Abstract

The objective of mining is to supply society with mineral and therefore to extract mineral deposits safely and economically, and as completely as possible. As shallow deposits are becoming more and more depleted and as the mineral demand is rising, mining has to advance to greater depths or more challenging mining environments. Operational and technical challenges arise consequently. The different challenges are discussed briefly, and it is shown that in particular the importance of rock mechanics increases because the resulting stress and energy changes can cause rock pressure phenomena and rock pressure problems. The intensity of rock pressure phenomena and rock pressure problems is a function of several parameters, of which the prevailing stress magnitudes and the rock mass strength are central. Whilst rock pressure phenomena are manageable and do not endanger the objectives of mineral extraction, rock pressure problems threaten the objective of mineral extraction and may in extreme cases prevent the continuation of an operation. As the stress magnitudes rise with depths, but the rock mass strength does generally not increase with depths, the importance of rock pressure control increases with depth. To control the rock pressure, two different strategies, a passive and an active strategy, can be distinguished. The two strategies are discussed. Despite the advantages offered by the active strategy, the passive strategy is still dominantly applied. Reasons for this dominance are identified and discussed. To facilitate the application of the active strategy, a stress management concept is proposed. Finally, the requirements for a wider implementation of an active stress management strategy are briefly discussed.

Zusammenfassung

Das Ziel des Bergbaus ist die Versorgung der Gesellschaft mit Rohstoffen und aus diesem Grund der sichere, möglichst vollständige und wirtschaftliche Abbau von Lagerstätten. Da seichtliegende Lagerstätten zusehends erschöpft sind und der Rohstoffbedarf steigt, schreitet der Abbau von Rohstoffen in größere Teufen beziehungsweise in schwierigen Bedingungen voran. Aus diesem Umstand treten betriebliche und technische Herausforderungen auf. Die verschiedenen Herausforderungen werden kurz diskutiert. Die Diskussion zeigt, dass insbesondere die Bedeutung der Gebirgsmechanik mit zunehmender Teufe und komplexeren Gebirgsbedingungen zunimmt, weil die vom Abbau hervorgerufenen Änderungen der Gebirgsspannungen und die Freisetzung von Energie Gebirgsdruckerscheinungen und Gebirgsdruckprobleme hervorrufen können. Die Ausprägung der Gebirgsdruckerscheinung und der Gebirgsdruckprobleme hängt von mehreren Parametern ab, jedoch kommt den vorliegenden Gebirgsspannungen und der Gebirgsfestigkeit eine besondere Bedeutung zu. Gebirgsdruckerscheinungen sind im Betrieb gut beherrschbar und gefährden daher nicht die Ziele des Bergbaus. Demgegenüber gefährden jedoch Gebirgsdruckprobleme die Erreichung der Ziele des Bergbaus und sie können im Extremfall die Weiterführung des Abbaus verhindern. Da die Gebirgsspannungen mit der Teufe zunehmen und da die Gebirgsfestigkeit nicht mit der Teufe zunimmt, nimmt die Wichtigkeit der Kontrolle des Gebirgsspannungen mit der Teufe zu. Zwei verschiedene Strategien zur Gebirgsdruckkontrolle können unterschieden werden, nämlich eine proaktive Strategie und eine passive, reaktive Strategie. Die beiden Strategien werden diskutiert. Obwohl die aktive Strategie deutliche Vorteile aufweist, wird dennoch die passive Strategie vorwiegend angewendet. Die Gründe für die Bevorzugung der passiven Strategie werden diskutiert. Des Weiteren wird ein Konzept zur Gebirgsdruckkontrolle vorgeschlagen, um den Einsatz der aktiven Strategie zu fördern. Abschließend werden die Bedingungen für einen ausgeweiteten Einsatz der aktiven Strategie zur Gebirgsdruckkontrolle kurz diskutiert.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The objective of mining is to supply society with raw materials for its sustainable growth and development. For this reason, mineral deposits have to be extracted, and the aim of the extraction is to be safe, economical, and as complete as possible. The raw material demand is expected to rise in future significantly amongst others due to the increasing population, the development of the economy and wealth, and also the need to reduce the carbon footprint. To fulfill the increasing demand, the mineral production has to increase. Hence, operations in extraction have to be extended and new operations have to be developed. Extending or developing new operations is generally associated with an increasing depth of mining because deposits are finite and become depleted. As the same deposit in the same mining environment is generally easier to extract at shallower depth than at a greater depth, the shallow deposits are mined first. After the shallow deposits have been depleted, mining typically advances to greater depth. Evidence for advancing mineral extraction to greater depth is:

-

Increasing depths of discovered deposits [8]

Besides advancing to greater depths, mining also moves into more challenging mining environments, which are characterized for example by smaller deposit sizes, lower grades, more complex deposit shapes and orientations, weaker rock mass conditions, or more difficult geographical locations. In a wider sense, also greater depth represents a more challenging mining environment.

A further trend in mining is that underground mining is becoming more popular again. One reason for moving towards underground mining is the generally increasing depth of mining, but another non-technical reason, particularly in industrialized countries, is the increasing sensibility of the society to mining and its impact on the environment. Hence, underground mines are preferable due to their smaller surface footprint than open pit mines. In this respect also the utilization of large-scale caving operations with their significant surface impact may not be possible.

In summary, the outlined trends in mining impose various operational and technical complications and challenges, which have to be overcome to guarantee the safe, as complete as possible and economic mineral extraction. This contribution addresses the faced challenges and puts an emphasis on rock mechanics related aspects. In particular, the consequences of the increasing stress levels in comparison to the rock mass strength and strategies to manage them are discussed.

2 Increasing Depth, More Challenging Environments and More Underground Operations

As mining advances to greater depth, more challenging environments, and from open pit towards underground extraction, a number of aspects change and additional costs, constraints, risks, and further difficulties are added.

2.1 Implications of Transferring Open Pit to Underground Operations

A first, quite obvious aspect of increasing extraction depth is that open pit mining is no longer viable mainly due to cost reasons resulting from an increasing waste to ore ratio, and mines are transferred to underground operations. Besides exceeding a critical waste to ore ratio, the need for underground extraction is expected to grow in future due to societal and environmental considerations. Underground mining itself is more complex and is associated with additional operational and technical difficulties. The main differences to open pit mining are related to rock mechanics and mine stability, production volumes, machinery sizes, and productivity as well as ventilation.

2.2 Implications of Increasing Depth in Underground Mining

An increasing mining depth in underground operations is associated with increasing costs, constraints, risks, and difficulties. Central aspects comprise:

-

Rock mechanics

-

Ventilation

-

Transportation

-

Development times

-

Exploration

2.2.1 Rock Mechanics

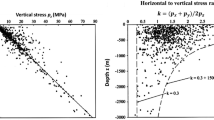

The primary stress magnitudes increase with depth. However, the rock and rock mass strength principally do not increase with depth. For this reason, there will be a depth at which the stress magnitudes start to exceed the strength of the rock and rock mass. Consequently, fracturing and the associated formation of fractured zones in rock and rock mass start to occur.

Additionally, the extraction of excavations alters the stress field further. In general, stress magnitudes near excavations increase, highly stressed zones are established, and low confinement zones are created. The higher the degree of extraction of a deposit becomes, the more pronounced are these stress field alterations. Overall, these stress field alterations increase the difficulty of extraction because it becomes more likely that stresses exceed the strength of the rock and rock mass. The intensity of fracturing and the extent of fractured zones increases. Depending on the intensity of fracturing, the impact may be locally confined, manageable with support, and without consequences for safety and production, or the impact may be so large that active infrastructure required, active stopes or even whole active extraction areas may have to be rehabilitated, redeveloped, temporarily closed, or in extreme cases even abandoned.

Hence, controlling the rock pressure, fracturing, and fractured zones is paramount to guarantee the success of an operation, once the depth at which rock and rock mass fracturing start to occur is exceeded. This depth is referred to as transition depth to deep mining conditions from a rock mechanics perspective and depends on the prevailing primary stress field and the rock mass strength. The transition depth can be as low as a several of hundred meters or up to one to two kilometers [9, 10]. The change in rock mechanics conditions is a step-change, which becomes relevant at the transition depth.

2.2.2 Ventilation

The rock temperature in mines increases with depth due to the geothermal gradient. Health and safety regulations require that the temperature at the work place must not exceed a specified limit. Consequently, it is necessary to increase either the air flow volume or to install additional cooling measures, once a certain depth, which depends mostly on the prevailing geothermal gradient, is exceeded.

2.2.3 Transportation

As extraction advances to deeper levels, the transportation distances and the elevations to be overcome for moving workforce, ore, waste, water, machinery and other material increase. Consequently, the capacity and efficiency of certain transportation systems decrease and the energy demand rises. On top the transportation times increase. This instance affects, in particular, the productivity of the personnel because the effective work time decreases.

2.2.4 Development Times

Deeper operations require longer development times before stoping can commence, and hence the payback is delayed. Additionally, investment volumes increase.

2.2.5 Exploration

Deeper deposits are more difficult and costly to explore because large elevations must be covered. As a consequence, the exploration activities may be cut and the uncertainties increase. Furthermore, there is often a concentration on geology, ore body definition, and reserve estimation and for this reason the collected data and information on the geotechnical conditions are often rather limited and insufficient. The situation regarding exploration may, though, be better for brownfield projects because experience in the prevailing mining environment is available and because the depth of the core drill holes is smaller.

2.3 Implications of More Challenging Mining Environments

More challenging mining environments comprise for example smaller deposits, lower grades, more complex deposit shapes and orientations, weaker rock mass conditions, or more difficult geographical locations. As a result, the costs, difficulties, and the risk of extraction increase.

3 The Relevant Role of Rock Mechanics

The considerations show that the implications of mining at greater depths, in more challenging environments, and in underground operations make it more difficult to achieve the aims of mining, namely the safe, as complete as possible and economic extraction. One reason are the increasing costs of extraction, which affects the profitability and the completeness of extraction because lower grades become uneconomic and may even not be mined later if prices increase because they may be situated in remnants or because they may not be accessible anymore. Common approaches to limit the cost increase are:

-

Situating infrastructure close to the ore body

-

Increasing the stope size, extraction area size and production

-

Applying large-scale mining methods offering a high productivity

Another central reason are rock mechanics related considerations. Ensuring the local and regional stability of an underground operation is a complex and demanding engineering task, but it is critical for the success of the operation. An improper design can jeopardize the operation in terms of safety, completeness of extraction, and profitability. Particularly, the increased stress regime and the presence of deep mining conditions require specific attention to ensure the achievement of the safety, completeness and economic extraction.

For the rock engineering design, a critical aspect is that major design decisions, such as the mining method, the stope size, the position of infrastructure, and the mining sequence, are locked in early and that major changes in the design are often associated with considerable costs and potential ore losses, particularly if an inflexible mining method is used. However, the data and information at the design stage may be rather limited. Another aspect is that rock mechanics related issues typically do not start to occur soon after the extraction commences; indeed, they normally start to occur after some time when the degree of extraction in the deposit is increased because the stress changes caused by the extraction become more pronounced at this stage. Hence, errors in the rock engineering design may only be recognized at a stage at which the possibilities for changes are often limited or associated with a major impact on the production.

The identified implications of greater depths and more challenging environments and the common approaches to counteract increased extraction cost even complicate the rock engineering design because amongst others:

-

The data and information are more limited,

-

The rock engineering design in general becomes more complex in challenging mining environments, and

-

The placement of infrastructure closer to the ore body, the utilization of larger stope sizes, and higher production and productivity methods are principally often not favorable from a rock engineering perspective.

In summary, the relevant role of rock mechanics must be recognized and acknowledged from the initial planning stage on and over the lifetime of the operation. Furthermore, a sound strategy, in particular how to manage the rock pressure in a deep mining situation, must be developed and implemented.

4 Rock Pressure Control Strategies

An increasing relevance of rock mechanics as mining goes deeper and to more complex environments is identified. In a deep mining situation, the prevailing stress magnitudes start to exceed the strength of the rock and rock mass and, thus, the control of the rock pressure is central. If the fracturing and the formation of fractured zones do not endanger the safety, completeness of extraction, and profitability, they are referred to as rock pressure phenomena. Examples for rock pressure phenomena are the formation of a local, stable zone of fractured rock mass near an excavation, or the occurrence of mining-induced seismicity. Rock pressure phenomena are a common observation in a deep mining situation, but they do not have an adverse impact on the operation. However, if rock pressure phenomena become so intense that they put the safety, completeness of extraction, or profitability at risk, they are referred to as rock pressure problems and the consequences on the operation could be considerable. Examples for rock pressure problems are the functional failure of infrastructure excavations due to excessive fracturing and corresponding deformation and the occurrence of rock burst damage. Rock pressure problems may even prohibit the continuation of the operation in extreme cases. The root causes of rock pressure phenomena and rock pressure problems are the mining-induced stress and energy changes and the corresponding formation of highly stressed zones and the release of large amounts of energy in and near active infrastructure and active extraction areas. The objective in a deep mining situation is to control rock pressure phenomena in such a way that they do not evolve to rock pressure problems. Two different strategies can be distinguished:

-

Passive reactive strategy

-

Active foresighted strategy

4.1 Passive Reactive Strategy

The passive reactive strategy aims at minimizing the consequences of rock pressure problems. The root cause of the rock pressure problems is generally not addressed.

Therefore, ground support, which is installed to control fracture processes and to retain and stabilize the fractured zone, has a central, dominant role. Further commonly used elements of a passive strategy are minor changes in the position of the infrastructure or the extraction sequence as well as the application of pre-conditioning methods, such as de-stress blasting or hydraulic fracturing.

The advantage of the passive reactive strategy is that major changes in the overall mining system and extraction strategy are mostly not required and that the alleviating measures can be implemented on demand. However, the passive strategy has its limitations. The limitations are that the root cause of rock pressure problems is not addressed and that the applied measures to minimize the consequences have a technical and economic limit. For this reason, the passive strategy may only be successfully applicable up to a certain severity of rock pressure problems, which is defined by the technical and economic limit of the alleviation measures.

4.2 Active Foresighted Strategy

The active foresighted strategy aims at eliminating the root cause of rock pressure problems or at least at minimizing the severity of rock pressure problems so that they can easily be managed with the passive reactive strategy.

The root cause of rock pressure problems are high stress zones and high energy releases in and near active infrastructure and active mining areas. Hence, an active strategy must limit the stress magnitudes and the energy release in these areas sufficiently. The relevant stress and energy changes result from the extraction of stopes. For this reason, the layout of stopes and the sequence of stope extraction are essential. Furthermore, strategically placed pillars, which can direct the stresses into certain areas and which can limit the energy release, may be utilized for stress and energy release control. In comparison, the stress and energy changes resulting from the development of infrastructure are relatively small. However, the position and time of infrastructure development has a strong impact on the stress magnitudes and energy changes to which the infrastructure is exposed to over their lifetime. In summary, active stress control is a four-dimensional task, namely space and time, and demands proper, strategic mine planning.

The advantage of an active foresighted strategy is clearly that the root cause of rock pressure problems is addressed. An unfavorable, complex rock pressure situation should be avoided. For this reason, the active stress control strategy could be superior over the passive strategy in many situations. However, an active strategy has distinct disadvantages compared to the passive strategy, which are mainly related to the mine planning process. Uncertainties related to the prevailing mining environment, such as the deposit size and shape, the rock mass properties and their distribution and the primary stress state, and the limited knowledge and understanding of the behavior of rock and rock mass complicate the design. Complexity and variability of the mining environment even aggravates the design. Providing flexibility in the layout and sequence is paramount to be able to react to uncertainties and more. The larger the uncertainties are, the more flexibility is required. Obviously, advanced personnel skills in rock engineering and powerful design tools are mandatory. Furthermore, the design must not be solely based on rock engineering; indeed it is essential to involve all relevant disciplines and to balance requirements. However, the critical, central role of rock mechanics should not be overruled by production planning, which normally prefers simple, straightforward layouts and sequences with little constraints, large stopes and high production volumes, infrastructure close to stopes, and pre-development of infrastructure. The preference of production planning is often contradictory to the rock engineering requirements on active stress management.

4.3 Utilization of Stress Management Strategies

The active stress management strategy is considered advantageous in many situations. However, it has only been widely applied in the deep South African gold mines. Different layouts and sequences according to the principles of active stress management have been developed for shallow-dipping, tabular deposits [11] and for shallow-dipping massive deposits [12, 13] and successfully applied up to depth of close to 4000 m. The layouts and sequences have in common that, in a first step, stress shadows are created by the extraction of stopes or de-stressing slots. Only a limited amount of infrastructure is used for this high stress mining activity. The development of the remaining infrastructure and extraction of stopes in case of massive deposits is then conducted in the provided stress shadows. Pillars are utilized strategically on a regional scale to control stress magnitudes and energy release.

Outside deep South African gold mines, an active strategy has not been widely applied. Instead, the passive strategy is dominating. Examples are increasing the capacity of support systems [14,15,16], minor changes to the layout and sequence [17,18,19], and applying of pre-conditioning measures [15, 20,21,22]. Reasons for the preference of the passive strategy comprise [10]:

-

Demand of a high production and productivity: Increasing extraction costs are commonly addressed with increasing production and productivity. However, the mining methods, layouts and sequences, which are used, are often not in-line with the rock engineering requirements on active stress control. Instead of making required far-reaching changes to mining methods, layouts, and sequences, passive stress control measures are added. A further aspect to consider is that far-reaching changes would most likely require a high-level management decision and additional expenditures, which could affect the share value. In contrast, increasing costs for passive control measures may not be accounted for as additional costs because they could be seen as a consequence of an increased extraction depth.

-

Lack of recognition of the importance of rock mechanics in deep mining: Rock mechanics often does not receive the required attention in the selection of the mining method and the design of the layout and sequence. Instead, the emphasis is often on maximizing production and productivity. Whether this approach yields overall the highest project value is unknown and uncertain. A problematic issue therefore is that the real costs arising from an improper rock engineering design and of rock pressure problems encountered during the operation are often not well known or appreciated. Hence, in the decision on a mining project, which is normally based on a cost, profit, and risk perspective, the rock mechanics aspects may not be fully and truly included.

-

Lack of knowledge, information, and methods: On the one hand, there are limited information and uncertainties related to the prevailing mining environment, and on the other hand, our knowledge and understanding of the behavior of rock mass and our rock engineering design methods are often insufficient for an active stress management strategy. As mining advances, experience is gained, which could be used to overcome these drawbacks. A flexible mining method, layout, and sequence are required to implement necessary changes. However, flexibility can often only be established at the expense of production and productivity and hence is associated with additional cost. Further options, which come with additional costs, are research and development or more extensive exploration.

-

Lack of research and development and education and training: Active stress management strategy demands a profound and deep knowledge in the field of rock mechanics and high personnel skills. However, the current knowledge in rock mechanics is too limited in many aspects and the skills of personnel is often not on the required level. Hence, long-term strategic research and development is required and training and education for personnel must be established. Despite its importance, there has been a constant decline in research and development as well as education and training capacities and institutions. The focus in research and development is mostly on short-term, reactive, and passive solutions, which are urgently required to tackle a certain rock pressure problem, whereas education and training does not seem to receive sufficient attention by industry. On top, due to the constant, ongoing decline in research and development and training and education institutions, the situation is expected to worsen in future.

5 Improving the Application of the Active Stress Control Strategy

5.1 Proposal of a Stress Management Concept

A stress management concept has been proposed to address the lack of active stress control strategies in deep mining [10]. The stress management concept aims at facilitating the mineral extraction at great depth or, in some instances, even at enabling the extraction. The concept is shown in Fig. 1 and it is based on main and auxiliary elements. The prevailing mining environment, which comprises the primary stress situation, the rock mass formations and properties, and the deposit size and shape, provides the framework for the concept. The elements are used in the prevailing mining environment. They have a physical effect on the mining environment. The element properties and characteristics are used to control the effect. The main elements are central for the implementation of the concept. They include excavations, pillars, loading system and time. The auxiliary elements have an assisting role and they are: support and reinforcement, and monitoring and observation. The physical effect of one element or a combination of more element results in a function. The different functions are: access function, extraction function, stress blocking function, regional stress transfer function, stress distribution function, protection function, strength enhancing function, and data and experience collection function. The elements and their functions are used in a specific combination, which is adapted to the prevailing mining environment to implement the proposed stress management concept. It is important for the stress management concept to be an integral part of the extraction activities and hence to be connected to all mining activities. It cannot be seen in isolation. A detailed description of the proposed stress management concept and considerations related to its practical implementation can be found in [10]. An example for the application of the proposed stress management concept is the raise caving mining method [23,24,25].

Proposed stress management concept [10]

5.2 Actions to Widen the Utilization of an Active Stress Control Strategy

Despite an active stress control strategy is rather powerful, several reasons for why the strategy is still not widely used have been identified and discussed. In order to overcome these reasons, the following actions should be considered.

-

1.

First, the importance and benefits of an appropriate active stress control must be recognized and acknowledged, particularly by high-level management. Therefore, it would be helpful if the complete costs of rock pressure problems are accounted for. These costs do not only include the costs for rehabilitation, but they rather comprise also costs for a generally increased capacity of ground support system, costs for special pre-conditioning measures, costs for production losses, or costs for ore losses. Additionally, safety improvements and a potentially increased overall extraction of the deposit must be clearly highlighted. Additionally, it must be acknowledged that an unfavorable, difficult rock pressure situation and the associated occurrence of rock pressure problems are often caused through an improper mine design and that it is not a general aspect of a deep mining environment. Finally, the benefits of an active stress control strategy in terms of costs, benefits, and risks must be compared to a design relying on a passive stress control strategy for decision making. Case studies of past mining experience and operations could be very helpful to highlight the benefits of active stress control.

-

2.

Second, a high level of personnel skills and expertise, not only in rock engineering but also in other relevant disciplines for mine planning and mine operation, is required for the design of an operation with an active stress control strategy. Hence, education and continuous training are essential. However, there has been a constant decline of institutions that can offer such a high-quality training and education, and the required skills, expertise, and number of personnel may not be available. For this reason, a long-term strategy emphasizing the establishment of dedicated education and training centers is recommended.

-

3.

Third, the knowledge in rock mechanics for several reasons is too limited to design an operation according to an active stress control strategy. Aspects that require a particular attention are the mechanical properties and behavior of rock mass, geological structures and pillars, methods for geotechnical characterization in the exploration stage, and the development of rock engineering design criteria and design methods. Therefore, a long-term research and development strategy is recommended. The research and development must be done in close collaboration between industry and research organization because in-situ data, experience, and observations as well as targeted in-situ test campaigns are central for the required developments. A main reason is that the complex behavior of rock mass cannot be adequately represented and replicated in analytical, numerical, and laboratory conditions without in-situ data, which is used for calibration. A further aspect of such a long-term research and development strategy must be the development of mining methods, mine layout, and mining sequences with a sufficient degree of flexibility, which are suited for active stress management. However, there has been a constant decline of research organizations and there is a lack of highly skilled personnel and expertise at research organizations. These two issues must be addressed as well.

-

4.

Fourth, there are inherent uncertainties regarding the mining environment as well as a currently limited knowledge related to rock mechanics. In-situ observations, data collection, and back analyses are best suited to address these issues at the moment. However, skilled and trained personnel, adequate and efficient monitoring measures, and flexible layouts and sequences are required for that. The need for education and training and the development of flexible mining methods has already been highlighted. Furthermore, observation and monitoring measures must be developed.

-

5.

Fifth, an active stress management requires commitment on all levels of an operation including high-level management because it is a challenging, multidisciplinary tasks calling for high level of skills. Different disciplines and organizational units must therefore work closely together. Hence, awareness for the importance of active stress management and its advantages must be created, and all disciplines and units must be involved to generate the required commitment.

6 Conclusions

There is a need for mining to advance towards greater depth and into more challenging rock mass conditions to meet the growing long-term demand for minerals. Potential consequences, which complicate the mineral extraction, are outlined. It is found that rock mechanics has a central role and that the control of rock pressure, which has the objective to prevent rock pressure problems, is paramount for success. From the two different general strategies, the active foresighted strategy and the passive reactive strategy, the active strategy is found to be advantageous because the root cause of rock pressure problems is addressed. However, the passive strategy is still dominantly applied. Reasons are manifold and comprise technical and non-technical aspects. A stress management concept, which aims on widening an active stress control strategy, has been proposed.

In conclusion, active stress management requires a multidisciplinary approach and must be seen as an integral part of the extraction activities. Highly-skilled personnel is central for success. Furthermore, generating commitment for stress management, creating awareness regarding the importance of rock mechanics, and investing into long-term strategic research and development and education and training are considered to be decisive to widen the application of an active stress management strategy. Particularly, the last point may become more and more difficult in future as there has been a constant decline in research and education institutions in terms of quantity and quality.

References

Brown, E.T.: Block caving geomechanics, 2nd edn. Julius Kruttschnitt Mineral Research Centre, The University of Queensland, Queensland (2007)

Flores, G., Catalan, A.: A transition from a large open pit into a novel “macroblock variant” block caving geometry at Chuquicamata mine, Codelco Chile. J. Rock Mech. Geotech. Eng. 11(3), 549–561 (2019). https://doi.org/10.1016/j.jrmge.2018.08.010

Casten, T., Johnson, M., Zimmer, C., Mahayasa, M.: PT freeport Indonesia—the transition to underground production. In: Castro, R., Báez, F., Suzuki, K. (eds.) Proceedings of the eighth international conference & exhibition on mass mining Chile. pp. 23–38. (2020)

Mercier-Langevin, F.: LaRonde Extension—mine design at three kilometres. In: van Sint, J.M., Potvin, Y. (eds.) Proceedings of the fifth international seminar on deep and high stress mining Perth. pp. 3–16. (2010)

Quinteiro, C.: Design of a new layout for sublevel caving at depth. In: Potvin, Y., Jakubec, J. (eds.) Proceedings of the Fourth International Symposium on Block and Sublevel Caving Perth. pp. 433–442. (2018)

Araneda, O.: Codelco: present, future and excellence in projects. In: Castro, R., Báez, F., Suzuki, K. (eds.) Proceedings of the Eighth International Conference & Exhibition on Mass Mining Chile. pp. 1–9. (2020)

Paetzold, H., Lourens, P., Brazier, R.: Reopening and closure of a block cave. In: Castro, R., Báez, F., Suzuki, K. (eds.) Proceedings of the Eighth International Conference & Exhibition on Mass Mining Chile. pp. 103–114. (2020)

Schodde, R.: Recent trends and outlook for global exploration. Presentation at PDAC, Toronto, 6 Mar 2017. (2017)

Wagner, H.: Deep mining: a rock engineering challenge. Rock Mech Rock Eng 52(5), 1417–1446 (2019). https://doi.org/10.1007/s00603-019-01799-4

Ladinig, T.: A contribution towards the practical implementation of stress management concepts in underground mining. PhD Thesis, Montanuniversität Leoben (2022)

Jager, A.J., Ryder, J.A.: A handbook on rock engineering practice for tabular hard rock mines. The Safety in Mines Research Advisory Committee (SIMRAC), Johannesburg (1999)

Watson, B.P., Pretorius, W., Mpunzi, P., Du Plooy, M., Matthysen, K., Kuijpers, J.S.: Design and positive financial impact of crush pillars on mechanized deep-level mining at South Deep Gold Mine. J. South. African Inst. Min. Metall. 114(10), 863–873 (2014)

Andrews, P.G., Butcher, R.J., Ekkerd, J.: The geotechnical evolution of deep level mechanised destress mining at South Deep. In: Joughin, W. (ed.) Proceedings of the Ninth International Conference on Deep and High Stress Mining Johannesburg. pp. 15–28. (2019)

Jacobsson, L., Töyrä, J., Woldemedhin, B., Krekula, H.: Rock support in the Kiirunavaara Mine. In: Potvin, Y., Brady, B. (eds.) Proceedings of the Seventh International Symposium on Ground Support in Mining and Underground Construction Perth. pp. 401–409. (2013)

Morissette, P., Hadjigeorgiou, J., Punkkinen, A.R., Chinnasane, D.R.: The influence of change in mining and ground support practice on the frequency and severity of rockbursts. In: Hudyma, M., Potvin, Y. (eds.) Proceedings of the Seventh International Conference on Deep and High Stress Mining Perth. pp. 165–178. (2014)

Landry, D., Reimer, E.: Failure mechanisms and ground support applications at Coleman mine, Sudbury Basin. In: Hadjigeorgiou, J., Hudyma, M. (eds.) Proceedings of the Ninth International Symposium on Ground Support in Mining and Underground Construction Perth. pp. 253–266. (2019)

Yao, M., Chinnasane, D.R., Harding, D.: Mitigation plans for mining in highly burst-prone ground conditions at vale Inco Copper Cliff North mine. In: Diederichs, M., Grasselli, G. (eds.) Proceedings of the 3rd CANUS Rock Mechanics Symposium Toronto. (2009)

Varden, R., Esterhuizen, H.: Kanowna Belle—evolution of seismicity with increasing depth in an ageing mine. In: Potvin, Y. (ed.) Proceedings of the Sixth International Seminar on Deep and High Stress Mining Perth. pp. 211–228. (2012)

Esterhuizen, H.C.J.: Controlling the effects of stress and seismicity in a sublevel caving operation. In: Potvin, Y., Jakubec, J. (eds.) Proceedings of the Fourth International Symposium on Block and Sublevel Caving Perth. pp. 607–622. (2018)

Toper, A.Z., Kabongo, K.K., Stewart, R.D., Daehnke, A.: The mechanism, optimization and effects of preconditioning. J. South. African Inst. Min. Metall. 100(1), 7–15 (2000)

Morales, R.F., Henriquez, J.O., Molina, R.E., Araneda, O.A., Rojas, E.G.: Rock preconditioning application in virgin caving condition in a panel Caving Mine, CODELCO Chile el Teniente division. In: Potvin, Y. (ed.) Proceedings of the Fourth International Seminar on Deep and High Stress Mining Perth. pp. 111–120. (2007)

Catalan, A., Onederra, I., Chitombo, G.: Evaluation of intensive preconditioning in block and panel caving—part II, quantifying the effect on seismicity and draw rates. Min. Technol. 126(4), 221–239 (2017)

Ladinig, T., Wagner, H., Bergström, J., Koivisto, M., Wimmer, M.: Raise Caving—A new cave mining method for mining at great depths. In: Proceedings of the 5th International Future Mining Conference Melbourne. pp. 368–384. (2021)

Ladinig, T., Wagner, H., Karlsson, M., Wimmer, M., Grynienko, M.: Raise caving—A hybrid mining method addressing current deep cave mining challenges. Berg Huettenmaenn Monatsh 167(4), 177–186 (2022). https://doi.org/10.1007/s00501-022-01217-3

Ladinig, T., Wimmer, M., Wagner, H.: Raise caving: a novel mining method for (deep) mass mining. In: Potvin, Y. (ed.) Caving 2022: Fifth International Conference on Block and Sublevel Caving, Australian Centre for Geomechanics Perth. pp. 651–666. (2022)

Funding

Open access funding provided by Montanuniversität Leoben.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ladinig, T. Considerations Related to Active Stress Management in Deep Mining. Berg Huettenmaenn Monatsh 168, 476–483 (2023). https://doi.org/10.1007/s00501-023-01391-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-023-01391-y