Abstract

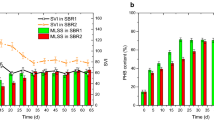

Several carbon sources were investigated for the production of 1,3-propanediol (PDO) and 2,3-butanediol (BDO) simultaneously, using an isolated indigenous Klebsiella sp. Ana-WS5. The results indicate that glycerol is a suitable carbon source for both BDO and PDO production. Further investigation suggests that adjustment of the pH could alter the metabolic pathway, which affects the ratio of PDO and BDO obtained. The batch with pH controlled at 7.0 had the highest total diol (PDO + BDO) productivity of 0.86 g/L h and the highest PDO/BDO of 7.67, as compared to a batch with pH controlled at 6.0. However, the batch without pH control could achieve a maximum total diol concentration of 48.1 ± 1.6 g/L and the highest yield of 86 % (total diols produced/glycerol consumed). The effects of pH control on the distribution of PDO and BDO concluded in this study could be further applied to the process design for enhancing PDO or BDO production.

Similar content being viewed by others

References

Ji XJ, Huang H, Ouyang PK (2011) Microbial 2,3-butanediol production: a state-of-the-art review. Biotechnol Adv 29:351–364

Xiu ZL, Zeng AP (2008) Present state and perspective of downstream processing of biologically produced 1,3-propanediol and 2,3-butanediol. Appl Microbiol Biotechnol 78:917–926

Zeng AP, Sabra W (2011) Microbial production of diols as platform chemicals: recent progresses. Curr Opin Biotechnol 22:749–757

Jiayang Q, Zijun X, Cuiqing M (2006) Production of 2,3-butanediol by Klebsiella pneumoniae using glucose and ammonium phosphate. Chin J Chem Eng 14:132–136

Syu MJ (2001) Biological production of 2,3-butanediol. Appl Microbiol Biotechnol 55:10–18

Rao B, Zhang LY, Zhang LY, Sun J, Su G, Wei D, Chu J, Zhu J, Shen Y (2012) Characterization and regulation of the 2,3-butanediol pathway in Serratia marcescens. Appl Microbiol Biotechnol 93:2147–2159

Biswas R, Yamaoka M, Nakayama H, Kondo T, Yoshida KI, Bisaria VS, Kondo A (2012) Enhanced production of 2,3-butanediol by engineered Bacillus subtilis. Appl Microbiol Biotechnol 94:651–658

Nakashimada Y, Marwoto B, Kashiwamura T, Kakizono T, Nishio N (2000) Enhanced 2,3-butanediol production by addition of acetic acid in Paenibacillus polymyxa. J Biosci Bioeng 90:661–664

Jiang LQ, Fang Z, Feng G, Yang LB (2012) Production of 2,3-butanediol from acid hydrolysates of Jatropha hulls with Klebsiella oxytoca. Bioresour Technol 107:405–410

Jun SA, Moon C, Kang CH, Kong SW, Sang BI, Um Y (2009) Microbial fed-batch production of 1,3-propanediol using raw glycerol with suspended and immobilized Klebsiella pneumoniae. Appl Biochem Biotechnol 161:491–501

Cheng KK, Zhang JA, Liu DH, Sun Y, Liu HJ, Yang MD, Xu JM (2007) Pilot-scale production of 1,3-propanediol using Klebsiella pneumoniae. Process Biochem 42:740–744

Cheng KK, Liu Q, Zhang JA, Li JP, Xu JM, Wang GH (2010) Improved 2,3-butanediol production from corncob acid hydrolysate by fed-batch fermentation using Klebsiella oxytoca. Process Biochem 45:613–616

Petrov K, Petrova P (2009) High production of 2,3-butanediol from glycerol by Klebsiella pneumoniae G31. Appl Microbiol Biotechnol 84:659–665

Wu KJ, Lin YH, Lo YC, Chen CY, Chen WM, Chang JS (2011) Converting glycerol into hydrogen, ethanol, and diols with a Klebsiella sp. HE1 strain via anaerobic fermentation. J Taiwan Inst Chem Eng 42:20–25

Sattayasamitsathit S, Prasertsan P, Methacanon P (2011) Statistical optimization for simultaneous production of 1,3-propanediol and 2,3-butanediol using crude glycerol by newly bacterial isolate. Process Biochem 46:608–614

Metsoviti M, Paraskevaidi K, Koutinas A, Zeng AP, Papanikolaou S (2012) Production of 1,3-propanediol, 2,3-butanediol and ethanol by a newly isolated Klebsiella oxytoca strain growing on biodiesel-derived glycerol based media. Process Biochem 47:1872–1882

Acknowledgments

The authors gratefully acknowledge financial support from Taiwan’s National Science Council.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yen, HW., Li, FT., Wong, CL. et al. The pH effects on the distribution of 1,3-propanediol and 2,3-butanediol produced simultaneously by using an isolated indigenous Klebsiella sp. Ana-WS5. Bioprocess Biosyst Eng 37, 425–431 (2014). https://doi.org/10.1007/s00449-013-1008-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-1008-1