Abstract

This work presents a novel methodology for speeding up the assembly of stiffness matrices for laminate composite 3D structures in the context of isogeometric and finite element discretizations. By splitting the involved terms into their in-plane and out-of-plane contributions, this method computes the problems’s 3D stiffness matrix as a combination of 2D (in-plane) and 1D (out-of-plane) integrals. Therefore, the assembly’s computational complexity is reduced to the one of a 2D problem. Additionally, the number of 2D integrals to be computed becomes independent of the number of material layers that constitute the laminated composite, it only depends on the number of different materials used (or different orientations of the same anisotropic material). Hence, when a high number of layers is present, the proposed technique reduces by orders of magnitude the computational time required to create the stiffness matrix with standard methods, being the resulting matrices identical up to machine precision. The predicted performance is illustrated through numerical experiments.

Similar content being viewed by others

References

Ainsworth M, Andriamaro G, Davydov O (2011) Bernstein-Bézier finite elements of arbitrary order and optimal assembly procedures. SIAM J Sci Comput 33(6):3087–3109. https://doi.org/10.1137/11082539X

Antolin P, Buffa A, Calabrò F, Martinelli M, Sangalli G (2015) Efficient matrix computation for tensor-product isogeometric analysis: the use of sum factorization. Comput Methods Appl Mech Eng 285:817–828. https://doi.org/10.1016/j.cma.2014.12.013. http://www.sciencedirect.com/science/article/pii/S0045782514004927

Auricchio F, Calabrò F, Hughes TJR, Reali A, Sangalli G (2012) A simple algorithm for obtaining nearly optimal quadrature rules for NURBS-based isogeometric analysis. Comput Methods Appl Mech Eng 249–252:15–27. https://doi.org/10.1016/j.cma.2012.04.014. http://www.sciencedirect.com/science/article/pii/S004578251200134X

Bartoň M, Calo VM (2016) Optimal quadrature rules for odd-degree spline spaces and their application to tensor-product-based isogeometric analysis. Comput Methods Appl Mech Eng 305:217–240. https://doi.org/10.1016/j.cma.2016.02.034. http://www.sciencedirect.com/science/article/pii/S0045782516300640

Bartoň M, Calo VM (2017) Gauss–Galerkin quadrature rules for quadratic and cubic spline spaces and their application to isogeometric analysis. Comput Aided Des 82:57–67. https://doi.org/10.1016/j.cad.2016.07.003. http://www.sciencedirect.com/science/article/pii/S0010448516300665

Bazilevs Y, Calo V, Cottrell J, Hughes T, Reali A, Scovazzi G (2007) Variational multiscale residual-based turbulence modeling for large eddy simulation of incompressible flows. Comput Methods Appl Mech Eng 197(1–4):173–201. https://doi.org/10.1016/j.cma.2007.07.016. https://linkinghub.elsevier.com/retrieve/pii/S0045782507003027

Bazilevs Y, Calo VM, Cottrell JA, Evans JA, Hughes TJR, Lipton S, Scott MA, Sederberg TW (2010) Isogeometric analysis using T-splines. Comput Methods Appl Mech Eng 199(5):229–263. https://doi.org/10.1016/j.cma.2009.02.036. http://www.sciencedirect.com/science/article/pii/S0045782509000875

Bazilevs Y, Hsu MC, Kiendl J, Wüchner R, Bletzinger KU (2010) 3D simulation of wind turbine rotors at full scale. Part II: fluid-structure interaction modeling with composite blades. Int J Numer Methods Fluids 65(1–3):236–253. https://doi.org/10.1002/fld.2454

Beirão Da Veiga L, Buffa A, Sangalli G, Vázquez R (2013) Analysis-suitable T-splines of arbitrary degree: definition, linear independence and approximation properties. Math Models Methods Appl Sci 23(11):1979–2003. https://doi.org/10.1142/S0218202513500231

Brenner S, Scott R (2008) The mathematical theory of finite element methods, 3rd edn. Texts in Applied Mathematics. Springer, New York. https://www.springer.com/us/book/9780387759333

Bressan A (2013) Some properties of LR-splines. Comput Aided Geom Des 30(8):778–794. https://doi.org/10.1016/j.cagd.2013.06.004. http://www.sciencedirect.com/science/article/pii/S0167839613000575

Buffa A, Sangalli G, Vázquez R (2010) Isogeometric analysis in electromagnetics: B-splines approximation. Comput Methods Appl Mech Eng 199(17):1143–1152. https://doi.org/10.1016/j.cma.2009.12.002. http://www.sciencedirect.com/science/article/pii/S0045782509004010

Calabrò F, Sangalli G, Tani M (2017) Fast formation of isogeometric Galerkin matrices by weighted quadrature. Comput Methods Appl Mech Eng 316:606–622. https://doi.org/10.1016/j.cma.2016.09.013. http://www.sciencedirect.com/science/article/pii/S0045782516311495

Carrera E (1999) Multilayered shell theories accounting for layerwise mixed description, Part 1: governing equations. AIAA J 37(9):1107–1116. https://doi.org/10.2514/2.821

Carrera E (2002) Theories and finite elements for multilayered, anisotropic, composite plates and shells. ARCO 9(2):87–140. https://doi.org/10.1007/BF02736649

Carrera E (2003) Theories and finite elements for multilayered plates and shells: a unified compact formulation with numerical assessment and benchmarking. ARCO 10(3):215–296. https://doi.org/10.1007/BF02736224

Carrera E, Brischetto S (2008) A survey with numerical assessment of classical and refined theories for the analysis of sandwich plates. Appl Mech Rev 62(1): 010803–010803–17. https://doi.org/10.1115/1.3013824

Ciarlet P (2002) The finite element method for elliptic problems. 2 edn. No. 40 in Classics in Applied Mathematics. Society for Industrial and Applied Mathematics. https://doi.org/10.1137/1.9780898719208

Collier N, Dalcin L, Pardo D, Calo V (2013) The cost of continuity: performance of iterative solvers on isogeometric finite elements. SIAM J Sci Comput 35(2):A767–A784. https://doi.org/10.1137/120881038

Collier N, Pardo D, Dalcin L, Paszynski M, Calo VM (2012) The cost of continuity: a study of the performance of isogeometric finite elements using direct solvers. Comput Methods Appl Mech Eng 213–216:353–361. https://doi.org/10.1016/j.cma.2011.11.002. http://www.sciencedirect.com/science/article/pii/S0045782511003392

Cottrell JA, Hughes TJR, Bazilevs Y (2009) Isogeometric analysis: toward integration of CAD and FEA, 1st edn. Wiley, Chichester

Cottrell JA, Reali A, Bazilevs Y, Hughes TJR (2006) Isogeometric analysis of structural vibrations. Comput Methods Appl Mech Eng 195(41):5257–5296. https://doi.org/10.1016/j.cma.2005.09.027. http://www.sciencedirect.com/science/article/pii/S0045782505005451

De Lorenzis L, Wriggers P, Hughes TJR (2014) Isogeometric contact: a review. GAMM-Mitteilungen 37(1):85–123. https://doi.org/10.1002/gamm.201410005

Dokken T, Lyche T, Pettersen KF (2013) Polynomial splines over locally refined box-partitions. Comput Aided Geom Des 30(3):331–356. https://doi.org/10.1016/j.cagd.2012.12.005. http://www.sciencedirect.com/science/article/pii/S0167839613000113

Dufour JE, Antolin P, Sangalli G, Auricchio F, Reali A (2018) A cost-effective isogeometric approach for composite plates based on a stress recovery procedure. Compos B Eng 138:12–18. https://doi.org/10.1016/j.compositesb.2017.11.026. http://www.sciencedirect.com/science/article/pii/S1359836817320383

Elguedj T, Bazilevs Y, Calo VM, Hughes TJR (2008) \({\bar{B}}\) and \({\bar{F}}\) projection methods for nearly incompressible linear and non-linear elasticity and plasticity using higher-order NURBS elements. Comput Methods Appl Mech Eng 197(33):2732–2762. https://doi.org/10.1016/j.cma.2008.01.012. http://www.sciencedirect.com/science/article/pii/S0045782508000248

Evans JA, Bazilevs Y, Babuška I, Hughes TJR (2009) n-Widths, sup-infs, and optimality ratios for the k-version of the isogeometric finite element method. Comput Methods Appl Mech Eng 198(21):1726–1741. https://doi.org/10.1016/j.cma.2009.01.021. http://www.sciencedirect.com/science/article/pii/S0045782509000280

Farzam A, Hassani B (2018) A new efficient shear deformation theory for FG plates with in-plane and through-thickness stiffness variations using isogeometric approach. Mech Adv Mater Struct 14–14. https://doi.org/10.1080/15376494.2017.1400623

Ferreira AJM (2005) Analysis of composite plates using a layerwise theory and multiquadrics discretization. Mech Adv Mater Struct 12(2):99–112. https://doi.org/10.1080/15376490490493952

Ghafari E, Rezaeepazhand J (2019) Isogeometric analysis of shear refined delaminated composite beams using dimensionally reduced beam sectional analysis. Compos Struct 210:858–868. https://doi.org/10.1016/j.compstruct.2018.12.001. http://www.sciencedirect.com/science/article/pii/S026382231832720X

Giannelli C, Jüttler B, Speleers H (2012) THB-splines: the truncated basis for hierarchical splines. Comput Aided Geom Des 29(7):485–498. https://doi.org/10.1016/j.cagd.2012.03.025. http://www.sciencedirect.com/science/article/pii/S0167839612000519

Gibson RF (2016) Principles of composite material mechanics, 4th edn. CRC Press, Boca Raton

Guo Y, Nagy AP, Gürdal Z (2014) A layerwise theory for laminated composites in the framework of isogeometric analysis. Compos Struct 107:447–457. https://doi.org/10.1016/j.compstruct.2013.08.016. http://www.sciencedirect.com/science/article/pii/S0263822313004133

Guo Y, Ruess M (2015) A layerwise isogeometric approach for NURBS-derived laminate composite shells. Compos Struct 124:300–309. https://doi.org/10.1016/j.compstruct.2015.01.012. http://www.sciencedirect.com/science/article/pii/S0263822315000240

Gómez H, Calo VM, Bazilevs Y, Hughes TJR (2008) Isogeometric analysis of the Cahn-Hilliard phase-field model. Comput Methods Appl Mech Eng 197(49):4333–4352. https://doi.org/10.1016/j.cma.2008.05.003. http://www.sciencedirect.com/science/article/pii/S0045782508001953

Hiemstra RR, Sangalli G, Tani M, Calabrò F, Hughes TJR (2019) Fast formation and assembly of finite element matrices with application to isogeometric linear elasticity. ICES report 19–03

Hsu MC, Kamensky D, Xu F, Kiendl J, Wang C, Wu MCH, Mineroff J, Reali A, Bazilevs Y, Sacks MS (2015) Dynamic and fluid-structure interaction simulations of bioprosthetic heart valves using parametric design with T-splines and Fung-type material models. Comput Mech 55(6):1211–1225. https://doi.org/10.1007/s00466-015-1166-x

Hughes TJR (1987) The finite element method. Linear static and dynamic finite element analysis. Prentice-Hall Inc, Englewood Cliffs, NJ

Hughes TJR, Cottrell JA, Bazilevs Y (2005) Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput Methods Appl Mech Eng 194(39):4135–4195. https://doi.org/10.1016/j.cma.2004.10.008. http://www.sciencedirect.com/science/article/pii/S0045782504005171

Hughes TJR, Reali A, Sangalli G (2010) Efficient quadrature for NURBS-based isogeometric analysis. Comput Methods Appl Mech Eng 199(5):301–313. https://doi.org/10.1016/j.cma.2008.12.004. http://www.sciencedirect.com/science/article/pii/S0045782508004295

Jones RM (2018) Mechanics of composite materials, 2nd edn. CRC Press, Boca Raton

Kapoor H, Kapania RK, Soni SR (2013) Interlaminar stress calculation in composite and sandwich plates in NURBS Isogeometric finite element analysis. Compos Struct 106:537–548. https://doi.org/10.1016/j.compstruct.2013.05.028. http://www.sciencedirect.com/science/article/pii/S0263822313002389

Kiendl J, Bletzinger KU, Linhard J, Wüchner R (2009) Isogeometric shell analysis with Kirchhoff-Love elements. Comput Methods Appl Mech Eng 198(49):3902–3914. https://doi.org/10.1016/j.cma.2009.08.013. http://www.sciencedirect.com/science/article/pii/S0045782509002680

Kreja I (2011) A literature review on computational models for laminated composite and sandwich panels. Cent Eur J Eng 1(1):59–80. https://doi.org/10.2478/s13531-011-0005-x

Kulkarni P, Dhoble A, Padole P (2018) A review of research and recent trends in analysis of composite plates. Sādhanā 43(6):96. https://doi.org/10.1007/s12046-018-0867-1

Liew KM, Pan ZZ, Zhang LW (2019) An overview of layerwise theories for composite laminates and structures: development, numerical implementation and application. Compos Struct 216:240–259. https://doi.org/10.1016/j.compstruct.2019.02.074. http://www.sciencedirect.com/science/article/pii/S0263822319300820

Mantzaflaris A, Jüttler B, Khoromskij BN, Langer U (2017) Low rank tensor methods in Galerkin-based isogeometric analysis. Comput Methods Appl Mech Eng 316:1062–1085. https://doi.org/10.1016/j.cma.2016.11.013. http://www.sciencedirect.com/science/article/pii/S0045782516315377

Melenk JM, Gerdes K, Schwab C (2001) Fully discrete hp-finite elements: fast quadrature. Comput Methods Appl Mech Eng 190(32):4339–4364. https://doi.org/10.1016/S0045-7825(00)00322-4. http://www.sciencedirect.com/science/article/pii/S0045782500003224

Nguyen-Xuan H, Thai CH, Nguyen-Thoi T (2013) Isogeometric finite element analysis of composite sandwich plates using a higher order shear deformation theory. Compos B Eng 55:558–574. https://doi.org/10.1016/j.compositesb.2013.06.044. http://www.sciencedirect.com/science/article/pii/S1359836813003557

Pagano N (1970) Exact solutions for rectangular bidirectional composites and sandwich plates. J Compos Mater 4(1):20–34. https://doi.org/10.1177/002199837000400102

Patton A, Dufour JE, Antolin P, Reali A (2019) Fast and accurate elastic analysis of laminated composite plates via isogeometric collocation and an equilibrium-based stress recovery approach. Compos Struct 225:111026. https://doi.org/10.1016/j.compstruct.2019.111026. http://www.sciencedirect.com/science/article/pii/S0263822319301345

Pavan GS, Nanjunda Rao KS (2017) Bending analysis of laminated composite plates using isogeometric collocation method. Compos Struct 176:715–728. https://doi.org/10.1016/j.compstruct.2017.04.073. http://www.sciencedirect.com/science/article/pii/S0263822317308334

Planas J, Romero I, Sancho JM (2012) B free. Comput Methods Appl Mech Eng 217–220:226–235. https://doi.org/10.1016/j.cma.2012.01.019. http://www.sciencedirect.com/science/article/pii/S0045782512000308

Reddy JN (2004) Mechanics of laminated composite plates and shells: theory and analysis, 2nd edn. CRC Press, Boca Raton

Reddy JN, Miravete A (1995) Practical analysis of composite laminates, 1st edn. CRC Press, Boca Raton

Reddy JN, Robbins DH (1994) Theories and computational models for composite laminates. Appl Mech Rev 47(6):147–169. https://doi.org/10.1115/1.3111076. https://appliedmechanicsreviews.asmedigitalcollection.asme.org/article.aspx?articleid=1395123

Remmers JJC, Verhoosel CV, de Borst R (2015) Isogeometric analysis for modelling of failure in advanced composite materials. In: Camanho PP, Hallett SR (eds) Numerical modelling of failure in advanced composite materials, Woodhead Publishing Series in Composites Science and Engineering, pp 309–329. Woodhead Publishing, Chapter 11. https://doi.org/10.1016/B978-0-08-100332-9.00011-6. http://www.sciencedirect.com/science/article/pii/B9780081003329000116

Qatu MS, Asadi E, Wang W (2012) Review of recent literature on static analyses of composite shells: 2000-2010. Open J Compos Mater 2:61. https://doi.org/10.4236/ojcm.2012.23009

Schillinger D, Hossain SJ, Hughes TJR (2014) Reduced Bézier element quadrature rules for quadratic and cubic splines in isogeometric analysis. Comput Methods Appl Mech Eng 277:1–45. https://doi.org/10.1016/j.cma.2014.04.008. http://www.sciencedirect.com/science/article/pii/S0045782514001339

Schröder J, Gruttmann F, Löblein J (2002) A simple orthotropic finite elasto-plasticity model based on generalized stress-strain measures. Comput Mech 30(1):48–64. https://doi.org/10.1007/s00466-002-0366-3

Sun C, Li S (1988) Three-dimensional effective elastic constants for thick laminates. J Compos Mater 22(7):629–639. https://doi.org/10.1177/002199838802200703

Thai CH, Nguyen-Xuan H, Bordas SPA, Nguyen-Thanh N, Rabczuk T (2015) Isogeometric analysis of laminated composite plates using the higher-order shear deformation theory. Mech Adv Mater Struct 22(6):451–469. https://doi.org/10.1080/15376494.2013.779050

Varadan TK, Bhaskar K (1991) Bending of laminated orthotropic cylindrical shells-an elasticity approach. Compos Struct 17(2):141–156. https://doi.org/10.1016/0263-8223(91)90067-9. http://www.sciencedirect.com/science/article/pii/0263822391900679

Beirãda Veiga L, Buffa A, Rivas J, Sangalli G (2011) Some estimates for h-p-k-refinement in isogeometric analysis. Numer Math 118(2):271–305. https://doi.org/10.1007/s00211-010-0338-z

Vinson JR, Sierakowski RL (2004) The behavior of structures composed of composite materials. Solid mechanics and its applications. 2nd edn. Kluwer Academic Publishers, Dordrecht (2004). https://www.springer.com/la/book/9781402009044

Vuong AV, Giannelli C, Jüttler B, Simeon B (2011) A hierarchical approach to adaptive local refinement in isogeometric analysis. Comput Methods Appl Mech Eng 200(49):3554–3567. https://doi.org/10.1016/j.cma.2011.09.004. http://www.sciencedirect.com/science/article/pii/S0045782511002933

Vázquez R (2016) A new design for the implementation of isogeometric analysis in Octave and Matlab: GeoPDEs 3.0. Comput Math Appl 72(3): 523–554 (2016). https://doi.org/10.1016/j.camwa.2016.05.010. http://www.sciencedirect.com/science/article/pii/S0898122116302681

Zhang YX, Yang CH (2009) Recent developments in finite element analysis for laminated composite plates. Compos Struct 88(1):147–157. https://doi.org/10.1016/j.compstruct.2008.02.014. http://www.sciencedirect.com/science/article/pii/S0263822308000512

Zienkiewicz OC, Taylor RL, Zhu JZ (2013) The finite element method: its basis and fundamentals, 7th edn. Butterworth-Heinemann, Amsterdam

Acknowledgements

The author gratefully acknowledges the support of the European Research Council, through the ERC AdG No. 694515–CHANGE grant, and also thanks Annalisa Buffa and Alessadro Reali for their helpful insights and suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: A fast assembly of stiffness matrices for laminated composites without using Voigt’s notation

Appendix: A fast assembly of stiffness matrices for laminated composites without using Voigt’s notation

Planas et al. introduced in [53] an alternative methodology for the assembly of stiffness matrices in the context of solid mechanics, denoted as “\(\varvec{\mathsf {B}}\) free”, that overcomes the use of Voigt’s notation. Based on that approach, we detail in this Appendix the construction of the operators \(\varvec{\mathsf {P}}^{{ij_s}}_{l,\alpha \beta }\) defined in (27) avoiding the use of Voigt’s notation, i.e, without building the material matrix \(\varvec{\mathsf {D}}\) (11) and the strain-displacement operators \({\hat{\varvec{\mathsf {B}}}}^i\) (24).

Using the bracket operator \(\bullet \left\{ \bullet ,\bullet \right\} :\mathbb { R}^{3\times 3\times 3\times 3}\times \mathbb {R}^3\times \mathbb {R}^3\rightarrow \mathbb {R}^{3\times 3}\) defined in [53], the stiffness matrix (9) can be computed as

where the contraction \(\mathbb {C}(\varvec{x})\left\{ \nabla B^i(\varvec{x}), \nabla B^j(\varvec{x})\right\} \in \mathbb {R}^{3\times 3}\) is such that the vector \(\nabla B^i\) is contracted with the second component of \(\mathbb {C}\), and \(\nabla B^j\) with the fourth one, i.e.:

Thus, being \(\{\varvec{e}_1,\varvec{e}_2,\varvec{e}_3\}\) the Cartesian orthonormal basis, the contraction \(\mathbb {C}\left\{ \varvec{e}_i,\varvec{e}_j\right\} \in \mathbb {R}^{3\times 3}\) for small strain linear isotropic materials can be computed as [53]:

where \(\lambda \) and \(\mu \) are the Lamé coefficients and \(\varvec{I}\in \mathbb {R}^{3\times 3}\) is the identity tensor. For orthotropic materials the contraction reads:

with \(\bar{\varvec{a}}_{\beta ,i} = \left( \varvec{a}_\beta \cdot \varvec{e}_i\right) \,\varvec{a}_\beta \), where \(\varvec{a}_1\) and \(\varvec{a}_2\) are the main orthonormal in-plane material directions, and \(\lambda \), \(\mu \), \(\alpha _k\), with \(k=1,\dots ,7\), are the nine material coefficients (see e.g., [60, Section 3.3] for further details).

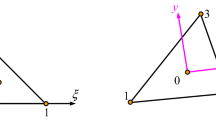

Let us now write the map gradient \({\hat{D}} \varvec{F}\) as a function of the covariant basis \(\{\varvec{g}_1,\varvec{g}_2,\varvec{g}_3\}\):

where the Assumption 2 was considered. In the same way, its inverse \({\hat{D}} \varvec{F}^{-\top }\) can be expressed as

where \(\{\varvec{g}^1,\varvec{g}^2,\varvec{g}^3\}\) is the contravariant basis, such that \(\varvec{g}^i\cdot \varvec{g}_i=1\) and \(\varvec{g}^i\cdot \varvec{g}_j=0\) if \(i\ne j\), for \(i,j=\lbrace 1,2,3\rbrace \).

Pulling-back the computation of \(\varvec{K}^{ij}\) to the parametric domain, as in (13), we obtain:

that can be rewritten as

where \({\tilde{\mathbb {C}}}\) is the pull-back of \({\hat{\mathbb {C}}}\) with \({\hat{D}}\varvec{F}^{-\top }\) for the second and fourth components.

On the other hand, \({\hat{\nabla }}{\hat{B}}^i\) can be split according to its Cartesian components as (see Assumption 1):

and the contraction \({\tilde{\mathbb {C}}}(\varvec{\varvec{\xi }})\left\{ {\hat{\nabla }} {\hat{B}}^i(\varvec{\xi }), {\hat{\nabla }} {\hat{B}}^j(\varvec{\xi })\right\} \in \mathbb {R}^{3\times 3}\) reads:

where \(\tilde{\varvec{C}}_{\alpha \beta }\in \mathbb {R}^{3\times 3}\) is

Finally, substituting (39) into (37), and including the Assumptions 2 and 3, the stiffness matrix terms can be rearranged in the same way as we did for (26), and the \(\varvec{\mathsf {P}}^{{ij_s}}_{l,\alpha \beta }\) matrices (27) become

The terms \(\tilde{\varvec{C}}_{\alpha \beta ,l}\) are computed following (40) and particularizing \({\hat{\mathbb {C}}}\) for every material layer l, with \(l=1,\dots ,m\). Therefore, the matrices \(\varvec{\mathsf {P}}^{{ij_s}}_{l,\alpha \beta }\) can be computed, avoiding the use of Voigt’s notation, by means of in-plane terms only.

Rights and permissions

About this article

Cite this article

Antolin, P. Fast assembly of Galerkin matrices for 3D solid laminated composites using finite element and isogeometric discretizations. Comput Mech 65, 135–148 (2020). https://doi.org/10.1007/s00466-019-01756-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-019-01756-6