Abstract

The advancements in technology have led to a growing interest in additive manufacturing owing to its numerous benefits such as increased degree of freedom, high flexibility, and material conservation. It has gained particular attention in the production of electrical machines and their active components such as windings, electrical insulation, magnetic core packs, and permanent magnets. This paper investigates the use of two methods, namely fused deposition modeling and cold spray, in the production of hard magnetic components for rotors with surface-mounted magnets. A comparative study was conducted through a combination of finite element simulations and experimental tests.

Zusammenfassung

Die Fortschritte in der Technologie haben zu einem wachsenden Interesse an additiver Fertigung aufgrund ihrer zahlreichen Vorteile wie erhöhter Gestaltungsfreiheit, hoher Flexibilität und Materialkonservierung geführt. Insbesondere in der Herstellung von elektrischen Maschinen und ihren aktiven Komponenten wie Wicklungen, elektrischer Isolation, magnetischen Kernpaketen und Permanentmagneten hat das besondere Aufmerksamkeit erregt. Diese Arbeit untersucht den Einsatz von zwei additiven Fertigungsverfahren, nämlich dem Fused Deposition Modeling und dem Kaltgasspritzen, in der Herstellung von Hartmagnet-Komponenten für Rotoren mit oberflächenmontierten Magneten. Eine vergleichende Studie wurde durch eine Kombination von Finite Elemente-Simulationen und experimentellen Tests durchgeführt.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As a critical component in electrical machines, permanent magnets (PM) have been produced since the 18th century by powder metallurgy. This intricate process involves the mixing and preparation of powders and alloys, followed by pressing and aligning, and finally sintering and heat treatment [1]. However, despite the long production time and complexity of the process, the shape and anisotropic direction of the produced magnets are heavily constrained by the pressing and aligning stages, which restrict their applicability in various fields. Therefore, the implementation of additive manufacturing (AM) presents novel opportunities for designing electrical machines in the construction sector. It offers several key benefits, including rapid and cost-effective production, enhanced flexibility in the manufacturing process, and the ability to create lightweight structures [2].

In electrical machine applications, the key materials for magnets are Ferrite, NdFeB and SmCo. These magnets can be manufactured using additive processes such as selective laser melting, fused deposition modeling (FDM), and cold spray (CS) [3]. Goll et al. [4] successfully produced high-performance selective laser melting based NdFeB magnets and concluded that this technique enables the realization of very fine microstructures with defined texture. Another study on isotropic FDM-based magnets was carried out in [5], where a comparison was made with injection-molded magnets using the same material. Lamarre et al. [6] demonstrated the direct shaping of NdFeB composite material on electric motor parts using the CS method. The study showcased the promising potential of manufacturing magnets by fine-tuning the process parameters during the CS process. Furthermore, due to the advantages of AM, numerous studies have concentrated on the design process and soft-magnetic components of rotors using such as laser powder bed fusion or laser beam melting [7,8,9]. However, the existing studies were predominantly concentrated on either the manufacturing of hard-magnetic materials using a single method or the design process involving soft-magnetic materials for electrical machines.

Therefore, this paper explores two different methods for manufacturing hard-magnetic materials and compares their performance in electrical machines. Firstly, magnets were manufactured using the FDM and CS methods, with a focus on generating anisotropic behavior. Secondly, demonstrators based on magnetic properties and corresponding magnetizing facilities were designed and simulated. Lastly, experimental investigations and comparisons were conducted on the demonstrators with AM-magnets.

2 Additive manufacturing and anisotropy generation

2.1 Fused deposition modelling (FDM)

FDM is one of the seven AM-methods according to EN ISO/ASTM 52921:2017 [10]. It belongs to the category of material extrusion and is widely recognized as one of the most popular technologies for rapidly prototyping products and conceptual models. In addition to the general advantages of AM, the FDM stands out as an appealing choice for manufacturing of PM due to the simplified plant setup, flexible processing environment, and compatibility with magnetic materials.

A FDM machine tool was designed and built in an open coverage method at Fraunhofer IPK. Figure 1a, b illustrates the functional principle and provides an overview of the facility. The rigid filament is fed to the hot end using extruder, where it undergoes melting (operating temperature at 275 °C). The viscous material is then printed layer by layer on the print bed through a nozzle. The resulting PM samples undergo further processing involving debinding, sintering and thermal treatment.

a Schematic representation and b developed extruder with HA of the fused deposition modeling method [2]; c schematic representation and d simulated and measured curves of HA

To induce anisotropy in the printed magnets, it is imperative to utilize a magnetic field ideally greater than 1 T during the processing procedure. Due to the spatial limitations within the FDM plant, a Halbach Array (HA) using permanent magnets was designed around the nozzle, as depicted in Fig. 1c, d. Comprising three layers, this array generates a magnetic field in the axial direction. Consequently, measurements along the centerline of the HA revealed a maximum magnetic field strength of 0.87 T, demonstrating notable alignment with the simulation results.

2.2 Cold spray (CS)

Another promising AM-process for manufacturing of hard-magnetic materials is cold spray. Unlike laser-based processes such as laser powder bed fusion or laser powder buildup welding, the CS process operates without the need of thermal energy. Instead, it utilizes the kinetic energy of powder particles, which provides significant advantages in terms of thermal effects. Since the spray material is not molten during the process, the thermal influence on the coating and the substrate material is minimized [11].

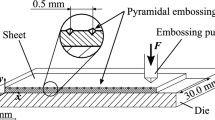

A CS process plant has been established in the Werner-von-Siemens Centre [12]. Figure 2 illustrates the operating principle. Initially, the carrier gas (usually nitrogen or helium) is compressed to 50 bar in the supply tank and heated up to a maximum of 1100 °C. The PM material powder and binder material are then introduced into the supply tank through the powder container. Simultaneously, the mixed powder is accelerated by the carrier gas to supersonic speeds of up to 1200 m/s. Utilizing the spray gun, both materials are propelled onto a carrier substrate, where they are applied in layers. The gas temperature is subsequently reduced to less than 100 °C at the outlet of the spray gun.

Schematic representation of the cold spray method [13]

2.3 Samples

To evaluate the magnetic properties and consequent anisotropy, cubic PM NdFeB samples were produced using the prescribed methods, followed by the measurement of corresponding hysteresis curves, as illustrated in Fig. 3.

The FDM green parts demonstrate a slight anisotropy, achieved by implementing the HA around the nozzle. In contrast, the CS samples exhibit isotropic characteristics due to the absence of a magnetic field during the process. The resulting magnetic characteristics are listed in Table 1, respectively.

3 Design of magnetizing coils

The manufactured samples of complete rotors are initially non-magnetic and acquire their polarization through magnetization. The conventional assembly process for PM motors can be intricate and pose potential hazards due to the electromagnetic force exerted by the manufactured and magnetized PMs. Considering of the assembly challenges, it is preferable to magnetize in-situ in a fully or partially assembled device using a pulse discharge magnetizer [14].

Furthermore, a continuous skew effect of an additively manufactured soft-magnetic rotor active part as investigated and analyzed in [15] has also been applied to the samples.

The AM-rotors discussed in this paper can fully benefit from the advantages offered by these approaches, as it enables the realization of theoretically arbitrary pole numbers and continuous skew angles by using special designed magnetizing coils.

3.1 Benchmark and AM-motors

To investigate the manufactured motors using the AM-methods mentioned above, we used a series-produced electric power steering (EPS) motor as benchmark motor. The rated specifications are derived and presented in Table 2. The 3D and 2D model of the motor and rotors are depicted in Fig. 4, respectively.

The EPS-motor designed as a 12-slot and 8‑pole servomotor with surface-mounted permanent magnets, has been installed in steering systems of VW group vehicles with the series number 5Q0 909 144 M. Its rotor, measuring 28.6 mm in length and 21.4 mm in radius, comprises two pairs of eight half-moon shaped magnets that are skewed by 7.5° to achieve smooth cogging torque. Subsequently, the AM rotors are simulated and manufactured with the same radius to fit into the EPS stators. The permanent magnets are manufactured in cylindrical form with a width of 5 mm, as indicated by the green color in the Fig. 4d.

3.2 Geometry design

To demonstrate the feasibility of achieving arbitrary pole numbers and skew angles for rotors, customized design of magnetizing coils is essential. In the case of the benchmark motor with 12 slots, magnetizing coils are designed for rotors with 8 and 16 poles. Compared to rotors with 8 poles, where the number of slots per pole and phase \(q\)= 1/2 results in the torque being generated by the stator fundamental field wave, the 16-pole rotors with \(q\)= 1/4 produce significantly less torque by the second harmonic of the stator field wave. By exploring these combinations, the theoretical skew angle can be calculated as follows:

In Eq. 1, k represents a freely selectable factor, np donates the period number, p refers to the pole pair number, N stands for the slot number, and gcd is the greatest common divisor.

To utilize the anisotropy of the FDM-manufactured magnets in the rotor a square slots design for the magnetizing coil is employed. This results in a rectangular magnetic field, while round slots are utilized for isotropic magnets to create a sinusoidal magnetic field. The design parameters can be found in Table 3.

3.3 Electrical and thermal design

Typically, capacitive storage devices are employed to generate pulse currents for a pulsed field magnetizer as illustrated in Fig. 5. The capacitor is charged by an input side supply to a voltage U0 and subsequently discharged through a switch over the inductive and resistive load, which is in this case, the magnetizing coil. The design procedure and electric characterization are described in [16].

Based on the designed geometry and construction of the magnetizing coils, the electrical parameters can be determined and presented in Table 4.

Furthermore, for safety reasons and to prevent undue thermal stress on the system, it is essential to ensure that the pulse current process causes few losses in the wires. The temperature rise in the magnetizing coil during magnetization can be considered adiabatic in such short time and calculated as follows:

In Eq. 2, Pv is the thermal loss and Cth is the thermal capacity of the total wire, which can be calculated with the specific thermal heat capacity cCu and mass of copper mCu.

Through an iterative calculation process, considering a temperature rise limitation of 40 K, the maximal current Imax for each coil can be determined.

3.4 Magnetizing results

The calculated field lines at the magnetizing points, where the maximal current flows through the coils, are illustrated in Fig. 6. The pole transition between poles is clearly visible. In most of the magnet area, the magnetic field strength exceeds 2500 kA/m, which, as indicated in [17], should be sufficient for complete magnetization. The radial flux density in the air gap 0.3 mm above surface of the 8‑pole rotors after magnetization was measured by Hall probe and depicted alongside simulated values in Fig. 7a.

It is evident that the FDM-rotor, featuring anisotropic magnets, exhibit a more rectangular flux density pattern, while the CS-rotor displays an almost sinusoidal pattern due to its isotropic behavior. The simulations closely match measurements within an acceptable margin of construction tolerance.

Furthermore, Fig. 7b and c demonstrate successful magnetization with adjustable continuous skew for 8‑pole and 16-pole configurations at the same rotor diameter.

4 Simulation and investigation

To compare the motor performance, the induced voltage and torque at no-load and load tests were simulated using Ansys Maxwell® for the AM motors.

4.1 Manufactured rotors

An experimental setup was devised to test the manufactured motors, consisting of a target machine and a load machine, which are mechanically coupled with a shaft. Supplementary peripheral equipment was integrated to regulate and control these machines. This enables the target machine to function as either a motor or a generator.

To conform to the benchmark stator, the AM rotors were produced at the same dimensions as the benchmark rotor, as depicted in Fig. 8.

4.2 Induced voltage

The induced voltage was simulated and measured in a no-load test with the rotor speed set at 100 rpm. As depicted in Fig. 9, the induced phase voltage of AM motors exhibited sinusoidal forms like that of the EPS motor. The measured values agree with the simulated one well. However, the amplitude of the induced voltage was significantly lower due to differences in magnetic specifications.

4.3 Torque

The torque was simulated for both no-load and load tests at a constant speed of 100 rpm. In the load test, the stator current was set to 2 A. The resulting torque values for 8‑pole motors are shown in Fig. 10.

As a result of in-situ magnetizing and continuous skewing, the AM motors exhibit reduced cogging torque at no-load test or torque pulsation at load test compared to the benchmark motor. However, the average torque achieved by these motors is lower due to the magnetic properties of the manufactured magnets.

5 Conclusion

This paper demonstrates the feasibility of manufacturing hard-magnetic materials using FDM and CS methods. Anisotropy during the FDM process was successfully generated in the manufactured magnets. Furthermore, motors with AM magnets were designed and simulatively investigated for an EPS-motor.

The results indicate that the AM motors exhibit reduced cogging torque and torque pulsation, due to the in-situ magnetizing and continuous skewing. Importantly, this paper highlights the realistic potential for implementing arbitrary pole settings and skew angles through additive manufacturing in this context.

References

Lalana, E. (2018) Review Permanent magnets and its production by powder metallurgy. Rev Met 54(2) e121: 10 pages

Conrad Electronic (2019) Handbuch 3D-Druck

Wu, F. et al (2020) Toward additively manufactured electrical machines: opportunities and challenges. IEEE Trans on Ind Applicat 56(2): pp.1306–1320

Goll, D. et al (2019) Refining the microstructure of Fe-Nd‑B by selective laser melting. Phys Status Solidi Rrl 13(3): 5 pages

Li, L. et al (2016) Big area additive manufacturing of high performance bonded NdFeB magnets. Sci Rep 6(36212): 7 pages

Lamarre, J. et al (2019) Permanent magnets produced by cold spray additive manufacturing for electric engines. Journal Thermal Spray Technology 28(7): pp.1709–1717

Lammers, S. et al (2016) Additive manufacturing of a ligh-weight rotor for a permanent magnet synchronous machine. 6th International Electric Drives Production Conference, Nuremberg, 5 pages

Gargalis, L. et al (2020) Additive manufacturing and testing of a soft magnetic rotor for a switched reluctance motor. IEEE Access 8: 10 pages

Urbanek, S. et al (2018) Additive manufacturing of a soft magnetic rotor active part and shaft for a permanent magnet synchronous machine. IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, pp. 668–674

Joamin, G. et al (2018) Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: a review and future perspectives. MDPI Mater 11(5): 36 pages

Braun, T. et al (2022) Evaluation of electric conductivity and mechanical load capacity of copper deposits for application in large winding components for electrical high-voltage machines made with cold spray additive manufacturing. International Thermal Spray Conference Proceedings (ITSC), Vienna, pp. 743–749

Werner-von-Siemens Centre https://wvsc.berlin. Accessed 8 Dec 2023

Impact Innovations Kaltgasspritz-Systeme. https://impact-innovations.com/produkte. Accessed 8 Dec 2023

Zhilichev, Y. et al (2002) In situ magnetization of isotropic permanent magnets. IEEE Trans Magn 38(5): 3 pages

Urbanek, S. et al (2020) Effects of continuous rotor skewing in Additively manufactured permanent magnet rotors. 2020 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, pp. 662–669

Dinca, C. et al (2015) Characterization of a 7 kJ magnetizing pulsed circuit for Online quality control of permanent magnets. IEEE Pulsed Power Conference (PPC), Austin, 7 pages

Binder, A. (1996) Design of coils for magnetizing rotors with surface rare earth permanent magnets. Proceedings of the International Conference on Electrical Machines (ICEM), Vigo, pp. 449–454

Acknowledgements

This research was funded by the Investitionsbank Berlin (IBB) with co-financing by the European Regional Development Fund (ERDF).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, T., Schwarzer, D., Neuwald, T. et al. Investigation and comparison of permanent magnet rotors produced by different additive manufacturing methods. Elektrotech. Inftech. 141, 155–163 (2024). https://doi.org/10.1007/s00502-024-01211-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00502-024-01211-2