Abstract

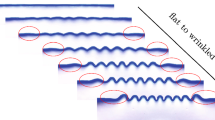

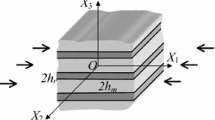

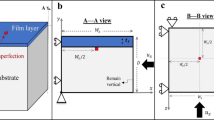

A computational method is proposed for the analysis and prediction of instability (wrinkling or necking) of multilayered compressible plates and sheets made by metals or polymers under plane strain conditions. In previous works, a basic assumption (or a physical argument) that has been frequently made is that materials are incompressible to simplify mathematical derivations. To account for the compressibility of metals and polymers (the lower Poisson’s ratio leads to the more compressible material), we propose a combined semi-numerical algorithm and finite element method for instability analysis. Our proposed algorithm is herein verified by comparing its predictions with published results in literature for thin films with polymer/metal substrates and for polymer/metal systems. The new combined method is then used to predict the effects of compressibility on instability behaviors. Results suggest potential utility for compressibility in the design of multilayered structures.

Similar content being viewed by others

References

Xu S, Zhang Y, Jia L, Mathewson KE, Jang K, Kim J, Fu H, Huang X, Chava P, Wang R, Bhole S, Wang L, Na YJ, Guan Y, Flavin M, Han Z, Huang Y, Rogers JA (2014) Soft microfluidic assemblies of sensors, circuits and radios for the skin. Science 344:70

Zhang Y, Fu H, Xu S, Fan JA, Hwang K, Jiang J, Rogers JA, Huang Y (2014) A hierarchical computational model for stretchable interconnects with fractal-inspired designs. J Mech Phys Solids 72:115

Eskil A, Sharon K, Per S (2014) Micro-mechanisms of a laminated packaging material during fracture. Eng Fract Mech 127:313

Massimilino F, Arsenio C, Luca E (2014) Delamination onset and design criteria of multilayer flexible packaging under high pressure treatments. Innov Food Sci Emerg Technol 23:39

Cohen Y, Albalak RJ, Dair BJ, Capel MS, Thomas EL (2000) Deformation of oriented lamellar block compolymer films. Macromolecules 33:6502

Makke A, Perez M, Lame O, Barrat J-L (2012) Nanoscale buckling deformation in layered copolymer materials. PNAS 109:680

Jin L, Chen D, Hayward RC, Suo Z (2014) Creases on the interface between two soft materials. Soft Matter 10:303

Jiang H, Khang D-Y, Song J, Sun YG, Huang Y, Rogers JA (2007) Finite deformation mechanics in buckled thin films on compliant supports. PNAS 104:15607

Wang S, Song J, Kim D-H, Huang Y, Rogers JA (2008) Local versus global buckling of thin films on elastomeric substrates. Appl Phys Lett 93:023126

Xiao J, Carlson A, Liu ZJ, Huang Y, Jiang H, Rogers JA (2008) Stretchable and compressible thin films of stiff materials on compliant wavy substrates. Appl Phys Lett 93:013109

Song J, Jiang H, Liu ZJ, Khang DY, Huang Y, Rogers JA, Lu C, Koh CG (2008) Buckling of a stiff thin film on a compliant substrate in large deformation. IJSS 45:3107

Jiang H, Sun Y, Rogers JA, Huang Y (2008) Post-buckling analysis for the precisedly controlled buckling of thin film encapsulated by elastomeric substrates. IJSS 45:3858

Jiang H, Khang DY, Fei H, Kim H, Huang Y, Xiao J, Rogers JA (2008) Finite width effect of thin-films buckling on compliant substrate: experimental and theorectical studies. JMPS 56:2585

Yu C, Jiang H (2010) Forming wrinkled stiff film on polymeric substrate at room temperature for stretchable interconnects applications. Thin Solid Films 519:818

Cao Y, Hutchinson JW (2012) Wrinkling phenomean in neo-Hookean film/substrate bilayers. Proc R Soc A 468:94

Cheng H, Zhang Y, Hwang K-C, Rogers JA, Huang Y (2014) Buckling of a stiff thin film on a pre-strained bi-layer substrate. IJSS 51:3113

Li T (2006) Suo Z deformability of thin metal films on elastomer substrate. Int J Solids Struct 43:2351

Li T, Suo Z (2007) Ductility of thin metal films on polymer substrates modulated by interfacial adhesion. Int J Solids Struct 44:1696

Hutchinson JW (2013) Deformability of thin metal films on elastomer substrate. Math Mech Solids 40:1

Chen D, Cai S, Suo Z, Hayward RC (2012) Surface energy as a barrier to creasing of elastomer films: an elastic analogy to classical nucleation. PRL 109:038001

Chan EP, Smith EJ, Hayward RC, Crosby AJ (2008) Surface wrinkles for smart adhesion. Adv Mater 20:711

Breid D, Crosby AJ (2009) Effect of stress state on wrinkle morphology. Soft Matter 5:425

Lacour SP, Wagner S, Huang ZY, Suo Z (2003) Stretchable gold conductors on elastomeric substrates. Appl Phys Lett 82:2404

Harrison C, Stafford CM, Zhang W, Karim A (2004) Sinusoidal phase grating created by a tunably buckled surface. Appl Phys Lett 85:4016

Kim JW, Yoon JH, Hayward RC (2010) Dynamic display of biomolecular patterns through an elastic creasing instability of stimuli-responsive hydrogels. Nat. Mater. 9:159

Wong WH, Guo TF, Zhang YW, Cheng L (2010) Surface instability maps for soft materials. Soft Matter 6:5743

Chen D, Yoon J, Chandra D, Crosby AJ, Hayward RC (2014) Stimuli-responsive buckling mechanics of polymer films. J Polym Sci Part B 52:1441

Hill R, Hutchinson JW (1975) Bifurcation phenomena in the plane tension test. J Mech Phys Solids 23:239

Storen S, Rice JR (1975) Localized necking in thin sheets. J Mech Phys Solids 23:421

Dorris JF, Nemat-Nasser S (1980) Instability of a layer on a half space. J Appl Mech 47:304

Steif PF (1986) Periodic necking instabilities in layered plastic solids. Int J Solids Struct 22:1571

Greaves GN, Greer AL, Lakes RS, Rouxel T (2011) Poisson’s ratio and modern materials. Nat Mater 10:823

Petit B, Gey N, Cherkaoui M, Bolle B, Humbert M (2007) Deformation behavior and microstructure/texture evolution of an annealed 304 stainless steel sheet. Experimental and micromechanical modeling. Int J Plast 23:323

Chung J, Jeon JB, Chang YW (2010) Work-hardening and ductility enhancement mechanism of cold rolled multiphase TRIP steels. Met Mater Int 16:533

Tang S, Ying L, Liu WK, Huang X (2014) Surface ripples of polymeric nanofibers under tension: the crucial role of poisson’s ratio. Macromolecules 47:6503–6514. doi:10.1021/ma5012599

Hutchinson JW, Tvergaard V (1980) Surface instability on statically strained plastic solids. Int J Mech Sci 22:339

Allen HG (1969) Analysis and design of sandwich panels, 1st edn. Pergammon, New York

Hong W, Zhao X, Suo Z (2009) Deformability of thin metal films on elastomer substrate. Appl Phys Lett 95:111901

Hohlfeld E, Mahdevan L (2012) Scale and nature of sulcification patterns. PRL 109:025701

Bertoldi K, Gei M (2011) Instabilities in multilayered soft dielectrics. J Mech Phys Solids 59:18

Tang S, Greene SM, Liu WK (2012a) A two-scale theory for nonlinear viscoelasticity. J Mech Phys Solids 60:199

Tang S, Greene SM, Liu WK (2012b) Renormalization approach to model interaction in microstructured solids: application to porous elastomer. Comput Methods Appl Mech Eng 213:217–220

Rosati L, Valoroso N (2004) A return map algorithm for general isotropic elasto/visco-plastic materials in principal space. Int J Numer Methods Eng 60:461

Acknowledgments

S.T. thanks NSF of Chongqing (Project No. 0211002431039) and NSF of China (Project No. 11472065). W.K.L. thanks the support of NSF. X.H.P. thanks for the support of NSFC (Project No. 11332013).

Author information

Authors and Affiliations

Corresponding authors

Appendix

Appendix

1.1 Derivation for neo-Hookean model

For neo-Hookean model, we start with the right Cauchy–Green tensor:

We have

where \(I_{1}\) and \(I_{3}\) is the first and third invariant of \(\mathbf {C.}\) The elastic deformation energy in Eq. (1) can be rewritten as:

If we define

and apply the following results,

then first PK stress may be obtained from Eq. (2) as,

The tangent modulus tensor in the undeformed configuration is,

After we obtain the tangent modulus tensor in the undeformed configuration, in the updated Lagrangian configuration it can be computed through Eq. (13). Substituting into Eqs. (12) and (14), then the coefficients in Eq. (15) can be obtained from,

The coefficients for the stress increments can be computed in the same way, giving,

1.2 Derivation for J2 deformation plasticity model

Suppose \(a_{i}\) is the ith eigenvalue, and \(\mathbf {a}_{i}\) the corresponding eigenvector of \(\bar{\mathbf {C}}\), then we have (see [43]),

and,

where \(\boxtimes \) is defined as follows,

and \(\mathbf {A,B,C}\) are second order tensors. With these results at hand, the first PK stress (4) is given by,

and the tangent modulus tensor

where subscripts \(I\) and \(M\) range from 1 to 3 (\(I\ne M=1\ldots 3\)). Through Eq. (13) we can obtain stress increments by Eq. (12). Substituting into Eq. (14), the coefficients in Eq. (15) \( a_{11},a_{12},a_{13},a_{22},a_{21},a_{23}\) and \(b_{11},b_{12},b_{21},b_{22}\) can be computed for hard metals. Unlike the hyperelastic materials, the resulting expressions turn out to be much more complicated. As such, they are not listed here. We instead compute them automatically.

Rights and permissions

About this article

Cite this article

Tang, S., Yang, Y., Peng, X.H. et al. A semi-numerical algorithm for instability of compressible multilayered structures. Comput Mech 56, 63–75 (2015). https://doi.org/10.1007/s00466-015-1155-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-015-1155-0