Abstract

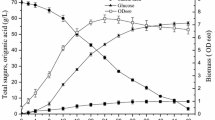

A metabolically engineered Escherichia coli KJ122 was efficiently utilized for succinate production from cassava pulp during batch separate hydrolysis and fermentation (SHF) under simple anaerobic conditions. Succinate concentration of 41.46 ± 0.05 g/L with yield and productivity of 82.33 ± 0.14 g/100 g dry pulp and 0.84 ± 0.02 g/L/h was obtained. In batch simultaneous saccharification and fermentation (SSF), hydrolysis of 12 % (w/v) cassava pulp with an enzyme loading of 2 % AMG + 3 % Cel (v/w) at pH 6.5 was optimized at 39 °C. Succinate concentration of 80.86 ± 0.49 g/L with a yield of 70.34 ± 0.37 g/100 g dry pulp and a productivity of 0.84 ± 0.01 g/L/h was attained using E. coli KJ122. Fed-batch SSF significantly enhanced succinate concentration to 98.63 ± 0.12 g/L at yield and productivity of 71.64 ± 0.97 g/100 g dry pulp and 1.03 ± 0.01 g/L/h. This result indicated an efficient and economical succinate production from cassava pulp using SHF and SSF by the use of E. coli KJ122.

Similar content being viewed by others

References

Zeikus JG, Jain MK, Elankovan P (1999) Biotechnology of succinic acid production and markets for derived industrial products. Appl Microbiol Biotechnol 51:545–552

Jantama K, Zhang X, Moore JC, Shanmugam KT, Svoronos SA, Ingram LO (2008) Eliminating side products and increasing succinate yields in engineered strains of Escherichia coli C. Biotechnol Bioeng 101:881–893

Sriroth K, Piyachomkwan K, Wanlapatit S, Oates CG (2000) Cassava starch technology: the Thai experience. Starch-Stärke 52:439–449

Virunanona C, Ouephanit C, Burapatana V, Chulalaksananukul W (2013) Cassava pulp enzymatic hydrolysis process as a preliminary step in bio-alcohols production from waste starchy resources. J Clean Prod 39:273–279

Zheng P, Fang L, Xu Y, Dong JJ, Ni Y, Sun ZH (2010) Succinic acid production from corn stover by simultaneous saccharification and fermentation using Actinobacillus succinogenes. Bioresour Technol 101:7889–7894

Chen K, Zhang H, Miao Y, Wei P, Chen J (2011) Simultaneous saccharification and fermentation of acid-pretreated rapeseed meal for succinic acid production using Actinobacillus succinogenes. Enzyme Microb Technol 48:339–344

Wang D, Li Q, Yang M, Zhang Y, Su Z, Xing J (2011) Efficient production of succinic acid from corn stalk hydrolysates by a recombinant Escherichia coli with ptsG mutation. Process Biochem 46:365–371

Li Q, Lei J, Zhang R, Li J, Xing J, Gao F, Gong F, Yan X, Wang D, Su Z, Ma G (2013) Efficient decolorization and deproteinization using uniform polymer microspheres in the succinic acid biorefinery from bio-waste cotton (Gossypium hirsutum L.) stalks. Bioresour Technol 135:604–609

Martinez A, Grabar TB, Shanmugam KT, Yomano LP, York SW, Ingram LO (2007) Low salt medium for lactate and ethanol production by recombinant Escherichia coli B. Biotechnol Lett 29:397–404

Thongchul N, Navankasattusas S, Yang ST (2010) Production of lactic acid and ethanol by Rhizopus oryzae integrated with cassava pulp hydrolysis. Bioprocess Biosyst Eng 33:407–416

Thang V, Kanda K, Kobayashi G (2010) Production of Acetone-Butanol-Ethanol (ABE) in direct fermentation of cassava by Clostridium saccharoperbutylacetonicum N1-4. Appl Biochem Biotechnol 161:157–170

AOAC (1990) Official methods of analysis, 15th edn. Association of official Analytical Chemists, Washington

Carta FS, Soccol CR, Ramos LP, Fontana JD (1999) Production of fumaric acid by fermentation of enzymatic hydrolysates derived from cassava bagasse. Bioresour Technol 68:23–28

Pandey A, Soccol CR, Nigam P, Soccol VT, Vandenberghe LPS, Mohan R (2000) Biotechnological potential of agro-industrial residues. II: cassava bagasse. Bioresour Technol 74:81–87

Rattanachomsri U, Tanapongpipat S, Eurwilaichitr L, Champreda V (2009) Simultaneous non-thermal saccharification of cassava pulp by multi-enzyme activity and ethanol fermentation by Candida tropicalis. J Biosci Bioeng 107:488–493

Thanaseelaan V (2013) Proximate analysis, mineral and amino acid profiles of de oiled rapeseed meal. Int J Food Agric Vet Sci 3:66–69

Zhu M, Li P, Gong X, Wang J (2012) A comparison of the production of ethanol between simultaneous saccharification and fermentation and separate hydrolysis and fermentation using unpretreated cassava pulp and enzyme cocktail. Biosci Biotechnol Biochem 4:671–678

Cantarella M, Cantarella L, Gallifuoco A, Spera A, Alfani F (2004) Effect of inhibitors released during steam-explosion treatment of poplar wood on subsequent enzymatic hydrolysis and SSF. Biotechnol Prog 20:200–206

Zheng P, Dong JJ, Sun ZH, Ni Y, Fang L (2009) Fermentative production of succinic acid from straw hydrolysate by Actinobacillus succinogenes. Bioresour Technol 100:2425–2429

Jiang M, Wan Q, Liu R, Liang L, Chen X, Wu M, Zhang H, Chen K, Ma J, Wei P, Ouyang P (2014) Succinic acid production from corn stalk hydrolysate in an E. coli mutant generated by atmospheric and room-temperature plasmas and metabolic evolution strategies. J Ind Microbiol Biotechnol 41:115–123

Zhang X, Jantama K, Moore JC, Jarboe LR, Shanmugam KT, Ingram LO (2009) Metabolic evolution of energy-conserving pathways for succinate production in Escherichia coli. Natl Acad Sci USA, Proc

Andersson C, Hodge D, Berglund KA, Rova U (2007) Effect of different carbon sources on the production of succinic acid using metabolically engineered Escherichia coli. Biotechnol Prog 23:381–388

Gokarn RR, Eiteman MA, Martin SA, Eriksson KEL (1997) Production of succinate from glucose, cellobiose, and various cellulosic materials by the ruminant anaerobic bacteria Fibrobacter succinogenes and Ruminococcus flavefaciens. Appl Biochem Biotechno 68:69–80

Ishida Y, Kori A, Ishihama A (2009) Participation of regulator AscG of the β-glucoside utilization operon in regulation of the propionate catabolism operon. J Bacteriol 191:6136–6144

Liu YP, Zheng P, Sun ZH, Ni Y, Dong JJ, Zhu LL (2008) Economical succinic acid production from cane molasses by Actinobacillus succinogenes. Bioresour Technol 99:1736–1742

Leung CCJ, Cheung ASY, Zhang AYZ, Lam KF, Lin CSK (2012) Utilisation of waste bread for fermentative succinic acid production. Biochem Eng J 65:10–15

Agarwal L, Isar J, Meghwanshi GK, Saxena RK (2006) A cost effective fermentative production of succinic acid from cane molasses and corn steep liquor by Escherichia coli. J Appl Microbiol 100:1348–1354

Van der Werf MJ, Guettler MV, Jain MK, Zeikus JG (1997) Environmental and physiological factors affecting the succinate product ratio during carbohydrate fermentation by Actinobacillus sp. 130Z. Arch Microbiol 167:332–342

Sassner P, Galbe M, Zacchi G (2006) Bioethanol production based on simultaneous saccharification and fermentation of steam-pretreated Salix at high dry-matter content. Enzyme Microb Technol 39:756–762

Chen C, Ding S, Wang D, Li Z, Ye Q (2014) Simultaneous saccharification and fermentation of cassava to succinic acid by Escherichia coli NZN111. Bioresour Technol 163:100–105

Acknowledgments

This work was financially supported by the Thailand Research Fund (TRF) under the Royal Golden Jubilee Ph.D. Program (Grant No. PHD/0135/2553). The authors thank Professor Lonnie Ingram who cordially provided E. coli KJ122 used in this study. Thanks to Bob Tremayne, Ubon Ratchathani University Office of International Relations for assistance with English.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sawisit, A., Jantama, S.S., Kanchanatawee, S. et al. Efficient utilization of cassava pulp for succinate production by metabolically engineered Escherichia coli KJ122. Bioprocess Biosyst Eng 38, 175–187 (2015). https://doi.org/10.1007/s00449-014-1257-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1257-7