Abstract

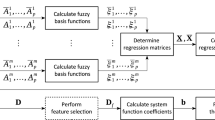

Estimating the time required for simulating a factory online is a crucial topic in manufacturing. However, this topic has rarely been discussed. A fuzzy back-propagation network (FBPN) approach for estimating the workload of a simulation task according to the required simulation time is proposed in this paper. In the proposed FBPN approach, tasks for which simulation times cannot be effectively estimated are considered as outliers and excluded, and therefore, more appropriate lower and upper bounds on the simulation time can be set. Thus, the ranges of all simulation times can be efficiently narrowed; however, this decrease is achieved at the expense of a slight decrease in the hit rate, which is still tolerable. A real case containing data of 90 simulation tasks was used to validate the proposed methodology. In addition, two existing FBPN methods, the adaptive-network-based fuzzy inference system method and the Chen (Comput Ind Eng 66:834–848, [2013]) method, were applied to these tasks for comparison. The experimental results showed that the proposed methodology was superior to the two existing FBPN methods in estimating precision and accuracy.

Similar content being viewed by others

References

Zott C (2003) Dynamic capabilities and the emergence of intraindustry differential firm performance: insights from a simulation study. Strateg Manag J 24(2):97–125

Chen T (2014) Strengthening the competitiveness and sustainability of a semiconductor manufacturer with cloud manufacturing. Sustainability 6:251–268

Fujimoto RM (1987) Performance measurements of distributed simulation strategies. Defense Technical Information Center, Fort Belvoir

Amin MB, Vinnakota B (1999) Data parallel fault simulation. IEEE Trans Very Large Scale Integr Syst 7(2):183–190

Majumdar A, Ochieng WY (2007) Factors affecting air traffic controller workload: multivariate analysis based on simulation modeling of controller workload. J Transp Res Rec J 1788:58–69

Meng W, Zhao G (2014) Effects of key simulation parameters on conical ring rolling process. Procedia Eng 81:286–291

Horikawa SI, Furuhashi T, Uchikawa Y (1992) On fuzzy modeling using fuzzy neural networks with the back-propagation algorithm. IEEE Trans Neural Netw 3(5):801–806

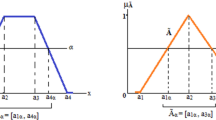

Chen T (2003) A fuzzy back propagation network for output time prediction in a wafer fab. Appl Soft Comput 2(3):211–222

Jang JS (1992) Self-learning fuzzy controllers based on temporal backpropagation. IEEE Trans Neural Netw 3(5):714–723

Chen T, Lin YC (2011) A collaborative fuzzy-neural approach for internal due date assignment in a wafer fabrication plant. Int J Innov Comput Inf Control 7(9):5193–5210

Chen T (2013) An effective fuzzy collaborative forecasting approach for predicting the job cycle time in wafer fabrication. Comput Ind Eng 66:834–848

Zimmermann HJ (1991) Fuzzy set theory and its applications. Kluwer Academic Publishers, Boston

Tesauro G (1995) Temporal difference learning and TD-Gammon. Commun ACM 38(3):58–68

Hans Raj K, Sharma RS, Srivastava S, Patvardhan C (2000) Modeling of manufacturing processes with ANNs for intelligent manufacturing. Int J Mach Tools Manuf 40(6):851–868

Bonnans JF, Gilbert JC, Lemaréchal C, Sagastizábal CA (2006) Numerical optimization: theoretical and practical aspects. Springer, Berlin

Benardos PG, Vosniakos GC (2002) Prediciton of surface roughness in CNC face milling using neural networks and Taguchi’s design of experiments. Robot Comput Integr Manuf 18(5–6):343–354

Sukthomya W, Tannock J (2005) The optimization of neural network parameters using Taguchi’s design of experiments approach: an application in manufacturing process modeling. Neural Comput Appl 14(4):337–344

Chen T (2009) A fuzzy-neural knowledge-based system for job completion time prediction and internal due date assignment in a wafer fabrication plant. Int J Syst Sci 40(8):889–902

Jang JS (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23(3):665–685

Chen T, Romanowski R (2013) Precise and accurate job cycle time forecasting in a wafer fabrication factory with a fuzzy data mining approach. Math Probl Eng 2013:1–14

Acknowledgments

This study is financially supported by the Ministry of Science and Technology, Taiwan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Toly Chen, TC. Fuzzy back-propagation network approach for estimating the simulation workload. Neural Comput & Applic 27, 1707–1715 (2016). https://doi.org/10.1007/s00521-015-1967-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-015-1967-z