Abstract

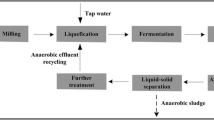

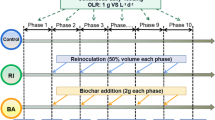

To solve the problem of extraction wastewater in citric acid industry, an integrated citric acid–methane fermentation process was proposed. In the integrated process, extraction wastewater was treated by mesophilic anaerobic digestion and then reused to make mash for the next batch of citric acid fermentation. In this study, an Aspergillus niger mutant strain exhibiting resistance to high metal ions concentration was used to eliminate the inhibition of 200 mg/L Na+ and 300 mg/L K+ in anaerobic digestion effluent (ADE) and citric acid production increased by 25.0 %. Air stripping was used to remove ammonium, alkalinity, and part of metal ions in ADE before making mash. In consequence, citric acid production was significantly improved but still lower by 6.1 % than the control. Results indicated that metal ions in ADE synergistically inhibited the activity of glucoamylase, thus reducing citric acid production. When 130 U/g glucoamylase was added before fermentation, citric acid production was 141.5 g/L, which was even higher than the control (140.4 g/L). This process could completely eliminate extraction wastewater discharge and reduce water resource consumption.

Similar content being viewed by others

References

Ates S, Dingil N, Bayraktar E, Mehmetoglu U (2002) Enhancement of citric acid production by immobilized and freely suspended Aspergillus niger using silicone oil. Process Biochem 38:433–436

Chang VS, Holtzapple MT (2000) Fundamental factors affecting biomass enzymatic reactivity. Appl Biochem Biotechnol 84–86:5–37

Mattey M (1992) The production of organic acids. Crit Rev Biotechnol 12:87–132

Dhillon GS, Brar SK, Verma M, Tyagi RD (2011) Recent advances in citric acid bio-production and recovery. Food Bioprocess Tech 4:505–529

Dhillon GS, Brar SK, Verma M, Tyagi RD (2011) Utilization of different agro-industrial wastes for sustainable bioproduction of citric acid by Aspergillus niger. Biochem Eng J 54:83–92

Imandi SB, Bandaru VVR, Somalanka SR, Bandaru SR, Garapati HR (2008) Application of statistical experimental designs for the optimization of medium constituents for the production of citric acid from pineapple waste. Bioresour Technol 99:4445–4450

Mayilvahanan D, Annadurial G, Raju V, Chellapandian M, Krishnan MRV, Kunthala J (1996) Citric acid production. Bioprocess Eng 15:323–326

Chiumarelli M, Ferrari CC, Sarantopoulos CI, Hubinger MD (2011) Fresh cut ‘Tommy Atkins’ mango pre-treated with citric acid and coated with cassava (Manihot esculenta Crantz) starch or sodium alginate. Innov Food Sci Emerg 12:381–387

Li CL, Yang HL, Xia XL, Li YJ, Chen LP, Zhang M, Zhang L, Wang W (2013) High efficient treatment of citric acid effluent by Chlorella vulgaris and potential biomass utilization. Bioresoure Technol 127:248–255

Zhu YR, Zhou C, Wang JH, Xie HS, Gao MX (2004) Treatment of high concentration wastewater from citric acid production. Tech Equip Environ Pollut Contr 5:64–66 (In Chinese)

Chen XD, Yang JL, Pei Q, Li ZX (2006) Development of the research on citric acid-production wastewater treatment techniques. Hebei Chem Eng 29:57–59 (In Chinese)

Zhi X, Yang H, Berthold S, Doetsch C, Shen J (2010) Potential improvement to a citric wastewater treatment plant using bio-hydrogen and a hybrid energy system. J Power Sources 195:6945–6953

Speece RE (1996) Anaerobic biotechnology for industrial wastewaters. Vanderbilt University, Archae Press, Tennessee

Luo SR (1996) Citric acid wastewater and anaerobic high temperature digestive treatment. Environ Eng 14:8–10 (In Chinese)

Wang XH, Guan XJ, Xu SJ, Zhong YQ (2006) Treatment of citric acid wastewater by hydraulic circulating UASB reactor. Technol Water Treat 32:61–65 (In Chinese)

Zhu LH, Xu X, Wang R (2007) Study on the treatment of wastewater from citric acid production by UASB-BIOFOR process. Ind Water Treat 27:39–41 (In Chinese)

Cheng T, Lin T (2008) Experimental study of lemon acid wastewater with microwave radiation by MnO2. Guizhou Chem Ind 33:41–42 (In Chinese)

Fu GL, Xu XY, Fan LH, Zhang M (2007) Experimental study of fenton’s reagent treated lemon acid wastewater. J Huaihai Inst Technol 16:44–46 (In Chinese)

Shi ZL, Li W, Yao SH (2009) Wastewater treatment of citric acid by emulsion liquid membrane method. J Shenyang Univ Chem Technol 23:289–293 (In Chinese)

Kayombo S, Mbwette TSA, Katima JHY, Jorgensen SE (2003) Effect of substrate concentration on the growth of heterotrophic bacteria and algae in secondary facultative ponds. Water Res 37:2937–2943 (In Chinese)

Valderrama LT, Del Campo CM, Rodriguez CM, de-Bashan LE, Bashan Y (2002) Treatment of recalcitrant wastewater from ethanol and citric acid production using the microalga Chlorella vulgaris and the macrophyte Lemna minuscula. Water Res 36:4185–4192

Qi H, Cheng F, Zhang H, Yang J (2001) Studies on recycling of neutralized wastewater from citric acid production. In: Proceedings of the Third Asia-Pacific Conference on Sustainable Energy and Environmental Technologies: Hong Kong, 3–6 December 2000. World Scientific Publishing Company. pp 289

Tian WJ, Jiang J (2001) Study on recycling neutralized wastewater from citric acid factory of Juxian. J Shandong Inst Min Tech 20:117–120 (In Chinese)

Xu J, Chen YQ, Zhang HJ, Tang L, Wang K, Zhang JH, Chen XS, Mao ZG (2014) Production of citric acid using its extraction wastewater treated by anaerobic digestion and ion exchange in an integrated citric acid-methane fermentation process. Bioprocess Biosyst Eng. doi:10.1007/s00449-014-1138-0

APHA (1995) Standard methods for the examination of water and wastewater, 17th edn. American Public Health Association (APHA), New York

Lodish H, Berk A, Matsudaira P, Kaiser CA, Krieger M, Scott MP, Zipursky L, Darnell (2004) Molecular cell biology, 5th edn. WH Freeman and company, New York

Jiang L (2012) Research of “ethanol- methane coupled process” -Research of inhibitor on ethanol fermentation and the recycled anaerobic efflux. M. E. Dissertation, Jiangnan University, Wuxi, Jiangsu

Kim YH, Yeom SH, Ryu JY, Song BK (2004) Development of a novel UASB/CO2-stripper system for the removal of calcium ion in paper wastewater. Process Biochem 39:1393–1399

Maria K, Wladyslaw L (1989) Effects of medium purity on submerged citric acid fermentation yield. Acta Aliment 15:97–105

Berg JM, Tymoczko JL, Stryer L (2002) Biochemistry, 5th edn. WH Freeman and company, New York

Grewal H, Kalra K (1995) Fungal production of citric acid. Biotechnol Adv 13:209–234

Kubicek C, Röhr M (1977) Influence of manganese on enzyme synthesis and citric acid accumulation in Aspergillus niger. Eur J Appl Microbiol Biotechnol 4:167–175

Papagianni M (2007) Advances in citric acid fermentation by Aspergillus niger: biochemical aspects, membrane transport and modeling. Biotechnol Adv 25:244–263

Soccol CR, Vandenberghe LP, Rodrigues C, Pandey A (2006) New perspectives for citric acid production and application. Food Technol Biotechnol 44:141–149

Sato K, Sudo S (1999) Small-scale solid-state fermentations. In: Demain AL, Davies JE (eds) Manual of industrial microbiology and biotechnology. ASM, Washington, pp 61–79

Haq IU, Ali S, Qadeer MA, Iqbal J (2002) Effect of copper ions on mould morphology and citric acid productivity by Aspergillus niger using molasses based media. Process Biochem 37:1085–1090

Rohr M, Kubicek CP, Kominek J (1996) Citric acid. In: Rehm HJ, Reed G (eds) Biotechnology, vol 6. Wiley-VCH, Weinheim, pp 307–345

Jernejc K, Legisa M (2002) The in£uence of metal ions on malic enzyme activity and lipid synthesis in Aspergillus niger. FEMS Microbiol Lett 217:185–190

Kristiansen B, Linden J, Mattey M (2002) Citric acid biotechnology. Taylor and Francis Inc, Philadelphia

Acknowledgments

This research was supported by the Henan Tianguan Co. Ltd., China and the Yixing Xielian Biological Chemical Co. Ltd., China. We are thankful for their supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, J., Chen, YQ., Zhang, HJ. et al. Optimization of the integrated citric acid–methane fermentation process by air stripping and glucoamylase addition. Bioprocess Biosyst Eng 38, 411–420 (2015). https://doi.org/10.1007/s00449-014-1280-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1280-8