Abstract

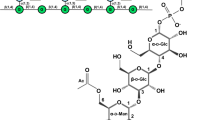

Employing aerobic fermentation, Gram-negative bacteria belonging to the genus Xanthomonas produce the high molecular weight natural heteropolysaccharide known as xanthan. It has various amounts of O-acetyl and pyruvyl residues together with D-glucosyl, D-mannosyl, and D-glucuronyl acid residues in a molar ratio of 2:2:1. The unique structure of xanthan allowed its various applications in a wide range of industries such as the food industry, pharmacology, cosmetics and enhanced oil recovery primarily in petroleum. The cultivation medium used in the manufacture of this biopolymer is critical. Many attempts have been undertaken to generate xanthan gum from agro-based and food industry wastes since producing xanthan gum from synthetic media is expensive. Optimal composition and processing parameters must also be considered to achieve an economically viable manufacturing process. There have been several attempts to adjust the nutrient content and feeding method, temperature, pH, agitation and the use of antifoam in xanthan fermentations. Various modifications in technological approaches have been applied to enhance its physicochemical properties which showed significant improvement in the area studied. This review describes the biosynthesis production of xanthan with an emphasis on the importance of the upstream processes involving medium, processing parameters, and other factors that significantly contributed to the final application of this precious polysaccharide.

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Cheah KW, Yusup S, Chuah LF, Bokhari A (2016) Physio-chemical studies of locally sourced non-edible oil: prospective feedstock for renewable diesel production in Malaysia. Proc Eng 148:451–458. https://doi.org/10.1016/j.proeng.2016.06.460

Khanra A, Vasistha S, Rai MP, Cheah WY, Khoo KS, Chew KW, Chuah LF, Show PL (2022) Green bioprocessing and applications of microalgae-derived biopolymers as a renewable feedstock: Circular bioeconomy approach. Environ. Technol Innov 28:102872. https://doi.org/10.1016/j.eti.2022.102872

Chuah LF, Chew KW, Bokhari A, Mubashir M, Show PL (2022) Biodegradation of crude oil in seawater by using a consortium of symbiotic bacteria. Environ Res 113721. https://doi.org/10.1016/j.envres.2022.113721

Mahmoud YAG, El-Naggar ME, Abdel-Megeed A, El-Newehy MH (2021) Recent advancements in microbial polysaccharides: synthesis and applications. Polymers 13(23):4136

Tosif MM, Najda A, Bains A, Kaushik R, Dhull SB, Chawla P, Walasek-Janusz M (2021) A comprehensive review on plant-derived mucilage: characterization, functional properties, applications, and its utilization for nanocarrier fabrication. Polymers 13(7):1066

Dailin DJ, Selvamani S, Michelle K, Mohd Jusoh YM, Chuah LF*, Bokhari A, El Enshasy HA, Mubashir M, Show PL (2022) Production of high-value added exopolysaccharide by biotherapeutic potential Lactobacillus reuteri strain. Biochem Eng J 188: 108691. https://doi.org/10.1016/j.bej.2022.108691.

Liu H, Lian B (2019) Quantitative evaluation of different fractions of extracellular polymeric substances derived from Paenibacillus mucilaginosus against the toxicity of gold ions. Colloids Surf, B 175:195–201

Kabir SF, Rahman A, Yeasmin F, Sultana S, Masud RA, Kanak NA, Haque P (2022) Occurrence, distribution, and structure of natural polysaccharides. In Radiation-Processed Polysaccharides (pp. 1–27). Academic Press

Zeidan AA, Poulsen VK, Janzen T, Buldo P, Derkx PMF, Oregaard G, Neves AR (2017) Polysaccharide production by lactic acid bacteria: from genes to industrial applications. FEMS Microbiol Rev 41:168-S200

Suryawanshi N, Naik S, Jujjawarapu SE (2022) Exopolysaccharides and their applications in food processing industries. Food Sci Appl Biotechnol 5(1):22–44

Tiwari ON, Sasmal S, Kataria AK, Devi I (2020) Application of microbial extracellular carbohydrate polymeric substances in food and allied industries. 3 Biotech. 10(5):1–17

Gangalla R, Gattu S, Palaniappan S, Ahamed M, Macha B, Thampu RK, Fais A, Cincotti A, Gatto G, Dama M Kumar A (2021) Structural characterisation and assessment of the novel Bacillus amyloliquefaciens RK3 exopolysaccharide on the improvement of cognitive function in alzheimer’s disease mice. Polymers 13(17):2842

Qamar SA, RiasatA JM, Fatima R, Bilal M, Iqbal HM, Mu BZ (2022) Prospects of microbial polysaccharides-based hybrid constructs for biomimicking applications. J Basic Microbiol 62(11):1319–1336

Nordin NZ, Rashidi AR, Dailin DJ, Abd Malek R, Wan Azelee NI, Abd Manas NH, Selvamani S, Abg Zaidel DN, Abd Alsaheb RA, Sukmawati D, El Enshasy H (2020) Xanthan biopolymer in pharmaceutical and cosmeceutical applications: critical review. Biosci Res 17:205–220

Dailin DJ, Low LZMI, Malek RA, Izyan N, El Enshasy H (2019) Pullulan, a biopolymer with potential applications in pharmaceutical and cosmeceutical: a review. Biosci Res 16(30):2604–2616

Dailin DJ, Elsayed EA, Malek RA, Hanapi SZ, Selvamani S, Ramli S, Sukmawati D, Sayyed RZ, El Enshasy HA (2020) Efficient kefiran production by Lactobacillus kefiranofaciens ATCC 43761 in submerged cultivation: Influence of osmotic stress and nonionic surfactants, and potential bioactivities. Arab J Chem 13(12):8513–8523

Ragab TI, Malek RA, Elsehemy IA, Farag MM, Salama BM, Abd EL-Baseer MA, Gamal-Eldeen AM, El Enshasy HA, Esawy MA (2019) Scaling up of levan yield in Bacillus subtilis M and cytotoxicity study on levan and its derivatives. J biosci. Bioeng. 127(6):655-662

Fonseca LR, Santos TP, Czaikoski A, Cunha RL (2022) Microfluidics-based production of chitosan-gellan nanocomplexes encapsulating caffeine. Food Res Int 151:110885

Berninger T, Dietz N, Gonzalez Lopez O (2021) Water-soluble polymers in agriculture: xanthan gum as eco-friendly alternative to synthetics. Microbial Biotechnol 14(5):1881–1896

Garcı́a-Ochoa F, Castro EG, Santos VE (2000) Oxygen transfer and uptake rates during xanthan gum production. Enzyme Microbial Technol. 27(9):680-690

García-Ochoa F, Santos VE, Casas JA, Gómez E (2000) Xanthan gum: production, recovery, and properties. Biotechnol Adv 18(7):549–579

Miri M, Bergayou H, Belmouden A, Moukrim A, Baazizi H, Boum’handi N (2021) Medium optimization for exopolysaccharides production by Bacillus Zhangzhouensis BZ 16 strain isolated from Khnifiss Lagoon. In E3S Web of Conferences (Vol. 234, p. 00099). EDP Sciences

Ozdal M, Kurbanoglu EB (2019) Use of chicken feather peptone and sugar beet molasses as low cost substrates for xanthan production by Xanthomonas campestris MO-03. Fermentation 5(1):9

Kumar A, Rao KM, Han SS (2018) Application of xanthan gum as polysaccharide in tissue engineering: a review. Carbohydr Polym 180:128–144

Roca C, Alves VD, Freitas F, Reis MAM (2015) Exopolysaccharides enriched in rare sugars: bacterial sources, production, and applications. Front Microbiol 6:288

Mooter MV, Steenackers M, Maertens C, Gossele F, Vos PD, Swings J, Kersters K, Ley JD (1987) Differentiation between Xanthomonas campestris pv. graminis (ISPP List 1980), pv. phleipratensis (ISPP List 1980) emend., pv. poae Egli and Schmidt 1982 and pv. arrhenatheri Egli and Schmidt 1982, by numerical analysis of phenotypic features and protein G. J Phytopathology. 118(2):135-156

Rottava I, Batesini G, Silva MF, Lerin L, Oliveira D, Padilha FF, Toniazzo G, Mossi A, Cansian RL, Luccio MD, Treichel H (2009) Xanthan gum production and rheological behavior using different strains of Xanthomonas sp. Carbohydr Polym 77(1):65–71

Niknezhad SV, Asadollahi MA, Zamani A, Biria D (2016) Production of xanthan gum by free and immobilized cells of Xanthomonas campestris and Xanthomonas pelargonii. Int J Biol Macromol 82:751–756

da Silva JA, Cardoso LG, de Jesus Assis D, Gomes GV, Oliveira MB, de Souza CO, Druzian JI (2018) Xanthan gum production by Xanthomonas campestris pv. campestris IBSBF 1866 and 1867 from lignocellulosic agroindustrial wastes. Appl. Biochem. Biotechnol. 186(3):750–763

Dye DW, Bradbury J, Goto M, Hayward AC, Lelliott RA, Schroth MN (1980) International standards for naming pathovars of phytopathogenic bacteria and a list of pathovar names and pathotype strains. Rev Plant Pathol 59(4):153–168

Margaritis A (1978) Biotechology review: mixing, mass transfer, and scale-up of polysaccharide fermentations. Biotechnol Bioeng 20(7):977–993

Farhadi GB, Khosravi-Darani K, Nejad BN (2012) Enhancement of xanthan production on date extract using response surface methodology. Asian J Chem 24(9):3887–3890

Leela JK, Sharma G (2000) Studies on xanthan production from Xanthomonas campestris. Bioprocess Eng 23(6):687–689

Miranda AL, Costa SS, de Jesus AD, Andrade BB, de Souza CO, Oliveira MB, Guimarães AG, Druzian JI (2018) Investigation of cellular fatty acid composition of Xanthomonas spp. as chemical markers of productivity and quality of xanthan gum. Carbohydr Polym 192:291–298

Miranda AL, Costa SS, Assis DD, de Jesus CS, Guimarães AG, Druzian JI (2020) Influence of strain and fermentation time on the production, composition, and properties of xanthan gum. J Appl Polym Sci 137(15):48557

Alhalmi A, Alzubaidi N, Altowairi M, Almoiliqy M, Sharma B (2018) Xanthan gum; its biopharmaceutical applications: an overview. World J Pharm Pharm Sci 7(1):1536–1548

Dailin DJ, Rithwan F, Hisham AM, Rasid ZIA, Azelee NIW, Sapawe N, Chuah LF, Yusof AHM, Enshasy HE (2022) A Review on current status of plastic waste biodegradation using microbial approach. Biosci Res 202219(3):1599–1606

Dailin DJ, Nordin NZ, Tan LT, Ramli S, Chuah LF, Sapawe N, Mohd Jusoh YM, Abang Zaidel DN, Sukmawati D, El-Enshasy H (2022) State of the art Bioremediation of textile dye in wastewater: a review. Biosci Res 19(2):914–924

Prajapati VD, Jani GK, Moradiya NG, Randeria NP (2013) Pharmaceutical applications of various natural gums, mucilages and their modified forms. Carbohydr Polym 92(2):1685–1699

Aziz T, Farid A, Haq F, Kiran M, Ullah N, Faisal S, Ali A, Ullah Khan F, You S, Bokhari A, Mubashir M, Chuah LF, Show PL (2023) Role of silica-based porous cellulose nanocrystals in improving water absorption and mechanical properties. Environ Res. 222. 115253. https://doi.org/10.1016/j.envres.2023.115253.

Gul S, Ahmad Z, Asma M, Ahmad M, Rehan K, Munir M, Bazmi AA, Ali HM, Mazroua Y, Salem MA, Akhtar MS, Khan MS, Chuah LF, Asif S (2022) Effective adsorption of cadmium and lead using SO3H-functionalized Zr-MOFs in aqueous medium. Chemosphere 307: 135633. https://doi.org/10.1016/j.chemosphere.2022.135633

Pu W, Shen C, Wei B, Yang Y, Li Y (2018) A comprehensive review of polysaccharide biopolymers for enhanced oil recovery (EOR) from flask to field. J Ind Eng Chem 61:1–11

Chatterji BP, Amonkar MV, Jose A, Almeida D, Acharya K, Nasir N, De O, Agera R, Darne R (2015) Utility of xanthan gum produced from agro food waste. Proceedings of the India International Science Festival-Young Scientists’ Meet, Department of Science and Technology, Government of India 4–8

Demirci AS, Palabiyik I, Apaydın D, Mirik M, Gumus T (2019) Xanthan gum biosynthesis using Xanthomonas isolates from waste bread: process optimization and fermentation kinetics. LWT 101:40–47

Becker A (2015) Challenges and perspectives in combinatorial assembly of novel exopolysaccharide biosynthesis pathways. Front Microbiol 6:687

Alves A, Miguel SP, Araujo AR, de Jesús Valle MJ, Sánchez Navarro A, Correia IJ, Ribeiro MP, Coutinho P (2020) Xanthan gum-konjac glucomannan blend hydrogel for wound healing. Polymers 12:99

Becker A, Vorhölter F-J (2009) Xanthan biosynthesis by Xanthomonas bacteria: an overview of the current biochemical and genomic data. In: Rehm BHA (ed) Microbial production of biopolymers and polymer precursors: applications and perspectives. Caister Academic Press, Norfolk, United Kingdom, pp 1–11

Chuah LF, Bokhari A, Yusup S, Saminathan S (2017) Optimisation on pretreatment of kapok seed (Ceiba pentandra) oil via esterification reaction in an ultrasonic cavitation reactor. Biomass Conversion and Biorefinery 7(1):91–99. https://doi.org/10.1007/s13399-016-0207-9

Chuah LF, Bokhari A, Yusup S, Klemeš JJ, Abdullah B, Akbar MM (2016) Optimisation and kinetic studies of acid esterification of high free fatty acid rubber seed oil. Arab J Sci Eng 41(7):2515–2526

Yusup S, Bokhari A, Chuah LF, Ahmad J (2015) Pre-blended methyl esters production from crude palm and rubber seed oil via hydrodynamic cavitation reactor. Chemical Engineering Transactions 43: 522

Bokhari A, Yusup S, Chuah LF, Kamil RNM (2016) Relative efficiency of esterified rubber seed oil in a hydrodynamic cavitation reactor and purification via distillation column. Chemical Engineering Transactions 52:775–780. https://doi.org/10.3303/CET1652130

Chuah LF, Klemes JJ, Bokhari A, Asif S (2021) A review of biodiesel production from renewable resources: chemical reactions. Chem Eng Trans 88:943–948. https://doi.org/10.3303/CET2188157

Chuah LF, Klemeš JJ, Bokhari A, Asif S, Cheng YW, Chong CC, Show PL (2022) A review of intensification technologies for biodiesel production. In: Gutierrez-Antonio, C., Gomez Castro, F.I. (eds). Biofuels and Biorefining. Volume 2: Intensification Processes and Biorefineries. Elsevier Inc. 87–116. https://doi.org/10.1016/B978-0-12-824117-2.00009-0

Haq F, Farid A, Ullah N, Kiran M, Khan RU, Aziz T, Mehmood S, Haroon M, Mubashir M, Bokhari A, Chuah LF, Show PL (2022) A study on the uptake of methylene blue by biodegradable and eco-friendly carboxylated starch grafted polyvinyl pyrrolidone. Environmental Research: 114241. https://doi.org/10.1016/j.envres.2022.114241

Chuah LF, Bokhari A, Asif S, Klemeš JJ, Dailin DJ, Enshasy HE, Yusof AHM (2022) A review of performance and emission characteristic of engine diesel fuelled by biodiesel. Chemical Engineering Transactions, 94, 1099–1104.https://doi.org/10.3303/CET2294183.

Fantou C, Roy AN, Dé E, Comesse S, Grisel M, Renou F (2017) Chemical modification of xanthan in the ordered and disordered states: An open route for tuning the physico-chemical properties. Carbohydr Polym 178:115–122

Patel J, Maji B, Moorthy NH, Maiti S (2020) Xanthan gum derivatives: review of synthesis, properties and diverse applications. RSC Adv 10(45):27103–27136

Jin C, Huang Z, Bao J (2020) High-titer glutamic acid production from lignocellulose using an engineered corynebacterium glutamicum with simultaneous co-utilization of xylose and glucose. ACS Sustain Chem Eng 8(16):6315–6322

Jin C, Hou W, Yao R, Zhou P, Zhang H, Bao J (2019) Adaptive evolution of Gluconobacter oxydans accelerates the conversion rate of non-glucose sugars derived from lignocellulose biomass. Biores Technol 289:121623

Lopes BD, Lessa VL, Silva BM, La Cerda LG (2015) Xanthan gum: properties, production conditions, quality and economic perspective. J Food Nutr Res 54(3):185–194

Murad HA, Abo-Elkhair AG, Azzaz HH (2019) Production of xanthan gum from nontraditional substrates with perspective of the unique properties and wide industrial applications. JSMC Microbiol 1(6)

Palaniraj A, Jayaraman V (2011) Production, recovery and applications of xanthan gum by Xanthomonas campestris. J Food Eng 106(1):1–12

El Enshasy H, Then C, Othman NZ, Al Homosany H, Sabry M, Sarmidi MR, Aziz RA (2011) Enhanced xanthan production process in shake flasks and pilot scale bioreactors using industrial semidefined medium. Afr J Biotechnol 10(6):1029–1038

Elsayed EA, Othman NZ, El Enshasy HA (2016) Bioprocess optimization of xanthan production by Xanthomonas campestris using semi-defined medium in batch and fed-batch culture. Pharm Lett 8(19):288–296

Esmaeili S, Noorolahi Z (2017) Application of starch processing enzymes in food technology-a review. Carpathian J Food Sci Technol 9(3):114–127

Moravej R, Alavi SM, Azin M, Salmanian AH (2020) Production and physicochemical characterization of xanthan gum by native lactose consuming isolates of Xanthomonas citri subsp. Citri Ukrainian Biochem J 92(1):92–102

Gondim TS, Pereira RG, Fiaux SB (2019) Xanthan gum production by Xanthomonas axonopodis pv. mangiferaeindicae from glycerin of biodiesel in different media and addition of glucose. Acta Sci. Biol. Sci. 41(1): 43661

Rončević Z, Grahovac J, Dodić S, Vučurović D, Dodić J (2019) Utilisation of winery wastewater for xanthan production in stirred tank bioreactor: bioprocess modelling and optimization. Food Bioprod Process 117:113–125

Jazini M, Ameri A, Sohrabi D, Karimi K (2018) Efficient xanthan gum production from phosphoric acid-pretreated cedar wood and elm wood. Adv res microb metab technol 1:51–64

Soleymanpour Z, Nikzad M, Talebnia F, Niknezhad V (2018) Xanthan gum production from acid hydrolyzed broomcorn stem as a sole carbon source by Xanthomonas campestris. 3 Biotech. 8(7): 1–2

Mohsin A, Zhang K, Hu J, Tariq M, Zaman WQ, Khan IM, Zhuang Y, Guo M (2018) Optimized biosynthesis of xanthan via effective valorization of orange peels using response surface methodology: a kinetic model approach’. Carbohydr Polym 181:793–800

Aqeel M, Ran J, Hu W, Irshad MK, Dong L, Akram MA, Eldesoky GE, Aljuwayid AM, Chuah LF, Deng J (2023) Plant-soil-microbe interactions in maintaining ecosystem stability and coordinated turnover under changing environmental conditions. Chemosphere 318. 137924. https://doi.org/10.1016/j.chemosphere.2023.137924

Obidah JS, Owuama CI (2017) Xanthan yield and conversion efficiency of pre-treated rice husk, sweet potato and cassava flours from Xanthomonas campestris fermentation. IJETT 49(8):477–481

de Sousa Costa LA, Inomata Campos M, Izabel Druzian J, de Oliveira AM, de Oliveira Junior EN (2014) Biosynthesis of xanthan gum from fermenting shrimp shell: yield and apparent viscosity. Int. J. Polym. Sci.

Moreno J, Lopez MJ, Vargas-Garcia C, Vazquez R (1998) Use of agricultural wastes for xanthan production by Xanthomonas campestris. J Ind Microbiol Biotechnol 21:242–246

Molina O, Fitzsimons R, Perotti N (1993) Effect of corn steep liquor on xanthan production by Xanthomonas campestris. Biotechnol. Lett. 15(5)

Lopez MJ, Ramos-Cormenzana A (1996) Xanthan production from olive-mill wastewaters. Int Biodeterior Biodegradation 38(3–4):263–270

Druzian JI, Pagliarini AP (2007) Xanthan gum production by fermentation from residue of apple juice. Food Sci Technol 27(1):26–31

Vidhyalakshmi R, Vallinachiyar C, Radhika R (2012) Production of xanthan from agro-industrial waste. J Adv Sci Res 3(2):56–59

Jazini MH, Fereydouni E, Karimi K (2017) Microbial xanthan gum production from alkali-pretreated rice straw. RSC Adv 7(6):3507–3514

Ngowatana N, Rudisirisak K (2016) Xanthan gum from sugar cane residue. Int J Geomate 11:2851–2856

Zhang Z (2015) Xanthan production with the hydrolysate of wheat straw. 6th International Conference on Manufacturing Science and Engineering. Guangzhou, China, 947–952.

Bajić B, Rončević Z, Puškaš V, Miljić U, Dodić S, Grahovac J, Dodić J (2015) White wine production effluents are used for biotechnological production of xanthan. J Process Energy Agric 19(1):52–55

Niknezhad SV, Asadollahi MA, Zamani A, Biria D, Doostmohammadi M (2015) Optimization of xanthan gum production using cheese whey and response surface methodology. Food Sci Biotechnol 24(2):453–460

Bhatia SK, Kumar N, Bhatia RK (2015) Stepwise bioprocess for exopolysaccharide production using potato starch as carbon source. 3 Biotech 5(5): 735–739

Katherine RF, Muthukumaran C, Sharmila G, Kumar NM, Tamilarasan K, Jaiganesh R (2017) Xanthan gum production using jackfruit-seed-powder-based medium: optimization and characterization. 3 Biotech, 7(4): 248

Abdullah A, Mat H (2008) Characterisation of solid and liquid pineapple waste. Reaktor 12(1):48–52

Jusoh N, Othman N, Idris A, Nasruddin A (2014) Characterization of liquid pineapple waste as carbon source for production of succinic acid. J Teknol 69(4):11–13

Abdullah A (2017) Solid and liquid pineapple waste utilization for lactic acid fermentation. Reaktor 11(1):50–52

Woiciechowski AL, Soccol CR, Rocha SN, Pandey A (2004) Xanthan gum production from cassava bagasse hydrolysate with Xanthomonas campestris using alternative sources of nitrogen. Appl Biochem Biotechnol 118(1–3):305–312

Abd El-Salam MH, Fadel MA, Murad HA (1994) Bioconversion of sugarcane molasses into xanthan gum. J Biotechnol 33(1):103–106

Souw P, Demain AL (1979) Nutritional studies on xanthan production by Xanthomonas campestris NRRL B1459. Appl Environ Microbiol 37:1186–1192

Psomas SK, Liakopoulou-Kyriakides M, Kyriakidis DA (2007) Optimization study of xanthan gum production using response surface methodology. Biochem Eng J 35(3):273–280

Trindade RA, Munhoz AP, Burkert CAV (2018) Impact of a carbon source and stress conditions on some properties of xanthan gum produced by Xanthomonas campestris pv. Mangiferaeindicae Biocatal Agric Biotechnol 15:167–172

Gilani SL, Najafpour GD, Heydarzadeh HD, Zare H (2011) Kinetic models for xanthan gum production using Xanthomonas campestris from molasses. Chem Ind Chem Eng Q 17(2):179–187

Papagianni M, Psomas SK, Batsilas L, Paras SV, Kyriakidis DA, Liakopoulou-Kyriakides M (2001) Xanthan production by Xanthomonas campestris in batch cultures. Process Biochem 37:73–80

Sherley KI, Priyadharshini RD (2015) Review on production of xanthan gum in batch and continuous reactors. Int J Chemtech Res 8(2):711–717

Shu CH, Yang ST (1990) Effects of temperature on cell growth and xanthan production in batch cultures of Xanthomonas campestris. Biotechnol Bioeng 35(5):454–468

Salah RB, Chaari K, Besbes S, Ktari N, Blecker C, Deroanne C, Attia H (2010) Optimisation of xanthan gum production by palm date (Phoenix dactylifera L.) juice by-products using response surface methodology. Food Chem. 121(2) : 627–633

Esgalhado ME, Roseiro JC, Collaço MA (1995) Interactive effects of pH and temperature on cell growth and polymer production by Xanthomonas campestris. Process Biochem 30(7):667–671

Hii YS, Law AT, Chuah LF, Mohamed Shazili NA, Abdul Rashid MK, Yong JC (2009) Inhibitive chemical cue of Pseudomonas pseudoalcaligene on biodegradation of anthracene in seawater medium. J Sustain Sci Manag 4(1):1–9

Rosalam S, England R (2006) Review of xanthan gum production from unmodified starches by Xanthomonas comprestris sp. Enzyme Microb Technol 39(2):197–207

de Jesus AD, Brandão LV, de Sousa Costa LA, Figueiredo TV, Sousa LS, Padilha FF, Druzian JI (2014) A study of the effects of aeration and agitation on the properties and production of xanthan gum from crude glycerin derived from biodiesel using the response surface methodology. Appl Biochem Biotechnol 172(5):2769–2785

Suh IS, Schumpe A, Deckwer WD (1992) Xanthan production in bubble column and air-lift reactors. Biotechnol Bioeng 39(1):85–94

Cadmus MC, Knutson CA, Lagoda AA, Pittsley JE, Burton KA (1978) Synthetic media for production of quality xanthan gum in 20 liter fermenters. Biotechnol Bioeng 20(7):1003–1014

Peters HU, Herbst H, Hesselink PG, Lünsdorf H, Schumpe A, Deckwer WD (1989) The influence of agitation rate on xanthan production by Xanthomonas campestris. Biotechnol Bioeng 34(11):1393–1397

Chuah LF, Abd Aziz AR, Yusup S, Klemeš JJ, Bokhari A (2016) Waste cooking oil biodiesel via hydrodynamic cavitation on a diesel engine performance and greenhouse gas footprint reduction. Chemical Engineering Transactions 50:301–306. https://doi.org/10.3303/CET1650051

Chuah LF, Yusup S, Abd Aziz AR, Bokhari A (2015) Performance of refined and waste cooking oils derived from palm olein on synthesis methyl ester via mechanical stirring. Aust J Basic Appl Sci 9(37):445–448

Mohd Shamsuddin NA, Yusup S, Ibrahim WA, Bokhari1 A, Chuah LF (2015) Oil extraction from Calophyllum inophyllum L. via soxhlet extraction optimization using response surface methodology (RSM). A paper presented at the 10th Asian Control Conference (10th ASCC). 31 May -3 June, 2015 at Sutera Harbour Resort, Kota Kinabalu, Sabah, Malaysia. IEEE Xplore. Doi.https://doi.org/10.1109/ASCC.2015.7244791

Mohd Sauid S, Krishnan J, Huey Ling T, Veluri MV (2013) Enhancement of oxygen mass transfer and gas holdup using palm oil in stirred tank bioreactors with xanthan solutions as simulated viscous fermentation broths. Biomed Res Int. Article ID 409675.

Rols JL, Goma G (1991) Enhanced oxygen transfer rates in fermentation using soybean oil-in-water dispersions. Biotechnol Lett 13(1):7–12

Kuttuva SG, Restrepo AS, Ju LK (2004) Evaluation of different organic phases for water-in-oil xanthan fermentation. Appl Microbiol Biotechnol 64(3):340–345

Tait MI, Sutherland IW, Clarke-Sturman AJ (1986) Effect of growth conditions on the production, composition and viscosity of Xanthomonas campestris exopolysaccharide. J Gen Microbiol 132(6):1483–1492

Flores F, Torres LG, Galindo E (1994) Effect of the dissolved oxygen tension during cultivation of X. campestris on the production and quality of xanthan gum. J Biotechnol 34(2): 165–173

Holzwarth G, Ogletree J (1979) Pyruvate-free xanthan. Carbohydr Res 76(1):277–280

Bhat IM, Wani SM, Mir SA, Masoodi FA (2022) Advances in xanthan gum production, modifications and its applications. Biocatal. Agric. Biotechnol 102328.

Zakeri A, Pazouki M, Vosoughi M (2017) Use of response surface methodology analysis for xanthan biopolymer production by Xanthomonas compestris: focus on agitation rate, carbon source, and temperature. Iran J Chem Chem Eng 36(1):173–183

Moshaf S, Hamidi EZ, Azizi MH (2014) Statistical optimization of xanthan gum production and influence of airflow rates in lab-scale fermentor. Appl Food Biotechnol 1(1):17–24

Nichols CM, Guezennec J, Bowman JP (2005) Bacterial exopolysaccharides from extreme marine environments with special consideration of the southern ocean, sea ice, and deep-sea hydrothermal vents: a review. Mar Biotechnol 7(4):253–271

Sheng GP, Yu HQ, Yue Z (2006) Factors influencing the production of extracellular polymeric substances by Rhodopseudomonas acidophila. Int Biodeterior Biodegradation 58(2):89–93

Shehni SA, Soudi MR, Hosseinkhani S, Behzadipour N (2011) Improvement of xanthan gum production in batch culture using stepwise acetic acid stress. Afr J Biotechnol 10(83):19425–19428

Lee Y, Seo H, Yeom J, Park W (2011) Molecular characterization of the extracellular matrix in a Pseudomonas putida dsbA mutant: implications for acidic stress defense and plant growth promotion. Res Microbiol 162(3):302–310

Luvielmo MD, Borges CD, Toyama DD, Vendruscolo CT, Scamparini AR (2016) Structure of xanthan gum and cell ultrastructure at different times of alkali stress. Braz J Microbiol 47(1):102–109

Hadde EK, Mossel B, Chen J, Prakash S (2021) The safety and efficacy of xanthan gum-based thickeners and their effect in modifying bolus rheology in the therapeutic medical management of dysphagia. Food Hydrocolloids for Health 1:100038

Zheng M, Chen J, Tan KB, Chen M, Zhu Y (2022) Development of hydroxypropyl methylcellulose film with xanthan gum and its application as an excellent food packaging bio-material in enhancing the shelf life of banana. Food Chem. 131794

Jagdale SC, Patil SA, Kuchekar BS (2012) Design, development and evaluation of floating tablets of tapentadol hydrochloride using chitosan. Asian J Pharm Clin Res 5(4):163–168

Kavitha K, Puneeth KP, Mani TT (2010) Development and evaluation of rosiglitazone maleate floating tablets using natural gums. Int J Pharmtech Res 2(3):1662–1669

Kar R, Mohapatra S, Bhanja S, Das D, Barik B (2010) Formulation and in vitro characterization of xanthan gum-based sustained release matrix tables of isosorbide-5-mononitrate. Iran J Pharm Sci 9(1):13

Benny IS, Gunasekar V, Ponnusami V (2014) Review on application of xanthan gum in drug delivery. Int J Pharmtech Res 6(4):1322–1326

Ahuja M, Kumar A, Singh K (2012) Synthesis, characterization and in vitro release behavior of carboxymethyl xanthan. Int J Biol Macromol 51(5):1086–1090

Savary G, Grisel M, Picard C (2015) Cosmetics and personal care products. natural polymers: industry techniques and applications. Springer, Switzerland, pp 219–261

Liang K, Han P, Chen Q, Su X, Feng Y (2019) Comparative study on enhancing oil recovery under high temperature and high salinity: Polysaccharides versus synthetic polymer 4 : 10620-10628

Chang I, Im J, Prasidhi AK, Cho GC (2015) Effects of xanthan gum biopolymer on soil strengthening. Constr Build Mater 74:65–72

William JK, Ponmani S, Samuel R, Nagarajan R, Sangwai JS (2014) Effect of CuO and ZnO nanofluids in xanthan gum on thermal, electrical and high pressure rheology of water-based drilling fluids. J Petrol Sci Eng 117:15–27

Sutherland I (2002) A sticky business. Microbial polysaccharides: current products and future trends. Microbiol Today 29:70–71

de Souza ER, Rodrigues PD, Sampaio IC, Bacic E, Crugeira PJ, Vasconcelos AC, dos Santos Silva M, dos Santos JN, Quintella CM, Pinheiro AL, de Almeida PF (2022): Xanthan gum produced by Xanthomonas campestris using produced water and crude glycerin as an environmentally friendlier agent to enhance oil recovery. Fuel. 310(PB): 122421

Han N, Wang S, Rana AK, Asif S, Klemeš JJ, Bokhari A, Long J, Thakur VK, Zhao X (2022) Rational design of boron nitride with different dimensionalities for sustainable applications. Renew Sustain Energy Rev 170:112910

Han N, Wang S, Yao Z, Zhang W, Zhang X, Zeng L, Chen R (2020) Superior three-dimensional perovskite catalyst for catalytic oxidation. EcoMat 2(3):e12044

Jiang M, Zhang M, Wang L, Fei Y, Wang S, Núñez-Delgado A, Bokhari A, Race M, Khataee A, Klemeš JJ, Xing L (2022) Photocatalytic degradation of xanthate in flotation plant tailings by TiO2/graphene nanocomposites. Chem Eng J 431:134104

Maji B, Maiti S (2021) Chemical modification of xanthan gum through graft copolymerization: Tailored properties and potential applications in drug delivery and wastewater treatment. Carbohydr Polym 251:117095

Malik S, Fatima F, Imran A, Chuah LF, Klemes JJ, Khaliq IH, Asif S, Aslam M, Jamil F, Durrani AK, Akbar MM, Shahbaz M, Usman M, Atabani AE, Naqvi SR, Yusup S, Bokhari A (2019) Improved project control for sustainable development of construction sector to reduce environment risks. J Clean Prod 240:118214. https://doi.org/10.1016/j.jclepro.2019.118214

Acknowledgements

The authors would like also to thank the Ministry of Higher Education Malaysia through Fundamental Research Grant Scheme (FRGS/1/2020/TK0/UTM/02/16), Universiti Malaysia Terengganu and Research Management Center at UTM, Malaysia. Heartfelt appreciation to Dr. Loy Kak Choon, Chew Kuan Lian, Teh Bee Bee, Timmy Chuah Tim Mie and Ong Shying Weei for their support.

Author information

Authors and Affiliations

Contributions

Data collection and analysis were performed by [ARR and NIWA]. The first draft of the manuscript was written by [ARR]. The manuscript was reviewed and edited by [DNAZ]. The manuscript was reviewed and edited by [HE-E, LFC and AB]. Funding, supervision and project management were done by [DJD]. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

All authors declare no conflicts of interest. The authors have no relevant financial or non-financial interests to disclose in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rashidi, A.R., Azelee, N.I.W., Zaidel, D.N.A. et al. Unleashing the potential of xanthan: a comprehensive exploration of biosynthesis, production, and diverse applications. Bioprocess Biosyst Eng 46, 771–787 (2023). https://doi.org/10.1007/s00449-023-02870-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-023-02870-9