Abstract

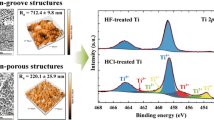

An adaptive neuro-fuzzy system (ANFIS) model was employed to predict the surface roughness. Surface roughening of titanium biomaterials has a crucial effect on increasing the biocompatibility. For this purpose, sandblasted, large-grit, acid-etched (SLA) has been introduced as an effective method to change the surface texturing and roughness. Subsequent processes—polishing, sandblasting and acid etching or SLA—were employed to modify the surface. Alumina particles for surface blasting and Kroll’s etchant (3 ml HF + 6 ml HNO3 + 100 ml H2O) for acid etching were utilized in this experiment. This was performed for three different periods of time (10, 20 and 30 s) and temperatures (25, 45 and 60 centigrade). Correspondingly, the Ti-13Zr-13Nb surfaces were evaluated using a field emission scanning electron microscope for texturing, contact mode profile meter for the average surface roughness (Ra) (nm) and atomic force microscopy for surface texturing at the nano-scale. In addition, the surface roughness was reduced in each condition, particularly in extremely high conditions. Significantly, the ANFIS model predicted the Ra amount of textured surface with an error band of 10 %. This research presents an idea to use the ANFIS model to obtain proper biological signs on the roughened surface in terms of surface roughness.

Similar content being viewed by others

References

Aydın M, Karakuzu C, Uçar M, Cengiz A, Çavuşlu M (2013) Prediction of surface roughness and cutting zone temperature in dry turning processes of AISI304 stainless steel using ANFIS with PSO learning. Int J Adv Manuf Technol 67(1–4):957–967. doi:10.1007/s00170-012-4540-2

Babajanzade Roshan S, Behboodi Jooibari M, Teimouri R, Asgharzadeh-Ahmadi G, Falahati-Naghibi M, Sohrabpoor H (2013) Optimization of friction stir welding process of AA7075 aluminum alloy to achieve desirable mechanical properties using ANFIS models and simulated annealing algorithm. Int J Adv Manuf Technol. doi:10.1007/s00170-013-5131-6

Suganthi XH, Natarajan U, Sathiyamurthy S, Chidambaram K (2013) Prediction of quality responses in micro-EDM process using an adaptive neuro-fuzzy inference system (ANFIS) model. Int J Adv Manuf Technol. doi:10.1007/s00170-013-4731-5

Azwadi CSN, Zeinali M, Safdari A, Kazemi A (2013) Adaptive-Network-Based Fuzzy Inference System analysis to predict the temperature and flow fields in a Lid-Driven Cavity. Numer Heat Trans Part A Appl 63(12):906–920

Goodarzi M, Freitas MP (2010) MIA–QSAR coupled to principal component analysis-adaptive neuro-fuzzy inference systems (PCA–ANFIS) for the modeling of the anti-HIV reverse transcriptase activities of TIBO derivatives. Eur J Med Chem 45(4):1352–1358

Vafaeenezhad H, Zebarjad S, Khaki JV (2013) Intelligent modeling using fuzzy rule-based technique for evaluating wood carbonization process parameters. Int J Adv Manuf Technol 68(5–8):1471–1478

Barzani MM, Zalnezhad E, Sarhan AA, Farahany S, Ramesh S (2015) Fuzzy logic based model for predicting surface roughness of machined Al–Si–Cu–Fe die casting alloy using different additives-turning. Measurement 61:150–161

Liu X, Chu PK, Ding C (2004) Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng 47(3–4):49–121

Geetha M, Singh AK, Asokamani R, Gogia AK (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Prog Mater Sci 54(3):397–425

Wennerberg A, Albrektsson T (2009) Effects of titanium surface topography on bone integration: a systematic review. Clin Oral Implant Res 20(s4):172–184

Deng F, Zhang W, Zhang P, Liu C, Ling J (2010) Improvement in the morphology of micro-arc oxidised titanium surfaces: a new process to increase osteoblast response. Mater Sci Eng C 30(1):141–147

Chang Q, Chen D, Ru H, Yue X, Yu L, Zhang C (2011) Three-dimensional fractal analysis of fracture surfaces in titanium–iron particulate reinforced hydroxyapatite composites: relationship between fracture toughness and fractal dimension. J Mater Sci 46(18):6118–6123

Elias CN, Oshida Y, Lima JHC, Muller CA (2008) Relationship between surface properties (roughness, wettability and morphology) of titanium and dental implant removal torque. J Mech Behav Biomed Mater 1(3):234–242

Kim B-S, Kim JS, Park YM, Choi B-Y, Lee J (2013) Mg ion implantation on SLA-treated titanium surface and its effects on the behavior of mesenchymal stem cell. Mater Sci Eng C 33(3):1554–1560

Son M-K, Choe H-C (2011) Evaluation of interfacial bonding strength between laser textured metal coping and porcelain. Procedia Eng 10:2286–2291

Oates CJ, Wen W, Hamilton DW (2011) Role of titanium surface topography and surface wettability on focal adhesion kinase mediated signaling in fibroblasts. Materials 4(5):893–907

Khanlou HM, Ang BC, Talebian S, Afifi AM, Andriyana A (2014) Electrospinning of polymethyl methacrylate nanofibers: optimization of processing parameters using the Taguchi design of experiments. Text Res J. doi:10.1177/0040517514547208

Al Jabbari YS, Zinelis S, Eliades G (2012) Effect of sandblasting conditions on alumina retention in representative dental alloys. Dent Mater J 31(2):249–255

Aparicio C, Javier Gil F, Fonseca C, Barbosa M, Planell JA (2003) Corrosion behaviour of commercially pure titanium shot blasted with different materials and sizes of shot particles for dental implant applications. Biomaterials 24(2):263–273

Wang C-S, Chen K-K, Tajima K, Nagamatsu Y, Kakigawa H, Kozono Y (2010) Effects of sandblasting media and steam cleaning on bond strength of titanium-porcelain. Dent Mater J 29(4):381–391

Carvalho DRd, Carvalho PSPd, Magro Filho O, Mello JDBd, Beloti MM, Rosa AL (2010) Characterization and in vitro cytocompatibility of an acid-etched titanium surface. Braz Dent J 21(1):3–11

Juodzbalys G, Sapragoniene M, Wennerberg A (2003) New acid etched titanium dental implant surface. Stomatool Bal Den Maxillofac J 5:101–105

Pypen CM, Plenk H Jr, Ebel M, Svagera R, Wernisch J (1997) Characterization of microblasted and reactive ion etched surfaces on the commercially pure metals niobium, tantalum and titanium. J Mater Sci Mater Med 8(12):781–784

Talebian S, Mehrali M, Mohan S, Mehrali M, Khanlou HM, Kamarul T, Afifi AM, Abass AA (2014) Chitosan (PEO)/bioactive glass hybrid nanofibers for bone tissue engineering. RSC Adv 4(90):49144–49152

Martin J, Schwartz Z, Hummert T, Schraub D, Simpson J, Lankford J, Dean D, Cochran D, Boyan B (1995) Effect of titanium surface roughness on proliferation, differentiation, and protein synthesis of human osteoblast-like cells (MG63). J Biomed Mater Res 29(3):389–401

Lamolle SF, Monjo M, Lyngstadaas SP, Ellingsen JE, Haugen HJ (2009) Titanium implant surface modification by cathodic reduction in hydrofluoric acid: surface characterization and in vivo performance. J Biomed Mater Res A 88(3):581–588

Lamolle SF, Monjo M, Rubert M, Haugen HJ, Lyngstadaas SP, Ellingsen JE (2009) The effect of hydrofluoric acid treatment of titanium surface on nanostructural and chemical changes and the growth of MC3T3-E1 cells. Biomaterials 30(5):736–742

Szmukler-Moncler S, Perrin D, Ahossi V, Magnin G, Bernard J (2004) Biological properties of acid etched titanium implants: effect of sandblasting on bone anchorage. J Biomed Mater Res B 68(2):149–159

Khanlou HM (2012) The Influence of Two Different Acid Solutions on Surface Texturing of Alumina Sandblasted Novel Non-Toxic Biomaterial. Aust J Basic Appl Sci 6(7):307–311

Rupp F, Scheideler L, Rehbein D, Axmann D, Geis-Gerstorfer J (2004) Roughness induced dynamic changes of wettability of acid etched titanium implant modifications. Biomaterials 25(7):1429–1438

Lu X, Zhao Z, Leng Y (2007) Biomimetic calcium phosphate coatings on nitric-acid-treated titanium surfaces. Mater Sci Eng C 27(4):700–708

Talebian S, Afifi A, Khanlou H (2014) Fabrication and characterisation of chitosan/poly vinyl alcohol nanofibres via electrospinning. Mater Res Innov 18(S6):S6331

Gotfredsen K, Berglundh T, Lindhe J (2000) Anchorage of titanium implants with different surface characteristics: an experimental study in rabbits. Clin Implant Dent Relat Res 2(3):120–128

Iwaya Y, Machigashira M, Kanbara K, Miyamoto M, Noguchi K, Izumi Y, Ban S (2008) Surface properties and biocompatibility of acid-etched titanium. Dent Mater J 27(3):415–421

Khanlou HM, Sadollah A, Ang BC, Kim JH, Talebian S, Ghadimi A (2014) Prediction and optimization of electrospinning parameters for polymethyl methacrylate nanofiber fabrication using response surface methodology and artificial neural networks. Neural Comput Appl 25(3–4):767–777

Khanlou HM (2012) FE-SEM and EDX Characterization of Sand Blasted and Sulfuric Acid Etched of Novel Biomaterial (Ti13Nb13Zr). Aust J Basic Appl Sci 6(6):125–131

Jang J-S (1993) ANFIS: adaptive-network-based fuzzy inference system. Syst Man Cybern IEEE Trans 23(3):665–685

Guney K, Sarikaya N (2007) A hybrid method based on combining artificial neural network and fuzzy inference system for simultaneous computation of resonant frequencies of rectangular, circular, and triangular microstrip antennas. Antennas Propag IEEE Trans 55(3):659–668

Jang J-SR, Sun C-T, Mizutani E (1997) Neuro-fuzzy and soft computing-a computational approach to learning and machine intelligence [Book Review]. Autom Control IEEE Trans 42(10):1482–1484

Novaes AB Jr, de Souza S, de Barros R, Pereira K, Iezzi G, Piattelli A (2010) Influence of implant surfaces on osseointegration. Braz Dent J 21(6):371–378

Talebian S, Afifi A, Hatami M, Bazgir S, Khanlou H (2014) Preparation and characterisation of electrospun silica nanofibres. Mater Res Innov 18(S6):S6-510

Liu X, Chu PK, Ding C (2010) Surface nano-functionalization of biomaterials. Mater Sci Eng 70(3):275–302

Barranco V, Onofre E, Escudero M, Garcia-Alonso M (2010) Characterization of roughness and pitting corrosion of surfaces modified by blasting and thermal oxidation. Surf Coat Technol 204(23):3783–3793

Orsini G, Assenza B, Scarano A, Piattelli M, Piattelli A (2000) Surface analysis of machined versus sandblasted and acid-etched titanium implants. Int J Oral Maxilofac Implant 15(6):779

Nishimoto SK, Nishimoto M, Park SW, Lee KM, Kim HS, Koh JT, Ong JL, Liu Y, Yang Y (2008) The effect of titanium surface roughening on protein absorption, cell attachment, and cell spreading. Int J Oral Maxilofac Implant 23(4):675–680

Acknowledgments

The authors would like to thank University of Malaya (UM.C/HIR/H-16001-00-D000027 and RP011D-13AET) for providing the research grant support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khanlou, H.M., Ang, B.C., Barzani, M.M. et al. Prediction and characterization of surface roughness using sandblasting and acid etching process on new non-toxic titanium biomaterial: adaptive-network-based fuzzy inference System. Neural Comput & Applic 26, 1751–1761 (2015). https://doi.org/10.1007/s00521-015-1833-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-015-1833-z