Abstract

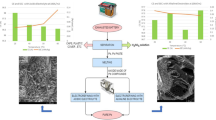

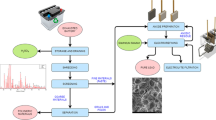

The direct electrorefining of anode particles obtained from lead acid battery sludge to produce electrolytic lead powder without application of the conventional leaching process is the aim of this work. To create this target, exhausted lead acid batteries were crushed to smaller particles and separated from the internal and external plastic covers and fed into a titanium nets basket which acts as the anode in the electrolytic cell. Two pure lead permanent cathode sheets together with the Ti-anode basket were immersed in an acidified leach liquor electrolyte containing 1.24 wt% HCl acid and 2.2 wt% Pb ions. Different parameters were investigated, such as addition of NaCl to the electrolyte, electrolyte stirring rate, electrolysis mode (electrorefining or electrowinning), and presence of suspended PbCl2 particles in the electrolyte. Electrolytic lead powders with a dispersed shape with about 0.7 % Ti were obtained. The obtained results indicated that the electrorefining technique is better than electrowinning with both cathodic current efficiency and powder productivity, while the energy required for the electrowinning process is lower. The electrorefining process was carried out with cathodic current efficiency up to 64.69 % and specific electrical energy demand in the range from 2.598 to 3.827 kWh/kg Pb with powder productivity up to 2.5 g/A.h.

Zusammenfassung

Die direkte elektrolytische Raffination von Anodenpartikel, die aus dem Schlamm der Bleibatterie zur Erzeugung von elektrolytischem Bleipulver ohne Anwendung des konventionellen Laugungsprozesses gewonnen wird, ist das Ziel dieser Arbeit. Die verbrauchte Bleibatterie wurde gebrochen und in einen Titankorb gefüllt, der als inerte Anode dient. Zwei Bleibleche als permanente Kathoden sowie der gefüllte Titankorb wurden in eine Elektrolysezelle mit einer Lösung, die 2,2 Gew.-% Blei und 1,24 Gew.-% Salzsäure enthielt, eingetaucht. Verschiedene Faktoren, wie die Zugabe von NaCl zur Elektrolyten, Rührgeschwindigkeiten des Elektrolyts, Art des Elektrolyseprozesses (Elektroraffination und Elektrogewinnung) und der Einfluss von suspendierten PbCl2 Partikeln im Elektrolyt, wurden untersucht. Es wurde Bleipulver mit 7 % Ti in feinst verteilter Form erzeugt. Die Ergebnisse zeigen, dass das Elektroraffinationsverfahren die bessere Methode ist als das Elektrogewinnungsverfahren sowohl in Hinblick auf die Kathodenstromeffizienz als auch auf die Produktivität. Jedoch ist der Energiebedarf für das Elektrogewinnungsverfahren niedriger. Das Elektroraffinationsverfahren wurde bei einer kathodischen Stromdichte von 64,69 % und einem spezifischen Energiebedarf von 2,598 bis 3,827 kWh/kg mit einer Produktivität für das Pulver von 2,5 g/A.h durchgeführt.

Similar content being viewed by others

References

Stavros, D.; Costas, P.; Theodore, V.: Applying life cycle inventory to reverse supply chains: a case study of lead recovery from batteries, Journal of Resources, Conservation and Recycling, 37 (2003), pp 251–281

Hoffmann, U.: Requirements for Environmentally Sound and Economically Viable Management of Lead as Important Natural Resource and Hazardous Waste in the Wake of Trade Restrictions on Secondary Lead by Decision III/1 of the Basel Convention: The Case of Used Lead-acid Batteries in the Philippines, Draft Study, July 1999, p 4

Sonmez, M.; Kumar, R.: Leaching of waste battery paste components. Part 1: Lead citrate synthesis from PbO and PbO2, Hydrometallurgy, 95 (2009), pp 53–60

Liniger, M.: Process for Recovering Lead from the Active Material of used Batteries, US patent 4,030,916, 1977

Birk, J.: Recovery of lead from batteries, US patent 4,085,396, 1977

Bergsoe, S.: Method of recovering lead from lead acid batteries, US patent 4,340,421, 1982

Huwald, E.; Koenig, R.: Method of recovering lead and lead compounds from discarded lead storage batteries, US patent 4,384,683, 1983

Prengaman, R.; Morgan, C.: Process for recycling lead-acid batteries, US patent 6,177,056 B1, 2001

Nedwed, T.; Clifford, D.: A survey of lead battery recycling sites and soil remediation processes, Waste Management, 17 (1997), no. 4, pp 257–269

Prengaman, R.; McDonald, H.: Method of recovering lead values from battery sludge, US patent 4,229,271, 1980

Ducati, U.: Hydrometallurgical method of recovering metal materials from spent lead-acid storage batteries, US patent 4,460,442, 1984

Montgomery, A.; Kube, W.: Methods for processing battery waste and other lead containing materials, US patent 5,173,277, 1992

Montgomery, A.; Kube, W.: Methods for processing battery waste and other lead contaminated materials, US patent 5,248,342, 1993

Modica, G.; Nannicini, R.: Method for the recovery of lead from exhausted lead acid storage batteries, US patent 5,944,869, 1999

Vaysgant, Z.; Morachevsky, A.; Demidov, A.; Klebanov, E.: A low-temperature technique for recycling lead/acid battery scrap without wastes and with improved environmental control, Journal of Power Sources, 53 (1995), pp 303–306

Sonmez, M.; Kumar, R.: Leaching of waste battery paste components. Part 2: Leaching and desulphurization of PbSO4 by citric acid and sodium citrate solution, Hydrometallurgy, 95 (2009), pp 82–86

Brandon, N.; Pilone, D.; Kelsall, G.; Yin, Q.: Simultaneous recovery of Pb and PbO2 from battery plant effluents. Part II, Journal of Applied Electrochemistry, 33 (2003), pp 853–862

Volpe, M.; Oliveri, D.; Ferrara, G.; Salvaggio, M.; Piazza, S.; Italiano, S.; Sunseri, C.: Metallic lead recovery from lead-acid battery paste by urea acetate dissolution and cementation on iron, Hydrometallurgy, 96 (2009), pp 123–131

Expoâsito, E.; Iniesta, J.; Gonzaâlez-garcõâa, J.; Montiel, V.; Aldaz, A.; Lead electrowinning in an acid chloride medium, Journal of Power Sources, 92 (2001), pp 260–266

Ferracin, L.; Chacon-Sanhueza, A.; Davoglio, R.; et al.: Lead recovery from a typical Brazilian sludge of exhausted lead-acid batteries using an electro-hydrometallurgical process, Hydrometallurgy, 65 (2002), pp 137–144

Spijkerman, J.; Groenen, R.: Process for the recovery of Metallic Lead from Battery Paste, US patent 5,514,263, 1996

Pradyot, P.: Handbook of inorganic chemicals, McGraw-Hill, 2002

Acknowledgements

The author would like to thank Dr. Eng. Mohamed Gepreel (Egypt-Japan University of Science and Technology) for his assistance in conducting the SEM & XRF analyses. Many thanks are also for Eng. Fuad Koriem (Techno Egypt Company- Helwan, Egypt) for supplying the battery sludge samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Owais, A. Direct Electrolytic Refining of Lead Acid Battery Sludge. Berg Huettenmaenn Monatsh 160, 134–144 (2015). https://doi.org/10.1007/s00501-014-0293-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-014-0293-6