Abstract

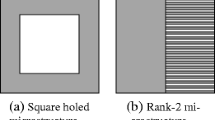

We present a computational method for the optimization of nanostructures, where our specific interest is in capturing and elucidating surface stress and surface elastic effects on the optimal nanodesign. XFEM is used to solve the nanomechanical boundary value problem, which involves a discontinuity in the strain field and the presence of surface effects along the interface. The boundary of the nano-structure is implicitly represented by a level set function, which is considered as the design variable in the optimization process. Two objective functions, minimizing the total potential energy of a nanostructure subjected to a material volume constraint and minimizing the least square error compared to a target displacement, are chosen for the numerical examples. We present results of optimal topologies of a nanobeam subject to cantilever and fixed boundary conditions. The numerical examples demonstrate the importance of size and aspect ratio in determining how surface effects impact the optimized topology of nanobeams.

Similar content being viewed by others

Notes

This is the same as taking the material derivative of \(\big \{\varvec{\Phi }(\mathbf{x}(t),t)=0\big \}\).

References

Xia Y, Yang P, Sun Y, Wu Y, Mayers B, Gates B, Yin Y, Kim F, Yan H (2003) One-dimensional nanostructures:synthesis, characterization, and applications. Adv Mater 15(5):353–389

Lieber CM, Wang ZL (2007) Functional nanowires. MRS Bull 32:99–108

Haiss W (2001) Surface stress of clean and adsorbate-covered solids. Rep Prog Phys 64:591–648

Cammarata RC (1994) Surface and interface stress effects in thin films. Prog Surf Sci 46(1):1–38

Zhou LG, Huang H (2004) Are surfaces elastically softer or stiffer? Appl Phys Lett 84(11):1940–1942

Park HS, Cai W, Espinosa HD, Huang H (2009) Mechanics of crystalline nanowires. MRS Bull 34(3):178–183

Park HS, Gall K, Zimmerman JA (2006) Deformation of FCC nanowires by twinning and slip. J Mech Phys Solids 54(9):1862–1881

Park HS, Gall K, Zimmerman JA (2005) Shape memory and pseudoelasticity in metal nanowires. Phys Rev Lett 95:255504

Liang W, Zhou M, Ke F (2005) Shape memory effect in Cu nanowires. Nano Lett 5(10):2039–2043

Weinberger CR, Cai W (2012) Plasticity of metal nano wires. J Mater Chem 22(8):3277–3292

Yvonnet J, Quang HL, He QC (2008) An XFEM/level set approach to modelling surface/interface effects and to computing the size-dependent effective properties of nanocomposites. Comput Mech 42:119–131

Yvonnet J, Mitrushchenkov A, Chambaud G, He GC (2011) Finite element model of ionic nanowires with sizedependent mechanical properties determined by ab initio calculations. Comput Methods Appl Mech Eng 200:614–625

Gao W, Yu SW, Huang GY (2006) Finite element characterization of the size-dependent mechanical behaviour in nanosystems. Nanotechnology 17(4):1118–1122

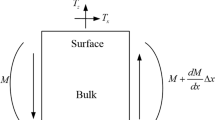

Farsad M, Vernerey FJ, Park HS (2010) An extended finite element/level set method to study surface effects on the mechanical behavior and properties of nanomaterials. Int J Numer Methods Eng 84:1466–1489

Gurtin ME, Murdoch A (1975) A continuum theory of elastic material surfaces. Arch Ration Mech Anal 57:291–323

Javili A, Steinmann P (2009) A finite element framework for continua with boundary energies. part I: the two dimensional case. Comput Methods Appl Mech Eng 198:2198–2208

Javili A, Steinmann P (2010) A finite element framework for continua with boundary energies. part II: the three dimensional case. Comput Methods Appl Mech Eng 199:755–765

Park HS, Klein PA, Wagner GJ (2006) A surface cauchy-born model for nanoscale materials. Int J Numer Methods Eng 68:1072–1095

Park HS, Klein PA (2007) Surface cauchy-born analysis of surface stress effects on metallic nanowires. Phys Rev B 75:085408

Park HS, Klein PA (2008) A surface cauchy-born model for silicon nanostructures. Comput Methods Appl Mech Eng 197:3249–3260

Javili A, McBride A, Steinmann P (2012) Thermomechanics of solids with lower-dimensional energetics: on the importance of surface, interface, and curve structures at the nanoscale a unifying review. Appl Mech Rev 65:010802

Park HS, Klein PA (2008) Surface stress effects on the resonant properties of metal nanowires: the importance of finite deformation kinematics and the impact of the residual surface stress. J Mech Phys Solids 56:3144–3166

Natarajan S, Chakraborty S, Thangavel M, Bordas S, Rabczuk T (2012) Size-dependent free flexural vibration behavior of functionally graded nanoplates. Comput Mater Sci 65:74–80

Yun G, Park HS (2009) Surface stress effects on the bending properties of fcc metal nanowires. Phys Rev B 79:195421

He J, Lilley CM (2008) Surface effect on the elastic behavior of static bending nanowires. Nano Lett 8(7):1798–1802

Bendsoe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71:197–224

Allaire G, Jouve F, Toader AM (2004) Structural optimization using sensitivity analysis and a level-set method. J Comput Phys 194:363–393

Luo Z, Wang MY, Wang S, Wei P (2008) A level set-based parameterization method for structural shape and topology optimization. Int J Nume Methods Eng 76(1):1–26

Melenk JM, Babuska I (1996) The partition of unity finite element method: basic theory and applications. Comput Methods Appl Mech Eng 139(1–4):289–314

Osher SJ, Sethian JA (1988) Fronts propagating with curvature dependent speed: algorithms based on the Hamilton-Jacobi formulations. J Comput Phys 79:12–49

Sethian JA, Wiegmann A (2000) Structural boundary design via level set and immersed interface methods. J Comput Phys 163:489–528

Osher S, Santosa F (2001) Level-set methods for optimization problem involving geometry and constraints: I frequencies of a two-density inhomogeneous drum. J Comput Phys 171:272–288

Wang MY, Wang XM, Guo DM (2003) A level set method for structural topology optimization. Comput Methods Appl Mech Eng 192:217–224

Nanthakumar SS, Lahmer T, Rabczuk T (2014) Detection of multiple flaws in piezoelectric structures using XFEM and level sets. Comput Methods Appl Mech Eng 275:98–112

Choi KK, Kim NH (2005) Structural sensitivity analysis and optimization. Springer, New York

van Dijk NP, Maute K, Langelaar M, Keulen FV (2013) Level-set methods for structural topology optimization: a review. Struct Multidiscip Optim 48:437–472

Malladi R, Sethian JA, Vemuri BC (1995) Shape modeling with front propagation: a level set approach. IEEE Trans Pattern Anal Mach Intell 17:158–175

Stolarska M, Chopp DL, Moes N, Belytschko T (2001) Modeling crack growth by level sets in the extended finite element method. Int J Numer Methods Eng 51:943–960

Sukumar N, Chopp DL, Moes N, Belytschko T (2001) Modeling holes and inclusions by level sets in the extended finite-element method. Comput Methods Appl Mech Eng 190:6183–6200

Moes N, Cloirec M, Cartraud P, Remacle JF (2003) A computational approach to handle complex microstructure geometries. Comput Methods Appl Mech Eng 192:3163–3177

Craighead HG (2000) Nanoelectromechanical systems. Science 290:1532–1535

Ekinci KL, Roukes ML (2005) Nanoelectromechanical systems. Rev Sci Instrum 76:061101

Huang XMH, Zorman CA, Mehregany M, Roukes ML (2003) Nanodevice motion at microwave frequencies. Nature 42:496

Mi C, Jun S, Kouris DA, Kim SY (2008) Atomistic calculations of interface elastic properties in noncoherent metallic bilayers. Phys Rev B 77:075425

Ji C, Park HS (2006) Geometric effects on the inelastic deformation of metal nanowires. Appl Phys Lett 89:181916

Sigmund O (2001) A 99 line topology optimization code written in matlab. Struct Multidiscip Optim 21:120–127

Allaire G, Jouve F, Toader AM (2004) Structural optimization using sensitivity analysis and a level-set method. J Comput Phys 194:363–393

Acknowledgments

Timon Rabczuk and Navid Valizadeh gratefully acknowledge the financial support of the Framework Programme 7 Initial Training Network Funding under grant number 289361 “Integrating Numerical Simulation and Geometric Design Technology”. Harold Park acknowledges the support of the Mechanical Engineering department at Boston University. S. S. Nanthakumar gratefully acknowledges the financial support of DAAD.

Author information

Authors and Affiliations

Corresponding authors

Appendix: Derivation of shape derivative

Appendix: Derivation of shape derivative

Firstly, the total potential energy objective function is considered. The objective function and its constraints are as follows,

Minimize \(J({\varOmega }) = \int \limits _{\varOmega } \mathbf{u}.\mathbf{b}\, d{\varOmega } + \int \limits _{{\varGamma }_N} \mathbf{u}.\mathbf{t}\, d{\varGamma }\)

subject to :

\(a(\mathbf{u},\delta \mathbf{u},{\varOmega })+a_s(\mathbf{u},\delta \mathbf{u},{\varOmega })= -l_s(\mathbf{u},{\varOmega })+l(\mathbf{u},{\varOmega })\)

(i.e.)

\(\int \limits _{\varOmega } \epsilon (\delta \mathbf{u}):\mathbb {C}^{bulk}:\varvec{\epsilon }(\mathbf{u})\;d{\varOmega } + \int \limits _{\varGamma } \big (\mathbf{P}\varvec{\epsilon }(\delta \mathbf{u})\mathbf{P}\big ):\varvec{\tau }_\mathbf{s}\;d{\varGamma } + \int \limits _{\varGamma } \big (\mathbf{P}\varvec{\epsilon }(\delta \mathbf{u})\mathbf{P}\big ):\mathbb {C}^s:\big (\mathbf{P}\varvec{\epsilon }(\mathbf{u})\mathbf{P}\big )\;d{\varGamma } = \int \limits _{\varOmega } \mathbf{u}.\mathbf{b}\;d{\varOmega } + \int \limits _{{\varGamma }_N} \mathbf{u}.\mathbf{t}\;d{\varGamma }.\)

The Lagrangian of the objective functional is,

The material derivative of the Lagrangian is defined as ,

All the terms that contain \(\mathbf{w}^{\prime }\) in the material derivative of Lagrangian are collected and the sum of these terms is set to zero, to get the weak form of the state equation,

All the terms that contain \(\mathbf{u}^{\prime }\) in the material derivative of Lagrangian are collected and the sum of these terms is set to zero, to get the weak form of the adjoint equation,

Considering that \({\varGamma }_N\) and \({\varGamma }_D\) are not modified in the optimization process and assuming that the body forces are zero, the shape derivative of the objective functional can be obtained from Eq. 63,

where,

The \(G\) obtained can be considered as the negative of velocity, \(V_n\) required in order to optimize the level set function. Therefore,

From the above equation it is evident that the derivative is negative (i.e.) it ensures decrease in the objective function with iterations.

If the objective function is a least square error compared to target displacement as shown below,

Substituting in Eq. 63 and collecting terms with \(\mathbf{u}^{\prime }\), the weak form of the adjoint can be obtained as,

where,

Rights and permissions

About this article

Cite this article

Nanthakumar, S.S., Valizadeh, N., Park, H.S. et al. Surface effects on shape and topology optimization of nanostructures. Comput Mech 56, 97–112 (2015). https://doi.org/10.1007/s00466-015-1159-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-015-1159-9