Abstract

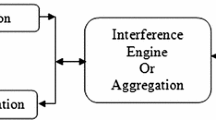

This study discusses the development of an Adaptive neuro–fuzzy inference system (ANFIS) model for determining the surface roughness (Ra) during machining of multidirectional woven fabric Carbon fiber reinforced plastics (CFRP) using Abrasive waterjet machining (AWM). Three variable input parameters—Jet pressure (JP), Traverse speed (TS), and Standoff distance (SOD)—were selected to assess the roughness of the CFRP along the traverse direction of the cut surface. The experimental results show that a lower JP deteriorated the finish by creating surface rupture. On the other hand, a poor surface finish was observed in the case of machining at higher TS and SOD. Further, the developed ANFIS model was used to validate the results and it was found that the predicted values were in good agreement with a 95 % confidence level. It was also evident that the ANFIS technique is helpful for better prediction of the experimental data with minimum error. Finally, the cut surface morphology was analyzed using a 3D non-contact surface profilometer and the results are discussed.

Similar content being viewed by others

References

M. Uthayakumar, M. A. Khan, S. T. Kumaran, A. Slota and J. Zajac, Machinability of nickel-based superalloy by abrasive water jet machining, Materials and Manufacturing Processes, 31 (13) (2016) 1733–1739.

V. A. Prabu, S. T. Kumaran and M. Uthayakumar, Performance evaluation of abrasive water jet machining on banana fiber reinforced polyester composite, Journal of Natural Fibers (2016) 10.1080/15440478.2016.1212768.

M. M. I. Wong, A. I. Azmi, C. C. Lee and A. F. Mansor, Kerf taper and delamination damage minimization of FRP hybrid composites under abrasive water-jet machining, International Journal of Advanced Manufacturing Technology (2016) 10.1007/s00170-016-9669-y.

A. Alberdi, T. Artaza, A. Suárez, A. Rivero and F. Girot, An experimental study on abrasive waterjet cutting of CFRP/Ti6Al4V stacks for drilling operations, International Journal of Advanced Manufacturing Technology, 86 (1) (2016) 691–704.

S. Madhu and M. Balasubramanian, Influence of nozzle design and process parameters on surface roughness of CFRP machined by abrasive jet, Materials and Manufacturing Processes (2016) 10.1080/10426914.2016.1257132.

A. Dhanawade and S. Kumar, Experimental study of delamination and kerf geometry of carbon epoxy composite machined by abrasive water jet, Journal of Composite Materials (2017) 10.1177/0021998316688950.

A. Sarkheyli, A. M. Zain and S. Sharif, A multi-performance prediction model based on ANFIS and new modified-GA for machining processes, Journal of Intelligent Manufacturing, 26 (4) (2015) 703–716.

A. I. Azmi, Monitoring of tool wear using measured machining forces and neuro-fuzzy modelling approaches during machining of GFRP composites, Advances in Engineering Software, 82 (2015) 53–64.

A. I. Azmi, R. J. T. Lin and D. Bhattacharyya, Tool wear prediction models during end milling of glass fibrereinforced polymer composites, International Journal of Advanced Manufacturing Technology, 67 (1) (2013) 701–718.

A. B. Chaudhari, V. Chaudhary, P. Gohil and K. Patel, Investigation of delamination factor in high speed drilling on chopped GFRP using ANFIS, Procedia Technology, 23 (2016) 272–279.

S. T. Kumaran, T. J. Ko, C. Li, Z. Yu and M. Uthayakumar, Rotary ultrasonic machining of woven CFRP composite in a cryogenic environment, Journal of Alloys and Compounds, 698 (2017) 984–993.

S. Palani, U. Natarajan and M. Chellamalai, On-line prediction of micro-turning multi-response variables by machine vision system using adaptive neuro-fuzzy inference system (ANFIS), Machine Vision and Applications, 24 (1) (2013) 19–32.

X. Chen, G. Cheng, H. Li and M. Zhang, Diagnosing planetary gear faults using the fuzzy entropy of LMD and ANFIS, Journal of Mechanical Science and Technology, 30 (6) (2016) 2453–2462.

B. L. Boada, M. J. L. Boada, A. Gauchía, E. Olmeda and V. Díaz, Sideslip angle estimator based on ANFIS for vehicle handling and stability, Journal of Mechanical Science and Technology, 29 (4) (2015) 1473–1481.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Haedo Jeong

S. T. Kumaran is currently a Research Professor in Yeungnam University, South Korea. He received M.Tech. degree from Government College of Technology, Tamil Nadu, India. He received Ph.D. degree in Mechanical Engineering from Kalasalingam University, Tamil Nadu, India. His research interests include tribological studies, surface modification, machining studies, cryogenics and materials characterization.

Tae Jo Ko is a Professor in Mechanical Engineering at Yeungnam University, South Korea. He received bachelor and master degrees from Pusan National University, South Korea. He received Ph.D. in Mechanical Engineering from POSTECH, South Korea. His research interests include development of machine tools, micro-cutting process, nontraditional machining, surface texturing using piezo electric actuator, surface texturing using grinding, bio-machining, textured surface on cutting tools and deburring process of CFRP composite.

Rights and permissions

About this article

Cite this article

Kumaran, S.T., Ko, T.J., Kurniawan, R. et al. ANFIS modeling of surface roughness in abrasive waterjet machining of carbon fiber reinforced plastics. J Mech Sci Technol 31, 3949–3954 (2017). https://doi.org/10.1007/s12206-017-0741-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0741-9