Abstract

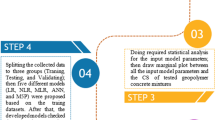

In this study, the effect of two water-reducer polymers with smooth and rough surfaces on the workability, and the compression strength of concrete from an early age (1 day) up to 28 days of curing was investigated. The polymer contents used in this study varied from 0 to 0.25% (wt%). The initial ratio between water and cement (\( \frac{w}{c} \)) was 60%, and it slowly reduced to 0.46 by increasing the polymer contents. The compression strength of concrete was increased significantly with increasing the polymer contents by 24–95% depending on the polymer type, polymer content, \( \frac{w}{c} \), and curing age. Because of a fiber net (netting) in the concrete when the polymers were added which leads to a decrease void between the particles, binding the cement particles, therefore, increased rapidly the viscosity for the fresh concrete and the compression strength of the hardened concrete. This study also aims to establish systematic multiscale models to predict the compression strength of concrete containing polymers and to be used by the construction projects with no theoretical restrictions. For that purpose, 88 concrete samples modified with two types of polymer (44 samples for each modification) has been tested, analyzed, and modeled. Linear, nonlinear regression, M5P-tree, and artificial neural network (ANN) approaches were used for the qualifications. In the modeling process, the most relevant parameters affect the strength of concrete, i.e., polymer incorporation ratio (0–0.25% of cement’s mass), water-to-cement ratio (0.46–0.6), and curing ages (1–28 days). Among the used approaches and based on the training data set, the model made based on the nonlinear regression, ANN, and M5P-tree models seem to be the most reliable models. The sensitivity investigation concludes that the curing time is the most dominating parameter for the prediction of the maximum stress (compression strength) of concrete with this dataset.

Similar content being viewed by others

Data availability statement

No data, models, or codes were generated or used during the study.

References

Amer AA, El-Sokkary TM, Abdullah NI (2015) Thermal durability of OPC pastes admixed with nano iron oxide. HBRC J 11(2):299–305

Kırgız MS (2016) Strength gain mechanism for green mortar substituted marble powder and brick powder for Portland cement. Europ J Environ Civil Eng 20(sup1):s38–s63

Ashikhmen VA, Pronina LÉ (1986) Rheological properties of dispersed cement grouts. Power Technol Eng Formerly Hydrotech Construct 20(10):598–603

Rosquoët F, Alexis A, Khelidj A, Phelipot A (2003) Experimental study of cement grout: rheological behavior and sedimentation. Cem Concr Res 33(5):713–722

Kirgiz MS (2015) Strength gain mechanisms of blended-cements containing marble powder and brick powder. KSCE J Civil Eng 19(1):165–172

Kırgız MS (2016) Fresh and hardened properties of green binder concrete containing marble powder and brick powder. European Journal of Environmental and Civil Engineering 20(sup1):s64–s101

Kirgiz MS (2015) Advance treatment by nanographite for Portland pulverised fly ash cement (the class F) systems. Compos B Eng 82:59–71

Al-Martini S, Nehdi M (2007) Impact of chemical admixtures on rheology of cement paste at high temperature. J ASTM Int 4(3):1–17

Soroka I, Ravina D (1998) Hot weather concreting with admixtures. Cement Concr Compos 20(2–3):129–136

Amudhavalli NK, Mathew J (2012) Effect of silica fume on strength and durability parameters of concrete. Int J Eng Sci Emerg Technol 3(1):28–35

Fu TC, Yeih W, Chang JJ, Huang R (2014) The influence of aggregate size and binder material on the properties of pervious concrete. Adv Mater Sci Eng 2014:963971. https://doi.org/10.1155/2014/963971

Dotto JMR, De Abreu AG, Dal Molin DCC, Müller IL (2004) Influence of silica fume addition on concretes physical properties and on corrosion behaviour of reinforcement bars. Cement Concr Compos 26(1):31–39

Shannag MJ (2000) High strength concrete containing natural pozzolan and silica fume. Cement Concr Compos 22(6):399–406

Mazloom M, Ramezanianpour AA, Brooks JJ (2004) Effect of silica fume on mechanical properties of high-strength concrete. Cement Concr Compos 26(4):347–357

Burhan L, Ghafor K, Mohammed A (2019) Modeling the effect of silica fume on the compressive, tensile strengths and durability of NSC and HSC in various strength ranges. J Build Rehabil 4:19

Kamal SM, Saeed JA, Mohammed A (2020) The characterization and modeling the mechanical properties of high strength concrete (HSC) modified with fly ash (FA). Eng Technol J 38(2A):173–184

Abdalla LB, Ghafor K, Mohammed A (2019) Testing and modeling the young age compressive strength for high workability concrete modified with PCE polymers. Results Mater 1:100004

Burhan L, Ghafor K, Mohammed A (2019) Testing and evaluation of flowability, viscosity and long-term compressive strength of cement modified with polymeric admixture WR superplasticizer. In: IOP conference series: materials science and engineering, vol 737, 4th International Conference on Buildings, Construction and Environmental Engineering 7–9 October 2019, Istanbul, Turkey

Burhan L, Ghafor K, Mohammed A (2019) Quantification the effect of microsand on the compressive, tensile, flexural strengths, and modulus of elasticity of normal strength concrete. Geomech Geoeng, pp 1–19

Burhan L, Ghafor K, Mohammed A (2020) Enhancing the fresh and hardened properties of the early age concrete modified with powder polymers and characterized using different models. Adv Civil Eng Mater 9(1):227–249

Liu X, Wang Z, Zheng Y, Cui S, Lan M, Li H, Zhu J, Liang X (2014) Preparation, characterization and performances of powdered polycarboxylate superplasticizer with bulk polymerization. Materials 7(9):6169–6183

Houst YF, Paul B, François P, Annika K, Pascal B, Laurent G, Jean-François LM et al (2008) Design and function of novel superplasticizers for more durable high-performance concrete (superplast project). Cement Concrete Res 38(10):1197–1209

Ferrari L, Kaufmann J, Winnefeld F, Plank J (2011) Multi-method approach to study influence of superplasticizers on cement suspensions. Cem Concr Res 41(10):1058–1066

Evangeline K, Neelamegam M, Brown H (2015) Effect of superplasticizer on workability and mechanical properties of self-compacting concrete. IOSR J Mech Civil Eng, pp 18–29

Sarwar W, Ghafor K, Mohammed A (2019) Regression analysis and Vipulanandan model to quantify the effect of polymers on the plastic and hardened properties with the tensile bonding strength of the cement mortar. Results Mater 1:100011

Sarwar W, Ghafor K, Mohammed A (2019) Modeling the rheological properties with shear stress limit and compressive strength of ordinary Portland cement modified with polymers. J Build Pathol Rehabilitat 4(1):25

Vipulanandan C, Mohammed A (2015) Smart cement modified with iron oxide nanoparticles to enhance the piezoresistive behavior and compressive strength for oil well applications. Smart Mater Struct 24(12):125020

Ghafor K, Qadir S, Mahmood W, Mohammed A (2020) Statistical variations and new correlation models to predict the mechanical behaviour of the cement mortar modified with silica fume. Geomech Geoeng. https://doi.org/10.1080/17486025.2020.1714083

Mohammed A, Mahmood W, Ghafor K (2020) Shear stress limit, rheological properties and compression strength of cement-based grout modified with polymers. J Build Pathol Rehabilitat 5(1):3

Mohammed A, Mahmood W, Ghafor K (2020) TGA, rheological properties with maximum shear stress and compression strength of cement-based grout modified with polycarboxylate polymers. Constr Build Mater 235:117534

Vipulanandan C, Mohammed A (2019) Smart cement compressive piezoresistive, stress-strain, and strength behavior with nanosilica modification. J Test Eval 47(2):1479–1501

Qadir W, Ghafor K, Mohammed A (2019) Evaluation the effect of lime on the plastic and hardened properties of cement mortar and quantified using Vipulanandan model. Open Eng 9(1):468–480

Khudhair MHR, Elyoubi MS, Elharfi A (2017) Study of the influence of water reducing and setting retarder admixtures of polycarboxylate “superplasticizers” on physical and mechanical properties of mortar and concrete

Mohammed AS (2018) Vipulanandan model for the rheological properties with ultimate shear stress of oil well cement modified with nanoclay. Egypt J Petrol 27(3):335–347

Sihag P, Jain P, Kumar M (2018) Modelling of impact of water quality on recharging rate of storm water filter system using various kernel function-based regression. Model Earth Syst Environ 4(1):61–68

Mohammed AR, Salih H (2018) Vipulanandan constitutive models to predict the rheological properties and stress–strain behavior of cement grouts modified with Metakaolin. J Test Evaluat, vol 48, no 5

Mohammed A, Rafiq S, Mahmood W, Noaman R, Ghafor K, Qadir W, Kadhum Q (2020) Characterization and modeling the flow behavior and compression strength of the cement paste modified with silica nano-size at different temperature conditions. Constr Build Mater 257:119590

Mohammed AS (2018) Vipulanandan models to predict the electrical resistivity, rheological properties and compression stress-strain behavior of oil well cement modified with silica nanoparticles. Egypt J Petrol 27(4):1265–1273

Mohammed A, Mahmood W (2019) Estimating the efficiency of the sandy soils-cement based grout interactions from particle size distribution (PSD). Geomech Geoeng. https://doi.org/10.1080/17486025.2019.1645361

Vipulanandan C, Mohammed A (2019) Smart cement compression piezoresistive, stress-strain, and strength behavior with nanosilica modification. J Test Evaluat 47(2):1479–1501

Vipulanandan C, Krishnamoorti R, Mohammed A, Boncan V, Narvaez G, Head B, Pappas JM (2015) Iron nanoparticle modified smart cement for real time monitoring of ultra-Deepwater oil well cementing applications. In: Offshore technology conference

Mohammed AS (2014) Characterization and modeling of polymer-treated and nano particle modified sulfate contaminated soils, drilling muds, and hydraulic fracturing fluids under groundwater (Doctoral dissertation)

Mohammed AS (2018) Electrical resistivity and rheological properties of sensing bentonite-drilling muds modified with lightweight polymer. Egypt J Petrol 27(1):55–63

Vipulanandan C, Mohammed A (2015) Effect of nanoclay on the electrical resistivity and rheological properties of smart and sensing bentonite drilling muds. J Petrol Sci Eng 130:86–95

Vipulanandan C, Mohammed A, Ganpatye AS (2018) Smart cement performance enhancement with nano Al2O3 for real time monitoring applications using vipulanandan models. In: Offshore technology conference

Vipulanandan C, Mohammed A, Samuel RG (2018) Fluid loss control in smart bentonite drilling mud modified with nanoclay and quantified with Vipulanandan fluid loss model. In: Offshore technology conference

Saridemir M (2009) Prediction of compression strength of concretes containing Metakaolin and silica fume by artificial neural networks. Adv Eng Softw 40:350–355

Mohammed AS (2018) Property correlations and statistical variations in the geotechnical properties of (CH) clay soils. Geotech Geol Eng 36(1):267–281

Vipulanandan C, Mohammed A (2020) Effect of drilling mud bentonite contents on the fluid loss and filter cake formation on a field clay soil formation compared to the API fluid loss method and characterized using Vipulanandan models. J Petrol Sci Eng, p 107029

Yaman MA, Elaty MA, Taman M (2017) Predicting the ingredients of self-compacting concrete using artificial neural network. Alexandria Eng J 56(4):523–532

Vipulanandan C, Mohammed A, Ganpatye AS (2018) Smart cement performance enhancement with nanoAl2O3 for real time monitoring applications using Vipulanandan models. In: Offshore technology conference

Zain MFM, Abd SM (2009) Multiple regression model for compression strength prediction of high-performance concrete. J Appl Sci 9:155–160

Emrah D (2009) Modeling the properties of high-performance construction materials using artificial neural network and nonlinear relation methods, University of Houston (Master dissertation)

Mahmood W, Mohammed A, Ghafor K (2019) Viscosity, yield stress and compression strength of cement-based grout modified with polymers. Results Mater 4:100043

Vipulanandan C, Mohammed A, Qu Q (2014) Characterizing the hydraulic fracturing fluid modified with nano silica proppant. In: AADE fluids technical conference and exhibition, Houston, pp 15–16

Qadir W, Ghafor K, Mohammed A (2019) Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times. Adv Civil Eng

Burhan L, Ghafor K, Mohammed A (2020) Evaluation and nonlinear quantification of early age strength of concrete containing PCE polymer. MS&E 737(1):012061

Vipulanandan C, Mohammed AS (2014) Hyperbolic rheological model with shear stress limit for acrylamide polymer modified bentonite drilling muds. J Petrol Sci Eng 122:38–47

Vipulanandan C, Mohammed A (2015) Smart cement rheological and piezoresistive behavior for oil well applications. J Petrol Sci Eng 135:50–58

Vipulanandan C, Mohammed A (2020) Effect of drilling mud bentonite contents on the fluid loss and filter cake formation on a field clay soil formation compared to the API fluid loss method and characterized using Vipulanandan models. J Petrol Sci Eng, p 107029

Mohammed AS (2017) Effect of temperature on the rheological properties with shear stress limit of iron oxide nanoparticle modified bentonite drilling muds. Egypt J Petrol 26(3):791–802

Vipulanandan C, Mohammed A (2020) Magnetic field strength and temperature effects on the behavior of oil well cement slurry modified with iron oxide nanoparticles and quantified with Vipulanandan models. J Test Evaluat, vol 48, no 6

Patil HS, Dwivedi AK, Chatterjee AM (2017) Optimize properties of concrete with silica fume. MAYFEB J Mater Sci, vol 2

Yildirim G, Sahmaran M, Ahmed HU (2015) Influence of hydrated lime addition on the self-healing capability of high-volume fly ash incorporated cementitious composites. J Mater Civ Eng 27(6):04014187

Mohammed A, Rafiq S, Sihag P, Kurda R, Mahmood W (2020) Soft computing techniques: systematic multiscale models to predict the compressive strength of HVFA concrete based on mix proportions and curing times. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101851

Mohammed A, Rafiq S, Sihag P, Kurda R, Mahmood W, Ghafor K, Sarwar W (2020) ANN, M5P-tree and nonlinear regression approaches with statistical evaluations to predict the compressive strength of cement-based mortar modified with fly ash. J Mater Res Technol 9(6):12416–12427

Contreras-Reyes JE, Arellano-Valle RB, Canales TM (2014) Comparing growth curves with asymmetric heavy-tailed errors: application to the southern blue whiting (Micromesistius australis). Fish Res 159:88–94

Acknowledgements

The Civil Engineering Department, University of Sulaimani, Gasin Cement Co. and Zarya Construction Co. supported this study.

Funding

No fund was received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohammed, A., Burhan, L., Ghafor, K. et al. Artificial neural network (ANN), M5P-tree, and regression analyses to predict the early age compression strength of concrete modified with DBC-21 and VK-98 polymers. Neural Comput & Applic 33, 7851–7873 (2021). https://doi.org/10.1007/s00521-020-05525-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-020-05525-y