Abstract

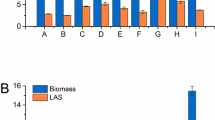

The effect of air flow rate upon scleroglucan production in batch cultures of S. glucanicum NRRL 3006 cultivated in airlift reactor with internal loop was studied using air flow rates from 0.25 m3/h to 1.00 m3/h. Biomass formation was favoured at high air flow rates (with maximum biomass at 0.75 m3/h), whilst scleroglucan synthesis was highest at relatively low air flow rates (maximal at 0.40 m3/h). S. glucanicum had a maximum specific growth rate of 0.018 h−1 at 0.75 m3/h.

The values of the key process optimisation parameters (scleroglucan yield, productivity and specific productivity) were all maximal at 0.4 m3/h. Since achievement of an adequate cell mass is essential for subsequent biopolymer synthesis, a bi-staged process was developed. In the first phase biomass formation was maximised by a high air flow rate of 0.75 m3/h, while in the second phase a lower air flow rate of 0.40 m3/h was used to stimulate biopolymer synthesis and minimise operational costs.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 13 July 1999

Rights and permissions

About this article

Cite this article

Kang, X., Wang, Y., Harvey, L. et al. Effect of air flow rate on scleroglucan synthesis by Sclerotium glucanicum in an airlift bioreactor with an internal loop. Bioprocess Engineering 23, 69–74 (2000). https://doi.org/10.1007/s004499900125

Issue Date:

DOI: https://doi.org/10.1007/s004499900125