Abstract

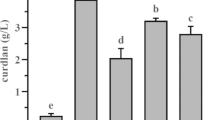

Curdlan is an edible microbial polysaccharide and can be used in food, biomedical and biomaterial fields. To reduce the cost of curdlan production, this study investigated the suitability of cassava starch hydrolysates as carbon source for curdlan production. Cassava starch was hydrolyzed into maltose syrup using β-amylase and pullulanase at various enzyme dosages, temperature, time and addition order of two enzymes. The maltose yield of 53.17% was achieved at starch loading 30% by simultaneous addition β-amylase 210 U/g starch and pullulanase 3 U/g starch at 60 °C for 9 h. Cassava starch hydrolysates were used as carbon source for curdlan production by Agrobacterium sp. DH-2. The curdlan production reached 28.4 g/L with the yield of 0.79 g/g consumed sugar and molecular weight of 1.26 × 106 Da at 96 h with cassava starch hydrolysate at 90 g/L initial sugar concentration. Curdlan produced from cassava starch hydrolysates was characterized using FT-IR spectra and thermo gravimetric analysis. This work indicated that cassava starch was a potential renewable feedstock for curdlan production.

Similar content being viewed by others

References

McIntosh M, Stone BA, Stanisich VA (2005) Curdlan and other bacterial (1→3)-β-D-glucans. Appl Microbiol Biotechnol 68:163–173. https://doi.org/10.1007/s00253-005-1959-5

Zhang R, Edgar KJ (2014) Properties, chemistry, and applications of the bioactive polysaccharide curdlan. Biomacromol 15:1079–1096. https://doi.org/10.1021/bm500038g

Funami T, Yada H, Nakao Y (1998) Curdlan properties for application in fat mimetics for meat products. J Food Sci 63:283–287. https://doi.org/10.1111/j.1365-2621.1998.tb15727.x

Zekovic DB, Kwiatkowski S, Vrvic MM, Jakovljevic D, Moran CA (2005) Natural and modified (1 → 3)-β-D-glucans in health promotion and disease alleviation. Crit Rev Biotechnol 25:205–230. https://doi.org/10.1080/07388550500376166

Negi S, Pahari S, Das DK, Khan N, Agrewala JN (2019) Curdlan limits Mycobacterium tuberculosis survival through STAT-1 regulated nitric oxide production. Front Microbiol. https://doi.org/10.3389/fmicb.2019.01173

Rui K, Tian J, Tang X, Ma J, Xu P, Tian X, Wang Y, Xu H, Lu L, Wang S (2016) Curdlan blocks the immune suppression by myeloid-derived suppressor cells and reduces tumor burden. Immunol Res 64:931–939. https://doi.org/10.1007/s12026-016-8789-7

Verma DK, Niamah AK, Patel AR, Thakur M, Sandhu KS, Chavez-Gonzalez ML, Shah N, Aguilar CN (2020) Chemistry and microbial sources of curdlan with potential application and safety regulations as prebiotic in food and health. Food Res Int. https://doi.org/10.1016/j.foodres.2020.109136

Klimek K, Przekora A, Benko A, Niemiec W, Blazewicz M, Ginalska G (2017) The use of calcium ions instead of heat treatment for β-1,3-glucan gelation improves biocompatibility of the β-1,3-glucan/HA bone scaffold. Carbohydr Polym 164:170–178. https://doi.org/10.1016/j.carbpol.2017.02.015

Basha RY, Kumar TSS, Selvaraj R, Doble M (2018) Silver loaded nanofibrous curdlan mat for diabetic wound healing: an in vitro and in vivo study. Macromol Mater Eng. https://doi.org/10.1002/mame.201800234

Qin Z, Lin S, Qiu Y, Chen Q, Zhang Y, Zhou J, Zhao L (2019) One-step immobilization-purification of enzymes by carbohydrate-binding module family 56 tag fusion. Food Chem. https://doi.org/10.1016/j.foodchem.2019.125037

Zhou Y, Xu T, Zhang Y, Zhang C, Lu Z, Lu F, Zhao H (2019) Effect of tea polyphenols on curdlan/chitosan blending film properties and its application to chilled meat preservation. Coatings 9:1–13. https://doi.org/10.3390/coatings9040262

Popescu I, Pelin IM, Butnaru M, Fundueanu G, Suflet DM (2013) Phosphorylated curdlan microgels Preparation, characterization, and in vitro drug release studies. Carbohydr Polym 94(889):898. https://doi.org/10.1016/j.carbpol.2013.02.014

Mangolim CS, da Silva TT, Fenelon VC, Koga LN, de Souza Ferreira SB, Bruschi ML, Matioli G (2017) Description of recovery method used for curdlan produced by Agrobacterium sp IFO 13140 and its relation to the morphology and physicochemical and technological properties of the polysaccharide. PLoS ONE. https://doi.org/10.1371/journal.pone.0171469

Saudagar PS, Singhal RS (2004) Fermentative production of curdlan. Appl Biochem Biotechnol 118:21–31. https://doi.org/10.1385/abab:118:1-3:021

Lee IY, Seo WT, Kim GJ, Kim MK, Park CS, Park YH (1997) Production of curdlan using sucrose or sugar cane molasses by two-step fed-batch cultivation of Agrobacterium species. J Ind Microbiol Biotechnol 18:255–259. https://doi.org/10.1038/sj.jim.2900378

Ben Salah R, Jaouadi B, Bouaziz A, Chaari K, Blecker C, Derrouane C, Attia H, Besbes S (2011) Fermentation of date palm juice by curdlan gum production from Rhizobium radiobacter ATCC 6466™: purification, rheological and physico-chemical characterization. Lwt-Food Sci Technol 44:1026–1034. https://doi.org/10.1016/j.lwt.2010.11.023

West TP, Peterson JL (2014) Production of the polysaccharide curdlan by an Agrobacterium strain grown on a plant biomass hydrolysate. Can J Microbiol 60:53–56. https://doi.org/10.1139/cjm-2013-0714

Zhang M, Xie L, Yin Z, Khanal SK, Zhou Q (2016) Biorefinery approach for cassava-based industrial wastes: current status and opportunities. Bioresour Technol 215:50–62. https://doi.org/10.1016/j.biortech.2016.04.026

Poomipuk N, Reungsang A, Plangklang P (2014) Poly-β-hydroxyalkanoates production from cassava starch hydrolysate by Cupriavidus sp. KKU38. Int J Biol Macromol 65:51–64. https://doi.org/10.1016/j.ijbiomac.2014.01.002

Yuangsaard N, Yongmanitchai W, Yamada M, Limtong S (2013) Selection and characterization of a newly isolated thermotolerant Pichia kudriavzevii strain for ethanol production at high temperature from cassava starch hydrolysate. Anton Leeuw Int J G 103:577–588. https://doi.org/10.1007/s10482-012-9842-8

Wang Q, Guo FJ, Rong YJ, Chi ZM (2012) Lipid production from hydrolysate of cassava starch by Rhodosporidium toruloides 21167 for biodiesel making. Renew Energy 46:164–168. https://doi.org/10.1016/j.renene.2012.03.002

Zhang Q, Sun J, Wang Z, Hang H, Zhao W, Zhuang Y, Chu J (2018) Kinetic analysis of curdlan production by Alcaligenes faecalis with maltose, sucrose, glucose and fructose as carbon sources. Bioresour Technol 259:319–324. https://doi.org/10.1016/j.biortech.2018.03.059

Wan J, Wang Y, Jiang D, Gao H, Yang G, Yang X (2020) Effects of carbon sources on production and properties of curdlan using Agrobaterium sp. DH-2. Prep Biochem Biotech 50:857–864. https://doi.org/10.1080/10826068.2020.1777423

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem. https://doi.org/10.1021/ac60147a030

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Azhari R, Szlak AM, Ilan E, Sideman S, Lotan N (1989) Purification and characterization of end and exo-lnulinase. Biotechnol Appl Biochem 11:105–117. https://doi.org/10.1111/j.1470-8744.1989.tb01400.x

Kalyanasundaram GT, Doble M, Gummadi SN (2012) Production and downstream processing of (1→3)-β-d-glucan from mutant strain of Agrobacterium sp. ATCC 31750. AMB Express 2:31–31. https://doi.org/10.1186/2191-0855-2-31

Diaz A, Sieiro C, Villa TG (2003) Production and partial characterization of a β-amylase by Xanthophyllomyces dendrorhous. Lett Appl Microbiol 36:203–207. https://doi.org/10.1046/j.1472-765X.2003.01289.x

Das R, Kayastha AM (2018) Enzymatic hydrolysis of native granular starches by a new β-amylase from peanut (Arachis hypogaea). Food Chem. https://doi.org/10.1016/j.foodchem.2018.10.058

Atia KS, Ismail SA, Elarnaouty MB, Dessouki AM (2003) Use of co-immobilized β-amylase and pullulanase in reduction of saccharification time of starch and increase in maltose yield. Biotechnol Prog 19:853–857. https://doi.org/10.1021/bp025661+

Yang QW (2017) Study on the enzymatic production of maltose syrup at high concentration substrate. Master’s thesis Jiangnan University.

Jin Y, Zhang HB, Yin YM, Nishinari K (2006) Comparison of curdlan and its carboxymethylated derivative by means of rheology, DSC, and AFM. Carbohydr Res 341:90–99. https://doi.org/10.1016/j.carres.2005.11.003

Mangolim CS, da Silva TT, Fenelon VC, do Nascimento A, Sato F, Matioli G, (2017) Use of FT-IR, FT-Raman and thermal analysis to evaluate the gel formation of curdlan produced by Agrobacterium sp. IFO 13140 and determination of its rheological properties with food applicability. Food Chem 232:369–378. https://doi.org/10.1016/j.foodchem.2017.04.031

Chen M, Liang P (2017) Synthesis and antibacterial activity of quaternized curdlan. Polym Bull 74:4251–4266. https://doi.org/10.1007/s00289-017-1951-0

Mayer FD, Gasparotto JM, Klauck E, Werle LB, Jahn SL, Hoffmann R, Mazutti MA (2015) Conversion of cassava starch to ethanol and a byproduct under different hydrolysis conditions. Starch-Starke 67:620–628. https://doi.org/10.1002/star.201500043

Gao H, Xie F, Zhang W, Tian J, Zou C, Jia C, Jin M, Huang J, Chang Z, Yang X, Jiang D (2020) Characterization and improvement of curdlan produced by a high-yield mutant of Agrobacterium sp. ATCC 31749 based on whole-genome analysis. Carbohydr Polym 245:116486. https://doi.org/10.1016/j.carbpol.2020.116486

Wu S, Jin Z, Tong Q, Chen H (2009) Sweet potato: a novel substrate for pullulan production by Aureobasidium pullulans. Carbohydr Polym 76:645–649. https://doi.org/10.1016/S0144-8617(00)00226-5

Li C, Kong H, Yang Q, Gu Z, Ban X, Cheng L, Hong Y, Lia Z (2020) A temperature-mediated two-step saccharification process enhances maltose yield from high-concentration maltodextrin solutions. J Sci Food Agric. https://doi.org/10.1002/jsfa.11005

Ming M, Rong L, Huang C, Bo J, Tao Z (2015) Impact of β-amylase degradation on properties of sugary maize soluble starch particles. Food Chem 177:1–7. https://doi.org/10.1016/j.foodchem.2014.12.101

Lin Q, Xiao H, Liu GQ, Liu Z, Li L, Yu F (2013) Production of maltose syrup by enzymatic conversion of rice starch. Food Bioprocess Tech 6:242–248. https://doi.org/10.1007/s11947-011-0681-9

Chen H, Lin Q, Tian W (2008) Research on liquefaction technology of rice starch by enzyme. Cereal and Food Ind 15(31–33):37. https://doi.org/10.3969/j.issn.1672-5026.2008.04.010

Wu S, Lu M, Fang Y, Wu L, Xu Y, Wang S (2018) Production of curdlan grown on cassava starch waste hydrolysates. J Polym Environ 26:33–38. https://doi.org/10.1007/s10924-016-0912-2

Pires AMB, Santana MHA (2010) Metabolic effects of the initial glucose concentration on microbial production of hyaluronic acid. Appl Biochem Biotech 162:1751–1761. https://doi.org/10.1007/s12010-010-8956-6

Giavasis I, Harvey LM, McNeil B (2006) The effect of agitation and aeration on the synthesis and molecular weight of gellan in batch cultures of Sphingomonas paucimobilis. Enzyme Microb Technol 38:101–108. https://doi.org/10.1016/j.enzmictec.2005.05.003

Wang D, Yu X, Wei G (2013) Pullulan production and physiological characteristics of Aureobasidium pullulans under acid stress. Appl Microbiol Biot 97:8069–8077. https://doi.org/10.1007/s00253-013-5094-4

Jeeva P, Doss SS, Sundaram V, Jayaraman G (2019) Production of controlled molecular weight hyaluronic acid by glucostat strategy using recombinant Lactococcus lactis cultures. Appl Microbiol Biot. https://doi.org/10.1007/s00253-019-09769-0

Funding

This work was financially supported by the Taixing Dongsheng Biotechnology Co. Ltd., China.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable.

Ethics approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wan, J., Shao, Z., Jiang, D. et al. Curdlan production from cassava starch hydrolysates by Agrobacterium sp. DH-2. Bioprocess Biosyst Eng 45, 969–979 (2022). https://doi.org/10.1007/s00449-022-02718-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-022-02718-8