Abstract

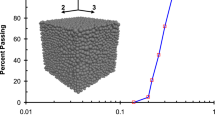

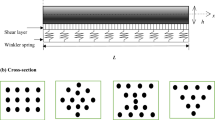

This contribution investigates a computational homogenization method for one-dimensional technical textiles i.e. ropes or cables. On the macroscopic level rope-like textiles are characterized by a large length-to-thickness ratio, such that a discretization with structural elements, i.e. beam elements, is numerically efficient. The material behavior is, however, strongly influenced by the heterogeneous micro structure. Here, the fibers at the micro structure are modeled explicitly via a representative volume element whereby the contact interactions between fibers are captured. To transfer the microscopic response to the macro level a beam specific homogenization scheme is introduced. Theoretical aspects are discussed, e.g. the advocated beam specific power averaging theorem and the corresponding scale transition, and numerical examples for periodic rope-like structures are given.

Similar content being viewed by others

References

Hemmerlein J (2005) Steel wire rope, http://de.wikipedia.org/wiki/Stahlseil#mediaviewer/Datei:Steel_wire_rope, License: creative commons by-sa 3.0 de

Miehe C (2003) Computational micro-to-macro transitions for discretized micro-structures of heterogeneous materials at finite strains based on the minimization of averaged incremental energy. Comput Method Appl Mech Eng 192:559–591

Kouznetsova VG, Geers MGD, Brekelmans WAM (2004) Multi-scale second-order computational homogenization of multi-phase materials: a nested finite element solution strategy. Comput Method Appl Mech Eng 193:5525–5550

Ponte Castañeda P, Tiberio E (2000) A second-order homogenization method in finite elasticity and applications to black-filled elastomers. J Mech Phys Solids 48:1389–1411

Temizer I, Wriggers P (2006) An adaptive method for homogenization in orthotropic nonlinear elasticity. Comput Method Appl Mech Eng 196:3409–3423

Bathe KJ, Bolourchi S (1979) Large displacement analysis of three-dimensional beam structures. Int J Numer Methods Eng 14:961–986

Betsch P, Steinmann P (2002) Frame-indifferent beam finite elements based upon the geometrically exact beam theory. Int J Numer Method Eng 54:1775–1788

Gruttmann F, Sauer R, Wagner W (2000) Theory and numerics of tree-dimensional beams with elastoplastic material behaviour. Int J Numer Method Eng 48:1675–1702

Fillep S, Mergheim J, Steinmann P (2013) Computational modelling and homogenization of technical textiles. Eng Struct 50:68–73

Geers MGD, Coenen E, Kouznetsova VG (2007) Multi-scale computational homogenization of structured thin sheets. Model Simul Mater Sci Eng 15:373–404

Cartraud P, Messager T (2006) Computational homogenization of periodic beam-like structures. Int J Solids Struct 43:686–696

Lefik M, Schrefler BA (1994) 3-D finite element analysis of composite beams with parallel fibres, based on homogenization theory. Comput Mech 14:2–15

Rabczuk T, Kim JY, Samaniego E, Belytschko T (2004) Homogenization of sandwich structures. Int J Numer Method Eng 61:1009–1027

Wriggers P, Zavarise G (1997) On contact between tree-dimensional beams undergoing large deflections. Commun Numer Methods Eng 13:429–438

Litewka P, Wriggers P (2012) Frictional contact between 3D beams. Comput Mech 28:26–39

Durville D (2005) Numerical simulation of entangled materials machanical properties. J Mater Sci 40:5941–5948

Konyukhov A, Schweizerhof K (2012) Geometrically exact theory for contact interactions of 1D manifolds. Algorithmic implementation with various finite element models. Comput Methods Appl Mech Eng 205–208:130–138

Nemov AS, Voynov IB, Borovkov AI, Boso DP, Schrefler BA (2010) Generalized stiffness coefficients for ITER superconducting cables, direct FE modeling and initial configuration. Cryogenics 50:304–313

Bajas H, Durville D, Devred A (2012) Finite element modelling of cable-in-conduit conductors. Supercond Sci Technol 25:054019

Frischkorn J, Reese S (2012) A solid-beam finite element and non-linear constitutive modelling. Comput Methods Appl Mech Eng 265:195–212

Drugan WJ, Willis JR (1996) A micromechanics-based nonlocal constitutive equation and estimates of representative volume element size for elastic composites. J Mech Phys Solids 44:497–524

Laursen TA, Simo JC (1993) A continuum- based finite element formulation for the implicit solution of multibody, large deformation frictional contact problems. Int J Numer Methods Eng 36:3451–3485

Green AE, Zerna W (1954) Theoretical elasticity. Clarendon Press, Oxford

Author information

Authors and Affiliations

Corresponding author

Appendix: weak form

Appendix: weak form

For the scale transitions the local Euler equations are needed. They result from the first equation of motion

where \(\rho _0\) is the material density and \({\varvec{b}}_0\) is the vector of volume forces in the material configuration. The traction vector is defined by \({\varvec{t}}_0= {\varvec{P}}\cdot {\varvec{n}}_0\) with the outward unit normal \({\varvec{n}}_0=n_i {\varvec{G}}^i\) with the covariant components \(n_i\) of \({\varvec{n}}\). It appears for an area element \(dA_i\) at the coordinate surface \(\theta ^i=\)const. that

and therewith

where \(\sqrt{G^{(ii)}}\) is the norm of the vector \({\varvec{G}}^i\) [23]. An incremental force \(d {\varvec{f}}\) follows as

with \(dA_i=\sqrt{G G^{(ii)}}d\theta ^j d\theta ^k\). It can be shown, that the tractions \({\varvec{t}}^i\) correspond to those in (24) by

Inserting (60) in the last term of (57) and applying the Gaussian theorem and a transformation to the parameter space of the curvilinear coordinates renders eventually

Therewith (57) in the parameter space results as

The first equation of motion in local form in the material configuration is therefore

If the acceleration is assumed to be zero and in the absence of volume forces (64) simplifies to

With the variation of the position \(\delta {\varvec{\varphi }}\) the weak form results as

and with the beam kinematics (2) it becomes

The integrals in thickness direction can be simplified by using Eq. (50) to render

and by introducing \([\theta ^\alpha {\varvec{t}}^\alpha ]_{,\alpha }= {\varvec{t}}^\alpha + \theta ^\alpha {\varvec{t}}^\alpha _{,\alpha }\) it holds that

Therewith (67) reads

The distributed line loads \({{\varvec{n}}}^\alpha \) and \({{\varvec{m}}}^\alpha \) are here considered to be zero and the local Euler equations thus result in

Rights and permissions

About this article

Cite this article

Fillep, S., Mergheim, J. & Steinmann, P. Computational homogenization of rope-like technical textiles. Comput Mech 55, 577–590 (2015). https://doi.org/10.1007/s00466-015-1124-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-015-1124-7