Abstract

Sublevel shrinkage (SLSh) is an underground mining method similar to sublevel caving (SLC) but with continuous backfilling from the top. It features a top-down mining sequence with production drifts orientated in a longitudinal or transverse way in the orebody. Fan drilling and blasting is done from the production drifts, from where the ore is then drawn. While drawing, backfill is introduced at the top and flows down by gravity, which supports the walls and prevents caving. In this contribution, a state-of-the-art literature review is performed using various sources. Four case studies show that SLSh could be a viable alternative for stoping (e.g. sublevel open stoping “SLOS” or longhole open stoping “LHOS”) and SLC in steeply dipping, moderately thick, tabular deposits. SLSh can be applied where caving must be prevented or caveability of the hangingwall rock mass is not provided due to rock mass properties or the geometry of the deposit. SLSh also proved to be an alternative to SLOS or LHOS when only small stope sizes would be possible due to geotechnical constraints. Critical points are dilution with backfill and the backfill handling infrastructure that must have a high capacity. Stability of this infrastructure is very important and must be monitored closely. Open points are the application in massive deposits and backfill supply and handling for mines with very high production.

Zusammenfassung

Sublevel Shrinkage (SLSh) ist ein untertägiges Abbauverfahren, das dem Teilsohlenbruchbau (TBB) stark ähnelt, jedoch mit kontinuierlicher Einbringung von Versatz von oben erfolgt. Die Abbausequenz ist fallend, und die Förderstrecken können in Längs- oder Querrichtung des Erzkörpers angelegt werden. Von den Förderstrecken aus werden Fächerbohrungen gesprengt, um das Erz zu lösen. Während des Abziehens wird von oben Versatz eingebracht, der durch Schwerkraft nachrutscht, das Gebirge stützt und einen Bruch des Hangenden verhindert. Es wird eine Literaturrecherche zum Stand der Technik von SLSh anhand verschiedener Quellen präsentiert. Vier Fallstudien zeigen, dass SLSh in steil einfallenden, mäßig mächtigen, tafelförmigen Lagerstätten eine brauchbare Alternative für Teilsohlenkammerbau und TBB sein könnte. SLSh kann dort eingesetzt werden, wo Bruchbau unerwünscht ist oder wo die Bruchfähigkeit des Hangenden aufgrund der Gebirgseigenschaften oder der Geometrie der Lagerstätte nicht gegeben ist. SLSh erwies sich auch als Alternative zum Kammerbau, wenn aufgrund geotechnischer Verhältnisse nur kleine Kammern möglich sind. Kritische Punkte sind die Verdünnung mit Versatz und eine geeignete Infrastruktur für den Versatztransport, die eine hohe Kapazität aufweisen muss. Die Stabilität dieser Infrastruktur ist sehr wichtig und muss genau überwacht werden. Offene Punkte sind der Einsatz in massiven Lagerstätten und Versatzversorgung und -transport für Bergwerke mit sehr hoher Produktion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The trend in the mining industry goes towards underground mass-mining. Sublevel shrinkage is an underground mining method developed and established as a viable mass-mining method at some mining operations and considered to be implemented at some mines [1,2,3,4]. A state-of-the-art review of SLSh was performed. Although the abbreviation SLS refers to sublevel shrinkage in several of the used sources, the acronym SLSh is used throughout this contribution to prevent confusion with the mining method and term “sublevel stoping”. The aim of this contribution is to summarize the findings about the SLSh method. It contains a short mining method description in the beginning, followed by case studies, and a summarizing discussion and conclusion at the end.

2 Layout and Sequence of Sublevel Shrinkage

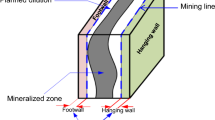

The production process, layout, and sequence of SLSh is adapted from SLC. It features a top-down general mining direction. At first, production drifts are developed either as longitudinal drifts (following the orebody in striking direction), or as transverse drifts (crosscuts through the deposit from the footwall to the hangingwall). A longitudinal layout is favorable for thinner orebodies and a transverse layout can be applied on thicker ones. Figure 1 shows a comparison of the two. From these drifts, fan drillings are made and the ore is blasted ring after ring in retreat. Production is done on multiple levels and drawpoints and progresses down-dip. The production drifts are connected with a drift in the footwall where ore transport continues with either trucks or ore passes. The major difference to SLC is a continuous backfilling from the top of the SLSh zone. This is done via a waste pass, which is a raise that connects the backfill dumping point to the SLSh zone. When ore is mucked at the drawpoints, backfill flows down by gravity. This results in an excavation that is constantly filled with either broken ore or backfill material, which passively confines the walls and prevents caving of the hangingwall [2]. To ensure this, full wall contact is needed at all times. For this reason, the material must be able to flow freely and therefore the use of unconsolidated backfill (rock fill) is mandatory [5]. The grain size should not be too fine as it could cause issues with water drainage and could impact the gravity flow negatively, resulting in high dilution. Because the head-grade ore is constantly in contact with rock fill, dilution is one of the method’s key issues. To ensure a full fill of the excavation, the volumes of extracted ore and introduced backfill must be balanced. Otherwise, voids will appear, which can lead to failures. Although the extraction process has much in common with SLC, the productivity is lower. This is due to the backfilling that requires additional infrastructure, equipment, and work force. Figure 2 shows a schematic comparison between SLC and SLSh.

Vertical cross-section of a sublevel cave (showing caving of the overlying strata) compared with a vertical cross-section of sublevel shrinkage with continuous fill (caving of the overlying strata is prevented) [6]

3 Case Studies

This section summarizes experiences and considerations for the SLSh method. The focus is on why the SLSh method was chosen at these mines and how they address critical issues and challenges. Table 1 gives an overview about the mines that are featured in this section. This table also shows that SLSh is applied in steeply dipping, tabular deposits with moderate thickness.

3.1 Mt Charlotte

Mount Charlotte is an underground gold mine beneath the city of Kalgoorlie-Boulder in Western Australia. It is part of KCGM Operations, which is owned by Northern Star Resources Limited [9]. The deposit consists of many sub-vertical orebodies and multiple mining methods have been used over the last decades. At the Charlotte and Charlotte Deep orebodies (COB and CDOB), a combination of stoping and shrinkage called long hole open stoping with delayed mass blast (LHOS-MB) was used until 1998. COB is a near vertical, tabular orebody. It measures 235 m in strike, has a thickness of between 45 and 90 m, and extends from 100 to 900 m below surface. The LHOS-MB method creates large open stopes with crown pillars that retain the backfill (rock fill) from above. When mined out, the crown pillars are fired in large mass blasts (up to 900 kt per blast) allowing the ore and backfill to flow down the stope. The mucking is done via transverse drawpoints from both sides, and backfill is introduced from the glory hole on the surface. [1] Fig. 3 shows a vertical cross-section, describing the method.

LHOS-MB mining method [1]

Recently, the longitudinal SLC-retreat, called remnant mining, is used to mine out unrecovered parts around the backfilled orebodies. This method is very similar to the SLSh explained in Sect. 2. Figure 4 shows a schematic sketch of the method. The grey parts are the historic already backfilled stopes that were mined with LHOS-MB. The blue parts are the new production drifts, and the green parts are the remnant ore intended to be mined. Due to the high ore-grade, a high dilution was tolerable and a mining recovery at COB and CDOB of 95% could be achieved. [1]

3.2 Mt Wright

Mt Wright was an underground gold mine located near Ravenswood in North Queensland, Australia, operated by Carpentaria Gold, a subsidiary of Resolute Mining Limited [5]. The deposit is a vertical rhyolite pipe measuring 200 m in strike and 60 m in thickness. It extends from roughly 100 to 800 m below surface. [5, 7] Mining started in 2006 with bottom-up sublevel open stoping and lasted for three years [2]. Stope stability has been a problem since the beginning because of wall failures. Reducing stope size would have been uneconomic, and therefore an alternative method was needed. [2, 5] Only a bulk mining method (like caving) could realise the full potential of the orebody, but caving was not possible due to infrastructure in proximity and a too low caveability of the rock mass. This led to the development of SLSh in the Mt Wright mine (see Fig. 2, [2]). The initial longitudinal drawpoint layout was quickly changed to a transverse layout due to the major principal stress acting close to transverse [5]. Some advantages of SLSh over the before used stoping variant at Mt Wright are described by Mackay [2]:

-

Higher recovery

-

No need for cemented backfill

-

Broken ore and backfill provide passive confinement to the walls.

Rock fill from a stockpile of an old open pit was chosen as backfill because the quantity of underground development waste would not be sufficient. The backfill was transported to a waste pass on the surface that was linked to existing, backfilled stopes. The crown pillars of these old stopes above the SLSh zone were fired to connect them into the top of the SLSh zone. [7] The transition zone between waste pass and SLSh zone was called the “bell”. Figure 5 shows an overview of the mine. Because the waste pass was not centered above the SLSh, voids occurred on one side of the bell, leading to roof failures. After that a second underground fill point was developed directly into the failed side of the roof to ensure tight filling. Fill levels were monitored visually as well as by balancing the volumes of backfill and ore. The second backfill point also allowed for the disposal of development waste directly underground. [5] To reduce dilution with the rock fill, a low-grade ore blanket above the active SLSh was developed and the material flow was optimized through RFID marker trials [5, 6]. The underlying principle of the ore blanket is that head-grade ore is not in direct contact with rock fill, but with low-grade ore. The low-grade ore above the SLSh zone gets drilled and blasted. After that only the swell of the ore, which depends on its bulking factor, is drawn to make room for the next blast. The broken low-grade ore is then left to create a buffer between the backfill on top and the production front below. [2] Mt Wright was one of the world’s first operations to use SLSh in this form and is said to be a major success, although some issues, like the roof failure of the bell, appeared [5].

Mt Wright Layout [5]

3.3 Chirano

The Chirano gold mine is located in the Western Region, Ghana. It is currently owned and operated by Asante Gold Corporation and consists of multiple deposits. The complex consists of three surface pits and six underground operations. In one of these operations, namely Paboase, SLSh is used as mining method. They call the method “modified sublevel caving (MSLC)”. [3] Other methods used in Chirano are longhole open stoping (LHOS) and sublevel open stoping (SLOS). The Paboase deposit is a steeply dipping, thin tabular deposit. It measures around 300 m in strike and 800 m in depth extension. Maximum depth is 850 m below the open pit.

Underground mining at Paboase started in 2012. The mine is directly underneath an open-pit, so a 39 m thick crown pillar was left. The upper part of the orebody was mined out with the use of the avoca mining method. Operational changes were made, and the method was switched to SLC (mini SLC). In the lower zone, modified SLC (MSLC) is used. Because the orebody is rather thin, MSLC is applied logitudinally. Backfilling was initially done via a central waste pass from the surface. Alternate fill passes were used to introduce unconsolidated rock fill with LHDs. Because of ground instability, the central waste pass and fill passes became useless. Backfilling is now done via the failed crown pillar from the surface. The modified SLC method is essentially the same as SLSh described in this contribution. An overview of the mine is shown in Fig. 6. The Paboase reserve is nearly depleted. Dilution is higher compared to SLOS at other orebodies at Chirano (25% SLSh vs 12.5% SLOS). For this reason, newer operations use SLOS as the primary mining method. [3] The longitudinal layout might be the cause for the high dilution as the drawpoints are laterally surrounded by waste rock on three sides.

Long sectional view of Paboase UG mine [3]

3.4 Lac Des Iles

Lac des Iles Mine (LDIM) is a palladium mine operated and owned by Impala Canada Limited and is located in Ontario, Canada. Operations started with open-pit mining in 1993 and moved underground in 2006 utilising longhole stoping as the primary method and SLSh for the deeper parts. The Offset Zone orebody, where SLSh is used, is steeply dipping and tabular. The average strike dimension is 600 m, and the thickness is around 80 m. It extends from 600 to 1350 m below surface. At first, longhole open stoping (LHOS) with rib pillars and rock fill was chosen to mine the Offset Zone, but problems with seismicity and the inability to use consolidated backfill called for an alternative mining method for the lower Offset Zone. A trade-off study was performed in 2015, and the result was to choose SLSh. [4] The reasons for that are low operating costs, high ROI, high margin, lesser problems with seismicity (because SLSh is pillarless), high productivity, and high recovery [4, 8]. The transition from LHOS to SLSh, started in 2016, was completed in 2017 [8]. LDIM uses SLSh with transverse drawpoints (compare Fig. 2). Rock fill is sourced from underground development waste and from surface pits and stockpiles. It is introduced from the surface via a waste pass and then flows down through the old backfilled stopes (see Fig. 7). Development waste can be directly dumped into the stopes of the Upper Offset Zone (see Fig. 7). The SLSh operation is designed for a maximum production of 4600 t/d (1.6 Mt/a). The draw strategy was derived from existing SLC mines. On the first level, only 40% and, on the second, 70% will be drawn. This creates an ore buffer between the backfill on the top and the head-grade ore on the lower levels to reduce and delay dilution. A software model came to a result of 76% recovery and 22% dilution. To determine geotechnical risks (infrastructure is in near proximity of the SLSh zone), a numerical simulation concluded that the areas above, where the ramp and backfill pass are located, can be affected. It is expected that the backfill will make it manageable, but close monitoring is necessary to detect deformations early. [4] Especially the stability of the backfill transport infrastructure is critical because production is only possible when a steady flow of backfill is guaranteed. To determine the amount of rock fill needed for tight fill, borehole cavity monitor surveys are in use. [8]

Section showing Offset Zone and backfill raise [8]

4 Discussion

SLSh proved to be a viable alternative to SLC in areas where the surface must be protected or caveability of the hangingwall is too low because of rock mass conditions or orebody geometry. Due to the similarity of the extraction process, productivity is high although the additional backfill handling lowers it compared to SLC. Some mines mentioned in this contribution changed from stoping to SLSh because of geotechnical and seismic issues associated with stoping methods. These problems are minimized in the SLSh method by the continuous backfill introduction, which confines the walls and leaves no open voids. SLSh is and has been applied in steeply dipping, tabular deposits with moderate thickness. Critical points of the method are the dilution with rock fill as the ore is constantly in contact with it as well as the sourcing and handling of backfill. Rock fill is the only type possible, and waste from underground development is not enough due to the development volume being far less than the extracted ore volume. Therefore, the most part of it must be sourced from the surface. Material from stockpiles can be used or can also be quarried in nearby pits. Because backfill handling infrastructure is directly above the SLSh zone, its stability can be affected and must be closely monitored as it is crucial for production. A steady flow of backfill must be provided as ore can only be extracted when enough rock fill is present. Fill levels must be sufficient to prevent the creation of voids that could lead to failures or air blasts. The rock fill volume needed is proportional to the extracted ore volume, and therefore it might be a limiting factor for future large-scale operations. Further research is needed for the application in more massive orebodies with large footprints. It might be a problem because of undercutting the backfilling infrastructure (a single waste pass might not be sufficient anymore and a whole backfill introduction level with various fill points is needed). Due to the similarity to SLC, SLSh can profit from research in SLC regarding drawpoint design, layout, and draw strategy to optimise gravity flow and dilution.

5 Conclusion

The case studies show that SLSh enables mining with a high production capability but without the negative aspects associated with caving. The mining method also proves to be an alternative for uneconomic stoping methods. In comparison to caving methods, SLSh can also be applied when the existing infrastructure (e.g. from previous operations) above the production zone needs to be protected, although it can be affected,and close monitoring is needed. Compared to caving, SLSh does not depend on the caveability of the orebody (block caving) or the hangingwall (SLC). Key aspects in operating a SLSh mine successfully are controlling the recovery and dilution as well as the sourcing and handling backfill material. The backfill provides support to the walls, but this only works when a steady backfill supply is guaranteed to constantly have tight fit to the walls. For this reason, large amounts of rock fill must be sourced, transported, and introduced into the stopes. If it is used more frequently in the future, more experience has been gained, and more research has been done, new potentials but also issues of the SLSh method might arise.

References

Mikula, P.A., Lee, M.F.: Bulk low grade mining at Mt Charlotte mine. In: Proceedings MassMin 2000, pp. 623–635. Australasian Institute of Mining and Metallurgy, Melbourne (2000)

Mackay, D.: Implementing and improving the mine plan at the Mt Wright Project. In: Proceedings 11th Underground Operators’ Conference 2011, pp. 135–142. The Australasian Institute of Mining and Metallurgy, Melbourne (2011)

Begg, D.M., Bezuidenhout, G., Claridge, D., Mandava, S.M.: NI 43–101 technical report: Chirano gold mine Ghana, West Africa. Asante Gold Corporation (2022)

Buss, B., Roney, C., Peck, D., Decharte, D., Marrs, G., Canosa, J., Hutton, K., Ritchie, L., Therrien, L.: NI 43–101 technical report: feasibility study incorporating the life of mine plan for lac des Iles mine. Nordmin Engineering (2017)

Wilson, P.: Mt Wright—geotechnical learnings from a sub level shrink. In: Proceedings The Fourth Australasian Ground Control in Mining Conference (AusRock), pp. 119–132. Australasian Institute of Mining and Metallurgy, Sydney (2018)

Mackay, D., Long, S., Koen, A.J.: Sublevel shrinkage—the Mt Wright story. In: Proceedings 12th AusIMM Underground Operators’ Conference 2014, pp. 205–216. The Australasian Institute of Mining and Metallurgy, Melbourne (2014)

De Vries, R.: Sub Level Shrinkage at the Mt Wright Underground Gold Mine. Master thesis, Curtin University of Technology (2013)

Decharte, D., Hofton, T., Marrs, G., Olson, S., Peck, D.: Feasibility study for lac des Iles mine incorporating underground mining of the Roby zone. North American Palladium (2018)

Northern Star: KCGM Operations. https://www.nsrltd.com/our-assets/kalgoorlie-production-centre/kcgm-operations, Accessed 3 Apr 2023

Funding

Open access funding provided by Montanuniversität Leoben.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Brand, L., Haider, K. Sublevel Shrinkage (SLSh) Mining—A State-of-the-art Review. Berg Huettenmaenn Monatsh 168, 274–280 (2023). https://doi.org/10.1007/s00501-023-01354-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-023-01354-3