Abstract

This publication aims to describe a simple methodology for predicting caving and cave propagation, for mining purposes, using numerical simulations. The methodology is designed to be user-friendly and easy to set up and analyse, making it practical for real-world applications. The algorithm is performed in FLAC3D, version 7.0, and is based on an elastic model due to its simplicity and low running times. The methodology uses a series of routines to describe and quantify the rock failure process during caving. The emphasis is on simplicity, achieved by implementing reasonable assumptions about the caving situation and rock mass behaviour. The caving propagation is driven by plastic behaviour which the algorithm represents by a simplified softening behaviour to make it more practical.

The degradation processes occurring in the rock mass during caving are accounted for by reducing the mechanical properties of the rock mass and the stress state in degraded zones in a controlled and systematic manner. Sensitivity tests are performed to analyse the weight of the mechanical parameters involved in the caving processes and to optimize the reduction rate of the mechanical properties of the rock mass.

The current stage of development for the Simplified Caving Predicting tool, SCPT, is the performance of an extensive sensitivity test of the caving algorithm. In parallel, the outcome is being assessed for verification purposes. This is done by analysing the results obtained in the numerical models and the outcome of the semi-empirical methods available in the literature as well as an analytical comparison of results. The latter analysis aims to determine the weight of the different parameters involved in the simulations.

The caving tool is being developed for its application on the novel Raise Caving (RC) mining method. The tool will provide understanding regarding the caving initiation and propagation for the novel Raise Caving method.

Zusammenfassung

Dieser Beitrag zielt darauf ab, mit Hilfe numerischer Simulation eine einfache Methodik zur Vorhersage der Bruchvorgänge und deren Ausbreitung im Hangenden von Bruchbauabbauverfahren zu entwickeln. Die Benutzerfreundlichkeit steht bei dieser Methodik im Fokus. Dies wird durch die Eingabe von wenigen Parametern realisiert und soll die Analyse von praktischen Anwendungen im Bergbau ermöglichen. Das Analyseverfahren ist FLAC3D, Version 7.0, und basiert auf einem elastischen Modell. Dieses Modell wurde aufgrund seiner Einfachheit und geringen Simulationslaufzeiten gewählt. Die Methodik verwendet eine Reihe von Simulationsdurchgängen, um den Prozess des Gesteinsversagens während der Hohlraumbildung schrittweise zu beschreiben und zu quantifizieren. Die gewählte Vorgehensweise gestaltet sich durch Implementierung vereinfachten Annahmen über sowie das Verhalten des Gebirges und der Bruchzone im Hangenden des Abbaus sehr übersichtlich. Der Bruchvorgang wird durch plastisches Materialverhalten vorangetrieben, aber der Algorithmus basiert auf einem elastischen Verhalten und spezifischen Funktionen, die plastisches Verhalten imitieren. Die während des Bruchvorgangs auftretende Reduzierung der Festigkeitsparameter des Gebirges wird durch eine kontrollierte und systematische Reduzierung der mechanischen Eigenschaften des Gesteins und des Spannungszustandes in beanspruchten Zonen berücksichtigt. Sensitivitätstests werden durchgeführt, um die Gewichtung der mechanischen Parameter, die an den Hohlraumausbildungsprozessen beteiligt sind, zu analysieren und die Degradationsrate der mechanischen Eigenschaften des Gesteins zu optimieren.

Aktuell werden für das sogenannte SCPT (Simplified Caving Predicting Tool) umfangreiche Sensitivitätstests für den Algorithmus durchgeführt. Gleichzeitig wird das Ergebnis zu Verifizierungszwecken evaluiert. Dies geschieht durch die Analyse der Ergebnisse von numerischen Modellen und verschiedener semi-empirischer Methoden sowie durch die Analyse der in der Literatur verfügbaren Ergebnisse. Der Algorithmus wird für die Anwendung bei der neuartigen Raise Caving (RC) Bergbaumethode entwickelt. Das SCPT soll ein besseres Verständnis für die Vorgänge bei der Entstehung der Bruchzone insbesondere bei der neuartigen Raise Caving-Methode liefern.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 State of the Art

Caving mass mining methods are safe, highly productive, and efficient extraction methods, especially when automation implementation is possible. These methods allow low-grade deposits to be safely and profitably exploited. The constant research and development in this field has been reducing the risks related to caving operations, and this trend is expected to continue, thus reducing the risks and hazards further [1,2,3,4]. The prediction of the nature of the caving process is a critical issue for all cave mining systems. Therefore, over the past decades, different methods to determine the cavability of the rock mass and predict the caving progression have been developed. Two points are critical, namely the initiation of caving and the propagation. These determine whether hangingwall caving method is feasible provided the rock mass conditions (structure, quality, depth, stress environment amongst other factors that determine the behaviour of the rock mass) are suitable [4].

Empirical methods, commonly known as “stability chart methods” are popular in this field. Mathews [5] defined a simple approach for determining the caving conditions provided a series of case studies. In this graph, two entry values are required: the rock mass quality, as the N’ stability number, and the hydraulic radius (known as well as shape factor). Similarly, Laubscher [6] proposed in 1976 a new rock mass quality method (MRMR) and reported in 1994 a stability graph as well, in order to predict caving situations, based on the MRMR [7].

Other authors focused on the analysis of the caving and developed analytical methods for this topic. Panek [8] and Rice [9] developed their own analytical methods to predict caving propagation. Rice focused on the block caving mining method. Panek’s focus was on the propagation of the caving in a 2D sequence with a special objective on the subsidence on the surface. The issues with the analytical methods were found to be critical for certain aspects of the caving process. The initial assumptions for these methods were that the caving initiation would always take place and the caving propagation was limited to the vertical direction. Additionally, the analytical methods determined that the caving rate was kept constant.

Numerical simulations require high computational effort, long running times, and a comprehensive list of parameters, which might not be available in many instances. The caving predicting tool proposed here is based on simple assumptions and aims to provide a prognosis of caving and cave propagation. The numerical simulations are performed in finite difference type of software, more specifically FLAC3D version 7.00 [10], which benefit from less complex situations based on these assumptions and simplifications. Due to its simplicity, fewer input parameters are required, and the computational times are drastically reduced compared to those reported in the literature, especially those based on discrete element models.

In the last decades, the development of the technology has been enormous, making these advances more accessible in the scientific field. Therefore, more complex methodologies were developed based on the numerical methods. There is a vast list of software for conducting numerical simulations, which are divided in different categories based on their modelling techniques or codes. Among the most common methods used, there are the FEM and FDM (finite elements and finite difference methods) and the DEM (distinct element methods). The current state of the art are hybrid methods, which include two of the latter (e.g. FEM and DEM coupled). However, the more sophisticated software and/or modelling techniques require high profile hardware (GPU, for instance), numerous input values, which are not always tested or measured in-situ, and long computing times (weeks or even months, based on the dimensions of the model).

2 SCPT—Simplified Caving Predicting Tool

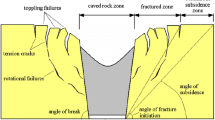

The main objective of the SCPT is to determine whether caving occurs for a specific mining layout, rock mass characteristics and stress environment [4]. In order to achieve this objective, Duplancic and Brady [11] developed a conceptual caving model (Fig. 1) to describe the problem to be solved. The main focus is on the loosening and seismogenic zones defined by Duplancic and Brady [11], where the rock mass starts to degrade (opening fractures due to stress redistributions around the excavation).

Duplancic and Brady’s caving conceptual model after Duplancic and Brady [11] including the so called “damaged” area which outlines the limits of the seismogenic zone on the uppermost part and the yielded or loosening zone as the lowermost limit of the damaged area

These two areas are determined in the SCPT as one, so called “damaged” area, where the softening process occurs. The softening is produced by reducing the initial GSI value of the rock mass, as the rock mass exceeds he Hoek and Brown failure criterion [12]. Every element of the model (zones) is assessed for failure, if zone fails under the failure criterion, then its GSI value is reduced by the GSI reduction factor. As the GSI is reduced, so are other properties such as the elasticity modulus of the rock mass. Along with these modifications, the stress environment of the element is reduced consequently. The complete sequence of the SCPT, shown in Fig. 2, is described in the following:

-

1.

The model is solved to equilibrium after defining the geometry and applying the initial rock mass properties and stresses. The constitutive model used is the elastic model, which is simple and fast, allowing for easy understanding of material behaviour under stress.

-

2.

The stress situation of every cell is checked, and the script compares the stress applied on it with the Hoek and Brown criterion ([12]; Fig. 3). If the stresses in the cell exceed the Hoek and Brown envelope, then the cell is marked as “damaged”. This calculation is carried out for every cell of the model that belongs to the “near zone” area, the target zone for this study.

-

3.

If a cell is marked as “damaged”, its GSI value is reduced. The user defines the reduction of the GSI (1 or 5 units). The GSI reduction is applied to the cell that has been marked as “damaged”.

-

4.

After a cell is marked as “damaged” and its GSI value is reduced, the cell will undergo a different stress situation in the following solving-cycle. Therefore, the new stresses acting on it must be recalculated and stored. For instance, if a cell in a compressive environment has a maximum principal stress that exceeds the Hoek and Brown envelop, it will get a new maximum principal stress equal to the projection of it on the envelop. Once the new principal stress values are assigned, the normal stresses are calculated, stored, and applied for the next cycle.

-

5.

The model is screened again to assess if any cell is detaching from the rock mass. The detachment criterion defines two main conditions that must be satisfied to mark that cell as detached. Firstly, the cell must have a free-face, which is an open surface where the cell can fall through on its way to the muck pile.

Scheme of the SCPT steps [4]

Scheme of principal stress reduction [4]

This criterion has been refined to properly define the free face, especially in complex situations such as sub-vertical walls. The second condition determines the stress situation under which the unconfinement is sufficient to let the cell move, leading to free fall from the rock mass. The tangential stresses that lay on the free surface of the cell are the critical factor in this case.

3 Critical Overview of the SCPT

3.1 Advantages of the SCPT

There are some requirements that have to be fulfilled in order for the SCPT to perform as it should. The SCPT requires a bricked-type of mesh in principle, which means hexahedrons as the primary geometrical figure for creating the model. The creation of such a geometry can be done by different tools. In FLAC3D, the following tools could be employed: coding the geometry, which mainly requires FISH language, or building blocks, a new feature of FLAC3D version 7.00 [10]. Building blocks allow the user to create geometries based on bricks, which can be deformed by modifying the coordinates of the gridpoints of the bricks. Therefore, it allows the user to create a model as complex as one could code with the only exception that bricks are the primary mesh shape. While coding the geometry can be time-consuming for a new user, it is a sure method to construct models, even large ones with several groups.

Other software can provide hexahedral type of meshes that can be imported into FLAC3D, but it is out of the scope of the present report. The material properties are set up in the model by FISH commands, which is an embedded coding language for FLAC3D, in a common manner, such as density, elastic modulus, and Poisson’s ratio. Other parameters, such as the ones employed directly in the Hoek and Brown failure criterion (e.g., UCS, GSI among others ) and the GSI Reduction Factor, are input as “extra” parameters in the model. The latter can be accessed as “extra” variables and employed in calculations as well as to be updated and later plotted, for analysis purposes.

The properties of the damaged zones are modified according to the GSI Reduction Factor. The parameters are recalculated as presented in the previous sections, as is the stress tensor for every damaged cell. The modification occurs through a series of routines, which consist of a loop (“for” loop type) that checks for the damaged cells, identifies them, and modifies the properties targeting only the damaged cells. The routines are indispensable for the functioning of the SCPT.

As mentioned in previous sections, the minimum number of input parameters required for the model’s elastic functioning (embedded in FLAC3D) and the Hoek and Brown failure criterion is eight values. These values include UCS, GSI, GSI Reduction Factor, mi, D (which is set to 0), Poisson’s ratio, density, and Elastic modulus for each rock mass unit. Additionally, the initial stress state (tensor) must be given to initialize the model as it begins to be solved. The elastic model requires density, Poisson’s ratio, elasticity modulus, and stress environment, while the Hoek and Brown failure criterion requires UCS, GSI, mi, and D (set to 0).

The model elastic behaviour is the constitutive model to be solved before any modifications or checks are done by the SCPT. Compared to other models, the model elastic is the fastest constitutive model to be solved. The GSI-softening process is a simplification of the rock mass softening that occurs when the stresses around an excavation are redistributed, forming fractures along it. This softening procedure only relies on the stress state of the “damaged” zone and the rock mechanical properties initially set related to the GSI value. The GSI value determines the speed at which the rock mass degrades, whether it is a slow or abrupt reduction when the cell is found as damaged.

3.2 Disadvantages of the SCPT

As mentioned in the previous section, the geometry presents some constraints based on the needs of the SCPT, mainly related to the densifying action in the model. When the “densify” command is employed to enhance the number of cells in a specific zone, it might cause some issues for the SCPT to identify the damaged cell and adapt the properties if the cell is damaged. The routines employed in the SCPT rely on the ID of the cells, which is an ID number given when building the model that cannot be modified to any extent. If the densify command is employed, the new cells in this denser area will get new ID numbers, and the initial IDs in this area will be then deleted. This causes problems for the identification of the cells by the SCPT and should be avoided.

The modification of the properties of the damaged zones is done by means of routines (“for” loops), which are not quite fast and are slowed down as the number of cells increases. Additionally, the application of new properties to the model is carried out by FISH commands, which are also not quite fast. This means that, if a specific model requires a vast number of cells to be modified (since they are categorized as damaged), the running time increases.

The time required to perform a simulation depends to a high degree on the number of cells used in total in the model. The more detailed the model, thus the more cells, the more time-consuming it is. The employment of several “for” loop routines makes it more time-consuming as the number of cells increases. In close-tight relation with the previous point, there is a cell size dependency and the outcome obtained, as well as the time consumption per simulation. However, the cell dependency is not directly linked to the SCPT but to the model on its own. This can be categorized as a disadvantage for all large models, independently of the model or tool implemented. However, this is one of the points to raise when it comes to efficiency.

As explained in the advantages section (3.1 Advantages of the SCPT), the GSI Reduction Factor determines the damage that occurs within the host rock over the redistribution of stresses around the excavation. Its major task is reducing the mechanical properties of the rock mass over the caving propagation process. However, it must be studied further to understand the scientific dimension of this parameter and the implications it has on the results.

4 Conclusions

The SCPT is a simplified model that allows the user to understand how the caving mechanisms occur after the opening of an excavation or a full sequence of excavation opening, based on the Duplancic and Brady [11] conceptual model. The model works on the model elastic behaviour, which is complemented with routines under which the rock mass is assessed under the Hoek and Brown criterion. The failed zones under Hoek and Brown [12] are denominated “damaged”. If a zone falls under the latter category, its properties are modified. The initial property modified is the GSI, which is reduced according to the GSI Reduction Factor. Other parameters are recalculated based on the new GSI value, as is the stress tensor on those damaged cells exclusively.

The stress environment is checked a second time to verify if a cell fulfils the detachment criteria: low tangential stresses (clamping stresses) and a free face. If the cells are located in an unconfined environment and have a free face, with a direction favourable to detachment, it will be detached from the model. The process can be referred to as a GSI-softening procedure, and the key point of the process is the GSI Reduction Factor, which determines ultimately how much the rock mass mechanical properties are degraded every time a cell is damaged.

The SCPT is a simplified model that allows the user to understand how the caving mechanisms occur after the opening of an excavation or a full sequence of excavation opening. The model is simple and rather fast compared to other constitutive models, and the number of input parameters is set to a minimum of 8 (density, Young’s modulus, Poisson’s ratio, UCS, GSI, GSI Reduction Factor, mi, clamping stresses limit) and the initial stress environment (the whole tensor or at least all principal stresses). However, the model has some limitations in regards to its construction. The running times are mainly dependent on the cell size: the more cells, the more time. Additionally, in a scenario where there is a large portion of the model that requires modifications on the properties and stress tensor and/or requires a large chunk to be detached, the simulation times may lengthen. Despite these limitations, the other aspects determining the SCPT turn it into a simple and easy tool that is rather fast.

The implementation of the SCPT is rather simple, and the modification or adaptation degree of the original tool is determined by two points: the implementation of the SCPT with other studies or coded tools and the implementation of an extraction sequence in a different manner as proposed in the SCPT. The SCPT can be determined as a simplified caving forecasting tool that is rather fast, easy to implement, use, and also provides straightforward numerical and illustrative outcomes that allow a quick analysis.

References

Ladinig, T., Wimmer, M., Wagner, H.: Raise Caving – A novel mining method for (deep) mass mining. Caving 2022: Fifth International Conference on Block and Sublevel Caving, Adelaide, 30 August – 1 September 2022, Adelaide (2022)

Ladinig, T., Wagner, H., Bergström, J., Koivisto, M., Wimmer, M.: Raise caving – a new cave mining method for mining at great depths. Proceedings of the 5th International Future Mining Conference, Melbourne, Melbourne (2021)

Butcher, R.J.: DEESA – An approach to determine if an orebody will cave. Proceedings MassMin 2004. Proceedings MassMin 2004, Santiago (2004)

Folgoso Lozano, E., Nöger, M., Ladinig, T., Wagner, H.: Development of an unsophisticated numerical simulation model for caving systems. Caving 2022: Fifth International Conference on Block and Sublevel Caving, Australian Centre for Geomechanics. Caving 2022: Fifth International Conference on Block and Sublevel Caving, Australian Centre for Geomechanics, Adelaide, Perth (2022)

Mathews, K.E., Hoek, E., Wyllie, D.C., Stewart, S.B.V.: Prediction of Stable Excavation Spans for Mining at Depths Below 1000 Metres in Hard Rock (1981). Report to Canada Centre for Mining and Energy Technology, (CANMET), Department of Energy and Resources. Report to Canada Centre for Mining and Energy Technology, (CANMET), Department of Energy and Resources (802-1571)

Laubscher, D.H.: Class distinction in rock masses in coal, gold and base metals of South Africa. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 13(7), 37–50 (1976). https://doi.org/10.1016/0148-9062(76)91732-0

Laubscher, D.H.: Cave mining—the state of the art. J. S. Afr. Inst. Min. Metall. 94(10), 279–293 (1994)

Panek, L.A.: Subsidence in Undercut-Cave Operations, Subsidence Resulting from Limited Ex-traction of Two Neighboring-Cave Operations. Department of Mining Engineering, Michigan Technological University (1984)

Rice, G.S.: Ground movement from mining in Brier Hill mine, Norway, Michigan. Min. Metall. 15(325), 12–14 (1934)

Itasca Consulting Group: FLAC3D—Fast Lagrangian Analysis of Continua in Three-Dimensions. computer software. Itasca Consulting Group, Itasca (2019)

Duplancic, P., Brady, B.H.: Characterisation of caving mechanisms by analysis of seismicity and rock stress. Proceedings of the 9th International Congress on Rock Mechanics, Rotterdam, Rotterdam (1999)

Hoek, E., Brown, E.T.: The Hoek-Brown failure criterion and GSI—2018 edition. J. Rock Mech. Geotech. Eng. 11(3), 445–463 (2019). https://doi.org/10.1016/j.jrmge.2018.08.001

Acknowledgements

This publication was developed based on the PhD research, driven from the Raise Caving project. The authors would like to thank Prof. Horst Wagner for the review, assistance, advice and discussions. In addition, the author would like to thank LKAB for funding this research and for allowing the publication.

Funding

Open access funding provided by Montanuniversität Leoben.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Folgoso Lozano, E. Introduction to the Simplified Caving Predicting Tool SCPT. Berg Huettenmaenn Monatsh 168, 294–298 (2023). https://doi.org/10.1007/s00501-023-01359-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-023-01359-y