Abstract

A curved non-isoparametric Reissner–Mindlin shell element is developed for analyzing thin-walled structures. The standard kinematic description of the element requires the calculation of the director vector. To address this demand accurately, similar to isogeometric analysis (IGA), the geometry is defined by utilization of the non-uniform rational B-splines (NURBS) imported directly from computer-aided design (CAD) files. Then, shape functions of the Legendre spectral element method (SEM) are used to interpolate the displacements. Consequently, the shell director vector and Jacobian of the transformation are calculated properly according to the presented formulation. On the other hand, in Legendre SEM combined with Gauss–Lobatto–Legendre quadrature, the integration points and the element nodes coincide. Thus, the easily computable local coordinate systems at the integration points can be used directly as nodal basis systems. A separate calculation of nodal basis systems at control points, which is the source of either complexity or error in IGA shells, is not required. Given the condition number of the stiffness matrix in the developed method, super high-order elements can also be used. Very high order p-refined elements are used in addition to h-refinement of the mesh to show the capability of higher order elements to analyze problems without mesh refinement. The validity and convergence rate of the method are investigated and verified through various cases of h- and p-refinement in challenging obstacle course problems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Based on favorable ratios between own weight and applicable load, shell type structures are ubiquitous in load carrying systems both in nature and in human made structures. Thus, there exists a continuous line of research related to analysis of shell structures and, nowadays, one of the most common simulation methods is the finite element method (FEM). Historically, numerical methods for the analysis of structures - such as FEM - evolved decades before the beginnings of CAD [1]. This explains the use of different and hardly compatible methods for the representation of the geometry in CAD and FEM, whereby the latter uses an inexact representation of the geometry, called finite element meshes [1]. In order to overcome this problematic separation of models, isogeometric analysis (IGA) was introduced by Hughes et al. [1]. Given the exact representation of geometry and integration of CAD and computer aided engineering, IGA found its way into many applications [2]. Due to the prevalent definition of complex shell structures by two-parametric surfaces, shell analysis is naturally one of those. Based on Kirchhoff-Love theory, in [3] an isogeometric shell element is developed and used for nonlinear analysis of thin shell structures. However, it cannot be used to analyze thick shells and yields inaccurate results in regions of high plastic deformations [4]. The first isogeometric shell element for the analysis of thick shells, based on Reissner–Mindlin theory, was developed in [5]. In this work, the use of higher order NURBS justifies omitting measures against locking effects. More recent works point out the presence of locking effects despite high orders of basis functions and present methods to alleviate these effects [6,7,8,9]. Solid-shell elements, which include thickness stretch, together with methods to alleviate various locking phenomenon have been developed in [10, 11]. However, the lack of proper volumetric geometry definition in industrial CAD software largely hinders the use of solid-shell formulations.

A further controversial point in isogeometric Reissner–Mindlin shell analysis is the interpolation of the director vector and its rotation field [12, 13]. In Reissner–Mindlin shell elements a further quantity, usually the rotation of the director vector, has to be interpolated from nodal values. This additional interpolation entails the need for nodal coordinate systems, which have to be defined at the control points if an isogeometric approach is used. Since control points do in general not lie on the physical shell surface, there is no unique and straightforward choice of the decisive nodal basis vector in thickness direction, which is called director vector. In [5], the use of an orthonormal nodal coordinate system constructed at the closest point on the physical surface is proposed. Since it has been shown in [12] that this approach diverges for rising orders of basis functions, recent works use projection approaches to compute nodal basis systems from exact basis systems at integration points [8, 12]. However, the interpolation of the rotation itself remains a much-discussed topic. For low order Lagrange-based finite element shell formulations, this topic has been studied and clarified in [14] where it was found that the simple method of interpolation of rotated director vectors using Rodrigues’ formula to calculate the rotated nodal vectors is entirely sufficient. Due to the large support of spline basis functions, the situation is entirely different for NURBS-based isogeometric analysis. Nodal director vectors may have largely varying directions within one element. Thus, in [12] Rodrigues’ formula is used to rotate the interpolated director vector. This prevents artificial thinning, which occurs for the shell formulation of [5] for high orders and arbitrary curvature. The use of an additional mesh with Lagrange basis functions in [15] avoids the interpolation of vectors with highly continuous basis functions, but the numerical effort for integration of the stiffness matrix and the global solution is very high since significantly more Lagrange basis functions in comparison to NURBS basis functions are required. Instead of using rotations, it is also possible to use shear deformations or shear angles as additional interpolated quantity for Reissner–Mindlin shells [6]. These approaches entirely avoid problems arising from the interpolation of the director vector at the cost of a significantly more complex coupling of patches with unaligned local directions, e.g., at kinks. Besides the presented formulations, a multitude of further isogeometric shell formulations, which all can be classified to be similar to one of the above mentioned, is given in literature. However, until now no isogeometric shell formulation exists which solves the issues raised by the high - and potentially gradated - continuity.

The idea of using a type of basis functions for the analysis, which ab initio avoids the main issues mentioned above, seems to be very promising. A naturally good choice is to use the spectral element method in time domain (SEM), first utilized by Patera [16], in which nodal and integration points coincide and lie on the surface, which allows a straightforward interpolation of the director vector. The SEM bases on changing the position of nodes in a standard isoparametric element in the way that the amount of error with the equal degrees of freedom is reduced in comparison to FEM. To this end, in SEM, the positions of nodal values are calculated based on the root of different polynomials and in this paper only Lobatto polynomials are utilized [17]. The accuracy and capability of SEM is vastly investigated and proved, especially in wave propagation analysis in [18,19,20], but also in shell analysis [21, 22]. In [19] it is shown that SEM requires far less nodes per wavelength in comparison to FEM to obtain the same precision level of results.

In this work we will use the IGA shape functions to calculate exact geometrical quantities while for setting up the numerical model and meshing, SEM will be used. Although utilization of high order spectral elements is reported as a measure to alleviate shear locking in plates [23], we will investigate the locking phenomenon by careful selection of examples which are prone to both shear and membrane locking. In this stage we will focus on the small deformation to investigate the capability of the proposed element to pass some well known obstacle course problems. The outline of the work is as follows. In Sect. 2 a brief introduction to IGA and SEM is provided. Sect. 3 provides a detailed description of different spaces involved in developing the element and also the element formulation. Various challenging numerical examples are solved in Sect. 4 followed by the conclusion in Sect. 5.

2 IGA and SEM terminology

The presented shell formulation is based on both NURBS and SEM. Therefore, we divide the parametric spaces into two basic spaces, the first is associated with NURBS and the second with SEM shape functions. So, a very brief introduction to the shape functions in IGA and SEM is presented here. A NURBS curve can be defined by utilization of a set of n control points and B-Splines basis functions \(N^p_i\) which can be defined according to Cox-de Boor formula beginning with order \(p=0\):

where p is the order of the B-Spline basis function and \(\eta _i\) belongs to the open and non-decreasing knot vector \(\varvec{\mathrm {\eta }}=\{\eta _1, \eta _2,\ldots ,\eta _{n+p+1}\}\) [24]. If not specified differently, Greek indices range from 1 to 2 and Latin indices from 1 to 3. The coordinate of a point, \(\varvec{\textrm{X}}\), on the NURBS mid-surface of a shell patch can be defined by utilizing a net of \(n\times m\) control points and 2D B-Splines basis functions of orders p in \(\eta ^1\) and q in \(\eta ^2\) directions as below

where

and

where \(w_{ij}\) is the weight coefficient and \(n_{en} = (1+p)(1+q)\) is the number of 2D shape functions that have impact on the arbitrary point with the coordinate \(\eta ^1\) and \(\eta ^2\) in the parametric space. \(\varvec{\textrm{X}}_L\) is the coordinate vector of Lth control point in the set of the control points which has impact on the arbitrary point. To be used in the next parts, the detailed algorithm to calculate the derivatives of NURBS functions can be found in [25]. In standard IGA shell formulation, exactly the same 2D NURBS shape function \({\hat{N}}_L\) are used to interpolate unknown fields.

In Legendre SEM, Lagrange shape functions are used and the coordinates of unevenly spaced nodes of elements are calculated based on the roots of Legendre polynomials. If we take the number of interpolating nodes as \((p+1)\), where p is the order of element, then the pth order 1D Lagrange shape function for the ith interpolating point is calculated according to [17] as

where \(\xi ^j\) is the coordinate of the jth node in the SEM parametric space. The parametric coordinates of the nodes are calculated with

where \( L_n(\xi )\) and \(Lo_{n-1}\) are nth order Legendre and \(n-1\) order Lobatto polynomials. After some algebra, the differentiation of Eq. (6) yields the derivatives

of the Lagrange shape functions. Details about the calculations can be found in [17]. The numerical integration method used within SEM is the Gauss–Lobatto–Legendre (GLL) method, for which

with

holds. The 2D Lagrange shape functions can be calculated by the tensor product of vectors of 1D shape functions. Further details about SEM can be found in .

It is noteworthy to mention that one benefit of IGA is to remove the meshing phase by using the same shape functions both in the geometry definition and in the analysis. As it will be shown, in the presented method, meshing and h-refinement is not the best option for convergence in the most problems. Therefore, in many cases meshing will not be necessary or a minimum number of elements will be sufficient. To clarify this point it should be mentioned that when polynomials alongside evenly spaced nodes are used to interpolate the unknowns, utilization of very high order elements causes the increase in amount of error. However, the proper choice of location of nodes utilized in SEM decreases the growth of the Lebesgue constant. This can end up with proper results when higher order elements are used and exclude some well known phenomenon in higher order polynomial interpolation such as deleterious Runge effect [17, 26]. So, the use of single very high order elements will also be considered in this paper.

3 Reissner–Mindlin shell element formulation

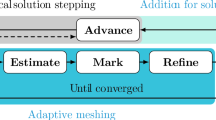

3.1 Connection between physical, IGA and SEM parametric spaces

Before explaining the shell formulation, a more detailed explanation of different spaces used in the method seems necessary. In the presented method, it can be considered that the whole geometry is imported into the numerical simulation process as a package whose responsibility is to provide the basic required geometrical quantities like physical coordinates as functions of parametric coordinates, Jacobian and director vectors. The first parametric space is connected with IGA and NURBS shape functions. There is another parametric space which is connected to each element by a simple linear transformation and named as second or SEM space. Figure 1 shows the connection between the spaces for the mid-surface of a shell structure. Meshing can be based on five scenarios: 1- elements coincide with the non-zero-length elements of IGA 2- internal borders of elements coincide only at the internal knots with predefined number of repetition (according to the continuity of the shell) 3- element borders at any arbitrary knot 4- a mixture of the all three previous cases 5- unstructured meshing in IGA space, it means that the element borders are not necessarily parallel with the \(\eta ^1\) and \(\eta ^2\) axes anymore. Therefore, in Fig. 1 meshing can be according to each possible method and not necessarily coincides with IGA meshing.

Given Fig. 1, the coordinates of a point in physical space on element ABCD are

3.2 Kinematics of the shell element

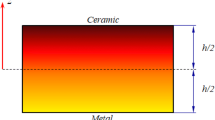

The geometry of a shell can be defined by its midsurface and unit director vector \({\bar{\varvec{\textrm{V}}}}\) (Fig. 2). The director vector is assumed to be normal to the midsurface. \(\varvec{\textrm{g}}_\alpha \) is the covariant tangent vector of the midsurface in \(\eta ^\alpha \) direction and is calculated by using NURBS shape functions provided in the CAD model

The global Cartesian coordinate vector of any material point in the shell body is

where \( {\textbf {X}}\) and t are the midsurface coordinate vector and varying thickness of the shell, respectively. For sake of the simplicity we consider surfaces with constant thickness, i. e. \(t(\eta ^1(\xi ^1, \xi ^2), \eta ^2(\xi ^1, \xi ^2))=t\). Additionally, \(\eta ^3(\xi ^3)=\xi ^3\) and \(-1\le \xi ^3\le +1\). Considering Eqs. (12) and (13), at each point within the body of the shell the Jacobian of transformation from physical to the IGA parametric space is

where \(\phi _i\) is the ith component of the coordinate vector of any point in the global Cartesian coordinate system and \((\varvec{\textrm{g}}_\alpha )_i\) and \({\bar{V}}_i\) are global Cartesian components of the covariant tangent vectors and the unit director vector. It should be mentioned that as Cartesian components of vectors are used, there is no difference between covariant and contravariant components. Given Eq. (14), the calculation of the derivatives of the unit director vector is required. For adding more precision to our calculations at this stage, we avoid the standard method which is interpolating the director vector and then making the derivation by differentiating the shape functions. Instead, the exact geometrical NURBS based definition of the director

is used. So,

and

where \(\varvec{\textrm{V}}\) is the non-unit director vector. In the calculation of the right side of Eq. (17), the derivative of \( \Vert \varvec{\textrm{V}}\Vert \) is needed. For this purpose, the following equations are presented. The square of the length of the director can be expressed as follows:

By differentiating both sides of Eq. (18), we get

So the derivative of the length of the director vector is achieved as below

From Eq. (20), the derivatives of the length of the director can be derived and used in Eq. (17). Consequently, the Jacobian of the transformation from physical to IGA parametric space can now be calculated exactly by using the IGA shape functions and Eqs. (12) to (20). The geometrical data such as control points, NURBS shape functions and their first and higher order derivatives are imported to our program directly from CAD files by using Ref. which is well connected to Ref. [25].

The Jacobian matrix of the transformation from IGA to SEM parametric spaces can be written as

Based on simple linear Lagrange shape functions, for the first four meshing scenarios explained in Sect. 3.1, the Jacobian matrix from IGA to SEM spaces for element ABCD is derived as

The constants are in fact the ratio of the sides of the rectangular element in IGA to SEM spaces (Fig. 1). For the fifth scenario, the general form given in Eq. (21) is used while the transformation is still based on linear Lagrange shape functions but the result will not be a diagonal matrix. Lastly, the Jacobian of the entire transformation from physical to SEM parametric space is

Remark 1

The implementation of the proposed formulation can be performed using an IGA code as basis. At the beginning of the analysis, the physical locations of the SEM nodes have to be computed. The position of these nodes is fixed in the SEM parametric space, which can be mapped linearly to the IGA parametric space. Thus, the physical coordinates of the SEM nodes are computed by a simple point evaluation of the NURBS surface. Similarly, the exact director vector can be computed for every SEM nodes according to Eq. (15). Both the position vector and the director vector have to be stored to be accessible in all further computational steps. The global assembly arrays have to be adapted to account for the element-node-relations of the SEM mesh. On the element level, besides the NURBS shape functions, which are required for the evaluation of the Jacobian, also the evaluation of the SEM basis functions has to be implemented. The computational costs for all these additional measures are not significant, since neither iterations occur nor any system of equations has to be solved.

3.3 Finite element formulation

Figure 3 shows a spectral element of degree \(p=4\) with its spectral nodes. The volume, area of midsurface and boundary lines of midsurface of the element are \( \Omega \), \( {\mathcal {A}} \) and \(\Gamma \), respectively. There are five degrees of freedom (DOF) at each node, three translational and two rotational. The former are defined in the direction of the global Cartesian coordinate system while the latter are defined around local Cartesian basis systems with unit vectors \(\varvec{\textrm{V}}_1\) and \(\varvec{\textrm{V}}_2\). We call this coordinate system director system. To define the local Cartesian basis at each node there is no unique method and we follow Ref. [28]

where \(\varvec{\textrm{e}}_2\) is the unit vector in \(x^2\) direction. Based on the unit director vector, the displacement vector is interpolated by

\(u_i\), \({\tilde{u}}_i\) are the displacement function and the nodal displacement in the ith global Cartesian direction. \(M_I\) is the 2D Lagrange shape function corresponding to node I. In this paper, only elements with equal number of nodes in each direction are used. \((\Delta \tilde{{\bar{V}}}_i)_I\) is the ith global Cartesian component of \( \Delta \varvec{\tilde{{\bar{V}}}}_I\) which is the difference between the rotated director (after deformation) and the initial director vector at node I. Considering only linear kinematics, the change of director vector is calculated by Eq. (26) which is written in director coordinate system as below

\(({\tilde{\varvec{\textrm{V}}}}_\alpha )_I\) is \(\varvec{\textrm{V}}_\alpha \) at node I and \((\Delta {\tilde{\theta }}_\alpha )_I\) is the rotation around \(({\tilde{\varvec{\textrm{V}}}}_\alpha )_I\). By using Eqs. (25) and (26) and the Cartesian components of \(({\tilde{\varvec{\textrm{V}}}}_\alpha )_I\), the relation between the global Cartesian coordinate of displacement vector and the nodal displacement values is summarized as

where \(\left( ({\tilde{\varvec{\textrm{V}}}}_\alpha )_I \right) _i\) is the global Cartesian component of \(({\tilde{\varvec{\textrm{V}}}}_\alpha )_I \) in the ith direction and \(\varvec{\textrm{d}}\) is the nodal displacement vector of the element. The small strain tensor in global Cartesian coordinates is

The strain–displacement matrix for the small strains in Voigt notation can be established as below

where \(\gamma _{ij}=2 \epsilon _{ij}\). \(\varvec{\textrm{B}}\) can be built by arranging the derivatives of deformations according to Eq. (28). The derivatives of the deformation can be calculated as

based on Eqs. (25), (26) and (28) and the Jacobian of the transformation (Eq. 23).

For establishing the constitutive law, it is assumed that the plane stress assumptions govern the stress and strain relation in a local Cartesian coordinate called material coordinate system, then the full elastic 3D matrix in global Cartesian coordinate system can be calculated by using a transform matrix (For more details about transformation and strain–displacement matrices see [28] and Appendix A). Consequently,

holds, where \( \varvec{\mathrm {\tau }}\), \(\varvec{\mathrm {\epsilon }}\) and C are Voigt representation of stress and strain components and elastic matrix in global Cartesian coordinates, respectively. By minimizing the total potential energy of the system the element stiffness matrix k and the load vector f are obtained,

where \(\varvec{\textrm{f}}_b\), \(\varvec{\textrm{f}}_s\) and \(\varvec{\textrm{f}}_l\) are the nodal load vectors produced by distributed body, midsurface and line loads, respectively and \(\varvec{\textrm{f}}_p\) is the point load vector. They are calculated by

As for a distributed line load, for the sake of simplicity, it is assumed that the line loads are applied only on the boundaries of the midsurface of an element, where \(\xi ^\beta = +1 \; \textrm{or} \;-1\). Therefore

There is no sum over \(\alpha \) and \(\varvec{\textrm{P}}_b\), \(\varvec{\textrm{P}}_s\) and \(\varvec{\textrm{P}}_l\) are external volume, surface and line load vectors. The integration in the direction of \(\xi ^3\) is taken by Gauss quadrature while for other two directions, GLL quadrature is utilized. The Jacobian and tangent vectors are calculated at each integration point based on the procedure described in Sect. 3.2. The global stiffness matrix and external load vector are assembled in the same way as in a standard finite element method.

Remark 2

The main advantage of the proposed formulation is the straightforward treatment of the rotations. Due to the use of SEM basis functions and GLL integration, nodal basis vectors \(\tilde{\bar{{\textbf{V}}}}_I\), which are required in Eq.(26), can be determined exactly by a simple point evaluation. In standard rotation-based IGA Reissner–Mindlin shell formulations, these values have to be computed by local [8] or global [12] projections, which yields additional errors or requires the solution of a system of equations, respectively. The implementation of the global projection of [12] has a similar complexity as the entire changes required for the implementation of the proposed formulation on top of an isogeometric code; see remark 1. Another aspect which is significantly simplified in the proposed formulation in comparison to the IGA shell formulations in [8, 12, 13] is the interpolation of the deformation of the director vector (second term in Eq. (25) in combination with Eq.(26)). We use a discrete interpolation as in standard low-order finite shell element formulation. This is conceptually simple and yields fast computations. It has been shown in [13] that in IGA a more accurate continuous interpolation has to be used in order to obtain convergence for order elevation. However, this yields a significant more complex implementation, introduces slight path-dependency and increases the computational costs for the formation of the global stiffness matrix by 30 to 70 percent; see Tab. 4 of [13].

4 Numerical example

To determine the capabilities and performance of the present element, a vast variety of well known examples are analyzed: Scordelis-Lo roof to test the ability of the element formulation to model complex states of membrane strains and pinched cylinder with diaphragms to test the capability of the element to capture inextensional bending modes, hemispherical shell with hole on top to assess the ability of the element formulation to model inextensional modes and also accurate modeling of rotation [29], cylindrical shell subjected to a line load to check the effect of membrane and shear locking [8] and a double curved free form shell structure to evaluate the capability of the method to capture the curvature variation properly [12]. To calculate the displacements, a machine with a single Intel Core i5-10210U CPU and the NumPy solver (NumPy.linalg.solver) [30] is used. The results of the proposed formulation are labeled as SEMN. For comparison, results using the isogeometric Reissner–Mindlin shell formulation of [13] are also provided. This formulation utilizes continuous interpolation of the rotation and is labeled solely by IGA. Alternatively, if labeled with IGA-RMD a discrete rotation interpolation is used. Summing up, we use the following abbreviations in the labels of the diagrams:

-

IGA: Isogeometric Reissner–Mindlin shell with continuous rotation of the director vector as proposed in [13] and global projection [12].

-

IGA-RMD: Isogeometric Reissner–Mindlin shell with discrete rotation of the director vector as proposed in [13] and global projection [12].

-

SEMN: Proposed formulation of this contribution.

In all of our numerical examples, we utilize scenario 2, which is explained in Sect. 3.1, in p-refinement and mesh the shell structure only where the continuity of elements in IGA is smaller or equal to \(C^1\). For example, in double curved free form shell structure (Appendix B), there are non-zero-length elements in IGA but the order of continuity of the shell is \(C^2\) at the borders of IGA elements. Therefore, we do not place border at any internal knots and only one element is used in SEMN. For h-refinement, we initially utilize scenario 3 and use elements with equal length in each direction. Then similar to p-refinement, scenario 2 is checked.

4.1 Scordelis–Lo roof

In this example the Scordelis–Lo roof is analyzed. At each end of the structure there is a rigid diaphragm which is parallel to \(x^1x^3\) plane and restrains the in-plane displacements in \(x^1\) and \(x^3\) directions and prevents the in-plane rotation. The roof is subjected to a distributed uniform gravity load equal to 90 per unit area. The radius of the roof is 25 and the thickness of the shell is 0.25. The length of the whole roof is 50. Young’s modulus and Poisson’s ratio are \(4.32\times 10^8\) and 0, respectively. Considering symmetry, only a quarter of the shell, as depicted in Fig. 4, is modeled and the vertical displacement at point A is compared with the value 0.3020 taken from [12].

Figure 5 shows the comparison between the normalized deformation for p-refinement for SEMN, IGA and IGA-RMD against the order of element. The comparison between IGA-RMD and IGA shows that the continuous rotation formulation is robust with respect to high orders, while the discrete rotation formulation turns instable for order \(p>11\). Even though the proposed SEMN element uses a discrete rotation formulation, it is highly accurate for high orders. Figure 6 depicts the normalized deformation against the number of elements in \(\eta ^1\) and \(\eta ^2\) direction and unrestrained dofs, respectively. For the sake of brevity from now on, we use dofs instead of unrestrained dofs in the figures. In Fig. 6b each point on a graph is a representative of the number of elements in \(\eta ^1\) or \(\eta ^2\) direction which starts from 1 and ends at 5. The same scheme is used for all other cases, so the first node in each graph shows a mesh with 1\(\times \)1 element and it increases up to a mesh with 5\(\times \)5 elements. The results clearly show that for low order computations, IGA is more precise, but for high order computations the accuracy between IGA and SEMN does not significantly differ when comparing discretizations with the same number of higher order elements. It must be mentioned that the definition of element in IGA is not completely compatible with FEM or SEM. So, with the same number of elements the degrees of freedom of IGA is less than SEMN with the equal order. Depending on the studied problem, the results of Fig. 6a or Fig. 6b might have higher relevance. If complicated material laws, such as plasticity, are used, then the number of elements has a significant influence on the total computational costs. If linear elastic materials are considered, then the number of dofs has a significant influence on the solution costs.

Figure 7 is a useful tool for selecting the refinement strategy for analyzing the roof. It shows the accuracy against the total time of the solution which consists of the time of assembling of the stiffness matrix plus solving the equations. As explained before each point for any order of element shows the number of elements starting from \(1\times 1\) and ending by \(5\times 5\) element mesh. Since the IGA and SEMN computations are performed in different frameworks, no reliable comparisons of efficiency can be provided. Figure 7b is like Fig. 7a but with a higher resolution to expand the initial phase of the graph. Figures 5 and 6 clearly show the rapid convergence of the method. As it is shown by an arrow in Fig. 7b, the normalized deformation calculated by utilization of a mesh with only 1\(\times \)1 element with order 5 is more than 0.995. So, without mesh refinement good results are also achievable in this example.

In Fig. 8 the condition numbers for p-refinement and partly for h-refinement are depicted for SEMN and IGA. The condition number for the IGA computations is obtained from the estimated inverse of the condition number provided by the function dsycon of the Intel® oneAPI Math Kernel Library for Fortran. The condition number for SEMN is computed by Numpy (Numpy.linalg.cond) [30]. The condition number for IGA does not differ significantly from IGA-RMD. In both cases, the condition for \(p>11\) is so bad that unstable results are expected. As can be seen in Fig. 5, the IGA-RMD computations turn unstable, while the IGA computations do not. Figure 8a shows that the increase of the condition number ultimately limits also the selection of the order of shape functions both in SEMN and IGA. However, the rate of increase in SEMN is much less than in IGA, allowing the use of very high order elements only in SEMN. The SEMN computations also reveal that inserting additional elements (h-refinement) yields a larger increase of the condition number than elevating the order of the elements (p-refinement). This clearly favors our idea of using a very low number of high order elements, which is also suggested by the efficiency comparison in Fig. 7. The figure is provided to introduce a base of comparison for more severe problems solved in this section.

A comparison of the circumferential shear force plotted over the \(x^1\)-coordinate at \(x^2=12.5\) between SEMN and IGA is provided in Fig. 9. The results show that for order \(p=5\), IGA is slightly more precise than SEMN, but for higher orders, the results correspond very well. Again, despite the very bad condition number of IGA, no oscillations occur. However, the results also show that the chosen simple discrete rotation formulation of SEMN is sufficient to obtain results that are as precise as the significantly more complex IGA formulation. In Fig. 10, the IGA-RMD results are compared to SEMN. Here, the picture is entirely different. Despite using the same rotation formulation, the SEMN results converge very well for rising orders, while IGA-RMD shows minor oscillations for \(p=8\) and \(p=10\) and very large oscillations for \(p=13\). These unstable results can clearly be attributed to the bad conditioning of IGA-RMD already revealed in Fig. 8a.

4.2 Pinched shell

A pinched shell subjected to opposing radial loads with the magnitude of 1 is depicted in Fig. 11. The total length of the cylinder, its radius and thickness are 600, 300 and 3, respectively. Like the Scordelis–Lo roof, the end of the cylinder is restrained by two rigid diaphragms which provide in-plane restraints. Considering symmetry, only a quarter of the shell, as depicted in Fig. 11, is modeled (consequently, the quarter of the unit load is also applied to the shell). Young’s modulus and Poisson’s ratio are \(3\times 10^6\) and 0.3, respectively. The vertical deformation under the concentrated load is calculated and normalized by \(1.83\times 10^{-5}\) [12]. In the point of view of shear and membrane locking, this example is the most severe one among the three introduced in [29].

Figures 12, 13, 14 show the results which are compared to IGA. Because of the nature of this example which includes severe locking and singularity, in comparison to Scordelis–Lo roof, higher order elements and also a finer mesh in h-refinement is required to obtain accurate results. Both methods provide similar results in p-refinement. In h-refinement, increasing the order of the element decreases the difference between the IGA and SEMN results. Regarding Fig. 13, the locking in low-order elements in both methods is explicit and it is alleviated by increasing the order of elements. Figure 15 shows error against time of analysis in p-refinement for SEMN. Each point is the representative of the element order, which starts from 2 (according to Fig. 12). As it can be seen a mesh of \(3\times 3\) SEMN elments with order 8 provides accurate enough result and is comparable to use only one element with order 13 from the amount of error and the time of analysis point of view.

To investigate more about the locking in unstructured meshes for the pinched shell, which exhibits severe locking in numerical simulation, two different groups of unstructured meshes are generated and depicted in Figs. 16 and 18. Also, four different cases have been defined for each group. In Figs. 16 and 18, the meshes in both the IGA space and the physical space are depicted for each case, with the top showing the former and the bottom showing the latter. In the first group shown in Fig. 16, it is intended to show the effect of skewed elements on the convergence rate, while in the second group depicted in Fig. 18, in addition to the distortion of elements, largely varying aspect ratios are also included. As it can be noticed in Figs. 16d and 18d, some elements are so distorted that they closely resembles a triangle, while the other elements exhibit a variety of angles and shapes. However, as illustrated in Figs. 17 and 19, the results for different cases in both groups are very similar to each other, and all of them exhibit relatively rapid convergence.

4.3 Hemisphere with a hole

In Fig. 20 a hemispherical shell with a \(18^\circ \) hole on top-center of it and radius of 10 is depicted.Young’s modulus and Poisson’s ratio are \(6.825\times 10^7\) and 0.3, respectively. The thickness of the shell is 0.04. Radial forces 2F alternating at \(90^\circ \) are applied to the shell as shown. Regarding the symmetry, only a quarter of the hemisphere subjected to load F is analyzed. The radial deformation under the point load is investigated. The value of deformation presented in [29] is for a hemisphere without the hole [31]. In [31] the value of 0.094 is utilized to normalize the results and then different elements have been used to calculate the deformation. Additionally in [31], a patch test also has been performed to compare the element performances. According to the result of the patch test, we pick the result of the finest mesh of QUAD4 element in [31] which is \(0.998\times 0.094\) to normalize our results. The results are presented and compared with IGA in Figs. 21, 22, 23, 24. The performance of the high order SEMN method can be observed form Fig. 24. A very rough mesh of high order elements or only one very high order element, namely \(p \ge 9\), can provide accurate results. Generally the pattern of difference between IGA and SEMN is similar to the previously explained examples in Sect. 4.1 and 4.2.

4.4 Curved cantilever beam subjected to a line load

The result of a curved circular beam subjected to a line load (Fig. 25) is presented in this section. The beam is the quarter of a circle with the radius of \(R=10\). Young’s modulus and Poisson’s ratio are 1000 and 0, respectively. Three different slendernesses \(\frac{R}{t}=100, 1000, 10000\) are chosen to investigate the locking effect with respect to the changes in thickness t. The uniform line load is equal to \(0.1t^3\). Based on the analytical solution of Euler-Bernoulli beam theory, the approximate radial displacement at the free end is equal to 0.942 [8].

As it can be seen in Fig. 26, the results of SEMN in p-refinement for different slenderness are the same for unaided eyes. This is also the case for IGA. In h-refinement, Figs. 27 and 28, at first glance the same behavior can also be observed and regardless of the slenderness the results are the same for \(p>2\). However a higher resolution depiction in Fig. 29 shows that there is a fluctuation in the results in the most slender curved beam in SEMN. This point can be justified according to Figs. 30 and 31 which show that the condition number increases with the increase in the slenderness and order of the elements. Similar to the previous examples, the condition number for the IGA method is greater than that for SEMN when higher-order elements are employed. To our view the slenderness equals to 10,000 can be a limit for feasibility of the method with double precision accuracy in this example. Nevertheless, the method still provides accurate deformation and rapid convergency as can be observed in Figs. 26 and 27 while \(\frac{R}{t}=10000\) is not something very common for an open section in practice. Again, Figs. 29, 30 and 31 clearly favor the use of one element with high order. In addition, in Fig. 32, the results of Fig. 5c of [8] are compared to the proposed SEMN formulation using pure p-refinement for the curved beam with \(R/t=10000\). The data related to [8] in Fig. 32 was kindly provided by Zhihui Zou. In this figure various methods proposed and utilized in [8] are compared. Here the label RMCM refers to the isogeometric Reissner–Mindlin shell with continuous rotation of the director vector based on mixed Bubnov-Galerkin method as proposed in [8]. The comparison between the IGA results of [8] and the proposed SEMN formulation shows the distinct advantages of utilizing high-order SEMN over low-order IGA in a mesh. In this challenging example, computations with high order SEMN provide highly accurate results and beginning from 200 dofs (p=6), the results are comparable to the mixed IGA element formulation of [8]. The discussion carried out in the preceding section was solely focused on the deformation results. One point should not be neglected: although the graphs for deformation display a satisfactory rate of convergence in all cases, when locking exists, in addition to underestimation of deflection, the spurious oscillation of shear forces are also considerable [32, 33]. As this example is the most severe example to check shear locking, we also depict the shear force diagrams in p-refinement along the length of the curved beam in Figs. 33 and 34, comparing SEMN to IGA and IGA-RMD, respectively. The shear forces per unit length are normalized to the maximum value, which is equal to the line load of the beam. It clearly shows that the alleviation of shear locking represented by spurious shear oscillation needs much more computational effort in comparison to excluding underestimation of deflection. In Fig. 33 we can observe that IGA performs better than SEMN, which is due to the more precise rotation formulation. However, with the exemption of the most slender case, SEMN provides very accurate results if the order is chosen high enough. As described before, slenderness equals to 10,000 is the limit also here. In this case, the spurious oscillation is considerable even when very high order elements are utilized, both for IGA and SEMN. It should be mentioned that although the convergence of the SEMN method in Fig. 26 seems not to be dependent on slenderness, spurious oscillations of shear force still exist and increase with rising slenderness. This is a clear sign, that locking is not entirely removed but, according to Fig. 33c, largely alleviated by using very high order basis functions. In Fig. 33c we can see that for \(p=19\), also SEMN suffers from a bad condition number. In Fig. 34, IGA-RMD is compared to SEMN. Beginning from \(p=10\), the IGA-RMD computations suffer from bad conditioning and divergence for order elevation occurs even for the thickest case in Fig. 34a. Note that for even orders the error of IGA-RMD is always higher than for the next higher uneven order. Even orders seem to be more sensible to bad conditioning, and in some cases the data are out of the depicted frame. In contrast to that, the SEMN computations are stable and converge for rising orders.

Curved beam normalized deformation for \(\frac{R}{t}=10,000\) [8]

4.5 Double curved free form geometry

The last example focuses on the ability of the presented method to deal with complex surfaces and comparing the results of different refinement methods. Therefore, a double curved free from surfaces depicted in Fig. 35 with the thickness of 0.1 is chosen to analyze. The geometry of the surface can be constructed by using the knot span and control points provided in Appendix B. A uniform line load of \(F=10\) per unit length in \(x^2\) direction is applied at the top edge of the surface. Young’s modulus and Poisson’s ratio are \(1.2\times 10^6\) and 0.3, respectively. The converged displacement at point A in direction of \(x^2\) axis utilized to normalize the result is 1.02786 [12]. Because of the complexity of the surface, we increase the maximum order of element in p-refinement from 15 to 20. Again for comparing SEMN and IGA, some results from IGA are also included in the figures. The IGA meshes are designed with a minimum of three elements in each direction, which is dictated by the internal knots provided in Appendix B. In contrast to that, in SEMN one single element is used. Figures 36 and 39 in comparison to Fig. 38 clearly show that if the order of element is chosen high enough, still one element can provide good results which are comparable with the accuracy and efficiency of the h-refinement method. This can also be verified if SEMN and IGA results are compared in Figs. 36b and 37b. Hence, the SEMN formulation can be regarded as an appropriate approach for establishing numerical models when dealing with more complex shells, even without introducing element borders at NURBS internal knot values.

5 Conclusion

A non-isoparametric element based on NURBS shape functions, for defining the exact geometry, and SEM shape functions, for interpolating the unknown displacements and rotations, has been introduced. It has been shown that:

-

The problems which arise for choosing the proper nodal coordinate system in IGA shells and also interpolation of the directors at integration points are automatically removed from numerical analysis.

-

Shear locking can be alleviated significantly by using high order elements. A mesh of elements with order 5 or using only one element with order greater than 8, in most cases, provides accurate results.

-

By comparing the SEMN results of p- and h-refinement, it has been shown that using one very high order element can reduce the cost of analysis while the accuracy of results is the same as for a mesh of lower order elements.

-

The comparison between IGA and SEMN results is more complex. In most cases, the convergence rates for p-refinement are very similar in IGA and SEMN. In h-refinement, when comparing results based on the number of elements, SEMN outperforms IGA. On the other hand, when assessing the results versus the number of degrees of freedom, IGA demonstrates superior accuracy. This difference is due to the different inter-element continuity, which is \(C^0\) in SEMN, and can be up to \(C^{p-1}\) in IGA. Thus, for the same number of elements, IGA yields less dofs, but a more densely populated stiffness matrix. For examples with full internal continuity, i. e. no internal knots in the geometry, IGA can exploit the advantage of k-refinement and requires significant less dofs than SEMN for the same number of elements. However, in practical shell applications, limited internal continuities occur frequently. The free form example in Sect. 4.5 deals with such a case. Despite the limited continuity, in SEMN one element of very high order can be used, while in IGA \(3\times 3\) elements have to be used. Figure 36b shows that in such cases SEMN can outperform IGA also in terms of accuracy per dof.

-

If more than one element is used in h-refinement, SEMN requires less elements, but more dofs than IGA to obtain a similar level of accuracy. Depending on the desired application, either the accuracy per dof or the accuracy per number of elements is of higher importance. The latter is the case for complicated nonlinear material laws that require local iterations, since the number of integration points usually depends linearly on the number of elements. The former is the case for systems with a large number of dofs and low effort on the element level.

-

Since the IGA and SEMN computations are performed in different frameworks, no reliable comparison of efficiency can be provided. Nevertheless, we want to provide some thoughts about efficiency. The effort for the computation of the element stiffness entries in each integration point is in general almost the same between IGA and SEMN if the same rotational concept is applied. However, in [12] it is shown, that in IGA a continuous rotational interpolation has to be used in order to obtain precise results, especially for high order computations. In the proposed SEMN a much simpler discrete rotation interpolation is used, without seeing a negative impact on accuracy. The effect of the usage of these two concepts on the formation of the global stiffness matrix has been studied in Tab. 4 in [13]. The continuous formulation yields about 76 per cent higher computational costs as the discrete formulation for IGA shells of order \(p=3\). For \(p=6\) the difference is still 30 percent. Thus, we can conclude that the SEMN formulation will be significantly faster than an IGA shell on element level due to the simpler rotational formulation.

-

The numerical integration scheme has a significant influence on the computational costs for the formation of the global stiffness matrix. The number of integration points in SEMN is fixed to \((p+1)^2\) per element due to the basic idea of SEM. In IGA, one can use \((p+1)^2\) integration points for full Gauss integration or \((\text {ceil}((p+1)/2))^2\) for reduced Gauss integration, which slightly reduces the accuracy of results. Furthermore, in the literature there are some faster strategies available [34, 35], which have not been applied and tested for NURBS-based Reissner–Mindlin shell elements, or impair the convergence rates [9]. Thus, we used full Gauss integration within the comparison of the paper. The usage of the optimal integration schemes [34, 35] would certainly improve the efficiency of the IGA results in case of computations with large number of elements. But in this paper we focus on computations with high order and very low number of elements, ideally only one element. In this case, only full integration is possible in order to prevent rank deficiencies. Thus, we omitted the inclusion of integration strategies in our comparison between IGA and SEMN.

The accuracy of the results and robustness of the method is examined and proved through different problems with various slenderness and geometries. As the result, further works will extend the presented formulation to the geometrically nonlinear case. In the nonlinear case, special care has to be taken to objectivity since by using a non-isoparametric approach, spurious strains might occur [29, 36]. This delicate topic will be treated in detail in future works.

Change history

16 April 2024

A Correction to this paper has been published: https://doi.org/10.1007/s00466-024-02474-4

References

Hughes TJR, Cottrell JA, Bazilevs Y (2005) Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput Methods Appl Mech Eng 194(39):4135–4195. https://doi.org/10.1016/j.cma.2004.10.008

Nguyen V, Anitescu C, Bordas S, Rabczuk T (2015) Isogeometric analysis: an overview and computer implementation aspects. Math Comput Simul 117:89–116. https://doi.org/10.1016/j.matcom.2015.05.008

Kiendl J, Bletzinger K-U, Linhard J, Wüchner R (2009) Isogeometric shell analysis with Kirchhoff-love elements. Comput Methods Appl Mech Eng 198(49):3902–3914. https://doi.org/10.1016/j.cma.2009.08.013

Benson DJ, Hartmann S, Bazilevs Y, Hsu M-C, Hughes TJR (2013) Blended isogeometric shells. Comput Methods Appl Mech Eng 255:133–146. https://doi.org/10.1016/j.cma.2012.11.020

Benson DJ, Bazilevs Y, Hsu MC, Hughes TJR (2010) Isogeometric shell analysis: the Reissner–Mindlin shell. Comput Methods Appl Mech Eng 199(5):276–289. https://doi.org/10.1016/j.cma.2009.05.011

Oesterle B, Sachse R, Ramm E, Bischoff M (2017) Hierarchic isogeometric large rotation shell elements including linearized transverse shear parametrization. Comput Methods Appl Mech Eng 321:383–405. https://doi.org/10.1016/j.cma.2017.03.031

Kikis G, Dornisch W, Klinkel S (2019) Adjusted approximation spaces for the treatment of transverse shear locking in isogeometric Reissner–Mindlin shell analysis. Comput Methods Appl Mech Eng 354:850–870. https://doi.org/10.1016/j.cma.2019.05.037

Zou Z, Scott MA, Miao D, Bischoff M, Oesterle B, Dornisch W (2020) An isogeometric Reissner–Mindlin shell element based on Bézier dual basis functions: overcoming locking and improved coarse mesh accuracy. Comput Methods Appl Mech Eng 370:113283. https://doi.org/10.1016/j.cma.2020.113283

Zou Z, Hughes TJR, Scott MA, Miao D, Sauer RA (2022) Efficient and robust quadratures for isogeometric analysis: reduced gauss and Gauss–Greville rules. Comput Methods Appl Mech Eng 392:114722. https://doi.org/10.1016/j.cma.2022.114722

Leonetti L, Liguori F, Magisano D, Garcea G (2018) An efficient isogeometric solid-shell formulation for geometrically nonlinear analysis of elastic shells. Comput Methods Appl Mech Eng 331:159–183. https://doi.org/10.1016/j.cma.2017.11.025

Bouclier R, Elguedj T, Combescure A (2013) Efficient isogeometric Nurbs-based solid-shell elements: mixed formulation and \({\bar{B}}\)-method. Comput Methods Appl Mech Eng 267:86–110. https://doi.org/10.1016/j.cma.2013.08.002

Dornisch W, Klinkel S, Simeon B (2013) Isogeometric Reissner–Mindlin shell analysis with exactly calculated director vectors. Comput Methods Appl Mech Eng 253:491–504. https://doi.org/10.1016/j.cma.2012.09.010

Dornisch W, Müller R, Klinkel S (2016) An efficient and robust rotational formulation for isogeometric Reissner–Mindlin shell elements. Comput Methods Appl Mech Eng 303:1–34. https://doi.org/10.1016/j.cma.2016.01.018

Simo JC, Fox DD, Rifai MS (1989) On a stress resultant geometrically exact shell model. Part II: the linear theory; computational aspects. Comput Methods Appl Mech Eng 73(1):53–92. https://doi.org/10.1016/0045-7825(89)90098-4

Lei Z, Gillot F, Jezequel L (2018) An isogeometric Reissner–Mindlin shell element based on mixed grid. Adv Mech Eng 10(4):1–12. https://doi.org/10.1177/1687814018766997

Patera AT (1984) A spectral element method for fluid dynamics: laminar flow in a channel expansion. J Comput Phys 54(3):468–488. https://doi.org/10.1016/0021-9991(84)90128-1

Pozrikidis C (2005) Finite and spectral element methods using Matlab. CRC Press, Boca Raton

Seriani G, Oliveira SP (2008) Dispersion analysis of spectral element methods for elastic wave propagation. Wave Motion 45(6):729–744. https://doi.org/10.1016/j.wavemoti.2007.11.007

Rucka M (2010) Experimental and numerical studies of guided wave damage detection in bars with structural discontinuities. Arch Appl Mech 80(12):1371–1390. https://doi.org/10.1007/s00419-009-0389-8

Azizi N, Saadatpour MM, Mahzoon M (2019) Analyzing first symmetric and antisymmetric lamb wave modes in functionally graded thick plates by using spectral plate elements. Int J Mech Sci 150:484–494. https://doi.org/10.1016/j.ijmecsci.2018.10.030

Payette GS, Reddy JN (2014) A seven-parameter spectral/HP finite element formulation for isotropic, laminated composite and functionally graded shell structures. Comput Methods Appl Mech Eng 278:664–704. https://doi.org/10.1016/j.cma.2014.06.021

Zak A, Krawczuk M (2018) A higher order transversely deformable shell-type spectral finite element for dynamic analysis of isotropic structures. Finite Elem Anal Des 142:17–29. https://doi.org/10.1016/j.finel.2017.12.007

Zak A (2009) A novel formulation of a spectral plate element for wave propagation in isotropic structures. Finite Elem Anal Des 45(10):650–658. https://doi.org/10.1016/j.finel.2009.05.002

Cottrell JA, Hughes TJ, Bazilevs Y (2009) Isogeometric analysis: toward integration of CAD and FEA. Wiley, Hoboken

Piegl L, Tiller W (1996) The NURBS Book. Springer, Berlin

Azizi N (2013) Using spectral element method for analyzing structures subjected to impact and moving loads, (Ph.D. Thesis). Isfahan University of Technology, Iran

Bingol OR, Krishnamurthy A (2019) Nurbs-python: an open-source object-oriented Nurbs modeling framework in python. SoftwareX 9:85–94. https://doi.org/10.1016/j.softx.2018.12.005

Bathe K-J (2006) Finite element procedures, New Jersey

Belytschko T, Stolarski H, Liu WK, Carpenter N, Ong JSJ (1985) Stress projection for membrane and shear locking in shell finite elements. Comput Methods Appl Mech Eng 51(1):221–258. https://doi.org/10.1016/0045-7825(85)90035-0

Harris CR, Millman KJ, van der Walt SJ, Gommers R, Virtanen P, Cournapeau D, Wieser E, Taylor J, Berg S, Smith NJ, Kern R, Picus M, Hoyer S, van Kerkwijk MH, Brett M, Haldane A, del Río JF, Wiebe M, Peterson P, Gérard-Marchant P, Sheppard K, Reddy T, Weckesser W, Abbasi H, Gohlke C, Oliphant TE (2020) Array programming with NumPy. Nature 585(7825):357–362. https://doi.org/10.1038/s41586-020-2649-2

Macneal RH, Harder RL (1985) A proposed standard set of problems to test finite element accuracy. Finite Elem Anal Des 1(1):3–20. https://doi.org/10.1016/0168-874X(85)90003-4

Bieber S, Oesterle B, Ramm E, Bischoff M (2018) A variational method to avoid locking-independent of the discretization scheme. Int J Numer Methods Eng 114(8):801–827. https://doi.org/10.1002/nme.5766

Golestanian M, Casquero H Extending CAS elements to remove shear and membrane locking from quadratic Nurbs-based discretizations of linear plane timoshenko rods. Int J Numer Methods Eng. https://doi.org/10.1002/nme.7257

Johannessen KA (2017) Optimal quadrature for univariate and tensor product splines. Comput Methods Appl Mech Eng 316:84–99. https://doi.org/10.1016/j.cma.2016.04.030

Hiemstra RR, Calabrò F, Schillinger D, Hughes TJR (2017) Optimal and reduced quadrature rules for tensor product and hierarchically refined splines in isogeometric analysis. Comput Methods Appl Mech Eng 316:966–1004. https://doi.org/10.1016/j.cma.2016.10.049

Argyris JH, Scharpf DW (1968) The Sheba family of shell elements for the matrix displacement method. Aeronaut J 72(694):873–883. https://doi.org/10.1017/S0001924000085250

Acknowledgements

The authors would like to express their sincere gratitude to Z. Zou for providing some data of Fig. 32.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declarations

This work is part of a project funded by the Deutsche Forschungsgemeinschaft (DFG) under project number 503246947.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original article has been revised due to error in equation.

The online version of the original article can be found under https://doi.org/10.1007/s00466-024-02444-w .

Appendices

Appendix A. Elastic matrix in global Cartesian coordinate

A material coordinate system can be constructed by cross product of the director and covariant tangent vector as below

Then in Eq. (31) the elastic matrix is

where E are \(\nu \) are Young’s modulus and Poisson’ ratio. k is the shear correction factor and is taken equal to \(\frac{5}{6}\). \(\varvec{\textrm{Q}}\) is the transformation matrix which is [28]

where

Appendix B. Geometry of double curved free form surface

Four boundary B-Spline curves define uniquely the double curved free form surface. The control points for these boundary curves are provided in table 1. Since all control points have a weight value of 1, they collectively create a B-Spline surface. The knot vector for all curves is

and the order of B-Spline basis functions is \(p=3\) [12].

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Azizi, N., Dornisch, W. A spectral finite element Reissner–Mindlin shell formulation with NURBS-based geometry definition. Comput Mech 74, 537–559 (2024). https://doi.org/10.1007/s00466-024-02444-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-024-02444-w