Abstract

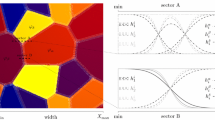

Computational models based on the phase-field method typically operate on a mesoscopic length scale and resolve structural changes of the material and furthermore provide valuable information about microstructure and mechanical property relations. An accurate calculation of the stresses and mechanical energy at the transition region is therefore indispensable. We derive a quantitative phase-field elasticity model based on force balance and Hadamard jump conditions at the interface. Comparing the simulated stress profiles calculated with Voigt/Taylor (Annalen der Physik 274(12):573, 1889), Reuss/Sachs (Z Angew Math Mech 9:49, 1929) and the proposed model with the theoretically predicted stress fields in a plate with a round inclusion under hydrostatic tension, we show the quantitative characteristics of the model. In order to validate the elastic contribution to the driving force for phase transition, we demonstrate the absence of excess energy, calculated by Durga et al. (Model Simul Mater Sci Eng 21(5):055018, 2013), in a one-dimensional equilibrium condition of serial and parallel material chains. To validate the driving force for systems with curved transition regions, we relate simulations to the Gibbs-Thompson equilibrium condition (Johnson and Alexander, J Appl Phys 59(8):2735, 1986).

Similar content being viewed by others

References

Voigt W (1889) Über die Beziehung zwischen den beiden Elastizitätskonstanten isotroper Körper. Annalen der Physik 274(12):573

Reuss A (1929) Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizittitsbedingung fiir Einkristalle. Z Angew Math Mech 9:49

Durga A, Wollants P, Moelans N (2013) Evaluation of interfacial excess contributions in different phase-field models for elastically inhomogeneous systems. Model Simul Mater Sci Eng 21(5):055018

Johnson WC, Alexander JID (1986) Interfacial conditions for thermomechanical equilibrium in two-phase crystals. J Appl Phys 59(8):2735

Moelans N, Blanpain B, Wollants P (2008) An introduction to phase-field modeling of microstructure evolution. Calphad 32(2):268

Chen LQ (2002) Phase-field models for microstructure evolution. Annu Rev Mater Res 32(1):113

Ammar K, Appolaire B, Cailletaud G, Forest S (2009) Combining phase field approach and homogenization methods for modelling phase transformation in elastoplastic media. Revue européenne de mécanique numérique 18(5–6):485

Khachaturyan A (1983) Theory of structural transformation in solids. Wiley, New York

Spatschek R, Müller-Gugenberger C, Brener E, Nestler B (2007) Phase field modeling of fracture and stress-induced phase transitions. Phys Rev E 75(6):1

Mennerich C, Wendler F, Jainta M, Nestler B (2011) A phase-field model for the magnetic shape memory effect. Arch Mech 63:549

Schneider D, Schmid S, Selzer M, Böhlke T, Nestler B (2014) Small strain elasto-plastic multiphase-field model. Comput Mech 55(1):27–35

Schneider D, Selzer M, Bette J, Rementeria I, Vondrous A, Hoffmann MJ, Nestler B (2014) Phase-field modeling of diffusion coupled crack propagation processes. Adv Eng Mater 16(2):142–146

Steinbach I, Apel M (2006) Multi phase field model for solid state transformation with elastic strain. Physica D 217:153

Apel M, Benke S, Steinbach I (2009) Virtual dilatometer curves and effective youngs modulus of a 3D multiphase structure calculated by the phase-field method. Comput Mater Sci 45(3):589

Silhavy M (1997) The mechanics and thermodynamics of continuous media, 1997th edn. Springer, Berlin

Kim SG, Kim WT, Suzuki T (1999) Phase-field model for binary alloys. Phys Rev E 60(6 Pt B):7186

Plapp M (2011) Unified derivation of phase-field models for alloy solidification from a grand-potential functional. Phys Rev E 84(3):031601

Choudhury A, Nestler B (2012) Grand Potential formulation for multi-component phase transformations combined with thin-interface asymptotics of the double obstacle potential. Phys Rev E Stat Nonlinear Soft Matter Phys, pp 1–36

Nestler B, Garcke H, Stinner B (2005) Multicomponent alloy solidification: phase-field modeling and simulations. Phys Rev E 71(4):1

Slawinski MA (2010) Waves and rays in elastic continua, 2nd edn. World Scientific Pub Co, London

Gross D, Seelig T (2011) Bruchmechanik: Mit einer Einführung in die Mikromechanik. Springer, Berlin

Mai AK, Singh SJ (1991) Deformation of elastic solids. Prentice Hall, Englewood Cliffs

Cha PR, Yeon DH, Yoon JK (2001) A phase field model for isothermal solidification of multicomponent alloys. Acta Mater 49(16):3295–3307

Voorhees PW, Johnson WC (1986) Interfacial equilibrium during a first-order phase transformation in solids. J Chem Phys 84(9):5108

Johnson WC (1987) Precipitate shape evolution under applied stress thermodynamics and kinetics. Metall Trans A 18(2):233–247

Simo J, Hughes T (1998) Computational inelasticity. Springer, New York

Acknowledgments

We thank the DFG for funding our investigations in the framework of the Research Training Group 1483. The work was further supported by the state Baden-Wuerttemberg and European Fonds for regional development with a center of excellence in Computational Materials Science and Engineering and by Helmholtz Portfolio topic “Materials Science for Energy and its Applications in Thin Film Photovoltaics and in Energy Efficiency”.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix

1.1 Transformation of stresses and strains in Voigt notation

In the Voigt notation, the strains and stresses can be written as

Then, the transformation (10) becomes \(\varvec{\sigma }^v_B=\varvec{M}^v_\sigma \varvec{\sigma }^v\), with the transformation matrix

An analogue transformation for the strain can be written as \(\varvec{\epsilon }^v_B=\varvec{M}^v_\epsilon \varvec{\epsilon }^v\), with the transformation matrix

We reorder the components of the strain and stress vectors and define

Due to this reformulation, we permute the rows of the previous matrices \(\varvec{M}^v_\sigma \) and \(\varvec{M}^v_\epsilon \), but the named properties remain

This follow the transformations of stresses and strains as used in Eqs. (20) and (21).

Driving force contributions of VT and RS model

The main assumption of the VT scheme [1] is that the strains of overlapping phases are equal. In a two phase system with \(\phi _{\alpha }\) and \(\phi _{\beta }\), the corresponding volume fractions follow Eq. (1) for the stress \(\varvec{\sigma }^{VT}\). The energy density results accordingly to [9–11]

Using Eq. (4), the corresponding contribution of the driving force for the VT model is given by

The assumption of the RS model is that the stresses are equal for the two overlapping phases. The system variables are now changed from strains to stresses. The corresponding elastic potential of phase \(\alpha \) for such a system can be derived by changing the system variable in Eq. (87) with the Legendre transformation to the form

This results in

with \(\varvec{\sigma }^{RS}\) given in Eq. (2). The corresponding contribution of the driving force for the RS model can be expresses as

Rights and permissions

About this article

Cite this article

Schneider, D., Tschukin, O., Choudhury, A. et al. Phase-field elasticity model based on mechanical jump conditions. Comput Mech 55, 887–901 (2015). https://doi.org/10.1007/s00466-015-1141-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-015-1141-6