Abstract

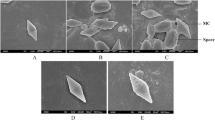

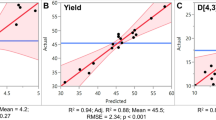

Bacillus thuringiensis (Bt) is one of the bioinsecticides used worldwide due to its specific toxicity against target pests in their larval stage. Despite this advantage, its use is limited because of their short persistence in field when exposed to ultra violet light and changing environmental conditions. In this work, microencapsulation has been evaluated as a promising method to improve Bt activity. The objective of this study was to develop and characterize native and modified amaranth starch granules and evaluate their potential application as wall materials in the microcapsulation of B thuringiensis serovar kurstaki HD-1 (Bt- HD1), produced by spray drying. Native amaranth starch granules were treated by hydrolyzation, high energy milling (HEM) and were chemically modified by phosphorylation and succinylation. The size of the Bt microcapsules varied from 12.99 to 17.14 μm adequate to protect the spores of Bt from ultraviolet radiation. The aw coefficient of the microcapsules produced by the modified starches after drying was low (0.14–1.88), which prevent microbial growth. Microcapsules prepared with phosphorylated amaranth starch presented the highest bacterial count and active material yield. Different concentrations of the encapsulated Bt formulation in phosphorylated amaranth starch showed a high level of insecticidal activity when tested on M. sexta larvae and has great potential to be developed as a bioinsecticide formulation, also, the level of toxicity is much higher than that found in some of the products commercially available.

Similar content being viewed by others

Abbreviations

- aw:

-

Water activity

- Bt :

-

Bacillus thuringiensis

- HEM:

-

High energy milling

- n-OSA:

-

n-Octenyl succinic anhydride

- OSA:

-

Octenyl succinic anhydride

- STP:

-

Sodium tripolyphosphate

- WAI:

-

Water absorption index

- WSI:

-

Water solubility index

References

Bravo A, Gill SS, Soberón M (2007) Mode of action of Bacillus thuringiensis Cry and Cyt toxins and their potential for insect control. Toxicon 49:423–435

Khetan S (2001) Bacterial Insecticide: Bacillus thuringiensis. In: Khetan SK (ed) Microbial Pest Control. Marcel Dekker AG, USA

Navon A (2000) Bacillus thuringiensis insecticides in crop protection-reality and prospects. Crop Prot 19:669–676

Brar S, Verma M, Tyagi R, Valéro J (2006) Recent advances in downstream processing and formulations of Bacillus thuringiensis based biopesticides. Process Biochem 41:323–342

Veloorvalappil NJ, Robinson BS, Sailas B (2013) An overview on the crystal toxins from Bacillus thuringiensis. Enzyme Technology Laboratory, Kerala

Bok SH, Hang WL, Son KH, Sung UK, Jee WL, Do YK, Kwon KK (1993) Process for preparing coated microbial pesticides and pesticides produces there from. US Patent # 5,273,749

McGuire MR, Shasha BS, Eastman CE, Oloumi-Sadeghi H (1996) Starch and flour based sprayable formulations: effect on rainfastness and solar stability of Bacillus thuringiensis. J Econ Entomol 89:863–869

Dunkle RL, Shasha BS (1988) Starch-Encapsulated Bacillus thuringiensis: a potential new method for increasing environmental stability of entomopathogens. Environ Entomol 17(7):120–126

Ramos LHM, McGuire MR, Wong LJG (1998) Utilization of several biopolymers for granular formulations of Bacillus thuringiensis. J Econ Ent 91:1109–1113

Navon A, Keren S, Levski S, Grinstein A, Riven J (1997) Granular feeding baits based on Bacillus thuringiensis products for the control of lepidopterous pests. Phytoparasitica 25(suppl):101S–110S

Yang W, He K, Zhang J, Shuyuan G (2012) pH-Controlled Bacillus thuringiensis Cry1Ac protoxin loading and release from polyelectrolyte microcapsules. PLoS One 7:e45233

McGuire MR, Shasha BS (1992) Adherent starch granules for encapsulation of insect control agents. J Econ Entomol 85:1425–1433

Bao J, Xing DL, Phillips DL, Corke H (2003) Physical properties of octenyl succinic anhydride modified rice, wheat and potato starches. J Agric Food Chem 51:2283–2287

Bangs WE, Reineccius GA (1988) Corn starch derivatives: possible wall material for spray-dried flavor manufacture pp:12–28. In: Risch SJ, Reineccius GA (Eds.) Flavor Encapsulation: ACS Symposium Series 370 American Chemical Society Washington DC

Sanna V, Moretti MDL (2008) Microencapsulation of Bacillus thuringiensis and insecticidal activity evaluation on larvae Lepidoptera. Sardinia Chem 2008. Giornata di Studio dedicata Allá chimica organica delle molecole biologicamente attive 30 Maggio 2008, Aula Magna de la Facoltà di Sienze - Sassari

Murúa-Pagola B, Beristain CI, Martínez-Bustos F (2009) Preparation of starch derivatives using reactive extrusion and evaluation of modified starches as shell materials for encapsulation of flavoring agents by spray drying. J Food Eng 91:380–386

Verdalet-Guzmán I, Martínez-Ortiz L, Martínez-Bustos F (2013) Characterization of new sources of derivative starches as wall materials of essential oil by spray drying. Food Sci Technol 33(4):1–8

Falfán-Cortés RN, Gaytán-Martínez M, Verdalet-Guzmán I, Amaya-Llano SL, Grosso CRF, Martínez- Bustos F (2014) Evaluation of modified amaranth starch as shell material for encapsulation of probiotics. Cereal Chem 91:300–308

Calzetta A, Suarez C (2001) Gelatinization kinetics of amaranth starch. Int J Food Sc Technol 36:441–448

Uriyapongson J, Duarte RP (1994) Comparison of yield and properties of amaranth starches using wet and dry–wet milling processes. Cereal Chem 71:571–577

AACC (1995) American Association of Cereal Chemists Approved methods of the American Association of Cereal Chemists, 9th edn. American Association of Cereal Chemists, St. Paul

Zambrano F, Camargo CRO (2001) ) Optimization of the conditions for the acid hydrolysis of cassava starch to obtain a fat replacer. Brazilian J Food Technol 4:147–154

Murúa-Pagola, B. Beristain-Guevara, I. and Martínez-Bustos,F. (2007) Application of phosphorylated waxy maize starch in the microencapsulation of flavors: Characterization and stability. In: Klening T.P. (Ed). Food engineering research developments, Nova Science Publishers, Inc. New York 11:14

Smith RJ, Caruso JL (1964) Determination of phosphorus and ash, pp 42–46. In: Sung HY, Wang SH (eds) Methods in Carbohydrate Chemistry. Academic Press, New York

Jeon YS, Viswanathan A, Gross RA (1999) Studies of starch esterification: reactions with alkenylsuccinates in aqueous slurry systems. Starch/Stärke 51(2–3):90–93

Song X, He G, Ruan H, Chen Q (2006) Preparation and properties of octenyl succinic anhydride modified early indica rice starch. Starch/Stärke 58:109–117

Galicia-García T, Martínez-Bustos F, Jiménez-Arevalo O, Martínez AB, Ibarra-Gómez R, Gaytán- Martínez M, Mendoza-Duarte M (2011) Thermal and microstructural characterization of biodegradable films prepared by extrusion–calendering process. Carb Polym 83:354–361

Rabek JF (1980) Experiment Methods in Polymer Chemistry: physical principles and applications. Wiley, Chichester Eng

Anderson RA, Conway HF, Pfeife FF, Griffin EL Jr (1969) Gelatinization of corn grits by roll-and-extrusion-cooking. Cereal Sci Today 14:4–12

AOAC (1999) Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Washington

Stotzky G (2000) Persistence and biological activity in soil of insecticidal proteins from Bacillusthuringiensis and of bacterial DNA bound on clays and humic acids. J Env Qual 29:691–705

Ibarra JE, Federici BA (1987) An alternative bioassay employing neonate larvae for determining the toxicity of suspended particles to mosquitoes. J Am Mosq Control Assoc 3(2):187–192

Saunders RM, Beciker R (1984) Amaranthus: A potential food and feed resource. In: Adv. Cereal Sci. Technol Vol. VI, ed. Y. Pomeranz,. Am. Assn. Cereal Chemists, St. Paul, MN

Zobel HF (1988) Molecules to granules: A comprehensive starch review. Starch/Stärke 40:44–50

Huang ZQ, Xie XL, Chen Y, Lu JP, Tong ZF (2008) Ball-milling treatment effect on physicochemical properties and features for cassava and maize starches. Comptes Rendus Chimie 11:73–79

Chang Y-H, y Lii C-Y (1992) Preparation of starch phosphate by extrusion. J Food Sci 57:203–205

Bhosale R, y Singhal RS (2006) Process optimization for the synthesis of octenyl succinyl derivative of waxy corn and amaranth starches. Carbohydr Polym 66:521–527

Tukomane T, Varavinit S (2008) Influence of octenyl succinate rice starch on rheological properties of gelatinized rice starch before and after retrogradation. Starch-Starke 60:298–304

García-Gutiérrez K, Poggy-Varaldo HM, Esparza-García F, Ibarra-Rendón J, Barrera-Cortés J (2011) Small microcapsules of crystal proteins and spores of Bacillus thuringiensis by an emulsification/internal gelation method. Bioprocess Biosyst Eng 34:701–708

Guzmán MJ (2010) Almidones modificados y su aplicación como agentes de encapsulación. Instituto Tecnológico de Orizaba, Tesis para obtener el título de Ingeniería Química

Jafari SM, He Y, Bhandari B (2007) Role of powder particle size on the encapsulation efficiency of oils during spray drying. Drying Technol 25:1091–1099

Anal A, Singh H (2007) Recent advances in microencapsulation of probiotics for industrial applications and targeted delivery: a review. Trends Food Sc Technol 18:240–251

Coté JC, Vincent C, Son KH, Bok SH (2001) Persistence of insecticidal activity of novel bio-encapsulated formulations of Bacillus thuringiensis var. kurstaki against Chroristoneura rosaceana [Lepidoptera: tortricidae]. Phytoprotection 82(2):73–82

Byeong Il K, Soon WJ, Kyoung GL, Tae JP, Jung YP, Jae JS, Seok JL, Chang. SL (2012) Synthesis of bioactive microcapsules using a microfluidic device. Sensors. 12:10136–10147

Dunkle RL, Shasha BS (1989) Response of Starch-Encapsulated Bacillus thuringiensis containing ultraviolet screens to sunlight. Environ Entomol 18:6

McGuire MR, Streett DA, Shasha BS (1991) Evaluation of starch encapsulation for formulation of grasshopper (Orthoptera: acrididae) entompox viruses. J Econ Entomol 84:1652–1656

McGuire MR, Rl Gillespie, Shasha BS (1994) Survival of Ostrinia nubi/alis (Hiibner) after exposure to Bacillus thuringiensis Berliner encapsulated in flour matrices. Environ Entomol 29:182–189

Ramírez-Suero M, Robles-Olvera V, Ramírez-Lepe M (2005) Spray-dried Bacillus thuringiensis serovar israelensis formulations for control of Aedes aegypti larvae. J Econ Entomol 98:1494–1498

Briegel H (2003) Physiological basis of mosquito ecology. J Vector Ecol 28:1–11

Rowe EG, Margaritis A (1987) Bioprocess developments in the production of bioinsecticides by Bacillus thuringiensis. CRC. Crit Rev Biotechnol 6(1):87–127

Schesser JH (1976) Commercial formulations of Bacillus thuringiensis for control of Indian meal moth. Appl Environ Microbiol 32(4):508–510

Polanczyk RA, De Bortoli SA, Placidi De Bortoli C (2012) Bacillus thuringiensis – Based Biopesticides Against Agricultural Pests in Latin America. In: Larramendy ML, Soloneski S. Integrated pest management and pest control—current and future tactics. In Tech, Croatia, pp 445–462

Aknowledgment

This work was funded by Project multi-05 supported by Cinvestav-IPN in the program multidisciplinary projects. We thank the technical support of Javier Luévano-Borrel and Regina Basurto-Ríos.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rodríguez, A.P.G., Martínez, M.G., Barrera-Cortés, J. et al. Bio-insecticide Bacillus thuringiensis spores encapsulated with amaranth derivatized starches: studies on the propagation “in vitro”. Bioprocess Biosyst Eng 38, 329–339 (2015). https://doi.org/10.1007/s00449-014-1273-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1273-7