Abstract

The vibration and acoustic behavior of electric machines is an important aspect of the design process. A crucial part of the modeling is the correct prediction of the stator’s vibration behavior, characterized by the stator’s eigenfrequencies and eigenmodes. For this purpose, a calculation approach called the analytical beam element model (ABM) was presented in a previous paper [18], where Euler–Bernoulli beams were used to describe the vibration behavior of the stator. The ABM introduced offers an alternative to the finite element (FE) method and to classical analytical models. In this paper, the model is examined and extended further. Different approaches conceived to better describe the influence of the stator yoke’s thickness by using Timoshenko beams and a multi-layer discretization are presented and discussed. Furthermore, a new feature that considers the lever arm effect of the stator teeth with respect to the yoke is introduced. The results are compared to FE calculations and measurements. Lastly, the improved ABM is used to calculate the vibration behavior of four stators with outer diameters ranging from \(160\,\text{mm}\) to \(7\,\text{m}\). The results are compared to FE results to prove the accuracy of the ABM.

Zusammenfassung

Die Berechnung des Schwingungsverhaltens elektrischer Maschinen ist ein wichtiger Bestandteil bei der Dimensionierung elektrischer Maschinen. Die schnelle und genaue Berechnung des mechanischen Schwingungsverhaltens, das durch die Eigenfrequenzen und -formen des Ständers bestimmt wird, stellt dabei eine Herausforderung dar. In dieser Arbeit wird ein neuer Berechnungsansatz vorgestellt, der auf einem analytischen Balkenelement beruht, und eine Alternative zu der Finite-Elemente-Methode (FEM) und den konventionellen analytischen Berechnungsansätzen ist. Das Analytische Balkenelement-Modell (ABM) wurde bereits in [18] eingeführt und anhand einer Beispielmaschine validiert. In dieser Arbeit wird das ABM weiter untersucht, erweitert und modifiziert. Der Einfluss der Ständerjochhöhe auf die Eigenfrequenzen und -formen wird modelliert. Dafür werden zwei unterschiedliche Balkenelement-Modelle, der Euler-Bernoulli-Balken und der Timoshenko-Balken, verwendet, und der Ständer wird mit mehreren Lagen von Balkenelementen modelliert. Zusätzlich wird die Verbindung der Zähne zum Ständerjoch untersucht. Eine Koordinatentransformation wird verwendet, um die Hebelwirkung der Ständerzähne auf das Ständerjoch zu berücksichtigen. Das modifizierte ABM wird anhand von Messungen und FE-Berechnungen der Beispielmaschine aus [18] validiert. Darüber hinaus wird das ABM verwendet, um das Schwingungsverhalten von vier unterschiedlichen Statoren mit Außendurchmessern von 160 mm bis 7 m zu bestimmen. Die Ergebnisse werden mit FE-Berechnungen verglichen, um die allgemeine Gültigkeit des ABM nachzuweisen.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

To determine the acoustic and vibration behavior of electric machines, the exciting magnetic forces in the air gap and the structural dynamic behavior of the machine must be calculated [1,2,3,4]. The forces in the air gap of the machine \(\vec{F}(\gamma^{\prime},t)\) can be converted into force waves \(\vec{\underline{F}}_{k}(\omega)\) with the order \(k\) describing the shape of the force wave. If the frequency and shape of a force wave coincide with an eigenmode and an eigenfrequency of the electric machine’s sound radiating parts, loud acoustic noise is emitted into the surroundings. Thus, the correct calculation in two domains, electromagnetic and structural dynamics, are important.

The vibration behavior of electric machines is characterized by the eigenfrequencies and eigenmodes of the sound radiating parts. The radiating parts are the stator, including the winding, and the housing. To calculate the vibration behavior, different approaches can be found in literature. Jordan and Frohne calculate the eigenfrequencies and eigenmodes using an analytical model based on a simplified circular ring of the machine’s stator [1, 5]. The stator teeth and the winding are considered as additional mass. This model is expanded in the axial direction by Gieras [6]. In [7, 8], Verma and Girgis present a model that is based on the energy method. Another calculation approach is the finite-element (FE) method. The geometry is discretized into small elements for which the equations of motion are solved. The FE method allows the definition of different components, such as the winding and the housing, using different material models [9,10,11,12,13]. Due to its high accuracy, the FE method is widely used to calculate the vibration behavior of electric machines [3, 10,11,12, 14,15,16,17].

The analytical models and the FE method have certain advantages and disadvantages. The analytical models can be implemented easily, need low computational resources and provide fast results. However, the models only provide valid results if certain boundary conditions are fulfilled: the ratio \(\frac{h_{\mathrm{y}}} {D_{\mathrm{o}}}\) of the yoke height \(h_{\mathrm{y}}\) to the outer diameter \(D_{\mathrm{o}}\) must be small and the tooth eigenfrequencies must be significantly higher than the yoke eigenfrequencies. Furthermore, it is impracticable or at least difficult to include different components such as winding, teeth and housing in the model. The FE models can consider different geometries and components and can give more accurate results. However, they require high computational resources, a long modeling time and typically a software license.

To provide a fast and accurate calculation model that combines the advantages of the analytical models and the FE method, the so-called analytical beam element model (ABM) is introduced in [18]. The model is based on an Euler-Bernoulli beam element model that consists of two nodes, each with three degrees of freedom. The beams are used to build up a 2D model of the stator, including the stator yoke and teeth. The system’s equation is derived from the beam element equations and is solved to determine the eigenfrequencies and eigenmodes. In [18], the ABM is validated using measurement results from the stator of a high-speed electric machine.

The goal of this work is to examine and extend the ABM further and to apply the model to machines of different sizes for validation. First, the basic approach of the ABM is summarized in Sect. 2. Then, different new approaches to the consideration of the stator yoke’s thickness are discussed in Sect. 3. These are the Timoshenko beam formulation, the multi-layer discretization of the yoke and a new feature which considers the lever arm effect of the stator teeth with respect to the yoke’s intermediate surface, which are introduced in this paper. The results are compared to measurements and FE simulations in Sect. 4. In order to prove the general applicability of the ABM, the vibration behavior of four different stators with outer diameters ranging from \(160\,\text{mm}\) to \(7\,\text{m}\) are calculated. The results from these machines are compared to FE simulations in Sect. 5.

2 Analytical Beam Element Model — Basic Approach

In this section, the ABM is briefly introduced. A detailed description can be found in [18]. The individual steps employed to build the ABM are shown in Fig. 1 and described in the Sects. 2.2 to 2.5. First, the basic equation and the solution of a multi-mass oscillator are described in Sect. 2.1. Based on the basic approach of the ABM, the new modeling approaches are introduced.

2.1 Basic Equation of a Multi-Mass Oscillator

The stator of an electric machine can be described by a multi-mass oscillator. This is a multi-degree-of-freedom (DOF) system without gyroscopic effects that can be generally described by

where \(\mathbf{M}\), \(\mathbf{D}\) and \(\mathbf{K}\) are the mass, damping and stiffness matrices, respectively. \(\vec{F}\) is the vector of the applied forces and \(\vec{x}\) is the vector of displacements for each DOF.

The system can be decomposed and diagonalized in terms of its eigenvectors \(\vec{\Psi_{r}}\), also known as its eigenmodes, and the corresponding eigenfrequencies \(f_{0,r}\). The eigenfrequencies \(\omega_{0,r}=2\pi f_{0,r}\) are calculated by solving

which will provide \(q\) solutions for a system with \(q\) DOFs. \(r\) is the order of the eigenmodes. In case of a cylindrical structure such as the stator of an electric machine, the order \(r\) represents the number of maxima or minima around the circumference.

The eigenvectors \(\vec{\Psi_{r}}\) are determined by replacing each of the \(q\) obtained eigenfrequencies in (1), rewritten in the frequency domain with no damping and no external forces. The base transformation or modal matrix \(\boldmath{\Psi}\) is then defined as the matrix formed by the \(q\) eigenvectors placed in its columns

The relationship between the vectors \(\vec{x}\) (in the original base) and \(\vec{X}\) (in the transformed base) is given by

Since the eigenvectors provide only the directions of the new vector base, they can be arbitrarily scaled. Typically, the mass matrix is used for the scaling, giving the relations

where \(r=1...q\). In (7), it is assumed that the damping matrix can be approximated as a linear combination of the mass and stiffness matrices, and \(d_{r}\) is the modal damping factor for eigenmode \(r\). As a result, the decoupled system equations in the transformed base become

Using this equation, the vibration response \(\vec{x}\) to a force excitation \(\vec{F}\) of the system can be calculated. This procedure forms the basis of the vibration and acoustic analysis. The purpose of the ABM is to describe the mass and stiffness matrices and to calculate the eigenfrequencies and eigenmodes.

2.2 Euler-Bernoulli Beam Element

In the basic approach introduced in [18], the Euler–Bernoulli beam element, as represented in Fig. 1a, is used to discretize the stator of an electric machine and to generate the mass and stiffness matrices.

The stiffness matrix \(\mathbf{K}_{\mathrm{e}}\) for such a beam element with three DOFs per node is

\(E\) is the material’s Young’s modulus, \(l\) is the beam element length, \(A\) is the cross-sectional area and \(I\) is the moment of inertia of the beam [19]. Shear strains are neglected in this formulation. Similarly, the element’s mass matrix \(\mathbf{M}_{\mathrm{e}}\) is defined as

where \(\rho\) is the beam material’s mass density [19]. The mass and stiffness matrices are defined by considering the node DOFs shown in Fig. 1a as a vector written in the sequence \([u_{\mathrm{A}},v_{\mathrm{A}},{\phi}_{\mathrm{A}},u_{B},v_{B},\phi_{B}]^{T}\).

2.3 Representation of the Stator Geometry with Beam Elements

The cross-sectional area of the elements in the yoke corresponds to the stator’s axial length \(l_{\mathrm{s}}\) multiplied by the yoke height \(h_{\mathrm{y}}\). The cross-section of the elements which represent the teeth is assumed to be constant and is defined by the stator’s axial length and the average width of the teeth. In case the teeth have tips with a larger width, the tip’s additional mass is accounted for by increasing the mass density of the last element of each tooth.

Initially, the elements are not connected to each other. This way, the free element equations, using their own local coordinate systems, can be written by replicating the single-element mass and stiffness matrices on the diagonal of a global matrix. This procedure produces the stiffness matrix \(\mathbf{K}_{\mathrm{raw}}\) and the mass matrix \(\mathbf{M}_{\mathrm{raw}}\) [18].

2.4 Coordinate Transformation

The next step is to connect the beam elements to each other. This is achieved by means of defined master nodes named P11… \(P_{Tn}\) and Q11…\(Q_{Tm}\), which use a cylindrical coordinate system and correlate with the beam nodes A, B, C, and D, as illustrated in Fig. 1c. The relation between an arbitrary element node EN in its local coordinate system and a corresponding master node MN in cylindrical coordinates is

\(\theta\) is the angle between the \(r\) and \(y\) axes of the cylindrical and local coordinate systems. Based on the trigonometric relations shown in Fig. 1c, the transformation matrices are calculated as

for nodes A, B, C, and D, respectively. The angle \(\alpha\) is the angle between adjacent elements in the stator yoke.

2.5 Stator Geometry with Master Nodes

Based on this, a complete nodal transformation from ABCD (element nodes) to PQ (master nodes) is performed by

\(\mathbf{A}\) is the assembly matrix obtained by combining the previously defined transformation matrices \(\mathbf{H}_{\mathrm{A}}\), \(\mathbf{H}_{\mathrm{B}}\), \(\mathbf{H}_{\mathrm{C}}\) and \(\mathbf{H}_{\mathrm{D}}\), surrounded by zeros. The final system stiffness matrix \(\mathbf{K}_{\mathrm{A}}\) and mass matrix \(\mathbf{M}_{\mathrm{A}}\) of the connected beams become

and

These two matrices are used for calculating the stator eigenmodes and eigenfrequencies according to the procedure described in Sect. 2.1.

3 Different Modeling Approaches

Different approaches are investigated for taking into account the effect of the stator yoke’s thickness on the eigenmodes and eigenfrequencies. These approaches use the Timoshenko beam element or the multi-layer structure which are presented and compared in the following subsections. Furthermore, a translation transformation is introduced to consider the lever arm effect of the stator teeth on the yoke’s intermediate surface.

3.1 Timoshenko Beam

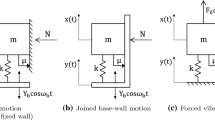

The first approach involves to replace the Euler-Bernoulli beam element used in [18] with the Timoshenko beam element. The Euler-Bernoulli beam element assumes that the beam cross-section remains perpendicular to the beam’s intermediate axis when deformed. This assumption neglects the shear deformations and is typically suitable for problems where the beam thickness is relatively small compared to its length. The Timoshenko formulation allows the beam cross-section to rotate with respect to the intermediate axis and, therefore, takes into account possible shear deformations. This allows the method to account for the natural tendency of the cross-section to rotate back to its initial position, relieving the internal stresses and making the Timoshenko formulation suitable for moderately thick beams. Fig. 2 illustrates the assumptions made using the two formulations discussed.

According to the Timoshenko formulation, the mass matrix

can be written as the sum of the translational mass \(\mathbf{M}_{\mathrm{trans}}\) and the rotational mass \(\mathbf{M}_{\mathrm{rot}}\). Together with the corresponding stiffness mass \(\mathbf{K}_{\mathrm{e}}\) they are [19]

and

\(C\) and \(\gamma\) are defined by

\(\kappa\) is the shear correction factor used to consider the non-uniform shear distributions. It is typically assumed to be \(5/6\) [19]. \(G\) is the shear modulus. Under the assumption that the material is isotropic, this can be calculated as [20]

\(\mu\) is the Poisson’s ratio. When considering an isotropic material, the material is defined if two of the three quantities \(E\), \(G\) and \(\mu\) are known. It is worth noting that (9) and (10) from the investigation of the Euler-Bernoulli beam correspond to a particular case of the Timoshenko beam in which the shear modulus \(G\) tends to infinity.

3.2 Multi-Layer Structure

Another possible approach to considering the stator yoke’s thickness accurately is to discretize the yoke with multiple Euler-Bernoulli beam element layers, as represented in Fig. 3. The layers are connected to each other by vertical beam elements with a cross-section dependent on the number of elements around the circumference and a length dependent on the number of layers. It is worth noting that the vertical elements’ masses would overlap with that of the yoke elements, since they occupy the same volume. Therefore, the mass density of all the vertical elements in the yoke is set to zero, so that they act solely as an ideal elastic connection between the layers.

This approach also requires an extension of the assembly matrix \(\mathbf{A}\) defined in (13) to consider the connection of the newly introduced beams. The extensions are made following the same principle as presented in Sect. 2.2.

3.3 Tooth Connection Modeling

Since the beam elements representing the stator yoke correspond to the yoke’s intermediate surface, a direct connection between the tooth base and the yoke nodes would produce a partial overlap of the tooth and yoke beam elements. Taking the yoke height as \(h_{\mathrm{y}}\), the overlapping height is \(\frac{h_{\mathrm{y}}}{2}\) as illustrated in Fig. 4. Evidently, this fact becomes more relevant for the case of a thick stator yoke.

In this work, an additional translational transformation of the master nodes \(P\) is considered as means to connect the nodes of the tooth bases to the yoke. This translation corresponds to the lever arm effect of the yoke cross-section modeled as a rigid body when it rotates. For an arbitrary translation of (\(\mathrm{\Delta}x\), \(\mathrm{\Delta}y\)) applied to a point \(P^{\prime}\) with respect to the point \(P\), the transformation matrix \(\mathbf{T}(\mathrm{\Delta}x,\mathrm{\Delta}y)\) can be defined as

In combination with the rotation matrix presented in (11), a generalized coordinate transformation including translations and rotation effects can be defined as the multiplication \(\mathbf{H}(\theta)\cdot\mathbf{T}(\mathrm{\Delta}x,\mathrm{\Delta}y)\). For the connection of the nodes in the tooth base to the yoke, for instance, the transformation matrix is calculated using \(\theta=\frac{\pi}{2}\), \(\mathrm{\Delta}x=0\) and \(\mathrm{\Delta}y=\frac{-h_{\mathrm{y}}}{2}\). Such complete transformation can be considered when generating the assembly matrix \(\mathbf{A}\), as explained in (13), so that the lever arm effect of the tooth base with respect to the yoke’s intermediate surface can be taken into account.

4 Comparison of the Modeling Approaches

For a comparison of the modeling approaches described in Sect. 3, the stator S1 shown in Table 1 will be used. At first, only the stator yoke without the teeth is analyzed. This allows the evaluation of the different methods for considering the yoke height without the effect of the teeth. Then, the complete model with the teeth is calculated using the ABM and is compared with measurements and FE simulations. The results of the FE simulations and the measurements have already been presented in [10, 21].

4.1 Stator Yoke

Table 2 summarizes the results of the ABM with the Euler-Bernoulli (EB) beam, the Timoshenko (TS) beam and the multi-layer (ML) approach to modeling the stator yoke. 120 elements are considered around the circumference for all the ABM models and the multi-layer model is calculated with two layers. The results are compared to the FE simulation results and the deviations \(f_{\mathrm{\Delta},r,EB/TS/ML}=\frac{f_{0,r,EB/TS/ML}-f_{0,r,\text{FE}}}{f_{0,r,\text{FE}}}\) between the individual approaches (EB/TS/ML) and the FE model are determined.

It can be seen that the model with the Euler-Bernoulli beam element produces the highest deviations \(f_{\mathrm{\Delta},r}\) when compared to the FE model. This is due to the fact that the shear strains are neglected in this method, which is appropriate for slender beams but becomes less accurate when the thickness of the beam increases in relation to its length. The ratio of the yoke height \(h_{\mathrm{y}}\) to the mean stator diameter \(D_{\mathrm{o}}\) is 0.103 for the stator S1. In this case, the results calculated using the Timoshenko beam element and the multi-layer approach are more accurate. Although these two aforementioned methods present similar deviations for the case studied (\(f_{\mathrm{\Delta},r}=0.02\%{\ldots}4.88\%\)), the Timoshenko approach is the one which offers more advantages. One is that it requires less elements than the multi-layer approach, since only one layer is necessary. Another is that the effect of the shear strain is intrinsically considered in the constituent equations of the Timoshenko beam, whereas, in the multi-layer approach, this is accounted for by means of the virtual vertical beams connecting the layers. As a consequence, the stiffness for shear displacements between the layers becomes dependent on the number of elements in the system in such a way that an excessive number of elements (with consequently very thin vertical beams) would produce a model which underestimates the shear stiffness. Accordingly, the multi-layer approach leads to different results for different numbers of vertical beam elements.

4.2 Stator Yoke with Teeth

In Table 3, the results for the stator with teeth are summarized and compared to measurements and results of the FE simulations. In this case, only the ABM with the Timoshenko beam element is considered since, as discussed in Sect. 4.1, this produces better results for the modeling of the stator yoke’s thickness. The ABMs are composed of 120 elements in the yoke and 5 elements per tooth. Two variants of the Timoshenko approach are compared: one including the effect of the lever arm discussed in Sect. 3.3 (TS,LA) and another one neglecting this effect (TS).

Furthermore, the results are compared to the FE model and to results of an experimental modal analysis. The experimental modal analysis is performed by means of an instrumented hammer and one accelerometer installed in the back of the yoke. Details concerning the test procedure and the results obtained can be found in the related papers [10, 21].

The deviations \(f_{\mathrm{\Delta},r}\) shown in Table 3 are calculated with respect to the measured values. An exception is made for the eigenmode \(r=5\), which could not be identified in the measurements due to its high frequency (see [10, 21]). In this case, the deviations marked with an asterisk (*) are calculated with respect to the FE model.

In general, it can be seen that the calculated eigenfrequencies show a good agreement with the measurements, with a maximum absolute deviation of 7.43%. Nevertheless, the deviations are generally lower when the lever arm effect discussed in Sect. 4.1 is taken into account. This becomes more evident for the mode \(r=4\), where large deflections of the teeth are present, as can be seen in Table 5. The absolute deviation decreases from 7.43% to 4.06% when the lever arm effect is considered.

5 Vibration Behavior of Different Stator Geometries

In this section, the ABM is used to calculate the vibration behavior of four different stators. The stators are shown in Table 4 together with their geometric and material data. The outer diameter of the stators ranges from \(D_{\mathrm{o}}=160\,\text{mm}\) to \(D_{\mathrm{o}}=7\,\text{m}\) and the number of teeth ranges from \(N_{1}=24\) to \(N_{1}=480\).

The stator S1 has already been introduced in Sect. 4 and is used in a high-speed electric machine for a traction application [22]. Stators S2, S3 and S4 are taken from real applications. The stator S2 is derived from a conventional electric machine for a traction application. The stator S3 is derived from a prototype hydrogenerator and the stator S4 from a real operational hydrogenerator.

The vibration behavior of the four stators is calculated using 2D FE models. The material data in Table 4 is used for the simulations. The results of the FE calculations are used as a reference for the results calculated with the improved ABM using the Timoshenko beam element, including the lever arm effect of the teeth relative to the yoke. The eigenmodes \(\vec{\Psi}_{r}\), the eigenfrequencies \(f_{0,r}\) and their deviations \(f_{\mathrm{\Delta},r}\) are given in Table 5.

5.1 Stator S1

The eigenfrequencies of the eigenmodes \(r=2\), \(r=3\), \(r=0\), \(r=4\) and \(r=5\) of stator S1 are shown in Table 5. As discussed in Sect. 4, the deviations are lower than \(5\%\). The eigenmodes calculated using the ABM show a good accordance with the eigenmodes calculated using the FE model. Beside the eigenmode \(r=0\), the deviations \(f_{\mathrm{\Delta},r}\) between the ABM and the FE model are negative, indicating that the ABM is tendentially less stiff than the FE model in this case.

5.2 Stator S2

Due to the larger size of stator S2, its eigenfrequencies are reduced in comparison to stator S1. According to the conclusions of Jordan [1], the bending eigenmodes \(r=2\), \(r=3\), \(r=4\), \(r=5\) of the stator are reduced more sharply than the eigenmode \(r=0\) due to the increased size of the machine. The deviations \(f_{\mathrm{\Delta},r}\) between the calculated eigenfrequencies of the ABM and the FE models are lower than \(2\%\), except for eigenmode \(r=5\). For the eigenmode \(r=5\), the deviation is around \(6\%\). The calculated eigenmodes show a good accordance. For the stator S2, the deviations between the ABM and the FE model are both negative or positive.

5.3 Stator S3

The eigenmodes and eigenfrequencies of stator S3 show a good accordance between the ABM and the FE model. The deviations between the eigenfrequencies \(f_{\mathrm{\Delta},r}\) are lower than \(3\%\) (see Table 5). It is striking that the deviations are all negative. In comparison to stators S1 and S2, the eigenfrequencies are lower due to the larger size of the stator.

5.4 Stator S4

The calculated eigenmodes and eigenfrequencies of stator S4 confirm the results so far. The deviations between the ABM and FE model \(f_{\mathrm{\Delta},r}\) are lower than \(1.5\%\). Accordingly, it can be concluded that the ABM and the FE model show a very high accordance. As with the stator S3, the deviations \(f_{\mathrm{\Delta},r}\) are all negative (see Table 5).

The comparison of the four stators’ vibration behavior using the ABM and the FE model proves that the ABM is capable of correctly predicting the vibration behavior of electric machines with outer diameters from \(D_{\mathrm{o}}=160\,\text{mm}\) to \(D_{\mathrm{o}}=7\,\text{m}\). Despite the eigenfrequency \(f_{r=5}\) of stator S2, the deviation \(f_{\mathrm{\Delta},r}\) is lower than \(5\%\), indicating a good agreement between the ABM and the respective FE model.

The deviations between the ABM and the FE model are mainly negative. This indicates that the ABM tends to be less stiff than the FE method. Furthermore, it is noteworthy that the deviation \(f_{\mathrm{\Delta},r}\) decreases with increasing size of the machine. To analyze this, the mean deviation \(\overline{f}_{\mathrm{\Delta}}=\frac{\sum_{r_{\mathrm{min}}}^{r_{\mathrm{max}}}|f_{\mathrm{\Delta},r}|}{n_{r}}\) is calculated.

The ratio \(\frac{h_{\mathrm{y}}}{D_{\mathrm{o}}}\) between the yoke height and the outer diameter decreases with increasing size as well (see Table 4). Accordingly, the influence of the shear strain in the stator yoke is higher for machines with a high ratio of \(\frac{h_{\mathrm{y}}}{D_{\mathrm{o}}}\). The shear strain is only approximated by the Timoshenko beam element and is better described by the FE models. Thus, the deviations between the FEM and ABM decrease with increasing size of the stators S1 to S4. These observations can also be made when calculating the vibration behavior using the analytical model of Jordan [1]. This analytical model is not capable of correctly calculating the vibration behavior of small machines with a high ratio of \(\frac{h_{\mathrm{y}}}{D_{\mathrm{o}}}\). For machines with a small ratio of \(\frac{h_{\mathrm{y}}}{D_{\mathrm{o}}}\), the analytical model leads to better results. Accordingly, the correct description of the stator yoke’s vibration behavior is the major challenge in the calculation of the vibration behavior for machines with a high ratio of \(\frac{h_{\mathrm{y}}}{D_{\mathrm{o}}}\). It can be concluded that the approach presented, using the Timoshenko beam element model, is capable of calculating the vibration behavior of machines of different sizes, taking into account the vibration behavior of the stator yoke.

6 Conclusion

In this paper, the ABM originally presented in [18] is examined and expanded further. Different modeling approaches are investigated to enhance the calculation accuracy of the ABM and the model is applied to machines of different sizes for validation.

One major challenge is the correct description of the stator yoke’s thickness and its influence on the vibration behavior. To consider this effect in the ABM, two different approaches are compared in this work: the use of the Timoshenko beam element and the modeling of the stator using a multi-layer structure. Furthermore, the model is enhanced by adding a feature which considers the lever arm effect of the stator teeth with respect to the yoke’s intermediate surface.

When comparing the results of the ABM with FE and measurement results, it can be concluded that the use of the Timoshenko beam element is the best means to consider the stator yoke’s thickness. The modeling approach using a multi-layer structure does not lead to convincing results, since the model accuracy depends on the number of vertical beam elements used. Additionally, the feature which considers the lever arm effect of the stator teeth increases the calculation accuracy yet further.

In order to validate the method presented for a large range of applications, the improved ABM, using the Timoshenko beam element and considering the lever arm effect, is used to calculate the vibration behavior of four stator cores of different sizes. The results are compared to FE results and show a high accordance. The deviation of the eigenfrequencies is mostly less than \(5\%\). It is noteworthy that the deviation between the ABM and FE even decreases with increasing size of the machines. For the stator S4, the deviation of the eigenfrequencies is even lower than \(1.5\%\).

Overall, the measures presented in this work improve the calculation quality of the ABM further and enable it to calculate the vibration behavior of machines of different sizes.

The ABM can be used in combination with calculated electromagnetic forces to predict the machine’s vibration during operation. Furthermore, the model has the potential to be extended to include the winding and the stator’s frame or housing, and also to be expanded in the axial direction, allowing it to consider axial eigenmodes.

Change history

01 June 2023

An Erratum to this paper has been published: https://doi.org/10.1007/s00502-023-01136-2

Abbreviations

- A :

-

Cross-sectional area

- \(\mathbf{A}\) :

-

Assembly matrix

- \(\mathbf{D}\) :

-

Damping matrix

- \(D_{\mathrm{i}}\) :

-

Inner yoke diameter

- \(D_{\mathrm{o}}\) :

-

Outer yoke diameter

- \(E\) :

-

Young’s modulus

- \(f\) :

-

Frequency

- \(\vec{F}\) :

-

Force vector

- \(h_{\mathrm{y}}\) :

-

Yoke height

- \(h_{\mathrm{t}}\) :

-

Tooth height

- \(h_{\mathrm{tt}}\) :

-

Tooth tip height

- \(I\) :

-

Moment of inertia

- \(\mathbf{K}\) :

-

Stiffness matrix

- \(k\) :

-

Order of force wave

- \(l\) :

-

Element length

- \(l_{\mathrm{s}}\) :

-

Stator length

- \(\mathbf{M}\) :

-

Mass matrix

- \(m\) :

-

Number of elements per tooth

- \(N_{1}\) :

-

Number of stator slots

- \(n\) :

-

Number of yoke elements per slot pitch

- \(q\) :

-

Number of degrees of freedom

- \(r\) :

-

Order of eigenmode

- \(t\) :

-

Time

- \(T\) :

-

Number of stator teeth

- \(u\) :

-

Displacement in direction \(x\) or \(t\)

- \(v\) :

-

Displacement in direction \(y\) or \(r\)

- \(w_{\mathrm{t}}\) :

-

Tooth width

- \(w_{\mathrm{tt}}\) :

-

Tooth tip width

- \(w_{\mathrm{so}}\) :

-

Slot opening width

- \(\vec{x}\) :

-

Node displacement vector

- \(\alpha\) :

-

Angle between adjacent elements

- \(\gamma^{\prime}\) :

-

Mechanical angle

- \(\rho\) :

-

Mass density

- \(\phi\) :

-

Bending angle

- \(\theta\) :

-

Angle between coordinate systems

- \(\vec{\Psi}\) :

-

Eigenvector

- \(\omega\) :

-

Angular frequency

References

Jordan H (1950) Der geräuscharme Elektromotor. Girardet, Essen

Braunisch D, Ponick B, Bramerdorfer G (2013) Combined analytical–numerical noise calculation of electrical machines considering nonsinusoidal mode shapes. IEEE Trans Magn 49(4):1407–1415

Vip S-A, Hollmann J, Ponick B (2019) Nvh-simulation of salient-pole synchronous machines for traction applications. In: Proceedings 2019 International Aegean Conference on Electrical Machines and Power Electronics (ACEMP) & 2019 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM). IEEE, Piscataway, pp 246–253

Hofmann A, Qi F, Lange T, de Doncker RW (2014) The breathing mode-shape 0: Is it the main acoustic issue in the pmsms of today’s electric vehicles? In: 17th International Conference on Electrical Machines and Systems (ICEMS). IEEE, Piscataway, pp 3067–3073

Frohne H (1959) Über die primäre Bestimmungsgrößen der Lautstärke bei Asynchronmaschinen. Dissertation thesis, Technische Hochschule Hannover, Hannover

Gieras JF, Wang C, Lai JC (2006) Noise of polyphase electric motors, volume 129 of Electrical and computer engineering. CRC/Taylor & Francis, Boca Raton

Verma SP, Girgis RS (1973) Resonance frequencies of electrical machine stators having encased construction, part i: Derivation of the general frequency equation. IEEE Transactions on Power Apparatus and Systems, PAS-92(5), pp 1577–1585

Girgis RS, Vermas SP (1981) Method for accurate determination of resonant frequencies and vibration behaviour of stators of electrical machines. IEEE Proc B Electr Power Appl 128(1):1–11

Schwarzer M (2017) Structural Dynamic Modeling and Simulation of Acoustic Sound Emissions of Electric Traction Motors. Dissertation thesis, Technische Universität Darmstadt, Darmstadt

Gerlach ME, Bender TN, Ponick B (2022) Influence of round wire winding and insulation on the vibration behavior of electric machines. In: 2022 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM). IEEE, Piscataway, pp 7–13

Gerlach ME, Weber S, Ponick B (2022) Influence of hairpin winding and insulation on the vibration behavior of electric machines. In: 2022 International Conference on Electrical Machines (ICEM). IEEE, Piscataway, pp 635–641

Gerlach ME, Weber S, Ponick B (2022) Influence of concentrated winding and insulation on the vibration behavior of electric machines. In: 2022 International Conference on Electrical Machines and Systems (ICEMS). IEEE, Piscataway

Wegerhoff M, Drichel P, Back B, Schelenz R, Jacobs G (2015) Method for determination of transversely isotropic material parameters for the model of a laminated stator with windings. In: 22nd international congress on sound and vibration Florence, pp 1–8

Wang K, Wang X (2017) The modal analysis of the stator of the interior permanent magnet synchronous motor. In: 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific). IEEE, Piscataway, pp 1–6

de Barros A, Galai A, Ebrahimi A, Schwarz B (2021) Practical modal analysis of a prototyped hydrogenerator. Vibration 4(4):853–864

Mair M, Weilharter B, Rainer S, Ellermann K, Bíró O (2013) Numerical and experimental investigation of the structural characteristics of stator core stacks. Compel 32(5):1643–1664

Tang Z, Pillay P, Omekanda AM, Li C, Cetinkaya C (2004) Young’s modulus for laminated machine structures with particular reference to switched reluctance motor vibrations. IEEE Trans on Ind Applicat 40(3):748–754

Allan de Barros MEG, Xang H, Langfermann M, Ponick B, Ebrahimi A (2022) Calculation of electric machines vibration using an analytical beam element model. In: 2022 International Conference on Electrical Machines (ICEM). IEEE, Piscataway, pp 2200–2206

Buntara SG (2018) An isogeometric approach to beam structures. Springer, Berlin Heidelberg

Gottstein G (2014) Materialwissenschaft und Werkstofftechnik: Physikalische Grundlagen, 4th edn. Springer-Lehrbuch. Springer Vieweg, Berlin

Gerlach ME, Ponick B (2020) Influence of the stator winding and forming of the end winding on the vibration behavior of electric machine’s stator core. In: Proceedings 2020 International Conference on Electrical Machines (ICEM). IEEE, Piscataway, pp 1171–1177

Gerlach ME, Zajonc M, Ponick B (2021) Mechanical stress and deformation in the rotors of a high-speed pmsm and im. E I Elektrotech Informationstech 138(2):96–109

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This work was supported by the German Federal Ministry of Economic Affairs and Energy on the basis of a decision by the German Bundestag.

The original online version of this article was revised to correct table 5.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gerlach, M.E., de Barros, A., Huang, X. et al. The analytical beam element model: novel approach for fast calculation of vibrations in electric machines. Elektrotech. Inftech. 140, 290–301 (2023). https://doi.org/10.1007/s00502-023-01125-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00502-023-01125-5

Keywords

- Electric machines

- Finite element analysis

- Magnetic cores

- Numerical models

- Stators

- Vibrations

- Eigenfrequencies

- Eigenmodes

- Analytical calculation

- Beam element