi-supervised affinity propagation clustering with fuzzy density fruit fly optimization. Neural Comput Appl 33(10):4695–4712. https://doi.org/10.1007/s00521-020-05431-3

Abou El-Ela AA, El-Sehiemy RA, Rizk-Allah RM, Fatah DA (2018) Solving multiobjective economical power dispatch problem using MO-FOA. In: Twentieth international middle east power systems conference (MEPCON), Cairo, Egypt, pp 19–24. https://doi.org/10.1109/MEPCON.2018.8635119

Shaheen AM, Ginidi AR, El-Sehiemy RA, Ghoneim SSM (2021) A forensic-based investigation algorithm for parameter extraction of solar cell models. IEEE Access 9:1–20. https://doi.org/10.1109/ACCESS.2020.3046536

Abou El-Ela AA, El-Sehiemy RA, Ali ES, Kinawy AM (2019) Minimisation of voltage fluctuation resulted from renewable energy sources uncertainty in distribution systems. IET Gener Transm Distrib 13(12):2339–2351. https://doi.org/10.1049/iet-gtd.2018.5136

Deng W, Yao R, Zhao H, Yang X, Li G (2019) A novel intelligent diagnosis method using optimal LS-SVM with improved PSO algorithm. Soft Comput 23(7):2445–2462. https://doi.org/10.1007/s00500-017-2940-9

Jia L, Zhao X (2019) An improved particle swarm optimization (PSO) optimized integral separation PID and its application on central position control system. IEEE Sens J 19(16):7064–7071. https://doi.org/10.1109/JSEN.2019.2912849

Abou-El-Ela AA, El-Sehiemy RA (2008) Optimized generation costs using a modified particle swarm optimization version. In: 2008 12th Int. Middle East Power Syst. Conf. MEPCON 2008, pp 420–424.https://doi.org/10.1109/MEPCON.2008.4562392

El-Sattar SA, Kamel S, El Sehiemy RA, Jurado F, Yu J (2019) Single- and multi-objective optimal power flow frameworks using Jaya optimization technique. Neural Comput Appl 31(12):8787–8806. https://doi.org/10.1007/s00521-019-04194-w

Gandomi AH (2014) Interior search algorithm (ISA): a novel approach for global optimization. ISA Trans 53(4):1168–1183. https://doi.org/10.1016/j.isatra.2014.03.018

Yildiz BS (2017) Natural frequency optimization of vehicle components using the interior search algorithm. Mater Test 59(5):456–458. https://doi.org/10.3139/120.111018

Rajagopalan A, Kasinathan P, Nagarajan K, Ramachandaramurthy VK, Sengoden V, Alavandar S (2019) Chaotic self-adaptive interior search algorithm to solve combined economic emission dispatch problems with security constraints. Int Trans Electr Energy Syst 29(8):1–26. https://doi.org/10.1002/2050-7038.12026

Mirjalili S (2016) SCA: A Sine Cosine Algorithm for solving optimization problems. Knowl Based Syst 96:120–133. https://doi.org/10.1016/j.knosys.2015.12.022

Thakur M (2014) A new genetic algorithm for global optimization of multimodal continuous functions. J Comput Sci 5(2):298–311. https://doi.org/10.1016/j.jocs.2013.05.005

Venkata Rao R (2016) Jaya: a simple and new optimization algorithm for solving constrained and unconstrained optimization problems. Int J Ind Eng Comput 7(1):19–34. https://doi.org/10.5267/j.ijiec.2015.8.004

Qin AK, Huang VL, Suganthan PN (2009) Differential evolution algorithm with strategy adaptation for global numerical optimization. IEEE Trans Evol Comput 13(2):398–417. https://doi.org/10.1109/TEVC.2008.927706

Mirjalili S, Mirjalili SM, Lewis A (2014) Grey wolf optimizer. Adv Eng Softw. https://doi.org/10.1016/j.advengsoft.2013.12.007

Zawbaa HM, Emary E, Grosan C (2016) Feature selection via chaotic antlion optimization. PLoS ONE 11(3):e0150652. https://doi.org/10.1371/journal.pone.0150652

Mirjalili S, Gandomi AH (2017) Chaotic gravitational constants for the gravitational search algorithm. Appl Soft Comput 53:407–419. https://doi.org/10.1016/j.asoc.2017.01.008

Bouchekara H (2020) Solution of the optimal power flow problem considering security constraints using an improved chaotic electromagnetic field optimization algorithm. Neural Comput Appl 32(7). https://doi.org/10.1007/s00521-019-04298-3

Gupta S, Deep K (2019) Improved sine cosine algorithm with crossover scheme for global optimization. Knowl Based Syst 165:374–406

Yin B, Guo Z, Liang Z, Yue X (2018) Improved gravitational search algorithm with crossover. Comput Electr Eng 66:505–516. https://doi.org/10.1016/j.compeleceng.2017.06.001

Wang G-G, Deb S, Zhao X, Cui Z (2018) A new monarch butterfly optimization with an improved crossover operator. Oper Res 18(3):731–755. https://doi.org/10.1007/s12351-016-0251-z

Wolpert DH, Macready WG (1997) No free lunch theorems for optimization. IEEE Trans Evol Comput 1(1):67–82. https://doi.org/10.1109/4235.585893

Derrac J, García S, Molina D, Herrera F (2011) A practical tutorial on the use of nonparametric statistical tests as a methodology for comparing evolutionary and swarm intelligence algorithms. Swarm Evol Comput 1(1):3–18. https://doi.org/10.1016/j.swevo.2011.02.002

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors have no conflicts of interest among the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rizk-Allah, R.M., Abdelwanis, M.I., El-Sehiemy, R.A. et al. An interior search algorithm based on chaotic and crossover strategies for parameter extraction of polyphase induction machines. Neural Comput & Applic 35, 6647–6664 (2023). https://doi.org/10.1007/s00521-022-08055-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-022-08055-x